Abstract

Given a scarcity of commercial-scale carbon capture and storage (CCS) projects, there is a great deal of uncertainty in the risks, liability, and their cost implications for geologic storage of carbon dioxide (CO2). The probabilities of leakage and the risk of induced seismicity could be remote, but the volume of geologic CO2 storage (GCS) projected to be necessary to have a significant impact on increasing CO2 concentrations in the atmosphere is far greater than the volumes of CO2 injected thus far. National-level estimates of the technically accessible CO2 storage resource (TASR) onshore in the United States are on the order of thousands of gigatons of CO2 storage capacity, but such estimates generally assume away any pressure management issues. Pressure buildup in the storage reservoir is expected to be a primary source of risk associated with CO2 storage, and only a fraction of the theoretical TASR could be available unless the storage operator extracts the saltwater brines or other formation fluids that are already present in the geologic pore space targeted for CO2 storage. Institutions, legislation, and processes to manage the risk, liability, and economic issues with CO2 storage in the United States are beginning to emerge, but will need to progress further in order to allow a commercial-scale CO2 storage industry to develop in the country. The combination of economic tradeoffs, property rights definitions, liability issues, and risk considerations suggests that CO2 storage offshore of the United States may be more feasible than onshore, especially during the current (early) stages of industry development.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The International Energy Agency (IEA) estimated that the electricity and heat generation (power) sector combined with the industrial sector accounted for about 61% of the world’s carbon dioxide (CO2) emissions in 2013, and these two sectors accounted for 50% of total U.S. emissions of CO2 during the same year (International Energy Agency 2015). The sources of CO2 emissions in these two sectors are stationary, and it is feasible to capture and concentrate their emissions, transport the liquid CO2 to a suitable geologic storage site, inject it deep underground into a geologic formation (a carbon sink), and isolate it from the atmosphere for hundreds to thousands of years, or even longer. This is different from the situation with diffuse and mobile sources of CO2 in the transportation sector (ranked second to the power sector in terms of its share of global and U.S. CO2 emissions), and implementation of carbon capture and storage (CCS) is far less feasible in that sector. Implementation of CCS for large stationary sources alone could make a substantial contribution to the mitigation of CO2 emissions, while further development and attempts to better integrate alternative low- or zero-carbon energy sources proceed. Additionally, some climate change goals may not be achievable without CCS, possibly including a goal to keep global warming below 1.5–2 degrees Celsius and other goals that were set at the 21st session of the Conference of the Parties (2015 Paris Climate Conference) (Intergovernmental Panel on Climate Change [IPCC] 2005, 2014; Climate Action 2015).

The benefits of CCS in mitigating rising atmospheric concentrations of CO2 would be global and nonexcludable, which means that investors will not be able to recoup the full social value of their CCS projects. On the other hand, local stakeholders will bear most of the CO2 storage costs and risks. Given the social nature of the benefits of CCS and the private costs and local risks, simply allowing free reign of market forces in this nascent sector could lead to far less implementation of CCS projects than necessary to meet goals for CO2 reduction. A possible approach to correcting this potential market failure could involve governments providing incentives for implementation of CCS. However, they will need more complete information concerning the potential risks, liabilities, and associated costs, in order to make better comparisons with other low- or zero-carbon (green) energy technologies (which compete with CCS for government support). The probabilities of significant risk events associated with long-term CO2 storage could be extremely low (Pawar et al. 2015), and national- and other high-level assessments of CO2 storage capacity (e.g., U.S. Geological Survey Geologic Carbon Dioxide Storage Resources Assessment Team [USGS] 2013) typically assume that any risks will be mitigated through brine extraction, other forms of active pressure management, and(or) other risk-minimizing strategies. Risk mitigation for geologic carbon storage (GCS) projects could be costly yet necessary to allay public concerns. High-level assessments are lacking crucial information on the potential risks and economics of GCS that policy makers will need to make critical decisions (Tietenberg 2003; International Energy Agency Greenhouse Gas R&D Programme [IEAGHG] 2009; Schrag 2009; Eide et al. 2014; IPCC 2014).

Risk can be defined as the probability of a hazard event multiplied by the magnitude of the impacts if it occurs. For geologic storage of CO2, the impacts of greatest concern are those associated with two types of potential risk events:

-

leakage of CO2, displaced fluids, and any mobilized hazardous elements out of the storage reservoir and

-

induced ground motion, including induced seismicity.

Impacts could include contamination of freshwater aquifers and other subsurface natural resources; damage to surface environments and structures; effects on people and animals from extremely high local concentrations of CO2 in the air; acidification and contamination of oceans and other bodies of water; damage to ecosystems; and possibly others. Impacts will be greater the higher the concentration of humans and other receptors within the areal extent of the CO2 plume and the area of elevated pressure, which could extend far beyond the borders of plume migration (IPCC 2005; Price and Smith 2008; IEAGHG 2009; Rutqvist 2012; National Academy of Sciences [NAS] 2013; Birkholzer et al. 2015; Pawar et al. 2015).

This paper reviews the potential technical risks associated with long-term geologic storage of CO2. The discussion of the potential risks of GCS is presented in the context of the expected regulatory environment in the United States. In addition to the technical risks, there are public perceptions of the risks that proponents of CCS will have to overcome in order to develop a commercial-scale CO2 storage industry. There are economic, legal, regulatory, and social issues involved with the technical risks and perceived risks of CO2 storage. For reasons that include these issues, establishing surface and pore-space rights for potential CO2 storage sites onshore could be prohibitively costly and difficult. Initially, stakeholders may have to prove the security of large-scale geologic storage of CO2 offshore, where the government owns the property rights, risks could be lower, and public perception may be less likely to override the economic, scientific, and technical merits of CO2 storage projects (IEAGHG 2007b, 2013; Carbon Sequestration Leadership Forum [CSLF] 2009, 2012; Schrag 2009; Stenhouse et al. 2009; Herzog 2011; Litynski et al. 2011; Herzog and Eide 2013).

GCS and Risk

Geologic carbon storage (GCS) can isolate CO2 from the atmosphere for hundreds to thousands of years (or even longer) through injecting it into permeable and porous rock formations deep (1–4 km [km]) underground. During the process of CCS, the CO2 is captured, concentrated to a supercritical (fluid) state, and injected deep into a suitable geologic formation. The injected CO2 has lower viscosity and density than oil, water, or other formation fluids, and it will tend to rise upward owing to its buoyancy relative to that of typical in situ fluids. However, pressurized CO2 will also flow along channels of least resistance, such as fractures and avenues of higher permeability and porosity in the rock. These subsurface conduits can divert the CO2 in any direction. As it flows, CO2 can be trapped in rock pores by capillary forces (residual trapping), immobilized by some other trapping mechanism, or continue to meander in a generally upward direction until it encounters impermeable rocks. The layer of impermeable rock that forms the primary seal against the CO2 escaping into the upper geological strata or to the surface is the caprock. If there are no lateral seals in addition to this primary seal, the CO2 can still migrate more or less horizontally along the underside of the caprock until it is trapped or finds a pathway to escape the storage reservoir (Szulczewski et al. 2012; Birkholzer et al. 2015). Geologic uncertainty concerning the pathways that injected CO2 and pressurized or displaced formation fluids will take is a major contributor to uncertainty in estimates of potential risk (Oldenburg et al. 2009; Pawar et al. 2015).

Fluids and gasses (such as oil, natural gas, and saline water [brines]) already occupy the geologic pore space of the potential CO2 storage reservoir. As greater volumes of CO2 are injected, the increase in fluid volume can create a buildup of pressure in the storage reservoir and beyond. The extent of pressure buildup will depend on geologic parameters (like permeability), the degree to which the reservoir is open, and other geologic formation characteristics (including temperature, fracturing, and salinity of formation fluids). If the in situ fluids and(or) gasses have been previously extracted during the production of hydrocarbons, and other formation fluids have not yet invaded the vacated pore space, then the current reservoir pressure may be significantly less than its fracture pressure. If so, the risks of injecting CO2 into such depleted reservoirs could also be reasonably low, even without any new fluid extraction. For a deep saline-filled formation (DSF) without a history of fluid extraction, the pressure at the beginning of CO2 injection could be closer to fracture pressure, and the storage operator may need to extract formation fluids to keep the risk below an acceptable level and(or) pressure buildup below a regulatory level (Birkholzer and Zhou 2009; Birkholzer et al. 2015). Unwanted pressure buildup could be the most important limitation on CO2 storage capacity in DSFs (Schrag 2009).

In order to minimize the risks associated with pressure buildup, storage reservoir pressure will need to be carefully managed at least until injection ceases, probably monitored for a significant amount of time after that, and possibly until all of the CO2 is immobilized. The costs of active pressure management include expenditures for extracting in situ fluids (and gasses), processing them, and then selling or disposing of them (including possible injection elsewhere). This contrasts with far lower (or approximately zero) costs of passive pressure management, where the pressure is allowed to normalize through natural migration of the in situ fluids out of the reservoir, the slow dissolution of the CO2 into those fluids, or some other natural mechanism. If active pressure management is necessary but the costs of this important method of risk mitigation are prohibitive, then a substantial portion of the technically accessible storage resource (TASR) may not meet economic feasibility criteria for CO2 storage capacity under current regulations (Schrag 2009; Birkholzer et al. 2012, 2015; Breunig et al. 2013; Heidug 2013; Cihan et al. 2014; Bachu 2015; Pawar et al. 2015).

Buoyant trapping could be a relevant trapping mechanism in geologic storage of CO2, especially in the early stages of development of CCS technologies. In buoyant trapping, the CO2 flows upward until it is immobilized in a stratigraphic or structural trap formed by the caprock, lateral seals, sealing faults, and(or) other seals. This is also how the natural geologic trapping of oil and gas occurs, and such traps could retain injected CO2 for thousands to millions of years, just as they have (historically) for hydrocarbons. If hydrocarbons are still present in the storage reservoir, then injected CO2 can help increase recoveries (e.g., enhanced oil recovery [EOR] projects). Production of hydrocarbons could provide revenues that would help discount CO2 storage costs, while mitigating risk through reducing pressure buildup in buoyant structures. Relative to storage in DSFs, there could also be less geologic uncertainty with buoyant structures (owing to greater availability of geologic data from previous exploration and production of hydrocarbons), and the costs and timeframe for monitoring and managing risks could be significantly less (IPCC 2005; Brennan et al. 2010; Bachu et al. 2013). However, the United States Geological Survey (USGS) estimated that buoyant traps account for only 2% of the mean total TASR onshore in the United States (USGS 2013).

Over 95% of the potential CO2 storage capacity in the United States (and the vast majority in the world) is in DSFs (U.S. Department of Energy, National Energy Technology Laboratory [NETL] 2012; Dooley 2013; USGS 2013). In these extensive geologic formations, residual trapping could be the most relevant mechanism for immobilizing CO2, at least in the short term (tens to hundreds of years). Solubility trapping may play an increasing role in the long run (over hundreds of years or longer), but may not add significantly to current estimates of storage capacities (Lu et al. 2013; Bachu 2015). Residual trapping occurs when droplets of CO2 are immobilized by capillary forces and remain trapped in the tight pore spaces of the rock as the plume of injected CO2 passes through (Brennan et al. 2010). This trapping mechanism does not rely on lateral seals and is effective at immobilizing CO2 in open geologic systems (not laterally confined by impermeable seals or low-permeability zones). As the CO2 occupies the pore space, however, it displaces or pressurizes formation fluids (brines). In an open system, this can create a pressure front that could extend for 100 km or more, given an areal extent of the CO2 plume of only about 10 km (Pruess et al. 2003). In a closed or semi-closed system (laterally bordered by impermeable seals or low-permeability zones, respectively) (Zhou et al. 2008), the pressure front is contained, but the resulting pressure buildup can be a source of risk (Birkholzer et al. 2015). Storing CO2 in DSFs could cost substantially more for monitoring and risk management, for a much longer time, and over a much greater area of review (AoR) than storage in buoyant traps.

Hazard and Risk

According to Ayyub (2003), technical risk

can be defined as the product of the likelihood of a hazardous event occurring (measured over the period of interest or concern) and the impact if that event occurs (measured as the consequences per event). The likelihood in Eq. 1 can be expressed as a probability. Proponents of GCS will probably also have to deal with perceived risk, which includes the technical risk, additional considerations of the nature of the hazard, and (subjective) perceptions of the impacts if it occurs (Ayyub 2003; NAS 2013; Pawar et al. 2015).

According to White et al. (2016), a hazard of leakage associated with GCS can be quantified as a probability of exceeding an acceptable volume or rate of leakage of CO2, brines, and/or total dissolved solids (TDS) out of the storage reservoir. Oldenburg et al. (2009) define the probability of leakage as the product of the likelihood of the injected CO2 (or displaced fluids) intersecting a conduit and the likelihood of that conduit intersecting a compartment that contains vulnerable receptors. Receptors could be on or near the surface, like the surface population, or located at various depths underground, like freshwater aquifers, deposits of hydrocarbon resources, or other natural resources. A risk of unacceptable leakage associated with GCS can be defined as a product of the probability of a leakage event and the severity of the impact(s) that it would have on the receptor(s) if the event occurs (Pawar et al. 2014). Often, analysts estimate the impacts on intermediate receptors (such as increased concentration of TDS in a potable water aquifer) as proxies of the ultimate consequences for vulnerable entities within a compartment (such as humans exposed to contaminated water). In addition, there is no risk if there is no probability of eventual impacts on humans, other living things, the environment, water, or other essential natural resources (Oldenburg et al. 2009).

According to the National Academy of Sciences (NAS) report on potential risks of induced seismicity, the quantifiable hazard of induced seismicity associated with GCS is the probability of seismic events caused by injecting CO2 deep underground that pose potential harm. The risk of induced seismicity will include some quantification of how much harm (losses, damage, and effects on humans) the seismic event could cause, if it occurs. In the NAS report, there is no risk if an induced seismic event occurs where it will have no impact on humans or structures (NAS 2013). White et al. (2016) quantify the induced seismic hazard associated with GCS as a probability of exceeding threshold values for ground motion or acceleration, which is a common measure used in evaluating the hazard of naturally occurring seismicity. The authors then suggest developing a vulnerability function that quantifies the probability of creating a certain level of damage or losses for each given threshold value of ground motion. In their probabilistic assessment of the risk of induced seismicity, they multiply the hazard probability by a measure of the vulnerability (Federal Emergency Management Agency 2015) to yield a measure of risk equal to the probability of consequences for each receptor given that the hazard has occurred (White and Foxall 2016).

The time dimension in Eq. 1 is very important. Hazard and risk are quantities that can vary extensively over time, and there is no consensus in the literature regarding the appropriate timeframe for evaluating risks associated with GCS. As long as it remains mobile, CO2 could invade and reactivate (distant) faults (owing to its corrosive and lubricating properties), and CO2 could remain mobile for a significant period after injection stops. In most risk scenarios in the literature, however, the greatest concern for induced seismicity is during the period of overpressure that occurs while injecting CO2 into the storage reservoir (NAS 2013). Overpressure could occur during injection and for some marginal period after injection stops, while the pressure normalizes. Especially for a greenfield CO2 storage project that involves injection in a DSF, careful monitoring and fast reaction times could be essential to managing the risk of induced seismicity. Pressures could normalize reasonably quickly after injection ceases, and the risk of induced seismicity could decrease quite rapidly. However, the time needed to monitor leakage risk (often called containment risk) could be far longer, because the buoyancy and other properties of CO2 allow it to access and flow along induced and preexisting pathways long after pressure buildup ceases. Leakage risk is also expected to decrease steadily after injection ceases, but it could decay at a much slower rate than the risk of induced seismicity (Foxall et al. 2013; White et al. 2016).

If the storage site is well characterized, the storage operator follows best practices with respect to site operation, and careful monitoring occurs both during and after the CO2 injection period, then analysts generally consider the likelihood of significant impacts from CO2 storage to be remote. However, geologic systems are inherently heterogeneous, the volumes of CO2 storage that are projected to be necessary to stem climate change far exceed any stored up to this point, and the stored CO2 will have to remain trapped for hundreds to thousands of years (or longer). Considerable uncertainty in the subsurface parameters enters into risk calculations, and some uncertainty may remain even after closure of the storage site. In addition, there is a lack of data on potential leakage conduits, stress fields, fault (and fracture) locations and properties, (old) well locations and leakage properties, and other reservoir characteristics, especially for DSFs where there has not been a history of hydrocarbon exploration and production, injection of fluid wastes, or other fluid and gas injection and storage operations. There are a number of geological analogs from which applicable data might be gleaned, but there remains significant uncertainty in estimates of leakage risk and the risk of induced seismicity from injecting commercial-scale volumes of CO2 (Price and Smith 2008; Birkholzer et al. 2015; Pawar et al. 2015; Miocic et al. 2016; White and Foxall 2016).

The Intergovernmental Panel on Climate Change (IPCC 2005) estimated that DSFs could be “very likely” to retain 99% of injected CO2 after 100 years and “likely” to still retain that same percentage even after 1000 years, or more, if certain assumptions are met (including adequate monitoring). If so, the probability of a leakage risk event occurring within a single year could be miniscule. Still, it could be useful for decision makers to have some idea of the probability of a risk event occurring in any given year and how the risk per year might evolve over time. Benson (2007) introduced the concept of an intertemporal risk profile to illustrate what the evolution of the risks of GCS could look like over time (Fig. 1), and there is an update of her schematic example in De Coninck and Benson (2014). The U.S. Department of Energy’s National Risk Assessment Partnership (NRAP) has been developing a methodology to quantify such risk profiles for a number of risks associated with GCS (Foxall et al. 2013). Typically, these intertemporal risk profiles show a peak during the latter portion of the injection period, and the annual risk probability decays shortly after injection ceases (Pawar et al. 2015). Pawar et al. (2014) estimated that the peak probability of the risk of leakage to the atmosphere per year was below 0.01.

A schematic example of an expected risk profile for a CO2 storage project (Benson 2007)

A Taxonomy

There are unique properties, behavior, and potential impacts of CO2 injected deep underground; differences in suitability of different types of reservoirs for injection and(or) storage of different substances; inherent heterogeneity and uncertainty with respect to geological systems; and other factors that could distinguish the possible risks associated with GCS. To help identify, characterize, and communicate the possible risks and potential costs, Table 1 contains a breakdown of some of the most probable risk sources, impact mechanisms, receptors, mitigation methods, and remediation options for GCS. Figure 2 is an illustration of some of the potential sources, impact mechanisms, and receptors listed in Table 1.

Illustration of some of the potential risks of CO2 storage (not to scale). The areas of this figure that are intended to depict regions where the potential risk scenarios described in the text could be most likely are indicated by the letters A to E. These letters correspond to columns in Table 1 that lists some of the potential mechanisms, impacts, receptors, mitigation, and remediation options for each of these scenarios. This figure was composed by Steven T. Anderson, and illustrated by Celeste D. Lohr

Risk Scenario A

The parameters assumed in scenario A are intended to reflect those for a CO2 storage project in a DSF bordered above and below by an impermeable caprock and bottom seal, respectively. Assume that CO2 injection in this scenario will occur at a secure distance from any identified wellbores and major faults, and that the storage formation is laterally open. The caprock is continuous but could be undulating, such that the CO2 could migrate updip along the underside of this upper seal to various depths. However, no part of the storage formation in this region is shallower than 1 km below the ground surface, and no freshwater occupies any of the pore space targeted for storage (U.S. Environmental Protection Agency [U.S.EPA] 2010c). The conditions assumed for scenario A are intended to agree with common assumptions and constraints utilized in large-scale assessments of CO2 storage capacity in DSFs (e.g., USGS 2013), except there is no assumption that any active pressure management needed to mitigate risk will occur.

Due to the openness of the geologic system assumed for scenario A, the mechanism of greatest concern is migration of injected CO2 and displaced formation fluids into parts of the open geologic system outside of the pore volume targeted for CO2 storage. This is the primary source of risk in this scenario. Leakage of CO2, brines, and mobilized elements (such as arsenic or mercury) could affect compartments and receptors at risk, including the atmosphere, ecosystems, humans and other species, and potable water resources. Given the relatively benign properties of CO2, inflows of brines and other displaced storage formation fluids could have a greater impact on freshwater aquifers than the CO2. In this scenario, migration allows the CO2 and brines to eventually intersect minor faults and fractures, but the probability of leakage to the surface via such potential conduits is extremely low (IEAGHG 2007b; Oldenburg et al. 2009; Stenhouse et al. 2009; Keating et al. 2013; Pawar et al. 2014, 2015; Birkholzer et al. 2015).

There may not be much (or any) historical exploration of DSFs, and the procedures necessary to determine permeability may be too costly for a CO2 storage operation. A lack of permeability data can be a significant source of uncertainty about the risks of storage in these formations. If there is low permeability, as for the portion of the TASR in the United States that the USGS classified as a residual trapping class 3 (storage in rocks with permeability less than 1 milliDarcy), then the CO2 could remain close to the injection well and not have substantial migration (Burke 2011). In this case, possible leakage back up the injection wellbore and pressure buildup immediately around the injection point in the storage reservoir could be of concern. Given the proximity to injection monitoring equipment, any risk this presents could be quickly identified and mitigated. On the other hand, the fluid pressure front could extend tens to even hundreds of kilometers away from the injection point if there is higher permeability, and much of the geological volume under the extended area of increased pressure may not be subject to the same characterization and monitoring as the AoR for the permitted CO2 storage site. Thus, potential risks far afield may not be identified and mitigated until they have caused a greater amount of damage. This could be more of a concern with respect to leakage risk. If there is only minor pressure buildup in the presence of high permeability, ground motion effects far afield could be insignificant in this scenario (CSLF 2009; 2012; Rutqvist 2012; IEAGHG 2013; Birkholzer et al. 2015; Pawar et al. 2015).

Risk Scenario B

Scenario B adds the presence of major faults and legacy wellbores to the other risk factors in scenario A. In general, the risk of CO2 leakage through a natural conduit is expected to be less than through man-made wellbores, especially if only considering the risk of leakage to the surface. Leakage through CO2 injection, monitoring, and other new wells within the AoR is possible, but the probability could be extremely low (especially for well blowouts) owing to recent completion of these wells using modern methods and materials. Undetected legacy wellbores could be of greater concern, because they may not be properly closed to seal against CO2 and pressurized formation fluids. In addition, public, historical records concerning their location may not exist. As in scenario A, geologic uncertainty could be higher if the distance from the permitted storage site is greater, possibly owing to less detailed geologic characterization outside of the AoR. Even within the AoR for the storage project, there will be geologic uncertainty about potential subsurface pathways for migration of CO2 and displaced fluids that may not be completely resolved through site characterization. Still, if leakage occurs onsite it is more likely to be detected and mitigated earlier than if it occurs further afield (IEAGHG 2007a, b, 2012; CSLF 2009, 2012; Oldenburg et al. 2009; Lu et al. 2013; Pawar et al. 2014, 2015).

In addition to geologic uncertainty, uncertainty concerning the number, location, and quality of closure of legacy wellbores contributes to uncertainty in estimating the leakage risks. In areas where there has been mineral exploration, production, or monitoring, injection of fluids into the subsurface including for disposal of industrial or other waste, monitoring of the subsurface (for a variety of reasons), and other instances where drilling has taken place, the primary risk of leakage of CO2 is through the existing boreholes and there can be great variability in the availability of data on vital characteristics of those potential leakage conduits (Duncan et al. 2009). Pawar et al. (2014) provide results from an example application of NRAP’s integrated assessment model for estimating geologic storage security in the presence of cemented (closed) legacy wellbores, where the location, spatial density, and cement permeability of the wellbores are unknown. To obtain these results, the authors ran simulations of their model for a variety of assumed wellbore densities (between 1 well per 100 square km and 10 wells per square km) and cement permeability distributions over a period of 1000 years (50 years of CO2 injection and 950 years after injection). Even for their worst-case scenario, the mean cumulative leakage of CO2 to the atmosphere was estimated to be below 1% of the total volume injected, which is the CO2 storage permanence goal suggested by the IPCC (2005).

Risk Scenario C

In addition to the geological characteristics assumed for scenarios A and B, scenario C allows for the presence of buoyant structures that could contain oil and natural gas. The AoR that will have to be evaluated for potential risks of storage in more extensive DSFs is generally expected to be larger than for projects to store CO2 in depleted oil or gas reservoirs (or to convert an EOR project to pure storage). This is primarily because buoyant structures (whether they contain hydrocarbons or not) are bounded laterally by impermeable or low-permeability rock, and these boundaries are better defined than those of DSFs, which are typically modeled as more open, laterally. Still, the lateral boundaries on buoyant structures may not extend to the bottom of the storage reservoir and instead form spill points with enough permeable pore space beneath them to allow displaced formation fluids and CO2 to eventually escape (IEAGHG 2007a, b, 2012; CSLF 2009, 2012; Bachu et al. 2013; Pawar et al. 2015).

Even CO2 storage in formations that have contained hydrocarbons for millennia can be subject to significant geologic uncertainty. At the Cranfield EOR and CO2 storage project in Mississippi, injected CO2 showed at a distant monitoring well before it showed at an observation well closer to the injection site, and this was suspected to be primarily owing the presence of thin, tortuous, high-permeability conduits that were not detected prior to injection (Lu et al. 2013). After injecting CO2 from 2004 to 2011 into the depleted Krechba gas field in Algeria, operations were indefinitely suspended at the In Salah project (at least partially) owing to increased concern about the potential leakage risk as a result of CO2 stimulating existing fractures and possibly creating new hydraulic fractures (Ringrose et al. 2013).

The impermeability of the rocks that form the buoyant structure could mean that the geologic system in this vicinity is relatively closed, and pressure buildup could be a significant concern. If oil, natural gas, or some other valuable commodities are still trapped in the structure, then pressure management would occur as a normal component of EOR or similar operations that inject CO2 to enhance production of hydrocarbons or other mineral commodities. However, that would no longer be the case upon conversion of such projects to storage of CO2 (only). In order to produce oil, CO2-EOR operators will need to keep pressure at least at minimum miscibility pressure, but they also need to maintain it below fracture pressure in order to maintain reservoir integrity. If injections of CO2 for EOR are deep enough and production of oil or extraction of fluids and gasses is not enough to sufficiently manage pressure buildup, EOR operations could run a considerable risk of inducing seismicity, and the current level of that risk is likely to depend on a very complex injection and production history (CSLF 2009, 2012; Bachu et al. 2013; IEAGHG 2013; Rubinstein and Mahani 2015; White and Foxall 2016).

According to Rubinstein and Mahani (2015), some secondary and tertiary oil production operations (that typically inject water, steam, and/or CO2) have induced seismicity in the United States. According to the authors, the largest of these induced seismic events was a medium magnitude (M4.6) earthquake at the Cogdell oil field in Texas in 1978 that was not associated with any injections of CO2. Most such induced seismic events are of low magnitude (<M3) and are not felt on the surface (which typically requires magnitude >M2–M3) or cause any noticeable damage. Gan and Frohlich (2013) attributed earthquakes larger than M1 at the Cogdell field or nearby to gas (CO2 and/or possibly methane) injection between 2006 and 2011, and a permanent regional seismic network detected eighteen earthquakes in the area that had magnitudes between 3 and 4.4 (White and Foxall 2016). One caveat to these findings is that similar histories of injection in similar fields near the Cogdell field were not associated with induced seismicity. This could be because a combination of numerous factors is required for fluid injections to cause felt seismicity. Some of these potential factors can be found in Rubinstein and Mahani (2015) and are listed below in the description of risk scenario D.

Historical experience from injecting CO2 for EOR in the United States could also provide some idea of the risk of CO2 leakage. Oilfield CO2 floods have been occurring for over 40 years in the United States, although data on the retention of CO2 during EOR projects have not been consistently reported (Olea 2015). Duncan et al. (2009) studied the 35-year history of CO2-EOR in the United States (at the time) and suggested that the probability of leakage was very low. Leakage of CO2 through old boreholes has occurred in relation to EOR projects in the United States,Footnote 1 but Porse et al. (2014) suggest that the perceived risk of CO2 well blowouts in EOR operations is greater than the technical risk. Kühn et al. (2013) tested 12 legacy boreholes for a possible enhanced gas recovery project in the depleted Altmark natural gas field in Germany, and the authors found that these existing wells would still maintain integrity after injecting 100,000 t of CO2. Still, leakage risks could be higher in areas that have historically produced oil and gas, primarily owing to the higher density of legacy wellbores. For example, the IPCC cited evidence that more than 350,000 wells had been drilled in the Alberta Basin (Canada), and that drilling was ongoing at a rate of about 20,000 wells per year there in 2005 (IPCC 2005). Even if the well densities are not as great as in this example, extensive effort and expense to locate and (possibly) rework all of the abandoned wells that are projected to come in contact with the CO2 plume could be necessary to address the potential leakage risk and that may not be feasible for a CO2 storage project (Dooley et al. 2009; Bachu et al. 2013).

Risk Scenario D

Rubinstein and Mahani (2015) list a number of factors that need to coincide for induced seismicity from injection of fluids to occur, including the presence of faults that are large enough, the presence of pathways to transport the injected or displaced fluids to these faults, changes in stress fields that are large enough, and fluid pressure changes large enough to induce earthquakes. Scenario D assumes that all necessary factors for there to be a significant risk of induced seismicity in the GCS system are present (White et al. 2016). Identifying the presence and location of these hazardous site characteristics or predicting the magnitude of the changes in stress fields and fluid pressures that will occur is subject to inherently large uncertainties that may take a substantial amount of time after the start of CO2 injection to resolve. In addition, geologic uncertainty could increase the deeper into the subsurface the storage operator needs to inject, and this depth could be an important factor in assessing the risks. For example, a fault that extends from the underside of the storage reservoir downward may not be identified (even during a careful storage site characterization), yet still be large enough to pose a significant risk of induced seismicity if (re)activated by injection of CO2 and pressure buildup in the reservoir (Rutqvist 2012; NAS 2013; Birkholzer et al. 2015; Pawar et al. 2015; White et al. 2016).

Zoback and Gorelick (2012) argue that injecting large volumes of CO2 into the brittle rocks that are typical for DSFs in continental interiors could trigger earthquakes that threaten seal integrity, even if they might not possess enough magnitude to cause significant harm or structural damage on the surface. Vilarrasa and Carrera (2015) contend with part of this conclusion by claiming that the caprock at depths of 1–3 km (that are typically discussed for CO2 storage) is considerably more ductile than the deeper crystalline basement and may not be critically stressed; pressure buildup could be limited by displaced brines flowing through the caprock and CO2 dissolving in the brines; and that the time of the greatest risk is during active injection, when the risks can be most easily mitigated. However, there might not be enough flexibility in the CCS system to halt or adjust the rate of injection, owing to the large volumes of CO2 that may need to be injected on a daily basis because of stringent limits on (large penalties for) CO2 emissions. In addition, flow of brine through the caprock and dissolution of CO2 in brines may not have a significant effect on pressure until after injection has ended, but the pressure buildup and risk could be greatest during the period of injection (Birkholzer et al. 2015). If a fault that accesses the basement is more of a risk concern for induced seismicity than one that extends from the storage formation up into the caprock (and beyond), then injecting CO2 at a shallower depth within a DSF could pose relatively lower overall risk (White and Foxall 2016). In that case, however, decision makers may have to weigh the benefit of decreasing the risk of induced seismicity against the costs of reduced storage efficiency related to CO2 only occupying the upper reaches of the reservoir (Bachu 2015).

According to the International Energy Agency Greenhouse Gas R&D Programme (IEAGHG) (2013) report on induced seismicity, there had not been any significant seismic events directly tied to injections of CO2, but the volumes of CO2 injected thus far are only a fraction of that being considered for future projects (Birkholzer et al. 2015). At the Illinois Basin-Decatur Project, 1 million metric tons (Mt) of CO2 was injected using 1 injection well over a period of 3 years, and no felt seismicity was observed (Kaven et al. 2015). Injecting this small amount of a volume of CO2 over this long period allowed injection pressures to be far below reservoir fracture pressure. As such, injection of CO2 probably did not create any new fractures, and scientists observed only some microseismicity in the same zones where natural (background) seismicity was already occurring (Will et al. 2016). This example illustrates some of the difficulties in differentiating what proportion of fluctuations in seismic activity could be induced from seismicity, which is naturally occurring (Bauer et al. 2016; Smith and Jaques 2016). In addition, it could be very difficult to predict the risk of induced seismicity for commercial-scale GCS projects based on evidence from relatively small-scale projects (White and Foxall 2016).

Risk Scenario E

In comparison with the previous scenarios, the potential impact mechanisms included in scenario E are the same, but could be of concern over a longer period of time and a greater areal extent, even for a storage site that is well characterized and estimated to be secure (Miocic et al. 2016). If the seal integrity is high and continuous over an extended area and the geologic storage system is open (permeability is high over the entire extent of the storage formation), then commercial-scale injection of CO2 could displace brines and create a pressure front on the order of hundreds of kilometers away from the injection point. Storage formations can extend updip to access freshwater resources near the surface, and there is a great deal of uncertainty in how far the pressure front will extend. Birkholzer and Zhou (2009) have estimated that the pressure front could extend three times as far as a result of lateral permeability in the storage formation being one order of magnitude higher. Even if the pressure buildup within the AoR is below the level permitted for a CO2 storage site, it may not be below the regulated limit within the entire areal extent of the pressure front (Birkholzer et al. 2009, 2015; IEAGHG 2010, 2011).

Liability Issues

In the United States, an activity that is considered abnormally dangerous could be subject to strict liability. To determine whether an activity is abnormally dangerous, one or more of the following questions will need to be considered (Cypser and Davis 1998; JGC Corporation 2013):

-

1.

Is there a high degree of risk of some harm to people, land, or the property of others?

-

2.

What is the likelihood that such harm will exceed acceptable thresholds?

-

3.

Can taking reasonable measures still not eliminate the risk?

-

4.

To what extent is the activity not common?

-

5.

To what degree is the activity inappropriate, given the location where it is carried out?

-

6.

To what extent is the value of the activity to the public outweighed by its hazardous nature?

Liability for losses caused by potential hazardous events associated with GCS could also be determined based on legal theories other than strict liability, including negligence, nuisance, and trespass (Majer et al. 2012).

The nature of the potential risks of GCS presents some unique issues with respect to assessing, assigning, and transferring liability. According to the example risk profile in Figure 1, the highest risk levels are expected to be during the period of injection. The issues with liability could be reasonably clear during that period, when the storage operator would probably be liable for most of the potential damages that could be caused by the CO2 storage operation. The risks are expected to decrease steadily after injection ceases and the operator plugs the injection wells and abandons the site, but there will likely remain some residual risk even hundreds of years after that (Fig. 1). In the event that any damages related to the CO2 storage operation occur tens or hundreds of years after the storage site is closed, who will be responsible for compensation and remediating the damage? What if future losses occur well outside the permitted and leased boundaries of the storage site that were agreed to for the period of injection? In 2015, long-term liability for GCS was still an unresolved issue of concern for policy makers, regulators, investors, and proponents of CCS (World Resources Institute 2008; Dooley et al. 2010b; Adelman and Duncan 2011; Dixon et al. 2015).

Some degree of liability protection or some form of liability limits may be necessary for development of a CO2 storage industry on a commercial scale. Perhaps, the most important issue with liability protection is the issue of moral hazard. According to Trabucchi and Patton (2008), moral hazard refers to a situation where the risks increase, because the responsible party is (partially) insulated from being held fully liable for the resulting consequences. For GCS operators, even partial liability limits could provide them with incentives to take less care in the characterization of the storage site, selecting its location, or managing risks during its operation. On the other hand, potential CO2 storage site operators and investors will be faced with site-specific geologic characteristics and other factors that will affect whether, when, and what degree any risks may manifest themselves over time, and there is inherent uncertainty regarding risk that may not be fully resolved even by the time of site closure. Faced with such risk uncertainty, it could be highly unlikely that operators will implement GCS on a commercial scale without some limits on their liability. If so, policy makers and regulators will have to balance the incentives for investing in GCS that liability protection could provide with the potential for moral hazard, and they will have to adjust policies and regulations as the risks evolve over a very long period of time (World Resources Institute 2008; Dooley et al. 2010b; Pawar et al. 2015).

Leakage Risk, Regulation, and Liability

On December 10, 2010, the U.S. Environmental Protection Agency (U.S. EPA) finalized a rule (U.S.EPA 2010c) that created a new class of injection well (Class VI) under their existing Underground Injection Control (UIC) program, and the Class VI rule was promulgated on September 7, 2011 (U.S.EPA 2011). The Class VI rule includes new minimum Federal requirements under the Safe Drinking Water Act (SDWA) to protect an underground source of drinking water (USDW) during underground injection of CO2 for the purpose of geologic storage. These include requirements for (Rubin et al. 2013; Dixon et al. 2015)

-

site characterization and selection,

-

an AoR within which the operator must identify potential leakage conduits (like wells and faults) that could allow the CO2 or displaced formation fluids to reach a USDW,

-

periodic reevaluation and updating of the AoR,

-

design and construction of wells to prevent invasion of fluids into USDWs,

-

operation of injection wells, including limitations on injection pressures,

-

monitoring during injection, and

-

postinjection monitoring and site care.

The Class VI rule also requires that the storage site owner demonstrate sufficient financial responsibility to be able to cover the following postinjection CCS liabilities:

-

corrective action for plugging of abandoned wells and underground mines in the injection area,

-

injection well plugging,

-

postinjection site care and site closure, and

-

emergency and remedial response.

These are classified as stewardship liabilities, and the owner will be responsible for such liabilities until the end of the postinjection period for site care and monitoring, which the U.S. EPA suggests should be approximately 50 years. At that time, the financial instruments held by the permitting authority to ensure financial responsibility to cover the above liabilities will be returned to the owner or operator, and they are released from Federal requirements under the SDWA (U.S.EPA 2010c, 2011; IEAGHG 2013; Rubin et al. 2013; Dixon et al. 2015).

In accordance with the SDWA, however, long-term stewardship liability for storage of CO2 cannot be transferred to the U.S. government, and the owner or operator will remain liable for future impacts on a USDW in the event of contamination by the CO2 or formation fluids indefinitely. However, a state government or other entity could accept transfer of ownership or long-term liability. The IEAGHG reported that state government agencies in Kentucky, Louisiana, Montana, and North Dakota can accept transfers of ownership or stewardship liability, and that North Dakota can also accept transfers of compensatory liability. If not, the operator could remain liable under state laws and other federal statutes, as well as under common law. Wyoming is an example of a U.S. state that has stated it will not assume long-term liability for CO2 storage. The IEAGHG has outlined an alternative, which does not require a state, provincial, or national government authority to assume responsibility for long-term liability issues with CO2 storage. This option would involve establishing an independent scientific advisory panel to monitor storage site integrity and administer a fund to cover CO2 storage liabilities. However, the IEAGHG suggests that this plan could be more expensive than the other options, and such a fund could contribute to a situation of moral hazard (World Resources Institute 2008; Dooley et al. 2010b; U.S.EPA 2010c; IEAGHG 2007a, 2012; Dixon et al. 2015).

The Class VI rule only addresses the potential risk of CO2 storage to USDWs. It does not address other potential leakage risks (such as contamination of other natural resources or leakage to the atmosphere) or potential risk of induced seismicity. The U.S. EPA can require GHG monitoring and reporting from the GCS operator through Subpart RR of its Greenhouse Gas Reporting Program. The Subpart RR rule applies to Class VI wells, and requires the operator to prepare a monitoring, verification, and reporting plan. This requirement targets the tracking and mitigation of risk of leakage to the surface, and verifying how much CO2 is retained. Determining liability (if there is leakage) does not appear to be the focus of this particular regulation (U.S.EPA 2010a; Dixon et al. 2015).

Induced Seismicity

As with liability for leakage risks in the United States, the operator/owner could be held liable for losses attributable to seismicity determined to have been induced by the CO2 storage project from the start of injection through some period of postinjection care, maintenance, and monitoring. However, this period has not yet been determined for the risk of induced seismicity. This postinjection period of responsibility could also be 50 years, as suggested in the Class VI rule for potential contamination of USDWs. Alternatively, it could be shorter, since the risk of induced seismicity could decrease more rapidly that leakage risk following the end of CO2 injection. The absence of regulations specific to requiring liability for damages caused by induced seismicity associated with CO2 storage or a case history of associated liability litigation, makes it very difficult to predict liability for seismic events that could potentially be induced by CO2 storage operations. According to Cypser and Davis (1998), a definitive cause and effect relationship will have to be established between CO2 storage and an induced seismic event, and between the portion of the seismic event that was determined to have been induced and the damages to the claimant (Wilson et al. 2007; Majer et al. 2012; JGC Corporation 2013; White et al. 2016).

If causality between CO2 storage and induced felt seismicity is established, there could be analogous cases in the United States that could support the application of trespass, strict liability, negligence, and(or) nuisance laws. Vibrations due to blasting or operation of heavy machinery for mining and construction have been occasionally viewed as a trespass. Even if the degree of risk is low, but the likelihood of seismicity causing significant harm is great (as in the case of it occurring in a densely populated area), then induced seismicity could be considered abnormally dangerous (and the operator could be held strictly liable). Limits on liability could create a situation of moral hazard, where the site operator could be found negligent in his site selection and/or operation of the CO2 storage project. A low-magnitude induced earthquake can be felt without causing physical damage. In this case, the plaintiff could claim nuisance, because the induced seismicity interfered with his use or enjoyment of his land. In May 2006, enhanced geothermal project operators drilled a deep well near the center of Basel, Switzerland, and began stimulating it with water injections to induce fractures for heat exchange with the geothermal source on December 2. On December 8, the operators stopped injection because they reached a predetermined seismicity threshold, and they immediately suspended the project. The local damage was inconsequential. Reportedly, the project was soon abandoned because the company liability for this project in a heavily populated area and a region found to be tectonically unstable was too high (Cypser and Davis 1998; Majer et al. 2012; JGC Corporation 2013; NAS 2013; White et al. 2016; Earth Sciences Division, Lawrence Berkeley National Laboratory, undated).

EOR Liabilities

Prior to promulgation of the Class VI rules, there were UIC program rules for five well classes in the United States, including Class II rules for wells to inject fluids associated with oil and gas production. In December 2013, the U.S. EPA issued draft guidance on transitioning from Class II permits for operators to inject CO2 for the purpose of enhanced recovery (of oil or natural gas) to the new Class VI permits for permanent CO2 storage (U.S.EPA 2013), and the U.S. EPA issued a memorandum in 2015 to clarify the key principles of the Class VI rule with respect to conversion of Class II wells to Class VI wells (Grevatt 2015). Three notable clarifications regarding transitioning from Class II to Class VI were (i) that (incidental) geologic storage of CO2 (during enhanced recovery [ER] operations) could continue to be permitted under the UIC Class II program; (ii) that the use of anthropogenic CO2 in ER operations does not necessarily require a Class VI permit; and (iii) that Class VI site closure requirements may not be required to close Class II CO2 injection operations (Dixon et al. 2015).

Probably owing to a longer history, responsibility for and potential transfer of liability could be better defined for CO2-EOR operations than for CO2 storage. In the United States, CO2-EOR operations are liable under state and federal laws for damages caused by their operations in a similar manner to how many industrial operators may be held liable. Once the injection, production, and other wells have been properly closed and abandoned, a state, federal, or other government agency could assume liability for any legacy effects, or not, depending on the jurisdiction. If a CO2-EOR operation is converted to pure CO2 storage before being abandoned, then liability could be similar to that under the Class VI rule. In particular, conversion of a CO2 operation to pure storage could mean that the CO2-EOR operator would be held responsible for liabilities for a longer period of time postclosure compared to that for a CO2-EOR operation with only incidental storage of CO2 (De Figueiredo et al. 2007; World Resources Institute 2008; Anderson 2010; Massachusetts Institute of Technology 2010; Bachu et al. 2013).

Liability Protection

There are institutions already in place for CO2-EOR operations to assist with covering liabilities for potential leakage of CO2 and other fluids through wells that have been abandoned long ago and do not have a current owner, but analogs to such “orphan well funds” still need to be developed for pure storage projects. Because CO2 storage is ostensibly for the public good, some have suggested that it falls within the role of government to assist storage operators with liability issues. Others have countered that there exist other options to mitigate GHG emissions (such as switching away from high-carbon fuels [to nuclear energy, natural gas, or other lower-carbon fuels], developing renewable energy sources, increasing efficiency, managing energy demand, and so forth), and that energy providers could be relied upon to choose the lowest cost option(s) to comply with emissions limits, including the costs of risk management. Liability protection for any particular option could distort this choice (IEAGHG 2007a, 2012; Massachusetts Institute of Technology 2010).

A lack of liability protection could skew the choices of energy providers toward what is privately least costly in the short run, but more costly for society in the long run. On the other hand, there is always a concern of creating moral hazard with government assistance. Industry risk-sharing arrangements with the government have been suggested to assist with managing liability while minimizing moral hazard, as long as the risk-sharing institution is mostly financed by industry. However, such arrangements could be more costly and less efficient than the other alternatives. Also, any jointly managed liability protection funds would have to be designed to make it difficult for the government to reallocate them to serve other purposes; otherwise the funds might not be readily available to take quick remedial or restorative action (De Figueiredo et al. 2007; IEAGHG 2007a, 2012; Massachusetts Institute of Technology 2010; Eide et al. 2014).

Economic Issues

Many models included in the IPCC’s reports on mitigation of climate change indicate that the costs of mitigating GHG emissions will be substantially higher if CCS is not an available option, but they may not be considering the expected costs of reducing and mitigating the potential risks associated with all of the options. Some costs that may not be clearly considered in assessments of the various low- or zero-carbon options could include long-term liability and monitoring costs and the costs of active pressure management for CO2 storage (as part of the costs of CCS), potential environmental costs owing to water use in bioenergy projects, costs of integrating solar and wind power into grids and systems to match demand with power generated from renewable energy resources, and legacy costs of nuclear waste and abandoned reactors. In order for policy makers to better compare GHG mitigation options, it would be useful to have estimates of the costs of reducing or mitigating CO2 storage risks, costs of covering possible long-term liabilities, risk-adjusted CO2 storage capacities, as well as better accounting of analogous costs for the other GHG mitigation options that CCS may be compared to (IPCC 2014).

An important issue to consider in comparing GHG mitigation options (including CCS) is that any realization of risk events could have mostly local impacts, which could mean that mitigation of the risk is likely to have mostly local benefits, and those unaffected by a risk event are generally not going to be interested in bearing the cost to mitigate a risk that is not likely to affect them, even if they enjoy benefits of lower GHG concentrations in the atmosphere. If not regulated otherwise, the economic incentives are to free ride on any nonexcludable social benefits and not bear any of the local costs or risks. These economic incentives can lead to unwillingness of most beneficiaries to allow deployment near to where they live. This has historically been a major issue in the development and deployment of energy technologies, even including recent interest in locating windmills offshore (Tietenberg 2003; Schrag 2009; Bureau of Land Management, undated).

For GCS, the risk mitigation strategies after the start of injection are very similar across all the scenarios in Table 1. Effort and expenditure to reduce the potential risk start preinjection with careful geologic characterization and site selection (Miocic et al. 2016). In addition, site selection should consider population densities and the presence of other potential receptors on the surface within the AoR and at some radial distance beyond which correlates to the expected extent of the pressure front. Providing for baseline, injection, and postinjection monitoring also represents necessary costs for reduction of risk. Monitoring is not listed in Table 1, but regulations that govern CO2 storage (such as the Subpart RR rule in the United States) will require monitoring, verification, and reporting by the storage operator (Dixon et al. 2015). After injection starts, the common risk mitigation methods in Table 1 are to

-

1.

decrease the rate of injection, the injection pressure, or completely stop injection of CO2 and

-

2.

extract the injected CO2 and/or formation fluids (mostly brines).

These risk mitigation methods are essential parts of active pressure management, will be the most important methods of risk mitigation after the start of CO2 injection, and could be significantly (or even prohibitively) costly (CSLF 2009, 2012; McCoy and Rubin 2009; Rubin et al. 2013).

Site Characterization

The costs of site characterization for a CO2 storage project in a DSF could be substantially greater than that for converting an EOR project or a depleted oil and gas reservoir to (pure) CO2 storage. Since residual trapping does not rely on lateral seals, the boundaries for CO2 storage in a DSF will generally be more extensive and not as well defined as in depleted oil and gas reservoirs. The AoR for monitoring and managing risks may extend much further beyond the areal extent of the CO2 plume for storage in DSFs than in converted CO2-EOR projects. A wider AoR can substantially increase the costs of site characterization. In turn, the AoR and other factors that heavily influence the costs of site characterization can be highly dependent on regulations (World Resources Institute 2008; CSLF 2009, 2012; McCoy and Rubin 2009; Bachu et al. 2013).

Site Selection, Risk, and Cost

To minimize CO2 transportation costs and to attract investment, the storage operator will face economic incentives to select a site that is as close to the stationary CO2 source (such as a power plant) as possible. The operator will also have to be confident that the targeted storage formation can handle the necessary rate of CO2 injection to store CO2 at the expected rate it is to be captured and transported to the site. Given the inherent uncertainty in geologic systems, it may not be possible to adjust volumetric storage capacity efficiency estimates for risk, directly based on the physical site characterization data. However, these data could be used in computer models to estimate pressure-limited capacities, which could serve as reasonable proxies for risk-adjusted CO2 storage capacity, because pressure buildup is a primary source of risk. A spatial consideration is that locations with the highest CO2 emissions (and highest demand for CO2 storage capacity) are likely to be in areas where there would be the highest remediation costs in the case of failure (significant leakage or induced seismicity). If the expected costs of risk mitigation are not considered, transportation–storage cost minimization and other models to determine the matched CO2 storage capacity could overestimate available storage capacity, and they will not include the necessary information to match CO2 sources with minimum-risk storage sites (Dahowski et al. 2005; Bachu et al. 2007; World Resources Institute 2008).

For stationary sources of anthropogenic CO2 in locations like the Eastern seaboard of the United States, geologic storage formations offshore may minimize the combination of transportation costs, storage costs, and risk. If risk and liability are taken into account, CO2 storage reservoirs that would have the risk-adjusted capacity to be able to handle the potential volumes captured by large CO2 emitters in the eastern part of the United States could be at a distance further inland than offshore (Herzog 2011). There is already some existing (pipeline) infrastructure to offshore oil and gas fields (e.g., in the Gulf of Mexico) that could possibly be converted to CO2 transportation and storage, and some site characterization may have already been done during the process of exploring for oil and gas that could help reduce the site characterization costs for CO2 storage. In addition to depleted oil and gas reservoirs, suitable deep saline formations (high permeability, seal integrity, and storage capacity) have been identified offshore (Litynski et al. 2011). Leakage risk in offshore sedimentary basins could be minimal, because the upper sealing layer could be dominated by unconsolidated clay in many marine settings, such that faults and other potential conduits do not persist. If the deep saline storage formation is found below deep water (below 3 km), the injected CO2 may be dense enough to be secured by gravitational forces (House et al. 2006). The risk of contamination of the ocean environment by leakage of displaced offshore brines could be less than the risk of brine (and TDS) contamination of onshore ecosystems, because brines in formations under the ocean floor could be chemically similar to seawater (Schrag 2009). Finally, there are fewer risk receptors of concern offshore, such as freshwater aquifers used by humans.

Pore-Space Rights

Another economic benefit of storing CO2 offshore is that there are few owners of the geological pore space (the Government, in most cases), and property rights could be less costly to manage than onshore. Onshore, very costly negotiations and compensation could be necessary to arrange for a multitude of property owners in order to use the pore space underneath their land for CO2 storage. The United States is one of only a few countries in the world that allow private ownership of the rights to minerals in the subsurface. However, pore-space rights for long-term CO2 storage could be treated very differently from mineral rights. Property owners may have to be compensated for the pore space used to store what could be defined as a waste product (World Resources Institute 2008; Bachu et al. 2013). If regulations are passed that create a value for geological storage of CO2, however, then the pore space can still have an asset value to the owner of the property rights, who then might wish to retain that asset (in the hopes that its value will appreciate) for future use (either for eventual CO2 storage or some competing use). Offshore, there could be fewer competing uses for the pore space deep under the ocean, and therefore less of an opportunity cost to storing CO2 (Tietenberg 2003).

If property rights specific to geologic storage of CO2 are not well defined, then a theoretical means to attempt to restore efficiency could be negotiations between the source of the CO2 (or the storage operator) and the property owner, but the efficacy of negotiations in restoring efficiency decreases as the number of affected parties increases. The plume of CO2 from a storage project (from one injection site) could eventually migrate over a very large lateral area (on the order of hundreds of square kilometers [km2]), depending on the geology of the storage formation, the physical parameters of the injection zone, and the degree of pressure maintenance undertaken to control plume migration. Additionally, the injection of CO2 could affect the subsurface pressure even beyond the expected area of migration of the CO2 plume, potentially thousands of km2 (Pruess et al. 2003; Pruess 2005; Birkholzer et al. 2009). As such, the storage operator may have to negotiate individually with a great quantity of landowners to obtain the legal right to use all of the affected pore space and avoid liability for trespassing or nuisance (Anderson 2009; Gresham and Anderson 2011). Successful negotiation with a large number of property owners may not be feasible, and the results of a model analyzed by Gresham et al. (2010) suggest that costs to acquire the rights to the pore space for an onshore CO2 storage project could be significant.

If individual negotiations are not feasible, then the courts could potentially help restore some economic efficiency by applying some form of liability rule. Liability rules are decision rules that award monetary damages to the affected party. Gresham and Anderson (2011) reviewed case law from industrial and commercial underground fluid injection operations and suggested that the U.S. courts had often maintained that fluid injection for enhanced hydrocarbon recovery, underground waste disposal, and groundwater storage and recharge were in the public interest and thus shielded from claims of trespass if

-

1.

the operation is licensed under a state or federal regulatory program and

-

2.

the property owner could not demonstrate actual harm to, or interference with, use and enjoyment of the land as a result of injection and migration of fluids.

If these two conditions are met, and the courts deem the injections of CO2 to be in the public interest, Gresham and Anderson (2011) suggest that receiving the appropriate regulatory approval to inject CO2 for the purpose of permanent geologic CO2 storage could suffice to shield the storage operator from liability. This could be far less costly than completing negotiations with hundreds or thousands of landowners and other concerned parties. However, the cases studied by these authors were only for potential analogs to injection of CO2, and it remains to be seen whether courts will apply similar liability rules to geologic CO2 storage. Also, the transaction costs of court time, lawyers’ fees, and so forth may imply that relying on the courts to decide these issues could be a very expensive means to try to correct the inefficiencies caused by ill-defined pore-space rights (World Resources Institute 2008).

Social Versus Private Values

There could be nonexcludable social benefits to storing CO2 in the ground, but the owner of the pore-space rights would have to give up the potential asset value of that pore space. The net value of this choice to the private owner of the pore space could be far less than the social net value, and the owner of the rights would then allow less current storage of CO2 than what is socially desirable. For example, the private owner of inland pore space may not value the possible benefits of decreasing CO2 concentrations in the atmosphere as much as people living nearer the coast, who could be more vulnerable to the potential effects of global warming. If individual negotiations between the property rights of owner and the wider populace are impractical, a government could have to intervene on behalf of society to compensate the owner, such that he or she would be willing to give up more of his or her private asset value for the benefit of society (Tietenberg 2003).

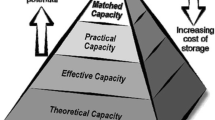

Active Pressure Management

High-level estimates of the TASR generally assume away any pressure management issues (Heidug 2013). If policy makers rely too heavily on estimates of the TASR that are not adjusted for risks (many of which are associated with pressure buildup), then they could significantly overestimate the practical availability of CCS to help mitigate climate change. In addition, the spatial distribution of available risk-adjusted capacity would probably be quite different from that of the TASR. Widespread deployment of a CCS system that matches CO2 emitters with risk-adjusted storage capacity instead of the nearest available TASR could be far more costly and difficult (IPCC 2005; Birkholzer and Zhou 2009; CSLF 2009; IEAGHG 2007a, 2010, 2013, 2014).

High-level estimates of TASR in the United States are dominated (95%) by estimates of potential storage capacity in DSFs. Without making any regulatory assumptions, Szulczewski et al. (2012) estimated that the pressure-limited CO2 storage capacity of the Mount Simon Sandstone (a prospective deep saline formation for CO2 storage) could be about 15 Gt, which is about 10% of the DOE-NETL’s upper bound on their 2010 estimate of the volumetric storage capacity and about 16% of the mean USGS estimate of the TASR for the same formation (NETL 2010, 2012; USGS 2013). Birkholzer and Zhou (2009) estimated the pressure-limited capacity for the Mount Simon Sandstone to be as low as 5 Gt of CO2, under assumptions about the regulatory environment that these authors considered to be realistic. Thus, already existing regulations and limitations on pressure buildup from injecting fluids in saline storage formations could have a drastic effect on the total volume and spatial distribution of CO2 storage capacity in the United States.

Flexibility with Injection

In Table 1, decreasing the injection rate, decreasing the injection pressure, or stopping CO2 injection altogether is an option to mitigate risk in every scenario. In the literature, this has often been called a traffic light approach. Decreasing the rate of injection or the injection pressure is analogous to heeding a yellow traffic light, and stopping injection is analogous to obeying a red light (Zoback 2012). Part of the cost of this risk mitigation strategy will depend on the flexibility the storage operator has to switch injection of already captured CO2 to another injection well or another storage reservoir. If commercial-scale CCS systems are deployed nationwide such that large volumes of CO2 have to be consistently injected into each available storage formation, then flexibility to switch injection sites may not exist. Without this flexibility and with high enough penalties for simply venting (captured) CO2, CCS operations may have to be suspended (at least temporarily). If the CO2 source is a power plant that is not allowed to operate (or has to pay a substantial cost to operate) without CCS, then this traffic light approach could be very costly. Thus, there is a real option value to having the flexibility to be able to switch CO2 storage reservoirs, and the cost of doing this will depend on the total number of CO2 storage sites available, the proximity of those to the leading sources of captured CO2, the proximity of feasible injection locations to each other, and other factors.

In the above example of the shutdown of the geothermal facility in Basil, Switzerland, injection was stopped according to a traffic light protocol that was triggered by unacceptably high seismic readings. Since it was a pilot project, there were no significant repercussions for current energy supply caused by closing this project, and the project operators were able to follow a strict protocol and mitigate the risk before any structural or other damage (NAS 2013). If a system of power plants with CCS were to provide the majority of energy to a major electrical grid, and there were no ready alternatives, then the costs of this type of risk mitigation could be more significant, although very difficult to quantify.

Formation Fluid Extraction

If a traffic light approach is not acceptable or too costly for a CCS project, extracting formation fluids and/or the injected CO2 is the other major option to mitigate risk in every scenario in Table 1. The net costs of this very important method of risk mitigation will depend not only on the fluid extraction costs, but also on the availability of alternative pore space in which to inject the extracted fluids, finding other secure receptacles, and economic opportunities to process the fluids for some (commercial) use. If the net costs of fluid extraction and processing are less than that for reducing or suspending injection, then the storage operator can continue injecting CO2 even after risks have become apparent. However, the costs of GCS will be significantly higher if the operator needs to extract, process, and dispose of formation fluids, and filling even a fourth of the TASR with CO2 may not be economically feasible (Birkholzer and Zhou 2009; Szulczewski et al. 2012; IEAGHG 2014).

Harto and Veil (2011) estimated that the average net costs of water management for CO2 storage could be about $1.50 per barrel of produced waters (at current prices between 1992 and 2006), and that this would correlate to costs of between $12/t and $14/t of stored CO2. The authors estimated these costs under the assumptions that saline waters (brines) have to be extracted at a ratio of 1:1 per volume of CO2 injected, the produced waters have to be transported, waste waters have to be processed before disposal, and that there are no commercial uses for the brines. Adding these costs could increase the total costs of GCS to more than double estimated costs of $8–$10/t CO2 in the United States (Dahowski et al. 2011). These potential costs need to be better estimated in order to quantify the probable economic constraints risk management could place on CO2 storage operations (Heidug 2013).

Need for Fluid Extraction

High-level assessments of the theoretically available TASR generally assume away any issues with pressure management, injection rates, and risk (e.g., USGS 2013). If these were not real concerns for an actual CO2 storage project, the storage operator would have tremendous flexibility regarding where, when, and how long he or she could take to inject the flow of captured CO2. There would be no need to bear the added costs of extracting, processing, and either selling or disposing of formation fluids to mitigate risk. Instead, the storage operator could immediately switch to injecting CO2 elsewhere, slow down injection rates to whatever degree necessary to stay below some pressure threshold, or even just stop injection altogether and wait until the pressure normalizes in the current storage reservoir. However, building this amount of flexibility in the storage operation is likely to be prohibitively costly, even if it were possible. In addition, there are inherent uncertainties with GCS, and storage operators will need to have a strategy for mitigating risks that may only become apparent after injection has started. Under current regulations in the United States, the storage operator might be more likely to stop injection and vent CO2 than to engage in costly production of formation fluids (to mitigate any unexpected risks). If so, there may need to be (much) higher penalties on venting CO2 before formation fluid extraction could be the preferred (lower-cost) option to mitigate risks associated with potential pressure buildup during CO2 storage operations.

Implications