Abstract

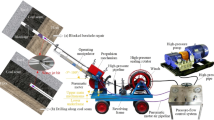

Gas drainage is critical for underground coal mining in coal seams that contain high coalbed methane. We propose an underground pressurized drilling method to overcome the difficulty of drilling drainage hole along such coal seams, whereby water-based drilling fluid is used instead of pure water or air to clean the borehole. However, drilling fluid leakage can cause a serious reduction in coal seam permeability and correspondingly changing its gas production characteristics. Therefore, it is important to clarify the damage characteristic for estimating the gas production capacity of drainage hole along such coal seams. In this paper, the permeability damage characteristics of contaminated coal sample were studied using a core flow test method. Results confirmed that the permeability of the contaminated coal samples decreased significantly because of water-sensitive damage, water locking, and bentonite and polymer molecule plugging. In addition, the longer infiltration time and higher effective stress were harmful to permeability. Because higher gas pressure more likely opens the blocked pores and fractures, the permeability of the contaminated coal sample increased significantly with the improvement of inlet gas pressure. Meanwhile, the intrusion of water and solid phase into coal sample decreased the influence of stress on its permeability. This study has theoretical and practical significance in supporting the reformation of the underground pressurized drilling methods and drilling fluid design.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Akpan, E. U., Enyi, G. C., Nasr, G., Yahaya, A. A., Ahmadu, A. A., & Saidu, B. (2019). Water-based drilling fluids for high-temperature applications and water-sensitive and dispersible shale formations. Journal of Petroleum Science and Engineering, 175, 1028–1038.

Al Jaberi, J., Bageri, B. S., Adebayo, A. R., Patil, S., Barri, A., & Salin, R. B. (2021). Evaluation of formation damages during filter cake deposition and removal process: The effect of primary damage on secondary damage. Petroleum Science, 18(4), 1153–1162.

Bobo, L., Kang, Y., Peng, X., Jiang, X., Mei, Y., & Min, Z. (2019). An experimental study on permeability characteristics of coal with slippage and temperature effects. Journal of Petroleum Science and Engineering, 175, 294–302.

Chen, S., Shi, Y., Yang, X., Xie, K., & Cai, J. (2019). Design and evaluation of a surfactant-mixed metal hydroxide-based drilling fluid for maintaining wellbore stability in coal measure strata. Energies, 12(10), 1862.

Cheng, Y. P., & Pan, Z. J. (2020). Reservoir properties of Chinese tectonic coal: A review. Fuel, 260, 116350.

Du, F., Wang, K., Zhang, X., Xin, C., Shu, L., & Wang, G. (2020). Experimental study of coal-gas outburst: Insights from coal-rock structure, gas pressure and adsorptivity. Natural Resources Research, 29(4), 2481–2493.

Freire Soares, A. S., Costa Marques, M. R., Calçada, L. A., Borges Filho, M. N., de Oliveira, L., & Petkowicz, C. (2018). Interaction of blockers on drilling fluids rheology and its effects on sealing of fractures and prevention of filtrate invasion. Journal of Petroleum Science and Engineering, 171, 260–270.

Han, X. M., Zhang, Q. Q., Wang, S. F., Li, J. L., & Chen, D. T. (2018). Influence of polycrystalline diamond compact bit geometric parameters on drilling performance during gas drainage borehole in soft coal seam. Advances in Mechanical Engineering, 10(1), 9.

Hodot, B. B. (1966). Coal and Gas Outburst (Chinese Translation). China Coal Industry Press.

Huang, Q., Wu, B., Liu, Y., Guo, Z., Wang, G., & Sun, L. (2022). Experimental and simulation investigations of the impact of polyacrylamide on CBM ad-/desorption. Journal of Petroleum Science and Engineering, 208, 109300.

Kang, Y., Xu, C., You, L., Yu, H., & Zhang, D. (2014). Temporary sealing technology to control formation damage induced by drill-in fluid loss in fractured tight gas reservoir. Journal of Natural Gas Science and Engineering, 20, 67–73.

Karacan, C. Ö., Ruiz, F. A., Cotè, M., & Phipps, S. (2011). Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. International Journal of Coal Geology, 86(2–3), 121–156.

Kumar, H., Mishra, M. K., & Mishra, S. (2018). Laboratory investigation of gas permeability and its impact on CBM potential. Journal of Petroleum Exploration and Production Technology, 8(4), 1183–1197.

Lei, M., Huang, W., Li, N., Jia, J., Li, J., Wang, Y., & Li, J. (2017). The damage mechanism of oil-based drilling fluid for tight sandstone gas reservoir and its optimization. Journal of Petroleum Science and Engineering, 158, 616–625. https://doi.org/10.1016/j.petrol.2017.09.003

Li, H., Ma, J. K., Wang, Z. Q., Wang, W., & Liu, Y. (2020a). A gas outburst prevention and control strategy for single thick coal seams with high outburst risk: A case study of Hudi Coal Mine in Qinshui Basin. Energy Science & Engineering, 8(7), 2471–2491.

Li, H., Wang, W., Liu, Y. W., Ma, J. K., & Gao, H. (2020b). An integrated drilling, protection and sealing technology for improving the gas drainage effect in soft coal seams. Energy Reports, 6, 2030–2043.

Li, Y. Z., Jiang, G. C., Li, X. Q., & Yang, L. L. (2022). Quantitative investigation of water sensitivity and water locking damages on a low-permeability reservoir using the core flooding experiment and NMR test. ACS Omega, 7(5), 4444–4456.

Liang, Y. P., Tan, Y. T., Wang, F. K., Luo, Y., & Zhao, Z. (2020). Improving permeability of coal seams by freeze-fracturing method: The characterization of pore structure changes under low-field NMR. Energy Reports, 6, 550–561.

Liu, H., Su, G., Okere, C. J., Li, G., Wang, X., Cai, Y., Wu, T., & Zheng, L. (2022). Working fluid-induced formation damage evaluation for commingled production of multi-layer natural gas reservoirs with flow rate method. Energy, 239, 122107.

Liu, J., Yang, T., Wang, L., & Chen, X. (2020). Research progress in coal and gas co-mining modes in China. Energy Science & Engineering, 8(9), 3365–3376.

Lyu, S. F., Wang, S. W., Chen, X. J., Shah, S. M., Li, R., Xiao, Y., Dong, Q., & Gu, Y. (2019). Experimental study of a degradable polymer drilling fluid system for coalbed methane well. Journal of Petroleum Science and Engineering, 178, 678–690.

Maiti, M., Bhaumik, A. K., & Mandal, A. (2021). Performance of water-based drilling fluids for deepwater and hydrate reservoirs: Designing and modelling studies. Petroleum Science, 18(6), 1709–1728.

Meng, Y., Li, Z. P., & Lai, F. P. (2021). Influence of effective stress on gas slippage effect of different rank coals. Fuel, 285, 119207.

Ni, X. M., Liu, Z. D., & Wei, J. P. (2019). Quantitative evaluation of the impacts of drilling mud on the damage degree to the permeability of fractures at different scales in coal reservoirs. Fuel, 236, 382–393.

Okere, C. J., Su, G., Zheng, L., Cai, Y., Li, Z., & Liu, H. (2020). Experimental, algorithmic, and theoretical analyses for selecting an optimal laboratory method to evaluate working fluid damage in coal bed methane reservoirs. Fuel, 282, 118513.

Saleh, T. A. (2022). Experimental and analytical methods for testing inhibitors and fluids in water-based drilling environments. TRAC Trends in Analytical Chemistry, 149, 116543.

Seright, R., & Brattekas, B. (2021). Water shutoff and conformance improvement: An introduction. Petroleum Science, 18(2), 450–478.

Sun, P., Han, M., Cao, H., Liu, W., Zhang, S., & Zhu, J. (2020). Development and performance evaluation of solid-free drilling fluid for CBM reservoir drilling in central Hunan. Energies, 13(18), 4857.

Taheri, A., Sereshki, F., Ardejani, F. D., & Mirzaghorbanali, A. (2017). Simulation of macerals effects on methane emission during gas drainage in coal mines. Fuel, 210, 659–665.

Tong, X., Fang, W. P., Yuan, S. Q., Ma, J., & Bai, Y. (2018). Application of Bayesian approach to the assessment of mine gas explosion. Journal of Loss Prevention in the Process Industries, 54, 238–245.

Tu, Q. Y., Cheng, Y. P., Ren, T., Wang, Z., Lin, J., & Lei, Y. (2019). Role of tectonic coal in coal and gas outburst behavior during coal mining. Rock Mechanics and Rock Engineering, 52(11), 4619–4635.

Wang, H. F., Cheng, Y. P., Wang, W., & Xu, R. (2014). Research on comprehensive CBM extraction technology and its applications in China’s coal mines. Journal of Natural Gas Science and Engineering, 20, 200–207.

Wang, H., Gu, S., & Chen, T. (2020). Experimental investigation of the impact of CO, C2H6, and H-2 on the explosion characteristics of CH4. ACS Omega, 5(38), 24684–24692.

Wang, J., & Zhou, F. J. (2020). Cause analysis and solutions of water blocking damage in cracked/non-cracked tight sandstone gas reservoirs. Petroleum Science, 18(1), 219–233.

Wang, L., Cheng, Y. P., Ge, C. G., Chen, J.-X., Li, W., Zhou, H.-X., & Hai-feng, W. (2013). Safety technologies for the excavation of coal and gas outburst-prone coal seams in deep shafts. International Journal of Rock Mechanics and Mining Sciences, 57, 24–33.

Wu, T., Pan, Z. J., Connell, L. D., Liu, B., Fu, X., & Xue, Z. (2020). Gas breakthrough pressure of tight rocks: A review of experimental methods and data. Journal of Natural Gas Science and Engineering, 81, 103408.

Wu, Y., Tao, S., Tian, W., Chen, H., & Chen, S. (2021). Advantageous seepage channel in coal seam and its effects on the distribution of high-yield areas in the Fanzhuang CBM Block, Southern Qinshui Basin. China. Natural Resources Research, 30(3), 2361–2376.

Xie, S. B., Yao, Y. B., Chen, J. Y., & Yao, W. (2015). Research of micro-pore structure in coal reservoir using low-field NMR. Journal of China Coal Society, 40, 170–176.

Xu, L., Zhu, F. H., Zha, F. S., Chu, C. F., & Yang, C. (2019). Effects of gas pressure and confining pressure on gas flow behavior in saturated cohesive soils with low permeability. Engineering Geology, 260, 105241.

Yao, Y. B., & Liu, D. M. (2012). Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel, 95, 152–158.

Yao, Y., Liu, D., Che, Y., Tang, D., Tang, S., & Huang, W. (2010). Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel, 89(7), 1371–1380.

Zhai, C., Xu, Y. M., Xiang, X. W., Yu, X., Zou, Q., & Zhong, C. (2015). A novel active prevention technology for borehole instability under the influence of mining activities. Journal of Natural Gas Science and Engineering, 27, 1585–1596.

Zhang, L., Huang, M., Xue, J., Li, M., & Li, J. (2021). Repetitive mining stress and pore pressure effects on permeability and pore pressure sensitivity of bituminous coal. Natural Resources Research, 30(6), 4457–4476.

Zhang, S., Wu, C., Fang, X., Liu, N., Jiang, X., & Han, J. (2022). Mapping of stress sensitivity affected by water variation to microscopic pore distributions in medium- and high-rank coals. Natural Resources Research, 31(3), 1601–1619.

Zhang, Y., Su, G., Zheng, L., Liu, D., Guo, Z., & Wei, P. (2019). The environmental friendliness of fuzzy-ball drilling fluids during their entire life-cycles for fragile ecosystems in coalbed methane well plants. Journal of Hazardous Materials, 364, 396–405.

Zhao, H. B., Li, J. Y., Liu, Y. H., Wang, Y., Wang, T., & Cheng, H. (2020). Experimental and measured research on three-dimensional deformation law of gas drainage borehole in coal seam. International Journal of Mining Science and Technology, 30(3), 397–403.

Zhao, X., Qiu, Z. S., Sun, B. J., Liu, S. J., Xing, X., & Wang, M. (2019). Formation damage mechanisms associated with drilling and completion fluids for deepwater reservoirs. Journal of Petroleum Science and Engineering, 173, 112–121.

Zheng, L., Su, G., Li, Z., Peng, R., Wang, L., Wei, P., & Han, S. (2018a). The wellbore instability control mechanism of fuzzy ball drilling fluids for coal bed methane wells via bonding formation. Journal of Natural Gas Science and Engineering, 56, 107–120.

Zheng, S. J., Liu, Y., Pan, Y., Liu, T., & Du, D. (2020). The invasion of drilling fluid into coal under fluctuating wellbore pressure. Arabian Journal of Geosciences, 13(9), 334.

Zheng, S. J., Yao, Y. B., Liu, D. M., Cai, Y. D., & Liu, Y. (2018b). Characterizations of full-scale pore size distribution, porosity and permeability of coals: A novel methodology by nuclear magnetic resonance and fractal analysis theory. International Journal of Coal Geology, 196, 148–158.

Zhou, F. B., Xia, T. Q., Wang, X. X., Zhang, Y., Sun, Y., & Liu, J. (2016). Recent developments in coal mine methane extraction and utilization in China: A review. Journal of Natural Gas Science and Engineering, 31, 437–458.

Zou, J. P., Chen, W. Z., Yang, D. S., Yu, H. D., & Yuan, J. Q. (2016). The impact of effective stress and gas slippage on coal permeability under cyclic loading. Journal of Natural Gas Science and Engineering, 31, 236–248.

Acknowledgments

This work is financially supported by the State key laboratory of coal mine disaster dynamics and control Key Research Program (Grant No. 2011DA105287-zd202009), the Natural Science Foundation of Chongqing (Grant No. cstc2019jcyj-msxmX0633 & No. cstc2020jcyj-msxmX0972), which are gratefully acknowledged. The authors also thank to the editor and anonymous reviewers for their valuable advices.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kong, L., Luo, Y., Tang, J. et al. Permeability Damage Mechanism and Evolution of Gas-Bearing Coal Seams Induced by Drilling Fluid. Nat Resour Res 32, 1639–1655 (2023). https://doi.org/10.1007/s11053-023-10212-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-023-10212-5