Abstract

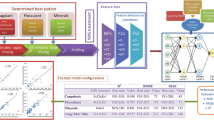

The forecasting of ore concentrate and tailings mass and metallurgical recovery at a processing plant is not a simple task. It starts with data collection, which is expensive and laborious, and progresses to multivariate data analysis, which is used to identify the independent variables that should be used to build a prediction model. This is followed by the choice of a statistical technique that is able to deal with data particularity. After building a model, the differences between the flotation batch test and the true plant circuit need to be considered because it is difficult to build a laboratory test that exactly mimics the plant configuration. When the model and its up-scaling factor have been defined, the last step is to check the efficiency of the model in terms of forecasting the geometallurgical variables under study. Bearing in mind that such geometallurgical predictions help in mine planning, economic forecasting and environmental studies (tailings mass and metallurgical recoveries), this paper proposes a methodology that is able to predict six plant outputs simultaneously. These are metallurgical recovery of Zn from Zn concentrate, metallurgical recovery of Zn from Pb concentrate and metallurgical recoveries of Zn from tailings, Zn concentrate mass, Pb concentrate mass and tailings mass. A neural networks technique was used, and the predictions of the model with an up-scaling factor were reconciled with the plant responses, which showed consistent results.

Similar content being viewed by others

References

Achterberg, E. P., Braungardt, C., Morley, N. H., Elbaz-Poulichet, F., & Leblanc, M. (1999). Impact of Los Frailes mine spill on riverine, estuarine and coastal waters in southern Spain. Water Research, 33(16), 3387–3394.

Bechir, J. L. C., Baptista, J. R., Souza, A. D., & Martins, E. (2019). Determination of maximum zinc recovery of Vazante mine ore by flotation process. REM-International Engineering Journal, 72(2), 315–320.

Cichosz, P. (2015). Data mining algorithms: Explained using R (p. 720). Hoboken: Wiley.

Deutsch, C. V. (2013). Geostatistical modelling of geometallurgical variables—problems and solutions. In Proceedings of the second ausimm international geometallurgy conference, Sept. 30–Oct. 2, Brisbane, Australia (pp. 7–15).

Dutta, S., Bandopadhyay, S., Ganguli, R., & Misra, D. (2010). Machine learning algorithms and their application to ore reserve estimation of sparse and imprecise data. Journal of Intelligent Learning Systems and Applications, 2(2), 86–96.

Hastie, T., Tibshirani, R., & Friedman, J. H. (2009). The elements of statistical learning: Data mining, inference, and prediction (2nd ed., pp. 241–249). New York: Springer.

Izenman, A. J. (2008). Modern multivariate statistical techniques (p. 733). New York: Springer.

Jorjani, E., Bagherieh, A. H., Mesroghli, S., Chehreh Chelgani, S., & Jorjani, H. (2008). Prediction of yttrium, lanthanum, cerium and neodymium leaching recovery from apatite concentrate using artificial neural networks. In Proceedings of MetPlant 2008, Aug. 18–19, Perth, Australia (pp. 433–446).

Kahraman, S. (2016). The prediction of penetration rate for percussive drills from indirect tests using artificial neural networks. Journal of the South African Institute of Mining and Metallurgy, 116, 793–800.

Modena, C. M., & Heller, L. (2016). Desastre da Samarco: Aproximações iniciais. Ciência e Cultura, 68(3), 22–24.

Nakhaei, F., Mosavi, M. R., Sam, A., & Vaghei, Y. (2012). Recovery and grade accurate prediction of pilot plant flotation column concentrate: Neural network and statistical techniques. International Journal of Mineral Processing, 110–111, 140–154.

Samanta, B., Bandopadhyay, S., Ganguli, R., & Dutta, S. (2005). A comparative study of the performance of single neural networks vs. Adaboost algorithm based combination of multiple neural networks for mineral resource estimation. Journal of the South African Institute of Mining and Metallurgy, 105, 237–246.

Srivastava, V., Bandopadhyay, S., Akdogan, G., & Ghosh, T. (2017). Dynamic neural network based model for SAG mill power prediction. In 38th international symposium on the application of computers and operations research in the mineral industry, Colorado School Mines, USA, 38 (pp. 227–233).

Tawo, E. E., & Al-Alawi, S. M. (1999). A comparison between artificial neural network and a geostatistical technique in the estimation of regionalized variables. Engineering Journal of the University of Qatar, 12, 125–149.

Werbos, P. J. (1974). Beyond regression: New tools for prediction and analysis in the behavioral sciences. Ph.D. thesis, Harvard University (p. 454).

Wu, X., & Zhou, Y. (1993). Reserve estimation using neural network techniques. Computers & Geosciences, 19(4), 567–575.

Acknowledgments

This work was supported by the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) [Grant Number 141594/2017-9]. The authors are also grateful for support provided by Fundação Luiz Englert and would like to thank the mining engineers Jorge Lucas Bechir and Breno Valente for all the assistance provided during the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niquini, F.G.F., Costa, J.F.C.L. Mass and Metallurgical Balance Forecast for a Zinc Processing Plant Using Artificial Neural Networks. Nat Resour Res 29, 3569–3580 (2020). https://doi.org/10.1007/s11053-020-09678-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-020-09678-4