Abstract

Airborne substances in the nanoparticle size range would mostly follow the primary airflow patterns, which emphasizes the importance of understanding the airflow dynamics to effectively control exposures to toxic airborne substances such as nanometer-sized particles. Chemical fume hoods are being utilized as primary controls for worker exposure to airborne substances including nanometer-scale materials due to their overall availability and history of effective contaminant. This study evaluates the impact of the body wake on the containment performance of a conventional constant air volume (CAV) and a new “nano” ventilated enclosing hood using numerical methods. Numerical studies have been performed to predict leaks of nanomaterials handled inside the hood. We further performed experiments in this study to validate the velocity fields predicted by the computational fluid dynamic (CFD) models and to provide a basis for evaluating the impact of the human body on fume hood containment performance. Using these validated models, the effects of the motion of the arms moving out of the hood were simulated using CFD to assess how one of the common actions of an operator/user may affect containment. Results of our simulations show that areas near the hood side airfoils and directly behind the sash are more likely to concentrate contaminants released inside the hood and potentially result in leakage based on internal airflow patterns. These areas are key to monitor when assessing fume hood containment along with the operator/mannequin breathing zone to get an understanding of potential leak areas which might contribute to operator exposure as well as exposure to others inside the laboratory.

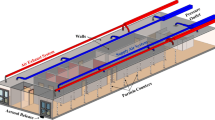

source at center of hood with a) nano hood with no arm motion. b) nano hood with 2.5 m/s arm motion. c) CAV hood with no arm motion and d) CAV hood with 2.5 m/s arm motion. The trajectories are colorized by red if they are released from the side source and blue if they are released from the center source

Similar content being viewed by others

References

Ahn K, Woskie S, DiBerardinis L, Ellenbecker M (2008) A review of published quantitative experimental studies on factors affecting laboratory fume hood performance. J Occup Environ Hyg 5(11):735–753. https://doi.org/10.1080/15459620802399989

ANSYS (2009) ANSYS FLUENT 12.0 Theory Guide

ASHRAE (2016) ANSI/ASHRAE standard 110-2016, methods of testing performance of laboratory fume hoods. ASHRAE, Inc., Atlanta

Asadi S, Bouvier N, Wexler A, Ristenpart W (2020) The coronavirus pandemic and aerosols: does COVID-19 transmit via expiratory particles? Aerosol Sci Technol 54(6):635–638

Bennett JS, Crouch KG, Shulman SA (2003) Control of wake-induced exposure using an interrupted oscillating jet. Am Ind Hyg Assoc J 64(1):24–29. https://doi.org/10.1080/15428110308984779

Bavasso I, Vilardi G, Stoller M, Chianese A, Di Palma L (2016) Perspectives in nanotechnology based innovative applications for the environment. Chem Eng 47

Braconnier R, Bonthoux F (2010) Fluid dynamics of cytotoxic safety cabinets. Ann Occup Hyg 54(2):236–246

Caplan KJ, Knutson GW (1982) Influence of room air supply on laboratory hoods. Am Ind Hyg Assoc J 43(10):738–746

Denev JA, Durst F, Mohr B (1997) Room Ventilation and Its Influence on the Performance of Fume Cupboards: A Parametric Numerical Study. Ind Eng Chem Res 36:458–466

DiBerardinis LJ, First MW, Ivany RE (1991a) Field Results of an in-place, quantitative performance test for laboratory fume hoods. Appl Occup Environ Hyg 6(3):227–231

DiBerardinis LJ, First MW, Ivany RE (1991b) Field Results of an in-place, quantitative perfromance test for laboratory fume hoods. Appl Occup Environ Hyg 6(3):227–231

Ding Y, Kuhlbusch TA, Van Tongeren M, Jiménez AS, Tuinman I, Chen R et al (2017) Airborne engineered nanomaterials in the workplace—a review of release and worker exposure during nanomaterial production and handling processes. J Hazard Mater 322:17–28

Dunn K, Tsai S, Woskie S, Bennett J, Garcia A, Ellenbecker M (2014) Evaluation of leakage from fume hoods using tracer gas, tracer nanoparticles and nanopowder handling test methodologies. J Occup Environ Hyg 11(10)

Flynn MR, Ljungqvist B (1995a) A review of wake effects on worker exposure. Ann Occup Hyg 39(2):211–221

Flynn MR, Ljungqvist B (1995b) A review of wake effects on worker exposure. Ann Occup Hyg 39:211–221

Flynn MR, Ahn K, Miller CT (1995) Three-dimensional finite-element simulation of a turbulent push-pull ventilation system. Ann Occup Hyg 39(5):573–589

George DK, Flynn MR, Goodman R (1990) The impact of boundary layer separation on local exhaust design and worker exposure. Appl Occup Environ Hyg 5(8):501–509

Hinds WC (1999) Aerosol technology - properties, behavior, and measurement of airborne particles. vol Book, Whole. Wiley-Interscience, New York

Hu P, Ingham DB, Wen X (1996) Effect of the location of the exhaust duct, an exterior obstruction and handle on the air flow inside and around a fume cupboard. Ann Occup Hyg 40(2):127–144

Hu P, Ingham DB, Wen X (1998) Effect of baffles and a louvered bypass on the airflow and the convective patterns of contaminant inside a fume hood. Am Ind Hyg Assoc J 59(5):303–312

Huang RF, Chen HD, Hung CH (2007a) Effects of walk-by and sash movement on contaminant leakage of air curtain-isolated fume hood. Ind Health 45(6):804–816

Huang RF, Wu YD, Chen HD, Chen CC, Chen CW, Chang CP et al (2007b) Development and evaluation of an air-curtain fume cabinet with considerations of its aerodynamics. Ann Occup Hyg 51(2):189–206. https://doi.org/10.1093/annhyg/mel051

Ivany RE, First MW, Diberardinis LJ (1989) A new method for quantitative, in-use testing of laboratory fume hoods. Am Ind Hyg Assoc J 50(5):275–280

Kim TH, Flynn MR (1991a) Airflow pattern around a worker in a uniform freestream. Am Ind Hyg Assoc J 52:287–296

Kim TH, Flynn MR (1991b) Modeling a worker’s exposure from a hand-held source in a uniform freestream. Am Ind Hyg Assoc J 52(11):458–463

Kim TH, Flynn MR (1992) The effect of contaminant source momentum on a worker’s breathing zone concentration in a uniform freestream. Am Ind Hyg Assoc J 53(12):757–766

Kulmala I, Saamanen A, Enbom S (1996) The effect of contaminant source location on worker exposure in the near-wake region. Ann Occup Hyg 40(5):511–523. https://doi.org/10.1016/0003-4878(96)00003-8

Lan NS, Viswanathan S (2001a) Numerical simulation of airflow around a variable volume/constant face velocity fume cupboard. AIHAJ 62(3):303–312

Lan NS, Viswanathan S (2001b) Numerical simulation of airflow around a variable volume/constant face velocity fume cupboard. Am Ind Hyg Assoc J 62(3):303–312

Ljungqvist B (1991) Aerodynamic design of fume cupboards. Safety Health Pract 8:36–40

Ljungqvist B (1992) Ventilated benches and enclosures in laboratories. Safety Health Pract 10:41–44

Mosovsky JA (1995) Sulfur hexafluoride tracer gas evaluations on hood exhaust reductions. Am Ind Hyg Assoc J 56(1):44–49

Nicholson GP, Clark RP, de Calcina-Goff ML (2000) Computational fluid dynamics as a method for assessing fume cupboard performance. Ann Occup Hyg 44(3):203–217

NIOSH (2009) Approaches to Safe Nanotechnology: Managing the Health and Safety Concerns Associated with Engineered Nanomaterials. Cincinnati, OH: US Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No 2009–125

Ong S, Tan Y, Chia P, Lee T, Ng O, Wong M et al (2020) Air, surface environmental, and personal protective equipment contamination by severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) from a symptomatic patient. JAMA E1–E3. https://doi.org/10.1001/jama.2020.3227

Tsai SJ (2013) Potential inhalation exposure and containment efficiency when using hoods for handling nanoparticles. J Nanopart Res 15:1880. https://doi.org/10.1007/s11051-013-1880-2

Tsai SJ, Ada E, Isaacs J, Ellenbecker MJ (2009) Airborne nanoparticle exposures associated with the manual handling of nanoalumina and nanosilver in fume hoods. J Nanopart Res 11(1):147–161. https://doi.org/10.1007/s11051-008-9459-z

Tsai SJ, Huang RF, Ellenbecker MJ (2010) Airborne nanoparticle exposures while using constant-flow, constant-velocity, and air-curtain-isolated fume hoods. Ann Occup Hyg 54(1):78–87

Tseng L, Huang RF, Chen CC, Chang CP (2006) Correlation between airflow patterns and performance of a laboratory fume hood. J Occup Environ Hyg 3:694–706

Tseng LC, Huang RF, Chen CC, Chang CP (2007) Aerodynamics and performance verifications of test methods for laboratory fume cupboards. Ann Occup Hyg 51(2):173–187. https://doi.org/10.1093/annhyg/mel057

Tseng LC, Huang RF, Chen CC (2010) Significance of face velocity fluctuation in relation to laboratory fume hood performance. Ind Health 48(1):43–51

Varley JO, Ghorashi B (1997) The effect of turbulent structures on hood design—a review of CFD and flow visualization studies. HVAC R Res 3(3):291–308

Welling I, Andersson I-M, Rosen G, Räisänen J, Mielo T, Marttinen K et al (2000) Contaminant dispersion in the vicinity of a worker in a uniform velocity field. Ann Occup Hyg 44(3):219–225

Acknowledgements

The authors acknowledge the financial support of the technical contract titled “Computational fluid dynamics analysis of ventilated enclosures for the handling of nanomaterials” provided by National Institute for Occupational Safety and Health (NIOSH) for this project. Dr. Kevin Dunn was supported by NIOSH for this manuscript.

The findings and conclusions in this manuscript are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of a specific product or company does not constitute endorsement by the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Candace Su-Jung Tsai is the project Principal Investigator of a contract with the US National Institute for Occupational Safety and Health.

Rights and permissions

About this article

Cite this article

Shen, C., Dunn, K.H., Woskie, S.R. et al. The effect of the body wake and operator motion on the containment of nanometer-scale airborne substances using a conventional fume hood and specially designed enclosing hood: a comparison using computational fluid dynamics. J Nanopart Res 24, 79 (2022). https://doi.org/10.1007/s11051-022-05445-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-022-05445-z