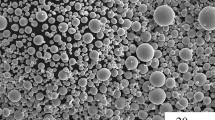

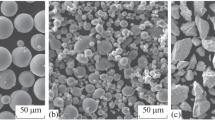

The possibility of fabrication of rapidly quenched fibers from alloy Ti – 22Al – 27Nb by extracting a hanging melt drop is studied. The special features of the production of electrodes for spraying the fibers by sintering mechanically alloyed powdered components of the alloy, i.e., titanium hydride, niobium, and aluminum dust, are studied. The rapidly quenched fibers with homogeneous phase composition and fine-grained structure produced from alloy Ti – 22Al – 27Nb are suitable for manufacturing compact semiproducts by hot pressing.

Similar content being viewed by others

References

D. Banerjee, “The intermetallic Ti2AlNb,” Progr. Mater. Sci., 42(1 – 4), 135 – 158 (1997).

L. Germann, D. Banerjee, I. Y. Guédou, and J. L. Strudel, “Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide,” Intermetallics, 13(9), 290 – 294, Sept. (2005).

J. Kumpfert, “Intermetallic alloys based on orthorhombic titanium aluminide,” Adv. Eng. Mater., 3(11), 851 – 864 (2001).

C. F. Yolton and J. P. Beckman, “Powder metallurgy processing and properties of the ordered orthorhombic alloy Ti – 22 at.% Al – 23 at.% Nb,” Mater. Sci. Eng. A, 192 – 193, Pt. 2, 597 – 603, Feb. (1995).

Kaifeng Zhang, Yuanxin Wang, Jianbo Jia, and Baoyong Li, “Deformation properties and bending/diffusion processing of a P_M Ti – 22Al – 25Nb alloy at elevated temperature,” Proc. Eng., 81, 2153 – 2158 (2014).

W. Chen and J. W. Li, “Development of Ti2AlNb alloys: opportunities and challenges,” Adv. Mater. Proc., 172(4), 23 – 27 (2014).

O. Kh. Fatkulin, G. B. Stroganov, A. A. Il’in, et al., The Metal Science and Technology of Rapidly Quenched Alloys [in Russian], MAI, Moscow (2009).

N. A. Nochovnaya, E. B. Alekseev, K. K. Yasinskii, and A. S. Kochetkov, “Specifics of melting and methods of fabrication of ingots of intermetallic titanium alloys with elevated content of niobium,” Vestn. MGTU Im. Baumana, Ser. Mashinostr., 53 – 59 (2011).

V. N. Antsiferov, M. M. Serov, V. P. Lezhnin, and A. A. Smetkin, “About fabrication, properties and application of rapidly cooled fibers,” Izv. Vysh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokryt., No. 4, 36 – 40 (2011).

M. M. Serov, “Microcrystalline and amorphous alloys obtained by the method of rapid quenching of melt,” Tekhnol. Legk. Splavov, No. 4, 43 – 40 (2008).

K. B. Povarova, N. K. Kazanskaya, A. A. Drozdov, et al., “Fabrication of ruthenium aluminide by the method of reaction sintering of a mixture of Ru and Al powders,” Metally, No. 3, 119 – 125 (2002).

M. Bououdin and Z. X. Guo, “Characterisation of structural stability of (Ti(H2) + 22Al + 23Nb) powder mixtures during mechanical alloying,” Mater. Sci. Eng., A332, 210 – 222 (2002).

Y. X.Wang, K. F. Zhang, and B. Y. Li, “Microstructure and high temperature tensile properties of Ti22Al25Nb alloy prepared by reactive sintering with element powders,” Mater. Sci. Eng., A608, 229 – 233 (2014).

Kyong-Ho Sim, Guofeng Wang, Jong-Min Ju, et al., “Microstructure and mechanical properties of a Ti – 22Al – 25Nb alloy fabricated from elemental powders by mechanical alloying and spark plasma sintering,” J. Alloys Compd., 704, 425 – 433 (2017).

V. N. Antsiferov and A. A. Smetkin, “Effect of consolidation conditions on the structure of mechanically alloyed Ti – Al – Nb composition,” Perspekt. Mater., No. 6, 63 – 67 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 66 – 69, July, 2017.

Rights and permissions

About this article

Cite this article

Senkevich, K.S., Serov, M.M. & Umarova, O.Z. Fabrication of Intermetallic Titanium Alloy Based on Ti2AlNb by Rapid Quenching of Melt. Met Sci Heat Treat 59, 463–466 (2017). https://doi.org/10.1007/s11041-017-0172-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-017-0172-3