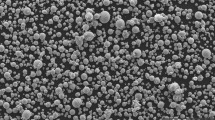

The effect of annealing at 700, 800, 900 and 1000°C on the microstructure and mechanical properties of alloy Ti – 6% Al – 4% V obtained by selective laser melting is studied. The ultimate tensile strength, the yield strength, the elongation, and the hardness of samples of the titanium alloy are determined in the initial condition and after annealing. X-ray diffraction and phase analyses are performed. The changes in the structure of the alloy during annealing at different temperatures are analyzed. It is shown that the intensity of the structural changes increases with the annealing temperature, while the microhardness and the strength characteristics decrease, and the ductility grows.

Similar content being viewed by others

References

Y.-Z. Xiong, R.-N. Gao, H. Zhang, et al., “Rationally designed functionally graded porous Ti6Al4V scaffolds with high strength and toughness built via selective laser melting for load-bearing orthopedic applications,” J. Mech. Behav. Biomed. Mater., 104, Art. 103673 (2020).

A. Arjunan, M. Demetriou, A. Baroutaji, and C. Wang, “Mechanical performance of highly permeable laser melted Ti6Al4V bone scaffolds.” J. Mech. Behav. Biomed. Mater., 102, Art. 103517 (2020).

J. S. Galindo-Valdés, D. A. Cortes-Hernandez, J. C. Ortiz-Cuellar, et al., “Laser deposition of bioactive coatings by in situ synthesis of pseudowollastonite on Ti6Al4V alloy,” Opt. Laser Technol., 134, Art. 106586 (2020).

Hafiz Muhammad Hamza, Kashif Mairaj Deen, and Waseem Haider, “Microstructural examination and corrosion behavior of selective laser melted and conventionally manufactured Ti6Al4V for dental applications., Mater. Sci. Eng. C, 113, Art. 110980 (2020).

S. Liu and Y. C. Shin, “Additive manufacturing of Ti6Al4V alloy: a review,” Mater. Des., 164, Art. 107552 (2019).

L. Thijs, F. Verhaeghe, T. Craehgs, et al., “A study of the microstructural evolution during selective laser melting of Ti – 6Al – 4V,” Acta Mater., 58, 3303 – 3312 (2010).

P. Ginestra, R. M. Ferraro, K. Zohar-Hauber, et al., “Selective laser melting and electron beam melting of Ti6Al4V for orthopedic applications: Acomparative study on the applied building direction,” Materials, 13(23), Art. 5584 (2020).

W. Ge, S. Han, S. J. Na, and J. Y. H. Fuh, “Numerical modelling of surface morphology in selective laser melting,” Comp. Mater. Sci., 186, Art. 110062 (2020).

W. Liu, C. Chen, S. Shuai, et al., “Study of pore defect and mechanical properties in selective laser melted Ti6Al4V alloy based on x-ray computed tomography,” Mater. Sci. Eng. A, 797, Art. 139981 (2020).

M. Hussain, P. Gupta, P. Kumar, and A. K. Das, “Selective laser melting of single track on Ti – 6Al – 4V powder: Experimentation and finite element analysis,” Arab. J. Sci. Eng., 45(2), 1173 – 1180 (2020).

X. Miao, X. Liu, P. Lu, et al., “Influence of scanning strategy on the performances of GO-reinforced Ti6Al4V nanocomposites manufactured by SLM,” Metals, 10(10), Art. 1379 (2020).

S.Wang, Z. Shi, L. Liu, et al., “The design of Ti6Al4V primitive surface structure with symmetrical gradient of pore size in biomimetic bone scaffold,” Mater. Des., 193(5), Art. 109930 (2020).

L. Bai, J. Zhang, Y. Xiong, et al., “Influence of unit cell pose on the mechanical properties of Ti6Al4V lattice structures manufactured by selective laser melting,” Addit. Manuf., 34, Art. 101222 (2020).

C. Qian, H. Xu, and Q. Zhong, “The influence of process parameters on corrosion behavior of Ti6Al4V alloy processed by selective laser melting,” J. Laser Appl., 32(3), 032010 (2020).

Z. Xiao, C. Chen, H. Zhu, et al., “Study of residual stress in selective laser melting of Ti6Al4V,” Mater. Des., 193, Art. 108846 (2020).

X. Miao, M. Wu, J. Han, et al., “Effect of laser rescanning on the characteristics and residual stress of selective laser melted titanium Ti6Al4V alloy,” Materials, 13(18), Art. 3940 (2020).

A. I. Rudskoy, I. M. Belov, S. K. Gordeev, et al., “Carbon nanostructured implants for substituting bone defects and process of their production,” Met. Sci. Heat Treat., 60(1 – 2) (2018).

B. Vrancken, L. Thijs, J.-P. Kruth, and J. Van Humbeek, “Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties,” J. Alloys Compd., 541, 177 – 185 (2012).

T. Vilaro, C. Colin, and J. D. Bartout, “As-fabricated and heat-treated microstructures of the Ti – 6Al – 4V alloy processed by selective laser melting,” Metall. Mater. Trans. A, 42(10), 3190 – 3199 (2011).

X. Yan, C. Shi, T. Liu, et al., 2020. “Effect of heat treatment on the corrosion resistance behavior of selective laser melted Ti6Al4V ELI,” Surf. Coat. Technol., 396, Art. 125955 (2020).

Q. Huang, X. Liu, X. Yang, et al., “Specific heat treatment of selective laser melted Ti – 6Al – 4V for biomedical applications,” Front. Mater. Sci., 9(4), 373 – 381 (2015).

J. Li, Z.Wei, L. Yang, et al., “Finite element analysis of thermal behavior and experimental investigation of Ti6Al4V in selective laser melting,” Optik, 207, Art. 163760 (2019).

O. V. Kondrat’eva, S. Yu. Kondrat’ev, and O. V. Shvetsov, “A study of modes of hardening heat treatment of titanium alloy VT23,” Met. Sci. Heat Treat., 60(11 – 12), 715 – 721 (2019).

Z. Zhan-Yong, L. Li, P.-K. Bai, et al., “The heat treatment influence on the microstructure and hardness of TC4 titanium alloy manufactured via selective laser melting,” Materials, 11(8), Art. 1318 (2018).

E. Leva, R. Caram, A. L. Jardini, and J. B. Fogagnolo, “Ductility improvement due to martensite α' decomposition in porous Ti – 6Al – 4V parts produced by selective laser melting for orthopedic implants,” J. Mech. Behav. Biomed Mater., 54, 149 – 158 (2016).

Q. Chao, P. D. Hodgson, and H. Beladi, “Ultrafine grain formation in a Ti – 6Al – 4V alloy by thermomechanical processing of a martensitic microstructure,” Metall. Mater. Trans. A, 45(5), 2659 – 2671 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 24 – 32, January, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qu, Y., Luo, Z., Dong, X. et al. Effect of Annealing Temperature on the Microstructure and Mechanical Properties of Selective Laser Melted Alloy Ti – 6% Al – 4% V. Met Sci Heat Treat 64, 26–33 (2022). https://doi.org/10.1007/s11041-022-00760-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00760-7