Abstract

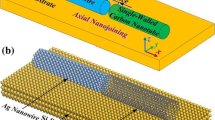

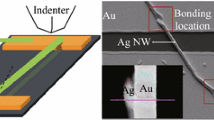

Ag nanowires are considered to be the promising candidates for future electronic circuit owing to the excellent electrical and thermal properties, with the miniaturization of electronics devices into nanometer scale. Though interconnect technology between Ag nanowires (Ag NWs) is essential for nanofunctional devices, it lacks sufficient experimental data. Besides, the determination of Ag NW interconnection configuration is experimentally difficult to do for lacking the sufficient investigation of atomic configuration evolution during nanojoining process. So the nanojoining between the crossed Ag NWs with the same diameter of 2 nm and different lengths was performed by molecular dynamics simulation to explain the unclear nanojoining mechanism based on thermal effect. As the simulation results present, when the nanojoining temperature is relatively high, though the Ag NWs are connected with the interpenetration effect of Ag atoms at the crossed nanojunction area, the nanostructures of Ag NWs have been seriously deformed with shorter length and larger diameter, showing relatively more obvious melting characteristics based on the chaotic atomic structures. If the temperature is reduced to 300 K as cold welding, the crossed Ag NWs can be partially contacted with the partial mixture of Ag atoms, and the interstices always exist between the Si surface and the upper Ag nanowire. In addition, the obvious dislocation phenomenon will appear and evolve as time goes on. Consequently, the dominant mechanism was revealed for providing a fundamental understanding of how ‘hot’ and ‘cold’ welding technology affects the atomic contact configuration, respectively.

Similar content being viewed by others

References

Chen C, Yan L, Kong ESW, Zhang Y (2006) Ultrasonic nanowelding of carbon nanotubes to metal electrodes. Nanotechnology 17:2192

Cui J, Yang L, Wang Y (2013a) Nanowelding configuration between carbon nanotubes in axial direction. Appl Surf Sci 264:713–717

Cui J, Yang L, Wang Y (2013b) Molecular dynamics study of the positioned single-walled carbon nanotubes with T-, X-, Y-junction during nanoscale soldering. Appl Surf Sci 284:392–396

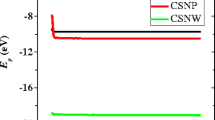

Cui J, Yang L, Wang Y (2013c) Molecular dynamics simulation study of the melting of silver nanoparticles. Integr Ferroelectr 145:1–9

Cui J, Yang L, Zhou L, Wang Y (2014a) Nanoscale soldering of axially positioned single-walled carbon nanotubes: a molecular dynamics simulation study. ACS Appl Mater Interfaces 6:2044–2050

Cui J, Yang L, Wang Y (2014b) Size effect of melting of silver nanoparticles. Rare Met Mater Eng 43:369–374

Cui J, Yang L, Wang Y, Mei X, Wang W, Hou C (2015) Nanospot soldering polystyrene nanoparticles with an optical fiber probe laser irradiating a metallic AFM probe based on the near-field enhancement effect. ACS Appl Mater Interfaces 7:2294–2300

Curto AG, Taminiau TH, Volpe G, Kreuzer MP, Quidant R, van Hulst NF (2013) Multipolar radiation of quantum emitters with nanowire optical antennas. Nat Commun 4:1750

Dockendorf CPR, Steinlin M, Poulikakos D, Choi TY (2007) Individual carbon nanotube soldering with gold nanoink deposition. Appl Phys Lett 90:193116

Duan X, Zhang J, Ling X, Liu Z (2005) Nano-welding by scanning probe microscope. J Am Chem Soc 127:8268–8269

Garnett EC, Cai W, Cha JJ, Mahmood F, Connor ST, Christoforo MG, Cui Y, McGehee MD, Brongersma ML (2012) Self-limited plasmonic welding of silver nanowire junctions. Nat Mater 11:241–249

Guo S (2010) The creation of nanojunctions. Nanoscale 2:2521–2529

Guo JY, Xu CX, Hu AM, Shi ZL, Sheng FY, Dai J, Li ZH (2012) Welding of gold nanowires with different joining procedures. J Nanopart Res 14:1–12

Kim SJ, Jang DJ (2005) Laser-induced nanowelding of gold nanoparticles. Appl Phys Lett 86:033112

Kim A, Won Y, Woo K, Kim CH, Moon J (2013) Highly transparent low resistance ZnO/Ag nanowire/ZnO composite electrode for thin film solar cells. ACS Nano 7:1081–1091

Lu Y, Huang JY, Wang C, Sun S, Lou J (2010) Cold welding of ultrathin gold nanowires. Nat Nanotechnol 5:218–224

Peng Y, Cullis T, Inkson B (2008) Bottom–up nanoconstruction by the welding of individual metallic nanoobjects using nanoscale solder. Nano Lett 9:91–96

Pereira ZS, Da Silva EZ (2011) Cold welding of gold and silver nanowires: a molecular dynamics study. J Phys Chem C 115:22870–22876

Semiconductor Industry Association. International Technology Roadmap for Semiconductors (2013). http://public.itrs.net/

Shen G, Lu Y, Shen L, Zhang Y, Guo S (2009) Nondestructively creating nanojunctions by combined-dynamic-mode dip-pen nanolithography. ChemPhysChem 10:2226–2229

Sun H (1994) Force field for computation of conformational energies, structures, and vibrational frequencies of aromatic polyesters. J Comput Chem 15:752–768

Sun H (1998) COMPASS: an ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J Phys Chem B 102:7338–7364

Timpel D, Scheerschmidt K, Garofalini SH (1997) Silver clustering in sodium silicate glasses: a molecular dynamics study. J Non-Cryst Solids 221:187–198

Tohmyoh H, Imaizumi T, Hayashi H, Saka M (2007) Welding of Pt nanowires by Joule heating. Scr Mater 57:953–956

van de Groep J, Spinelli P, Polman A (2012) Transparent conducting silver nanowire networks. Nano Lett 12:3138–3144

Wu W, Hu A, Li X, Wei J, Shu Q, Wang K, Yavuz M, Zhou Y (2008) Vacuum brazing of carbon nanotube bundles. Mater Lett 62:4486–4488

Xu S, Tian M, Wang J, Xu J, Redwing JM, Chan MHW (2005) Nanometer-scale modification and welding of silicon and metallic nanowires with a high-intensity electron beam. Small 1:1221–1229

Yan K, Xue Q, Xia D, Chen H, Xie J, Dong M (2009) The core/shell composite nanowires produced by self-scrolling carbon nanotubes onto copper nanowires. ACS Nano 3:2235–2240

Acknowledgments

This project was supported by National Natural Science Foundation of China (51505371), Hong Kong Scholars Program (XJ2015038), China Postdoctoral Science Foundation (2014M562397, 2015T81018), Fundamental Research Funds for the Central Universities (xjj2015009), and Open Research Fund of Key Laboratory of High Performance Complex Manufacturing, Central South University (Kfkt2015-06). All the authors gratefully acknowledge their support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cui, J., Wang, X., Barayavuga, T. et al. Nanojoining of crossed Ag nanowires: a molecular dynamics study. J Nanopart Res 18, 175 (2016). https://doi.org/10.1007/s11051-016-3479-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-016-3479-x