Abstract

Harvested wood products (HWPs) store a significant amount of carbon while long-lived products and wooden buildings can be among the most effective means for carbon storage. Wood products’ lifetime extension and appropriate waste management, recycling, and reuse can further contribute to the achievement of climate goals. In our study we projected under 10 different scenarios the carbon storage, carbon dioxide and methane emissions of the Hungarian HWP pool up to 2050 in order to find the combination of wood industry-related measures with the highest climate change mitigation effect. For the projection we used the country-specific HWP-RIAL model to predict emissions associated with the end-of-life and waste management of wood products. The main conclusion is that without additional measures the Hungarian HWP pool would turn from a carbon sink to a source of emissions by 2047. To maintain the Hungarian HWP pool to be a continuous carbon sink it is essential to implement additional climate mitigation measures including cascading product value chains, and approaches of a circular bioeconomy. We find the most effective individual measures are increasing product half-life, increasing recycling rate and increasing industrial wood production through increased industrial wood assortments and increased harvest. With the combination of these measures a maximum average annual climate change mitigation potential of 1.5 Mt CO2 equivalents could be reached during the 2022–2050 period.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The forest industry can contribute to climate change mitigation efforts through four means: carbon storage in forests, carbon storage in long-lived wood products, material substitution of emission intensive products, and energy substitution of fossil fuels (Verkerk et al. 2022). Wood is an energy efficient, low carbon construction material that if carefully managed can contribute significantly to European climate policy goals (Sikkema et al. 2023). Protective measures, such as biodiversity conservation or reduced harvest focus on storing carbon within forest ecosystems and require restricted wood use, while measures focusing on carbon storage in wood products or on substitution effects might have negative implications for carbon storage in forest ecosystems (Johnston and Radeloff 2019; Churkina et al. 2020; Verkerk et al. 2022). This contradiction can be resolved by the separation of forest functions (Kottek et al. 2023a). Forests with low level of naturalness can be regarded as carbon pumps, the role of which is not the storage of carbon but its sequestration and channeling into the wood product carbon storage pool providing raw material for an innovative, prosperous, and climate-friendly forest industry (Kottek et al. 2023a).

With ongoing climate change forests face increasing disturbance risks (Verkerk et al. 2022). Tree species distribution modelling shows that, in the coming decades almost all main European tree species will experience reductions of their suitable areas, especially in eastern and southern Europe (Verkerk et al. 2022). Climate envelope analysis of nine tree species currently spread in southern and south-eastern Europe shows that Fagus sylvatica L. and Picea abies H. Karst could lose 58% and 40% of their current distribution range, while Quercus pubescens Willd and Quercus cerris L. may win areas equal with 47% and 43% of their current ranges (Illés and Móricz 2022). This emphasizes the importance of innovation in wood industry as the use of drought tolerant species for industrial purposes seems inevitable in the future.

Many doubts accompany the resource potential of hardwoods and their softwood substituting potential within their material utilization (Auer and Rauch 2020). Recently the interest in heat treatment processes has been renewed due to the declining production of high-quality timber, and also attributable to the increasing demand for sustainable building materials (Boonstra 2008; Esteves and Pereira 2009). Numerous studies analyze methods for improving wood technological properties of drought tolerant tree species, and the need to provide further information on the characteristics and performance of species of less industrial use and lower durability timber is arising (Esteves and Pereira 2009; Todaro 2012). Promising results have been reported concerning the possible improvement of Turkey oak (Quercus cerris) wood properties by hydrothermal treating and enabling new industrial applications (Todaro et al. 2012; 2013; Cetera et al. 2016). Besides innovative wood products, technological advancement can also promote wood processing efficiency, minimize waste generation (Li et al. 2022) and foster recycling (Wilson 2010; Király et al. 2023).

In Hungary, the ForestLab project (Borovics 2024) was initiated in 2022 as a comprehensive climate change mitigation endeavor, aiming to guide the national forest industry towards achieving net zero emissions. In this context modeling and carbon balance projections are essential to evaluate future effects of planned policies and measures. Wood product models serve as valuable tools for estimating the future carbon dynamics of harvested wood products (HWPs), thereby enabling the evaluation of their potential contributions to climate change mitigation strategies (Brunet-Navarro et al. 2018, 2021; Király et al. 2023). In the framework of the ForestLab project a new wood product model, the HWP-RIAL model (Harvested Wood Product Recycling, Incineration and Landfill model) was developed (Király et al. 2023). This material flow model is based on IPCC methodology (IPCC 2006; 2019) and it is parametrized for Hungarian circumstances and supplemented with a self-developed recycling and waste-route-selection submodule. The model can project the amount of carbon stored in wood products in use and wood products accumulated in landfills, as well as the carbon dioxide (CO2) and methane (CH4) emissions originating from products going out of use and disposed of via incineration or solid waste disposal (Király et al. 2023).

In this study we used the HWP-RIAL model to estimate the impact of wood industry-related mitigation measures at the country level. The aim of our investigation was to simulate the net emissions originating from the Hungarian HWP pool under different scenarios and find the optimal combination of measures to reach the largest climate change mitigation effect.

2 Materials and methods

In this study we intended to estimate the future inflow into the HWP pool and the net emissions arising from the end-of-life treatment of HWPs for the 2022–2050 period under different scenarios. Ten scenarios were modeled to represent possible combinations of climate change mitigation measures in the Hungarian forest industry. First the historic HWP production was estimated. Then the amount of timber available for harvest under a BAU approach and under an increased harvest approach was projected. Afterwards the future assortment composition under a BAU approach and another approach where industrial wood assortments were increased was projected. Based on these projections the HWP production was modelled under four approaches. Thus, in the 10 scenarios two different harvest projections, and two assortment composition projections were used. The combination of these resulted in four HWP production approaches. These four approaches were combined with different half-life values and different recycling and waste management measures resulting in the 10 examined scenarios.

For the projection of end-of-life HWP emissions the HWP-RIAL model was used (Király et al. 2023, for detailed model description see also the Appendix) which was developed in the framework of the ForestLab project. We parametrized the model for 10 different scenarios assessing the impact of individual and bundled mitigation measures related to HWP production, use and end-of-life treatment. The data, projections, methodology of estimating emissions, and parameters used are described in detail in the subchapters 2.1‒2.6 below.

2.1 Historic HWP production data

In our study the same historic HWP production dataset (Fig. 1) was used as described by Király et al. (2022). These production data are also used in the Hungarian Greenhouse Gas Inventory (NIR 2023) and can be publicly accessed through the website of the United Nations Framework Convention on Climate Change (CRF 2023). However, in contrast to the study by Király et al. (2022) HWPs originating from imported wood were included in the estimation of the present study.

2.2 Projection of timber available for harvest up to 2050

For the parametrization of the scenarios, we used two different harvest projections (Fig. 2). In the first one it was assumed that the amount of timber harvested will be equal to the average harvest of the 2017–2021 years with the same tree species composition. In the second case we used the projection of Borovics et al. (2023). This latter one is a simple projection on the maximum amount of timber available for harvest for the period 2020–2100. It is based on the data of the National Forestry Database (NFD) and the cutting ages prescribed by the Forest Authority in the Forest Management Plans. The methodology of the projection does not count with tree species replacements during forest regeneration, all forest stands subject to final harvest are regenerated with the same tree species and remain in the same yield class and preserve their same cutting age during the whole projection period. In our study we used the 2022–2050 average of the timber becoming availabe anually for harvest as projected by Borovics et al. (2023). This amount is defined as the maximum harvesting potential that can be achieved under sustainable forest management criterion in Hungary. As Fig. 2 shows the projected maximum harvesting potential is well below the average annual increment of the last five historic years. Considering this and the fact that the used harvest projection is derived from the cutting ages prescribed by the Forest Management Plans it is assured that this amount of timber could be harvested without compromising sustainability concerns.

2.3 Projection of the future assortment composition

We used two different assortment composition projections (Fig. 3) in the construction of the different scenarios. One was derived from the historic data of the National Statistical Data Collection Programme (NFK 2023). Whereas the modified assortment composition ratios were estimated using expert judgement (Börcsök et al. 2023). We assumed that targeted technological advancements would enhance the industrial use of drought-tolerant tree species, thereby increasing the ratio of industrial assortments relative to firewood assortments.

Average 2017–2021 assortment composition and estimated potential for increased industrial wood assortment by tree species groups (‘i’ meaning increased industrial wood assortment; tree species groups: O oak, TO Turkey oak, B beech, H hornbeam, BL black locust, OHB other hard broadleaved, HP hybrid poplars, IP indigenous poplars, W willow, OSB other soft broadleaved, P pines)

The net volume of the sawlog, pulpwood and firewood assortments was projected based on the harvest projections and the two potential assortment compositions (Fig. 4). For both the average and increased harvest level the average historic assortment composition as well as the modified assortment composition was applied. By this way four different projections were created regarding the net volume of the wood assortments. The calculations were carried out by tree species groups and then the results were summed up by assortment types.

2.4 Projection of HWP production

For the projection of future HWP production the projected assortment volumes (Fig. 4) were used. Equation (1) describes the method of the projection.

where:

- HWPprodproj:

-

projected production of the HWP commodity (sawnwood, particle board or paper and paperboard);

- AVGHWPprod,dt:

-

2017-2021 average production of the HWP commodity produced from domestically harvested timber;

- Projia:

-

projected volume of the industrial wood assortment (sawlog, pulpwood for boards or pulpwood for paper);

- AVGia:

-

2017-2021 average volume of the industrial wood assortment (sawlog, pulpwood for boards or pulpwood for paper);

- AVGHWPprod,it:

-

2017-2021 average production of the HWP commodity from imported timber raw material.

Figure 5 shows the projected amount of HWP commodities under the four different HWP production approaches examined in this study.

2.5 The HWP-RIAL model

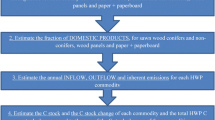

For modeling the impact of the different mitigation measures the HWP-RIAL model (Király et al. 2023) was used (Fig. 6, Appendix) which is a country specific material flow model calculating end-of-life HWP emissions as well as the impact of recycling.

The equations describing the calculations carried out during model runs are presented by Király et al. (2023) and also described in detail in the Appendix. The initial HWP stock (Ci t0) was calculated as described in Király et al. (2022) using the same carbon conversion factors (Appendix) and as recommended by IPCC (2019). The starting year of the HWP first order decay equations was 1964, and the initial stock was calculated for that year.

The recycling module of the HWP-RIAL model is redirecting one part of the outflow from the HWP first order decay equations to the inflow. The share of the recycled amount is regulated by the recycling rate. In this study the recycled wood waste was reiterated for the production of sawnwood (20%), particle board (50%), MDF (20%) and other board (10%). This means that in the recycling loop not the original product category was used to imitate cascading effects. For the estimation of the recycling rate, we used the expert judgement of Börcsök et al. (2023). The half-life of the recycled HWP commodities was set the same as the half-life of the particular HWP commodity when produced from virgin material. The waste sub-model of the HWP-RIAL model was modified as in this study the impact of HWPs in unmanaged solid waste disposal sites (SWDSs) is also considered. The waste model for managed and unmanaged SWDSs was parametrized consistently with the Hungarian Greenhouse Gas Inventory (Table 1). In order to get a realistic initial stock for HWPs in SWDSs the starting year of the waste sub-models was set to 1940, and a constant HWP waste outflow to SWDSs was assumed for the years 1940–1964 which was set equal to the average historic outflow from 1965–1969.

2.6 Scenario parametrization

In this study 10 different scenarios were examined (Table 2 and 3). For the parametrization of the BAU scenario country specific data derived from the Hungarian National Environmental Information System (OKIR 2023), the Hungarian Greenhouse Gas Inventory (NIR 2023), and the National Waste Management Plan (2021) was used as described by Király et al. (2023). In the model parametrization, unmanaged SWDSs without methane recovery were also taken into account which resulted in a smaller methane recovery rate as compared to Király et al. (2023). Half-life values were taken from IPCC (2019).

Scenarios were created to assess the impact of individual mitigation measures (HL, Recycl, W, IncInd, IncH) and their combination (IncH-IncInd, C1, C2, C3). Table 2 contains the description of the scenarios. The parametrization of the scenarios was carried out based on the National Waste Management Plan (2021) and expert judgement (Börcsök et al. 2023).

3 Results

According to our calculations between the period from 1964 to 2021 the carbon stock of the HWPs in use increased from 13.2 Mt carbon (C) to 17.5 Mt C. Under the BAU scenario the projected carbon stock of the HWPs in use is 19.8 Mt C by 2050 (Fig. 7). The long-term stored non-decomposable carbon accumulated in SWDSs and the decomposable degradable organic carbon (DDOCm) is also gradually increasing under the BAU scenario (Fig. 7) as the share of landfilled wood and paper waste is unchanged during the whole projection period.

Figure 8 shows annual historic and projected inflow to the HWP pool as well as annual CO2 emissions from end-of-life combustion of HWPs, and CO2 and CH4 emissions (expressed in CO2 equivalent units) originating from landfilled HWPs as well as total net CO2 equivalent (eq) emissions. Under the BAU scenario HWPs are turning into a source of emissions in 2047, and their projected annual emission for 2050 is 33 kt CO2 eq.

The projected net emissions under the 10 different scenarios are shown in Fig. 9. While under the BAU scenario HWPs turn into a source of emissions by 2047, in all other scenarios HWPs remain a carbon sink in the projection period. The BAU scenario results in the least carbon sequestered in the HWP pool up to 2050 (Fig. 10). The scenario with individual waste management measures (W scenario) has smaller emission reduction effect, while scenarios with increased recycling rate (scenarios Recycl and C1), increased half-life values (scenarios HL and C1) or increased HWP production (scenarios IncInd, IncH, IncH-IncInd, C2 and C3) result in less emissions and more carbon sequestered in the HWP pool. Half-life extension has a faster effect in emission reduction while recycling has a more prolonged effect. Increasing the inflow itself (through increased harvest or increased industrial assortments) has a one-time effect in carbon sequestration that gradually decreases in time. In contrast increasing half-life, increasing recycling rates and increasing CH4 recovery in SWDSs and decreasing the landfilled amount have prolonged effects that gradually increase in time.

Figure 10 shows total carbon stock of HWPs in use as projected under the different scenarios. The projected amount of carbon stored in HWPs by 2050 under the BAU scenario is 19.8 Mt C, whereas under C3 scenario it is 31.2 Mt C. This means that a great difference (up to 11.4 Mt C) exists between the scenarios in the magnitude of the carbon storage in products used. Carbon storage in SWDSs (Fig. 11) varies between 2.9 Mt C (IncH-IncInd scenario) and 3.8 Mt C (C1 scenario) by 2050.

Figure 12 shows the magnitude of average (2017–2021) annual historic net removals of the HWPs and the projected net annual average removals under the examined scenarios. Scenarios linked to individual mitigation measures had smaller average projected carbon removals than the average of the last five historic years. Scenarios with increased harvest or combined mitigation measures are characterized with larger removals as compared to the historic five-year average. Combining all the examined mitigation measures (C3 scenario) would result in -1.6 Mt CO2 net average annual removal in the projection period which is 3.5 times higher than the average removals of the last five historic years. Even without increasing the harvest -853 kt CO2 net average annual removal could be reached (C2 scenario) when combining half-life extension, increased recycling, increased industrial wood assortment with favouralbe solid waste disposal measures. This amount is 1.9 times higher than the average removals of the HWP pool of the last five historic years.

Average historic net annual carbon sequestration in HWPs in the 2017–2021 period and the projected average annual net emissions for the period 2022–2050 under 10 different scenarios. (Green coloumn indicates historic data whereas orange coloumns indicate projected data. Darker orange coloumns indicate the scenarios where the harvest is increased as compared to the average annual harvest of the 2017–2021 period.)

The average annual climate mitigation potential of each scenario is the difference between the average annual net emissions associated with that scenario and the average annual net emissions of the BAU scenario (Fig. 13). The mitigation potential associated with increasing half-life, recycling rates or industrial wood assortments had the same order of magnitude. Mitigation measures related to solid waste disposal had the smallest mitigation effects. While increasing harvest or combining individual measures had the largest mitigation effect.

4 Discussion

In this study we examined the effect of individual and bundled climate change mitigation measures related to the Hungarian wood industry. This was the extension of our investigation described in Király et al. (2023), which dealt with modeling mitigation measures related to the end-of-life treatment of particleboard produced in one single year. We came to similar conclusions on the country level as on the product level: the optimal is the combination of individual measures as these reinforce the effects of each other. Wood product half-life extension and recycling have proven to keep wood products longer in the pool thus prolonging the effects of increased HWP inflow (through increased harvest and changed assortment composition).

However, it is important to stress that scenarios assuming increased harvest as compared to the historic harvest of the last five years are to be interpreted with caution as in these cases additional carbon sequestered in the HWP pool implies less carbon stored in forests. Thus, these scenarios (i.e., IncH, IncH-IncInd and C3 scenarios), at least in the short term, have a greater mitigation effect considering the HWP pool only, whereas they have a smaller mitigation effect considering the whole Land Use Land Use Change and Forestry (LULUCF) sector. It is important to underline that the maximum harvesting potential assumed in this study is higher than the value set under the 'Increased logging rate' scenario of the National Energy and Climate Plan of Hungary (Hungary 2019). However, it must also be emphasized that even in the scenarios where we calculated with increased harvest levels the criterion of sustainable forest management was still met. This as only those forests were regarded available for harvest, which reached their prescribed cutting age (Borovics et al. 2023), and the average projected harvest remained below the average annual increment.

To assess the climate change mitigation potential of the HWP carbon storage from a system perspective, the biogenic carbon implications in the forest, as well as fossil GHG emissions from the forest industry, and substitution effects would have to be included in the analysis (Grassi et al. 2021). Fortin et al. (2012) built a set of models to represent the whole forest-wood product chain and estimate the carbon balance of the HWPs in use and landfilled together with emissions from HWP processing and substitution effects. Indeed, quantifying substitution effects in the case of Hungary may further support the importance of HWPs in mitigating climate change.

We consider the most important result of our research the fact that even without increasing harvest an additional annual mitigation potential of 721 kt CO2 year−1 could be reached. This annual mitigation potential is equal to the 12% of the average annual LULUCF carbon removals of the 2017–2021 period (NIR 2023), and it means in total 20.9 Mt CO2 eq additionally sequestered carbon in the 2022–2050 period as compared to the BAU scenario. Considering the scenarios associated with increased harvest a maximum of 1.5 Mt CO2 eq mitigation potential could be reached which is well above the current annual carbon sequestration of the Hungarian HWP pool, and which is equal to the 25% of the average annual LULUCF carbon removals of the 2017–2021 period (NIR 2023). This means that with increased harvests in total 42.7 Mt CO2 eq additional carbon removal could be reached in the HWP pool up to 2050. On the other hand, a joint modelling of the forestry and wood industry sector would be necessary in order to evaluate the mitigation potential of each scenario against the EU land-based sink target established for Hungary, set at -5.7 Mt CO2 eq for 2030 (EU 2018). Additional afforestation may be required to align increased harvest levels with climate targets.

Regarding the impact of the individual mitigation measures we can state that measures related to SWDSs have the smallest impact. This is attributable to the rate of landfilled wood waste being currently 6% and the rate of landfilled paper waste being 10% according to the data of the Hungarian National Environmental Information System (OKIR 2023). As the share of landfilled waste is that low the emission reduction effect of decreasing this rate further is only marginal. However, methane recovery for energy generation is a useful measure to mitigate the negative environmental impacts of solid waste disposal.

We found the impact of recycling and wood product half-life extension to hold a similar magnitude for climate change mitigation. These measures are the basis of a circular bioeconomy (EC 2020) and they can help keeping carbon sequestered in long-lived wood products as long as possible (IPCC 2022; Verkerk et al. 2022). This can be complemented by increasing industrial wood assortments which is favourable over the immediate energetic utilization of wood (Verkerk et al. 2022; Li et al 2022). However, the energy demands of society must not be compromised by increasing industrial wood assortments. In Hungary, the use of firewood is notably high (NFK 2023), with many rural households relying solely on wood-based heating systems. Consequently, the utilization of firewood remains virtually unavoidable in the country today. Despite the importance of wood in industrial applications, firewood remains a crucial component of the Hungarian bioeconomy. As a renewable source of bioenergy, wood can substitute for the use of fossil fuels thus bringing additional climate change mitigation potentials (Leskinen et al. 2018). Biomass for bioenergy is one of the most flexible sources of renewable energy as it is storable and can be used for production of electricity and heat (Sartori et al. 2006). When industrial wood assortments are increased new sources of firewood may be required when energetic wood use levels remain constant. In the case of the scenarios with increased harvest the amount of firewood is not decreasing as compared to the average 2017–2021 firewood extraction (Fig. 4). In contrast in the case of increased industrial wood assortments and unchanged harvest the projected firewood extraction is below the 2017–2021 average (Fig. 4). In order to maintain current firewood levels, long or short rotation forest plantations can be a source to provide additional firewood (Searchinger et al. 2008; Djomo et al. 2011). Following the concept of cascading systems (Budzinski et al. 2020) wood products reaching their end-of-life can also be energetically utilized if they are not appropriate for reusing, or recycling as raw materials (Verkerk et al. 2022). In addition, the use of more efficient combustion appliances in households can decrease the demand for firewood.

It is important to note that in this study emissions from end-of-life HWP combustion and emissions from HWPs disposed at SWDSs were aggregated, and HWPs produced from imported wood were included in the calculation. This means that the total net emissions calculated in this study are not completely comparable to emissions reported in the Hungarian National Greenhouse Gas Inventory (GHGI). The current methodology of the Greenhouse Gas Inventory is assuming instantaneous oxidation of the total outflow from the HWP pool, and Hungary does not account for emissions and removals originating from wood products produced from imported wood (NIR 2023). In the BAU scenario of this study the total net removals for the year 2021 are -571 kt CO2. According to the Hungarian GHGI the net removals of the HWP pool amount to -933 kt CO2 in 2021 (NIR 2023), this value however does not include emissions from SWDSs, nor does it include emissions from products produced from imported wood. Emissions from SWDSs are accounted for in the waste sector of the GHGI and they are not linked to the HWPs, but a combined waste category is applied including wood, wood waste and part of bulky waste together. In line with the methodology of the IPCC (2019) emissions from imported raw materials are not accounted for in the GHGI. As Király et al. (2022) point out the HWP subcategory which is produced from imported wood is a source of emissions since 1989, which implies that omitting imported wood from the HWP accounting results in higher net removals. In this study emissions from landfills and emissions from imported wood were considered in order to get a more holistic picture on the intersectoral effects (i.e., to examine trade-offs between the LULUCF and the Waste sector) and to assess the impact of the total production of the Hungarian wood industry.

Borovics et al. (2023) foresee decreasing industrial wood assortments after 2050 due to the age-class structure of the Hungarian forests and due to the substitution of hybrid poplar stands with indigenous poplars and the obligatory transformation of black locust (Robinia pesudoacacia) stands into native forests in nature conservation areas. On the other hand, climate change has an increasing effect on tree species distribution and future wood assortments (Illés and Móricz 2022; Verkerk et al. 2022). Nowadays European beech (Fagus sylvatica) and Norway spruce (Picea abies) are the species most negatively affected by global warming in Hungary, and a large part of low-elevation beech forests is projected to disappear due to the warming temperatures in the second half of the century (Mátyás et al. 2010). In Hungary increasing damage to Norway spruce forests has been reported recently (Mátyás et al. 2018; Ujvári-Jármay et al. 2016; Lakatos 1999) and the species is projected to vanish from low and mid-elevation areas (Verkerk et al. 2022). Beech and Norway spruce forests in Hungary are continuously converted to forests with more stable species like oaks mixed with hornbeam, and the importance of associate species in oak forests is also increasing (Borovics et al. 2023). In the future drought tolerant species with currently low industrial wood assortments like Turkey oak (Quercus cerris) and indigenous poplars are likely to gain large areas and become dominant species in timber production (Illés and Móricz 2022; Borovics et al. 2023). These facts underline the importance of increasing industrial wood assortments in the case of those species which are likely to gain more areas in the future. The IncInd, IncInd-IncH, C2 and C3 scenarios were set up in this study to model the effect of wood industry innovation and changing wood assortment composition. Our results showcase that it is possible to maintain or even increase carbon sequestration levels of the HWP pool under a changing climate and changing species composition using appropriate production technologies and producing long-lived wood products from drought tolerant species as a result of an innovative wood industry.

According to the model results, the most effective measures are extending product half-life, increasing recycling rates, and enhancing industrial wood production through improved assortments and increased harvesting. Therefore, innovation in the wood industry and the inclusion of new drought-tolerant species in producing high-quality wood products are essential. New wood-based product types should be designed to prioritize reuse and recycling. Additionally, it is important to ensure that at the end of their life cycle, the waste generated can be composted or incinerated cost-effectively and with low emissions (Borovics et al. 2023). Developing environmentally friendly coatings and preservatives could enable the energetic end-of-life utilization of wood products. Producing new innovative wood-based products in large quantities at competitive prices or developing a subsidy system for their introduction is also crucial (Borovics et al. 2023). Additional harvesting potential could be unlocked by offering professional integration, and technological assistance to forest managers and wood industry enterprises, using GIS applications to provide precise and geographically explicit information on the amount and value of wood stocks available for harvest in the country (Borovics et al. 2023).

Based on our study, we can state that the HWP-RIAL model proved to be suitable for predicting CO2 and CH4 emissions associated with the end-of-use and waste management of wood products at the country level, and to estimate the impact of wood-industry-related climate mitigation measures. The major limitation of our study is the lack of information on the forest carbon balance related to the modelled scenarios, especially in the case of increased harvest levels. Another weakness of the modelling approach is the fact that no country-specific half-life or carbon fraction values are available for the examined HWP commodities. Despite widespread recognition of the importance of cascade chains within the wood product lifecycle, several existing models employ recycling parameters that may inaccurately assign recycled wood to the same product category, potentially leading to overestimations of HWP carbon stocks (Schelhaas et al. 2004; Krankina et al. 2012; Fortin et al. 2012; Brunet-Navarro et al. 2018). In our modeling approach we use cascading recycled wood allocation, however we have not developed different halflife values for recycled wood products, which may lead to overestimation of carbon stocks. In the framework of the ForestLab project, we are planning to further improve our modelling approach in order to model the joint impact of forest and wood industry related climate change mitigation measures using the HWP-RIAL model and the DAS forest model (Kottek 2017; Kottek et al. 2023b) to project net emissions or removals arising from Hungarian forests and wood products up to 2050.

5 Conclusions

Here we projected under 10 different scenarios the carbon storage and the CO2 and CH4 emissions of the Hungarian HWP pool up to 2050. The purpose of this investigation was to identify the most climate-beneficial practices and find the combination of wood industry-related climate mitigation measures with the highest climate change mitigation effect. The first conclusion is that without additional mitigation measures the Hungarian wood product pool (including HWPs in use and HWPs in SWDSs) would turn from a carbon sink to a source of CO2 emissions by 2047. It is thus essential to increase the inflow to the pool or decrease the outflow in order to achieve continuous or increasing carbon sinks in the HWP pool. To achieve this the most effective measures found are increasing product half-lives, increasing recycling rates and higher industrial wood production through extended industrial wood assortments and increased harvest.

The second conclusion is that even without increasing harvests an additional annual mitigation potential of 721 kt CO2 eq could be reached when combining half-life extension, increased recycling, and extended industrial wood assortments with improved solid waste disposal measures. This annual climate change mitigation potential is equal to 12% of the average annual LULUCF carbon removals of the 2017–2021 period and amounts to a total additional 20.9 Mt CO2 eq being sequestered up to 2050. Ultimately, this indicates that even without increasing harvest rates the Hungarian wood industry has large climate change mitigation potentials by well-planned wood industry related measures thus contributing to reach climate goals set by 2050.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Auer V, Rauch P (2020) Assessing hardwood flows from resource to production through material flow analysis. In: Nemeth R, Rademacher P, Hansmann C, Bak M, Bader M (eds) 9th hardwood proceedings, vol 9 - pt I: an underutilized resource: hardwood oriented research. Sopron, Hungary, p 13–20. https://www.hardwood.uni-sopron.hu/wp-content/uploads/2021/06/HWC2020_proceedings_final_online_I.pdf. Accessed 19 May 2024

Boonstra M (2008) A two-stage thermal modification of wood. Ph.D. Thesis in applied biological sciences: soil and forest management. Henry Poincaré University, Nancy

Börcsök Z, Németh G, Kocsis Z (2023) Expert judgement on the future assortment composition of harvested wood in Hungary. University of Sopron, Unpublished manuscript. (In Hungarian)

Borovics A (2024) Mitigating climate change: the forestlab project. Scientia 4. https://doi.org/10.33548/SCIENTIA1010

Borovics A, Mertl T, Király É, Kottek P (2023) (2023): Estimation of the overmature wood stock and the projection of the maximum wood mobilization potential up to 2100 in Hungary. Forests 14(8):1516. https://doi.org/10.3390/f14081516

Brunet-Navarro P, Jochheim H, Cardellini G, Richter K, Muys B (2021) Climate mitigation by energy and material substitution of wood products has an expiry date. J Clean Prod 303:127026. https://doi.org/10.1016/j.jclepro.2021.127026

Brunet-Navarro P, Jochheim H, Kroiher F, Muys B (2018) Effect of cascade use on the carbon balance of the German and European wood sectors. J Clean Prod 170:137–146. https://doi.org/10.1016/j.jclepro.2017.09.135

Budzinski M, Bezama A, Thrän D (2020) Estimating the potentials for reducing the impacts on climate change by increasing the cascade use and extending the lifetime of wood products in Germany. Resources Conservation & Recycling x 6:100034. https://doi.org/10.1016/j.rcrx.2020.100034

Cetera P, Todaro L, Lovaglio T, Moretti N, Rita A (2016) Steaming treatment decreases MOE and compression strength of Turkey oak wood. Wood Res 61(2):255–264. ISSN: 13364561

Churkina G, Organschi A, Reyer CPO, Ruff A, Vinke K, Liu Z, Reck BK, Graedel TE, Schellnhuber HJ (2020) Buildings as a global carbon sink. Nature Sustainability 3:269–276. https://doi.org/10.1038/s41893-019-0462-4

CRF (2023) Common reporting format tables of Hungary as submitted to the UNFCCC. https://unfccc.int/documents/627846. Accessed 19 May 2024

Djomo SN, El Kasmioui O, Ceulemans R (2011) Energy and greenhouse gas balance of bioenergy production from poplar and willow: a review. Global Change Biology Bioenergy 3:181–197. https://doi.org/10.1111/j.1757-1707.2010.01073.x

EC (2020) European Commission. A New Circular Economic Plan for a Cleaner and More Competitive Europe, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM (2020) 98 final; European Commission: Brussels, Begium, 2020

Esteves MB, Pereira HM (2009) Wood modification by heat treatment: a review. Bioresour Technol 4(1):370–404. https://doi.org/10.15376/biores.4.1.370-404

EU (2018) Regulation (EU) 2018/841 on the inclusion of greenhouse gas emissions and removals from land use, land use change and forestry in the 2030 climate and energy framework, and amending regulation (EU) No 525/2013 and decision no 529/2013/EU. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02018R0841-20230511. Accessed on 4 June 2024

Fortin M, Ningre F, Robert N, Mothe F (2012) Quantifying the impact of forest management on the carbon balance of the forest-wood product chain: A case study applied to even-aged oak stands in France. For Ecol Manage 279:176–188. https://doi.org/10.1016/j.foreco.2012.05.031

Hungary (2019) National Energy and Climate Plan. English version submitted in 2019. https://energy.ec.europa.eu/system/files/2022-08/hu_final_necp_main_en.pdf (Accessed on 4 June 2024)

Illés G, Móricz N (2022) Climate envelope analyses suggests significant rearrangements in the distribution ranges of Central European tree species. Annals of Forest Science 79(1):35. https://doi.org/10.1186/s13595-022-01154-8

IPCC (2006) 2006 IPCC guidelines for national greenhouse gas inventories, prepared by the national greenhouse gas inventories programme. In: Eggleston HS, Buendia L, Miwa K, Ngara T, Tanabe K (eds). IGES, Kanagawa

IPCC (2019). 2019 refinement to the 2006 IPCC guidelines for national greenhouse gas inventories. In: Calvo Buendia E, Tanabe K, Kranjc A, Baasansuren J, Fukuda M, Ngarize S, Osako A, Pyrozhenko Y, Shermanau P, Federici S (eds). IPCC, Geneva

IPCC (2022) Sixth assessment report, climate change 2022: mitigation of climate change, the working group III contribution. Chapter 7 Agriculture, Forestry, and Other Land Uses (AFOLU). IPCC: Geneva, Switzerland

Johnston CMT, Radeloff VC (2019) Global mitigation potential of carbon stored in harvested wood prod¬ucts. Proc Natl Acad Sci USA 116:14526–14531. https://doi.org/10.1073/pnas.1904231116

Király É, Börcsök Z, Kocsis Z, Németh G, Polgár A, Borovics A (2022) Carbon Sequestration in Harvested Wood Products in Hungary an Estimation Based on the IPCC 2019 Refinement. Forests 13(11):1809. https://doi.org/10.3390/f13111809

Király É, Kis-Kovács G, Börcsök Z, Kocsis Z, Németh G, Polgár A, Borovics A (2023) Modelling Carbon Storage Dynamics of Wood Products with the HWP-RIAL Model—Projection of Particleboard End-of-Life Emissions under Different Climate Mitigation Measures. Sustainability 15(7):6322. https://doi.org/10.3390/su15076322

Kottek P (2017) National forest projection–2050; University of Sopron, Faculty of forestry, VI. Faculty scientific conference book of abstracts. In: Bidló A, Facskó F (eds). Publishing Office of the University of Sopron, Sopron, pp 59. (In Hungarian)

Kottek P, Király É, Mertl T, Borovics A (2023a): Trends of forest harvesting ages by ownership and function and the effects of the recent changes of the forest law in Hungary. Forests 14(4):679. https://doi.org/10.3390/f14040679

Kottek P, Király É, Mertl T, Borovics A (2023b) The re-parametrization of the DAS Model Based on 2016-2021 data of the national forestry database: new results on cutting age distributions. Acta Silvatica & Lignaria Hungarica 19(2):61–74. https://doi.org/10.37045/aslh-2023-0005

Krankina ON, Harmon ME, Schnekenburger F, Sierra CA (2012) Carbon balance on federal forest lands of Western Oregon and Washington: The impact of the Northwest forest plan. For Ecol Manage 286:171–182. https://doi.org/10.1016/j.foreco.2012.08.028

Lakatos F (1999) Bark beetles on pine in Hungary. In: Foster B, Knizek M, Grodzki W (eds) Methodology of forest insect and disease survey in central Europe. Proceedings of the 2nd workshop of the IUFRO WP 7.03.10, April 20–23, 1999, Sion-Châteauneuf, Switzerland. Swiss Federal Institute for Forest, Snow and Landscape Research, Birmensdorf. pp 248–249

Leskinen P, Cardellini G, González-García S, Hurmekoski E, Sathre R, Seppälä J, Smyth C, Stern T, Verkerk PJ (2018) Substitution effects of wood-based products in climate change mitigation. From science to policy 7. European Forest Institute. https://doi.org/10.36333/fs07

Li L, Wei XY, Zhao JH, Hayes D, Daigneault A, Weiskittel A, Kizha AR, Neill SRO (2022) Technological advancement expands carbon storage in harvested wood products in Maine. Biomass Bioenergy 161:106457. https://doi.org/10.1016/j.biombioe.2022.106457

Mátyás CS, Berki I, Bidló A, Csóka GY, Czimber K, Führer E, Gálos B, Gribovszki Z, Illés G, Hirka A, Somogyi Z (2018) (2018): Sustainability of Forest Cover under Climate Change on the Temperate-Continental Xeric Limits. Forests 9:489. https://doi.org/10.3390/f9080489

Mátyás CS, Berki I, Czúcz B, Gálos B, Móricz N, Rasztovits E (2010) Future of Beech in Southeast Europe from the perspective of evolutionary ecology. Acta Silvatica Lignaria Hung 6:91–110. ISSN 1786–691X

National Waste Management Plan 2021–2027. Ministry of Innovation and Technology (2021) Available online: https://kormany.hu/dokumentumtar/orszagos-hulladekgazdalkodasi-terv-2021-2027. Accessed 28 April 2023. (In Hungarian)

NIR (2023) National Inventory Report for 1985–2021. In: Somogyi Z, Tobisch T, Király É (eds) Hungary. Chapter: land-use, land-use change and forestry. Hungarian Meteorological Service, Budapest, Hungary

NFK (2023): Summary data on forests in Hungary; National Land Centre, Forestry Department: Tokyo, Japan, 2021. https://nfk.gov.hu/Magyarorszag_erdeivel_kapcsolatos_adatok_news_513. Accessed on 28 April 2023; in Hungarian

Okir (2023) National Environmental Information System. http://web.okir.hu/en/. Accessed on 28 April 2023

Grassi G, Fiorese G, Pilli R, Jonsson K, Blujdea V, Korosuo A, Vizzarri M (2021) Brief on the role of the forest-based bioeconomy in mitigating climate change through carbon storage and material substitution. In: Sanchez Lopez J, Jasinevičius G, Avraamides M (eds) European Commission, JRC124374. https://publications.jrc.ec.europa.eu/repository/handle/JRC124374. Accessed 19 May 2024

Sartori F, Lal R, Ebinger MH, Parrish DJ (2006) Potential soil carbon sequestration and CO2 offset by dedicated energy crops in the USA. Crit Rev Plant Sci 25:441–472. https://doi.org/10.1080/07352680600961021

Schelhaas MJ, Esch PW, Groen TA, Jong BHJ, Kanninen M, Liski J, Masera O, Mohren GMJ, Nabuurs GJ, Palosuo T et al (2004) CO2FIX V 3.1 – a modelling framework for quantifying carbon sequestration in forest ecosystems. ALTERRA Rapport No.1068. ALTERRA, Wageningen, pp 122. ISBN: 1566–7197

Searchinger T, Heimlich R, Houghton RA (2008) Use of US croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 319:1238–1240. https://doi.org/10.1126/science.1151861

Sikkema R, Styles D, Jonsson R, Tobin B, Byrne KA (2023) A market inventory of construction wood for residential building in Europe—In the light of the Green Deal and new circular economy ambitions. Sustain Cities Soc 90:104–370. https://doi.org/10.1016/j.scs.2022.104370

Todaro L (2012) Effect of steaming treatment on resistance to footprints in Turkey oak wood for flooring. European Journal of Wood and Wood Products 70(1–3):209–214. https://doi.org/10.1007/s00107-011-0542-2

Todaro L, Dichicco P, Moretti N, D’auria M (2013) Effect of combined steam and heat treatments on extractives and lignin in sapwood and heartwood of Turkey oak (Quercus cerris L.) wood. BioResources 8(2):1718–1730. https://doi.org/10.15376/biores.8.2.1718-1730

Todaro L, Zanuttini R, Scopa A, Moretti N (2012) Influence of combined hydrothermal treatments on selected properties of Turkey oak (Quercus cerris L.) wood. Wood Sci Technol 46(1):563–578. https://doi.org/10.1007/s00226-011-0430-2

Ujvári-Jármay É, Nagy L, Mátyás CS (2016) The IUFRO 1964/68 inventory provenance trial of Norway spruce in Nyírjes, Hungary—results and conclusions of five decades. Acta Silv Lign Hun 12:178. https://doi.org/10.1515/aslh-2016-0001

Verkerk P J, Delacote P, Hurmekoski E, Kunttu J, Matthews R, Mäkipää R, Mosley F, Perugini L, Reyer CPO, Roe S, Trømborg E (2022) Forest-based Climate change mitigation and adaptation in Europe. From science to policy 14. European Forest Institute, Joensuu. ISBN 978–952–7426–22–7. https://doi.org/10.36333/fs14

Wilson J (2010) Life-cycle inventory of particleboard in terms of resources, emissions, energy and carbon. Wood Fiber Sci 42(CORRIM Special Issue):90–106. file:///C:/Users/%C3%89va/Downloads/1349-Article%20Text-1349–1–10–20141206.pdf. Accessed 4 July 2023

Acknowledgements

This article was made in frame of the project TKP2021-NKTA-43 which has been implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NKTA funding scheme.

Funding

Open access funding provided by University of Sopron.

Author information

Authors and Affiliations

Contributions

Éva Király: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Visualisation, Writing—original draft. Nicklas Forsell: Validation, Writing—review & editing. Maximilian Schulte: Validation, Writing—review & editing. Gábor Kis-Kovács: Validation, Writing—review & editing. Zoltán Börcsök: Investigation, Supervision, Validation. Zoltán Kocsis: Investigation, Validation. Péter Kottek: Formal analysis, Investigation, Writing—review & editing. Tamás Mertl: Formal analysis, Investigation. Gábor Németh: Investigation, Validation. András Polgár: Investigation, Validation. Attila Borovics: Conceptualization, Funding acquisition, Investigation, Supervision.

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Király, É., Forsell, N., Schulte, M. et al. Climate change mitigation potentials of wood industry related measures in Hungary. Mitig Adapt Strateg Glob Change 29, 62 (2024). https://doi.org/10.1007/s11027-024-10161-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11027-024-10161-1