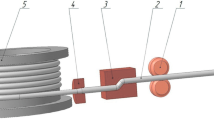

Results of deformation of aluminum of grade 6061 by the method of combined extrusion in a die with parallel channels and drawing are presented. It is shown that use of this technology makes it possible to increase the set of aluminum mechanical properties compared with conventional drawing.

Similar content being viewed by others

References

G. J. Raab, R. Z. Valiev, Y. T. Zhu, and T. C. Lowe, “Continuous processing of ultrafine grained Al by ECAP–Conform,” Mater. Sci. Eng., 382, 30 – 34 (2004).

I. E. Volokitina and G. G. Kurapov, “Effect of initial structural state on formation of structure and mechanical properties of steels under ECAP,” Metal Sci. Heat Treat., 59(11 – 12), 786 – 792 (2018).

G. G. Kurapov, E. P. Orlova, I. E. Volokitina, and A. Turdaliev, “Plasticity as a physical-chemical process of deformation of crystalline solids,” J. Chem. Technol. Metall., 51, 451 – 457 (2016).

A. A. Gazder, F. Dalla Torre, C. F. Gu. et al., “Microstructure and texture evolution of bcc and fcc metals subjected to equal channel angular extrusion,” Mater. Sci. Eng., 415, 126 – 139 (2006).

Y. Ywahashi, Z. Horita, M. L. Nemoto, and T. G. Langdon, “An investigations of microstructural evolution during equal-channel angular pressing,” Acta Mater., 45, 4733 – 4742 (1997).

A. I. Rudskoi, A. A. Bogatov, D. Sh. Nukhoov, and O. A. Tokushkin, “New metal intense plastic deformation method,” Metalloved. Term. Obrab. Met., No. 1, 1 – 5 (2018)

I. E. Volokitina, “Effect of cryogenic cooling after ECAP on mechanical properties of aluminum alloy D16,” Metal Sci. Heat Treat., 61(3 – 4), 234 – 238 (2019).

G. I. Raab, E. I. Fakhretdinova, R. Z. Valiev, et al., “Computer study of the effect of tooling geometry on deformation parameters in the plastic shaping of aluminum wire rod by MultiECAP-Conform,” Metallurgist, 59(11 – 12), 1007 – 1014 (2016).

D. V. Gunderov, A. V. Polyakov, and I. P. Semenova, “Evolution of microstructure, macrotexture and mechanical properties of commercially pure Ti during ECAP-conform processing and drawing,” Mater. Sci. Eng. A, 562, 128 – 136 (2013).

S. Lezhnev, E. Panin, and I. Volokitina, “Research of combined process rolling-pressing influence on the microstructure and mechanical properties of aluminium,” Adv. Mater. Res., 814, 68 – 75 (2013).

Yu. V. Gorkhov, V. G. Sherkunov, and I. L. Konstantinov, “Research methodology for combined metal continuous casting and extrusion,” Vestn. Uzhno-Ural. Gos. Univ., Ser. Metallurgiya, 15(2), 82 – 88 (2015).

A. G. Korchunov, M. V, Chukin, M. A. Polyakova, and D. G. Emaleeva, “Planning principles of a continuous casting method for steel wire preparation with an ultrafine structure,” Vestn. Magnitogorsk. Gos. Tekh. Univ. Im G. I. Nosova, No. 1, 43 – 46 (2011).

A. B. Naizabekhov, and É. M. Azbandaev, “Mathematical modeling of equal-channel angular drawing in a stepped tool,” Tekhnol. Proizvod. Metall. Vtor. Mater., No. 1, 178 – 186 (2011)

A. V. Volokitin, G. G. Kurapov, I. E. Volokitina, and E. A. Panin, “Modeling combined pressing and drawing process,” Respub. Nauch. Zh., Dokl. Nats. Akad. Nauk Respub. Kazakhstan, No. 2, 96 – 101 (2017).

S. N. Lezhnev, I. E. Volokitina, and A. V. Volokitin, “Evolution of microstructure and mechanical properties of steel during pressing–drawing,” Phys. Met. Metallogr., 118(11), 1167 – 1170 (2017).

I. E. Volokitina and A. V. Volokitin, “Evolution of the microstructure and mechanical properties of copper during the pressing–drawing process,” Phys. Met. Metallogr., 119(9), 917 – 921 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 51 – 55, June, 2021.

Rights and permissions

About this article

Cite this article

Volokitin, A.V., Kambarov, K.A. & Latypova, M.A. Effect of Extrusion and Drawing Deformation Method on Aluminum Alloy 6101 Structure and Mechanical Properties. Met Sci Heat Treat 63, 341–344 (2021). https://doi.org/10.1007/s11041-021-00692-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00692-8