The structure, phase composition and impact toughness of specimens cut from different-thickness regions of a billet with cross section 160 × 160 mm from continuously cast high-speed steel R6M5 are studied. It is shown that the macro- and microstructure, phase composition, and process ductility of the continuously cast high-speed steel R6M5 are substantially higher than those of the steel obtained by traditional casting into molds.

Similar content being viewed by others

References

L. S. Kremnev, “High-speed steel: basic material for cutting tools,” Nats. Metall., Perspekt. Mater., No. 3, 31 – 35 (2001).

M. K. Skakov, B. K. Rakhadilov, G. S. Karipbaeva, and A. B. Manapbaeva, “Structural and phase state of high-speed steel R6M5 after heat treatment,” KazNU Bull., Phys. Ser., No. 1(148), 53 – 59 (2014).

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1975), 584 p.

A. S. Chaus, “Structural and phase changes in carbides under heat treatment of high-speed steel,” Fiz. Met. Metalloved., 117(7), 706 – 714 (2016).

P. F. Nizhnikovskaya, E. P. Kalinushkin, L. M. Snagovskii, and G. F. Demchenko, “Formation of structure in high-speed steel under crystallization,” Metalloved. Term. Obrab. Met., No. 11, 23 – 30 (1982).

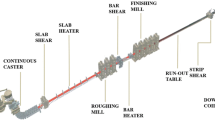

A. V. Soupov, N. M. Alexandrova, C. L. Parenkov, et al., “Industrial manufacturing of high-speed steels using the continuous casting method,” in: 3rd Int. Conf. on Continuous Casing, Madrid, Spain, October 20 – 23, 1988, pp. 981 – 985.

A. V. Supov, N. M. Aleksandrova, S. A. Paren’kov, et al., “Metallographic problems of the production of articles from continuously cast high-speed steels,” Metalloved. Term. Obrab. Met., No. 9, 6 – 13 (1998).

N. M. Aleksandrova, M. P. Galkin, S. Yu. Makushev, et al., “A new method for raising the process ductility of hard-to-deform tool steels and its implementation in continuous casting of tools,” Stal’, No. 12, 63 – 69 (2012).

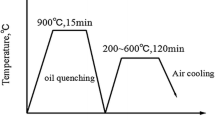

S. L. Paren’kov, R. V. Kakabadze, V. P. Pavlov, et al., “Complex process of casting-crystallization heat treatment in continuous casting of high-speed steels,” Metallurg, No. 11, 39 – 41 (1999).

N. M. Aleksandrova, A. V. Supov, R. B. Kakabadze, et al., “Technological features of production and heat treatment of continuously cast high-speed steel R6M5,” Stal’, No. 5, 58 – 63 (2002).

N. M. Aleksandrova, O. A. Bagmet, I. B. Chudakov, and A. O. Cheretaeva, “Structure and phase analysis of rolled sections and in a heat-treated continuously cast billet from high-speed steel R6M5,” Vest. Sovr. Tekhnol., No. 3(11), 4 – 11 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 13 – 20, November, 2020.

Rights and permissions

About this article

Cite this article

Aleksandrova, N.M., Cheretaeva, A.O., Mishet’yan, A.R. et al. Special Features of the Structure and Properties of Continuously Cast Billet from Steel R6M5. Met Sci Heat Treat 62, 669–676 (2021). https://doi.org/10.1007/s11041-021-00621-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00621-9