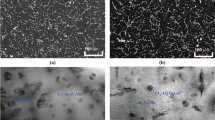

The evolution of the structure and mechanical properties of sheets from alloy Al – 4.7% Mg – 0.32% Mn – 0.21% Sc – 0.09% Zr during warm rolling and subsequent annealing is studied. It is shown that extended fibers with a thickness of 50 – 100 nm form inside the deformed grains in the rolling process. Post-rolling annealing of the sheets at 150 and 200°C results in substantial lowering of the elongation after a hold for 3 h; then the ductility recovers after a hold for 5 h. The lowering of the ductility is associated with precipitation of a fine β -phase over grain boundaries during the annealing. The phase grows and its volume fraction decreases when the annealing time is prolonged. The possibility of formation of high-level mechanical properties after warm rolling and subsequent annealing is shown.

Similar content being viewed by others

References

V. V. Rybin, High Plastic Deformations and Fracture of Metals [in Russian], Metallurgiya, Moscow (1986), 224 p.

S. S. Gorelik, S. V. Dobatkin, and L. M. Kaputkina, Recrystallization of Metals and Alloys [in Russian], MISiS, Moscow (2005), 432 p.

Yu. A. Filatov, G. G. Baydin, R. I. Dobrozhinskaya, et al., “Novel heat-hardenable weldable cryogenic alloy 1545K based on the Al – Mg – Sc system,” Tekhnol. Legk. Splavov, No. 1, 32 – 36 (2014).

Yu. A. Filatov, V. I. Yelagin, and V. V. Zakharov, “New Al – Mg – Sc alloys,” Mater. Sci. Eng. A, 280, 97 – 100 (2000).

V. I. Elagin and V. A. Livanova (eds.), Aluminum Alloys. Structure and Properties of Semiproducts from Aluminum Alloys [in Russian], Metallurgiya, Moscow (1984), 408 p.

V. G. Davydov, T. D. Rostova, V. V. Zakharov, et al., “Scientific principles of making an alloying addition of scandium to aluminum alloys,” Mater. Sci. Eng. A, 280, 30 – 36 (2000).

O. Roder, T. Wirtz, A. Gysler, and G. Lutjering, “Fatigue properties of Al – Mg alloys with and without scandium,” Mater. Sci. Eng. A, 234 – 236, 181 – 184 (1997).

A. Washikita, K. Kitagawa, V. I. Kopylov, and A. Vinogradov, “Tensile and fatigue properties of Al – Mg – Sc – Zr alloy fine-grained by equal-channel angular pressing,” in: Y. T. Zhu, T. G. Langdon, R. S. Mishra, S. L. Semiatin, M. J. Saran, and T. C. Lou (eds.), Ultrafine Grain Metals II, TMS (2002), p. 341.

R. Z. Valiev, A. V. Korznikov, and R. R. Milyukov, “Structure and properties of ultrafine-grained materials produced by severe plastic deformation,” Mater. Sci. Eng. A, 168, 141 – 148 (1993).

I. Sabirov, M. Yu. Murashkin, and R. Z. Valiev, “Nanostructured aluminum alloys produced by severe plastic deformation: New horizons in development,” Mater. Sci. Eng. A, 560, 1 – 24 (2013).

R. Z. Valiev and T. G. Langdon, “Principles of equal-channel angular pressing as a processing tool for grain refinement,” Prog. Mater. Sci., 51, 881 – 981 (2001).

A. P. Zhilyaev and T. G. Langdon, “Using high-pressure torsion for metal processing: Fundamentals and applications,” Prog. Mater. Sci., 53, 893 – 979 (2008).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, “Novel ultrahigh straining process for bulk materials—development of the accumulative roll-bonding (ARB) process,” Acta Mater., 47, 579 – 583 (1999).

A. Vinogradov, A. Washikita, K. Kitagawa, and V. I. Kopylov, “Fatigue life of fine-grain Al – Mg – Sc alloys produced by equal-channel angular pressing,” Mater. Sci. Eng. A, 349, 318 – 326 (2003).

H. J. Roven, H. Nesboe, J. C. Werenskiold, and T. Seibert, “Mechanical properties of aluminum alloys processed by SPD: Comparison of different alloy systems and possible product areas,” Mater. Sci. Eng. A, 410 – 411, 426 – 429 (2005).

E. V. Avtokratova, R. O. Kaibyshev, and O. Sh. Sitdikov, “Fatigue of a fine-grained high-strength Al – 6Mg – Sc alloy produced by equal-channel angular pressing,” Phys. Met. Metall., 105(5), 500 – 508 (2008).

O. Sh. Sitdikov, E. V. Avtokratova, and R. I. Babicheva, “Effect of temperature on the formation of a microstructure upon equal channel angular pressing of the Al – Mg – Sc 1570 alloy,” Phys. Met. Metall., 110(2), 153 – 161 (2010).

E. V. Avtokratova, O. Sh. Sitdikov, R. O. Kaibyshev, and Y. Watanabe, “Behavior of a submicrocrystalline aluminum alloy 1570 under conditions of cyclic loading,” Phys. Met. Metall., 107(3), 291 – 297 (2009).

V. S. Zolotarevskiy, R. I. Dobrojinskaja, V. V. Cheverikin, et al., “Evolution of structure and mechanical properties of Al – 4.7Mg – 0.32Mn – 0.21Sc – 0.09Zr alloy sheets after accumulated deformation during rolling,” Phys. Met. Metall., 117(11), 1163 – 1169 (2016).

V. S. Zolotarevskiy, R. I. Dobrojinskaja, V. V. Cheverikin, et al., “Strength and substructure of Al – 4.7Mg – 0.32Mn – 0.21Sc – 0.09Zr alloy sheets,” Phys. Met. Metall., 118(4), 407 – 414 (2017).

The work has been performed with support of the Ministry of Education and Science of the Russian Federation within State Provision No. 11.7172.2017/BCh for higher educational organizations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 20 – 25, July, 2019.

Rights and permissions

About this article

Cite this article

Pozdnyakov, A.V., Barkov, R.Y., Yakovtseva, O.A. et al. Warm Deformation of Alloy Al – 4.7% Mg – 0.32% Mn – 0.21% Sc – 0.09% Zr. Met Sci Heat Treat 61, 416–420 (2019). https://doi.org/10.1007/s11041-019-00439-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00439-6