Abstract

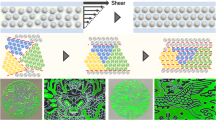

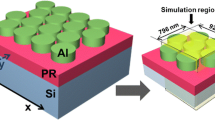

This study used colloidal lithography in conjunction with imprint lithography (embossing) to fabricate a light diffusion film based on the surface microstructure. An automated system was developed to arrange polystyrene (PS) spheres (diameter of 0.6 to 6 μm) on the substrate surface in a variety of configurations: single layer of spheres with constant diameter, single layer of spheres with multiple diameters, and double layer of spheres with multiple diameters. Optical diffusion testing revealed that PS spheres with a constant diameter created light patterns characterized by concentric circles induced by interference. PS spheres with multiple diameters were shown to reduce the interference. A double layer of spheres of various size presented the best optical diffusion performance. We reduced the effects of scattering between PS spheres through the use of embossing to duplicate the microstructure of the PS spheres, which resulted in outstanding diffusion performance with high transparency.

Similar content being viewed by others

References

Abdellatif MH, Salerno M, Abdelrasoul GN, Liakos I, Scarpellini A, Marras S, Diaspro A (2016a) Effect of Anderson localization on light emission from gold nanoparticle aggregates. Beilstein J Nanotechnol 7:2013–2022

Abdellatif MH, Ghosh S, Liakos I, Scarpellini A, Marras S, Salerno M (2016b) Effect of nanoscale size and medium on metal work function in oleylamine-capped gold nanocrystals. J Phys Chem Solids 89:7–14

Chang SI, Yoon JB (2004) Shape-controlled, high fill-factor microlens arrays fabricated by a 3D diffuser lithography and plastic replication method. Opt Express 12(25):6366–6371

Chang SI, Yoon JB, Kim HK, Kim JJ, Lee BK, Shin DH (2006) Microlens array diffuser for a light-emitting diode backlight system. Opt Lett 31(20):3016–3018

Choo H, Muller RS (2003) Optical properties of microlenses fabricated using hydrophobic effects and polymer-jet-printing technology. IEEE/LEOS International Conference on Optical MEMS

Chou YY, Lee KT, Lee YC (2016) Fabrication of hierarchical anti-reflective structures using polystyrenesphere lithography on an as-cut p-Si substrate. Appl Surf Sci 377:81–85

Guo S, Zhou SX, Li HJ, You B (2015) Light diffusing films fabricated by strawberry-like PMMA/SiO2 composite microspheres for LED application. J Colloid Interface Sci 448(15):123–129

Hu JG, Zhiou YM, Zhang T (2014) The novel optical diffusers based on the fillers of boehmite hollow microspheres. Mater Lett 136:114–117

Peng Q, Guo Y, Liu S (2002) Real-time gray-scale photolithography for fabrication of continuous microstructure. Opt Lett 27:1720–1722

Sales TRM (2003) Structured microlens arrays for beam shaping. Opt Eng 42:3084–3085

Sales TRM, Jian SC, Morris GM, Schertler DJ (2004) Engineered microlens arrays provide new control for display and lighting applications. Photonics Spectra 38(6)

Wang JH, Chen CF, Ho JR, Shih TK, Chen CC, Whang WT, Yang JY (2009) One-step fabrication of surface-relief diffusers by stress-induced undulations on elastomer. Opt Laser Technol 41:804–808

Zhong X, Hu JG, Zhou YM (2018) Template-free hydrothermal synthesis of 3D flower-like hollow Mg-Al layered double hydroxides microspheres for high-performance optical diffusers. Mater Lett 211:343–347

Funding

The support of this work was by the project from the Ministry of Science and Technology of Taiwan under grant number MOST 107-2221-E-033-067.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, JW., Kao, YM., Chiu, PW. et al. Light diffusion film fabricated using colloidal lithography and embossing. J Nanopart Res 23, 25 (2021). https://doi.org/10.1007/s11051-020-05125-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-020-05125-w