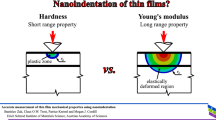

The dependence of microstructure and mechanical properties on the thickness of Ni/Ti coatings deposited on a Si(100) substrate by magnetron sputtering and on the temperature of their subsequent annealing is studied. The thickness and the surface roughness of the coatings are determined using profilometry and atomic force microscopy. Nanoindentation is used to determine the penetration resistance, the hardness, and the modulus of elasticity. The layers with minimum thickness are shown to possess the highest mechanical properties. Annealing conducted after the sputtering results in gradual retardation of the process of coarsening of atomic clusters and improvement of the mechanical properties of the layer.

Similar content being viewed by others

References

“MEMS materials and processes handbook,” Choice Rev. Online, 49, 49–0882 (2011). https://doi.org/10.5860/choice.49-0882

M. Kohl, B. Krevet, M. Ohtsuka, et al., “Ferromagnetic shape memory microactuators,” Mater. Trans., 47, 639 – 644 (2006).

E. Makino, T. Mitsuya, and T. Shibata, “Fabrication of TiNi shape memory micropump,” Sens. Actuator. A Phys., 88, 256 – 262 (2001).

J. J. Gill, D. J. Chang, L. A. Momoda, and G. P. Carman, “Manufacturing issues of thin film NiTi microwrapper,” Sens. Actuator. A Phys., 93, 148 – 156 (2001.

D. Xu D., L.Wang, G. Ding, et al., “Characteristics and fabrication of NiTi/Si diaphragm micropump,” Sens. Actuator. A Phys., 93, 87 – 92 (2001).

B. O’Brien,W. M. Carroll, and M. J. Kelly, “Passivation of nitinol wire for vascular implants — a demonstration of the benefits,” Biomaterials, 23, 1739 – 1748 (2002).

M. Bendahan, P. Canet, J. L. Seguin, and H. Carchano, “Control composition study of sputtered Ni – Ti shape memory alloy film,” Mater. Sci. Eng. B, 34, 112 – 115 (1995).

J. Van Humbeeck, “Shape memory alloys: A material and a technology,” Adv. Eng. Mater., 3, 837 – 850 (2001).

A. Kumar, D. Singh, and D. Kaur, “Grain size effect on structural, electrical and mechanical properties of NiTi thin films deposited by magnetron co-sputtering,” Surf. Coatings Technol., 203, 1596 – 1603 (2009).

A. Ishida and V. Martynov, “Sputter-deposited shape-memory alloy thin films: Properties and applications,” MRS Bull., 27, 111 – 114 (2002).

S. Miyazaki, Y. Q. Fu, and W. M. Huang, Thin Film Shape Memory Alloys: Fundamentals and Device Applications, Cambridge Iniversity Press (2009), 160 p.

A. Gyobu, Y. Kawamura, T. Saburi, and M. Asai, “Two-way shape memory effect of sputter-deposited Ti-rich Ti – Ni alloy films,” Mater. Sci. Eng. A, 312, 227 – 231 (2001).

A. Ishida, M. Sato, A. Takei, et al., “Effect of aging on shape memory behavior of Ti – 51.3 at. Pct Ni thin films,” Metall. Mater. Trans. A, 27, 3753 – 3759 (1996).

S. Kajiwara, T. Kikuchi, K. Ogawa, et al., “Strengthening of Ti – Ni shape-memory films by coherent subnanometric plate precipitates,” Philos. Mag. Lett., 74, 137 – 144 (1996).

A. Ishida, M. Sato, A. Takei, and S. Miyazaki, “Effect of heat treatment on shape memory behavior of Ti-rich Ti – Ni thin films,” Mater. Trans. JIM, 36, 1349 – 1355 (1995).

L. Zhang, C. Xie, and J.Wu, “Oxidation behavior of sputter-deposited Ti – Ni thin films at elevated temperatures,” Mater. Charact., 58, 471 – 478 (2007).

E. Quandt, C. Halene, H. Holleck, et al., “Sputter deposition of TiNi, TiNiPd and TiPd films displaying the two-way shape-memory effect,” Sens. Actuator. A Phys., 53, 434 – 439 (1996).

S. Yu. Kondrat’ev, G. Ya. Yaroslavskii, and B. S. Chaikovskii, “Classification of high-damping metallic materials,” Strength Mater., 18(10), 1325 – 1329 (1986).

S. Yu. Kondrat’ev, O. G. Zotov, G. Ya. Yaroslavskii, et al., “Investigation of interrelationship between damping capacity and mechanical properties as well as morphology of martensite in alloys with reversible martensite transformation,” Prob. Prochn., 14B(3), 79 – 82 (1983).

S. Yu. Kondrat’ev, G. Ya. Yaroslavsii, B. S. Chaikovskii, and V. V. Matveev, “Effect of doping and hardening conditions on mechanical properties and microstructure of Br.A10 alloy,” Prob. Prochn., 7(145), 98 – 101(1981).

J. Rao, T. Roberts, K. Lawson, and J. Nicholls, “Nickel titanium and nickel titanium hafnium shape memory alloy thin films,” Surf. Coat. Technol., 204, 2331 – 2336 (2010).

J. L. He, K. W. Won, C. T. Chang, et al., “Cavitation-resistant TiNi films deposited by using cathodic arc plasma ion plating,” Wear, 233 – 235, 104 – 110 (1999).

T. Girardeau, K. Bouslykhane, J. Mimault et al., “Wear improvement and local structure in nickel-titanium coatings produced by reactive ion sputtering,” Thin Solid Films, 283, 67 – 74 (1996).

D. J.Wever, A. G. Veldhuizen, J. De Vries et al., “Electrochemical and surface characterization of a nickel–titanium alloy,” Biomaterials, 19, 761 – 769 (1998).

W. Ni, Y. T. Cheng, M. Lukitsch, et al., “Novel layered tribological coatings using a superelastic NiTi interlayer,” Wear, 259, 842 – 848 (2005).

X. G. Ma and K. Komvopoulos, “Pseudoelasticity of shape-memory titanium-nickel films subjected to dynamic nanoindentation,” Appl. Phys. Lett., 84, 4274 – 4276 (2004).

W. Ni, Y. T. Cheng, and D. S. Grummon, “Recovery of microindents in a nickel-titanium shape-memory alloy: A “self-healing” effect,” Appl. Phys. Lett., 80, 3310 – 3312 (2002).

H. Pelletier, D. Muller, P. Mille, and J. J. Grob, “Structural and mechanical characterisation of boron and nitrogen implanted NiTi shape memory alloy,” Surf. Coat. Technol., 158 – 159, 309 – 317 (2002).

Y. Zhang, Y. T. Cheng, and D. S. Grummon, “Indentation stress dependence of the temperature range of microscopic superelastic behavior of nickel-titanium thin films,” J. Appl. Phys., 98, 033505 (2005).

E. Wibowo and C. Y. Kwok, “Fabrication and characterization of sputtered NiTi shape memory thin films,” J. Micromech. Microeng., 16, 101 – 108 (2006).

K. S. S. E. Raju, S. Bysakh, M. A. Sumesh et al., “The effect of ageing on microstructure and nanoindentation behaviour of dc magnetron sputter deposited nickel rich NiTi films,” Mater. Sci. Eng. A, 476, 267 – 273 (2008).

G. M. Pharr and W. C. Oliver, “Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology,” J. Mater. Res., 19, 3 – 20 (2004).

W. C. Oliver and G. M. Pharr, “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res., 7, 1564 – 1583 (1992).

A. Behera and S. Aich, “Characterisation and properties of magnetron sputtered nanoscale bi-layered Ni/Ti thin films and effect of annealing,” Surf. Interface Anal., 47(8), 805 – 814 (2015).

A. Behera, R. Suman, S. Aich, and S. S. Mohapatra, “Sputter-deposited Ni/Ti double-bilayer thin film and the effect of intermetallics during annealing,” 49(7), 620 – 629 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 40 – 45, March, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patro, S., Saxena, K.K. & Behera, A. Effect of Annealing Temperature and Thickness of Magnetron Sputtered Ni/Ti Film on Its Microstructure and Nanoindentation Behavior. Met Sci Heat Treat 65, 167–172 (2023). https://doi.org/10.1007/s11041-023-00909-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00909-y