Abstract

Globally, efforts to increase land sector contributions to net-zero emissions are pursued. Harvested wood products may retain carbon, and substitute emission-intensive products. The emission reductions achieved through substitution, or substitution benefits, can inform the design of climate-effective wood-use strategies. Mitigation analyses of a wood-based bioeconomy therefore need to include substitution to evaluate the mitigation outcomes across sectors. Substitution benefits can be estimated using displacement factors, which quantify the emissions avoided per unit of wood use. Here, we calculated the displacement factors of timber constructions and wood-derived biofuels to be around 1.03 and 0.45 tCO2e/tCO2e, respectively. Assuming substitution was achieved when changes in human behavior increased the share of wood use relative to the reference market share, we added the substitution benefits to a previous analysis that focused on biogenic emissions in British Columbia, Canada. At projected declining harvest rates, the theoretical maximum reduction that forest products can contribute over the period 2016 to 2050 is 66 MtCO2e·year−1 with an uncertainty range of 45–79 MtCO2e·year−1, relative to the baseline, by focusing on long-lived, high-displacement construction applications. However, because construction uses of wood in foreign markets are not guaranteed, and constrained by market access, the practical strategy that combines construction and biofuel uses can achieve 17.4 MtCO2e·year−1, equivalent to 30% of British Columbia’s 2050 target. Although a transformation of the bioeconomy may help achieve both climate and socio-economic benefits, potential conflict exists between maximizing regional and global benefits. How and where wood will be used can influence the desired mitigation outcomes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Assessing the mitigation potential of the forest sector relies on three core principles (Kurz et al. 2016):

-

1.

Quantification of the differences in net greenhouse gas (GHG) balances caused by changes in human activities, relative to a baseline

-

2.

Estimation of emissions when and where they occur and the type of gas emitted

-

3.

Quantification of the changes in carbon stocks and emissions in forest ecosystems, from harvested wood products (HWPs), and from the substitution of emission-intensive products

This paper evaluates the substitution benefits (principle 3) of various potential mitigation strategies in the province of British Columbia (BC), Canada. The substitution benefit refers to the GHG emissions avoided by using wood-based materials or wood-derived bioenergy in place of other materials and fuels. For example, engineered wood products generally require less energy from cradle to gate than their steel or concrete functional equivalents, producing fewer embodied emissions when used in the construction sector, and they store carbon that was previously removed from the atmosphere through forest growth (Sathre and O’Connor 2010; Athena 2016; Leskinen et al. 2018). The combustion of wood of any form, whether pellets or biofuel, results in an instantaneous release of the contained carbon to the atmosphere (IPCC 2006). However, the carbon emitted from wood was previously removed from the atmosphere by forests and can be re-captured by the forest; therefore, using wood-derived bioenergy can reduce the use of fossil fuels and contribute to reducing additions of fossil carbon to the biosphere–atmosphere system. Depending on the time frame, the feedstock types, the carbon intensity of the fossil fuels to be substituted, alternative land management opportunities, and other factors, wood-derived bioenergy may provide a positive or negative substitution benefit (Mitchell et al. 2012; Ter-Mikaelian et al. 2015; Pingoud et al. 2016; Laganière et al. 2017; Soimakallio et al. 2022). Quantification of the substitution benefit requires a detailed assessment of the GHG emissions throughout the life cycle of HWPs and their functional equivalents, including emissions during the material acquisition, production, and end-of-life stages (principle 2).

This study quantifies the substitution benefits of wood as a construction material and as a feedstock for “drop-in” biofuelsFootnote 1 for several reasons. First, transportation and construction are two important sectors contributing to BC’s bioeconomy and global GHG emissions (IPCC 2014b; BC 2018). Second, other than the construction sector, there is limited information on wood replacing other materials. Sathre and O’Connor (Sathre and O’Connor 2010) conducted a meta-analysis of 21 studies, all of which are for the construction sector. Leskinen et al. (2018) reviewed 51 studies and 79% of them were related to the construction sector. Third, in places that already have a low-emission electrical grid, generating electricity using woody biomass may not contribute to emission reduction. For example, BC generated 268 PJ of electricity in 2016, 88% of which was from hydro and 10.4% from other renewable sources (NEB 2017, 2018). Therefore, harvested biomass has mitigation potential only when it is used in a sector that is difficult to electrify, such as aviation and long-range transportation (ICAO 2016; Jensen et al. 2017; van Dyk et al. 2019). Fourth, alternative substitution options such as flooring, furniture, and decking have been shown to have small or even negative carbon benefits (Smyth et al. 2016). In terms of printing and writing paper, the benefit has been reported to be either negative or uncertain compared to digital media (Bull and Kozak 2014; Karapetyan et al. 2015; Achachlouei and Moberg 2015).

A commonly used measurement of the HWPs’ substitution effect is the displacement factor (DF) proposed by Schlamadinger and Marland (Schlamadinger and Marland 1996). It was defined as the GHG emissions avoided in mass unit of carbon dioxide equivalent (CO2e) per mass unit of CO2e contained in the additional wood used, indicating the efficiency of the substitution effect (Sathre and O’Connor 2010).

Several papers have quantified the DFs (e.g., Sathre and O’Connor 2010; Smyth et al. 2016; Leskinen et al. 2018). The preferred way, using wood replacing reinforced concrete in buildings as an example, is to use the results of a comparative life cycle assessment (LCA). The LCA should include GHG emissions of at least two functionally equivalent buildings — one built with wood and the other with reinforced concrete — from cradle to grave under the same scope and boundary conditions. “Functionally equivalent” means that the buildings should have similar square footage, location, and completion year. However, it is usually challenging to satisfy all of these conditions. Therefore, previous LCA studies usually contrast a timber building with a hypothetical concrete or steel functional equivalency (e.g., Grann 2014), or vice versa (e.g., Robertson et al. 2012). Even when two real-world functional equivalencies are found, a lack of context-specific data in the existing life cycle databases and tools still represents a major challenge (Teshnizi et al. 2018). This study selected nine comparative building LCAs and calculated their DFs. An uncertainty analysis was then conducted to estimate the substitution benefits of wood displacing emission-intensive materials in constructions.

The DFs of wood-derived “drop-in” biofuels have not been well documented, partly due to the uncertainties regarding the commercialization of the conversion technologies. Previous publications have focused on bioenergy substitution for heat and electricity generations (e.g., Smyth et al. 2016). “Drop-in” biofuels can be produced through oleochemical, biochemical, or thermochemical means. Oleochemical pathways utilize oil feedstocks such as oilseeds and animal fats. Biochemical and thermochemical technologies can convert woody biomass to biofuels (Thiffault et al. 2016). However, biochemical pathways create intermediate products, such as farnesene and succinic acid, that have higher commercial value than the fuel end product (Karatzos et al. 2014; Ringsred 2018). The commercial production of drop-in biofuels therefore has substantial economic challenges (Bullis 2012). Three thermochemical biofuel pathways exist — gasification, hydrothermal liquefaction (HTL), and pyrolysis (Thiffault et al. 2016). Gasification utilizes sophisticated chemical engineering technologies and consequently has a high capital intensity. Large plants need to be built in order to achieve economies-of-scale to offset these high capital requirements (over $500 million) (Anex et al. 2010). These large plants have very high biomass demands (a capacity of over 3000 dry tonnes/day), which severely constrains where they can be located (Sarkar et al. 2011). Given BC’s anticipated declining biomass harvest in the next decades (BCFLNRORD 2018c), gasification was not considered to be a viable option in the foreseeable future for this province. Consequently, this study calculated the DFs of biofuels produced using HTL and pyrolysis pathways.

Wood-derived “drop-in” biofuels are still undergoing active research and development, whereas the technology of timber construction is more mature. Forest biomass feedstocks contain high levels of oxygen and impurities that require extensive processing such as upgrading with hydro-treatment or more frequent turnover of catalysts (Thiffault et al. 2016). Substantial cost reduction and optimization are required before wood-derived transportation fuels can be commercialized (Karatzos et al. 2014). From a modeling perspective, however, this study did not assume a technological barrier for the biofuels.

Despite the evident challenges, quantifying the substitution benefit can inform decision making to develop climate-effective strategies and better utilize the forest resources in BC. Avoided emissions from substitution need to be added to our previous mitigation analyses to recognize the total impact beyond a direct carbon storage and emission perspective (Xie et al. 2021). This paper first estimates the DFs of timber constructions and wood-derived biofuels, then quantifies the avoided emissions of various bioeconomy scenarios, and lastly, develops a practical mitigation strategy for BC, from both a biogenic and a substitution perspective.

2 Methods

2.1 Displacement factor calculations

Data were collected from comparative LCA studies that analyzed a more wood-intensive building and a less wood-intensive building. The literature search focused on mid- to high-rise buildings because a majority of the single-family houses in Canada are already being built with wood. We selected LCAs that studied different functional types (i.e., residential and non-residential) and structural types (i.e., heavy timber, lightweight wood frame, concrete, and steel). Two important pieces of information were required — the whole building bill of materials and the associated embodied emissions — to calculate the DFs of timber constructions (Eq. 1).

where CE is the embodied carbon emissions, and CW is the amount of carbon contained in the wood products used to build the construction. The unit of carbon in the numerator and denominator cancels out and the DF is dimensionless (Sathre and O’Connor 2010). If the LCA study reported the embodied emissions, then those CE values were obtained directly. Otherwise, the CE is calculated by subtracting the operational emissions from the total GHG emissions. As the building sector responds to society’s increased focus on energy efficiency and deep decarbonization, the embodied emissions become more significant and they are able to provide immediate climate benefits through substitution (O’Connor and Bowick 2016). In addition, tall and heavy timber constructions are a relatively recent development, and there is a lack of information about operational emissions. It is common for comparative building LCAs to either assume that buildings would meet the same insulation requirement and have the same operational emissions (e.g., Grann 2014), or simply exclude operational energy from the scope of the study (e.g., Bowick and O’Connor 2017). Operational emissions are not included in this study and detailed DF calculations of selected buildings are presented in the Supplementary Information.

Facility location, energy mix, transportation distance, and feedstock availability are important factors for the environmental performance of wood-derived biofuel. For this reason, only LCAs that analyzed biofuel production facilities based in Canada were selected for these displacement factor calculations. Each study also contained various scenarios that yielded different DFs. The data-of-interest were the amount of feedstock per unit of biofuel output, the carbon intensity per unit of biofuel, and the carbon intensities of conventional fossil fuels. The DFs were then calculated using Eq. 2.

where CI is the carbon intensity per unit of fuel, and CW is the amount of carbon contained in the woody biomass feedstock to output one unit of biofuel. Detailed DF calculations for biofuels produced through HTL and pyrolysis pathways are presented in the Supplementary Information.

As technology evolves, future DFs may be lower or higher. Different regions may also have significantly divergent values due to factors such as energy mixes, transportation distances, and building standards. However, this study did not explore their temporal and spatial dependencies extensively. We focused the DF calculations on the substitution activities of BC-originated HWPs consumed in Canada, and within each model run, assumed constant DFs between 2016 and 2050.

2.2 Bioeconomy scenarios

In our previous work, nine scenarios were created to evaluate various HWP trades and utilization options (Xie et al. 2021). Here, we extend the analysis to include substitution effects and added an additional portfolio scenario. All scenarios addressed only changes in wood use and exports and are based on a single projection of future harvest rates that decline over the period 2016 to 2050. The ten scenarios are summarized below:

-

The BASE scenario — a business-as-usual baseline scenario based on the 2016 market partitions and production efficiencies of wood products and assumed that the partitions and efficiencies were time-invariant between 2016 and 2050. Wood-derived biofuels were not produced in this scenario.

-

The ALL_CONS scenario — a theoretical extreme scenario which assumed that all of BC’s harvested biomass was manufactured into products that can be used in construction. Consequently, all sawlogs were sent to sawmills or plywood mills. Pulp logs were sent to oriented strand board (OSB) mills. Milling residues were sent to medium density fiberboard (MDF) mills and particleboard mills. Sawnwood (cross-laminated timber (CLT) and glue-laminated timber (GluLam) included), plywood, and OSB were assumed to be used for structural applications in construction or renovation, with a majority of them displacing domestically produced cement. MDF and particleboard were assumed to be used to build non-structural components.

-

The ALL_FUEL scenario — a theoretical extreme scenario which assumed that all harvested biomass was used as feedstock to produce transportation biofuels.

-

The IN_POP scenario — an inward-focused scenario which assumed that the domestic HWPs demand increases in proportion to population growth rate. However, the market shares of wood products in various sectors remain the same.

-

The IN_CONS scenario — an inward-focused scenario which assumed the domestic demand of residential dwellings and non-residential buildings to be aligned with household growth over the study period, and the timber construction market share to be doubled in the domestic market, predominately replacing domestically produced reinforced concrete constructions.

-

The IN_FUEL scenario — an inward-focused scenario which assumed that all pulp logs and milling residues were sent to bioenergy feedstock to produce transportation biofuels while sawnwood’s and plywood’s production and market partition remained the same as the IN_POP scenario.

-

The OU_CONS scenario — an outward-focused scenario which assumed that the HWPs remaining after fulfilling the domestic demand in the IN_POP scenario were exported and used as construction materials.

-

The OU_CN scenario — an outward-focused scenario which assumed that the HWPs remaining after fulfilling the domestic demand in the IN_POP scenario were exported to China. This assumption resulted in a majority of the exported wood products being used for short-lived purposes.

-

The OU_PLTS scenario — an outward-focused scenario which assumed that the biomass remaining after fulfilling the domestic demand in the IN_POP scenario was manufactured into wood pellets and exported to the European Union (EU) and Japan.

-

The IN_PCF scenario — it is expected that the results of the above scenarios would help develop a practical portfolio of mitigation strategies for HWP uses in BC. The description and rationale of this strategy are discussed in the later sections.

It is worth noting that all the harvest originated from BC. The harvest rate projections were based on BC Ministry of Forests, Lands, Natural Resource Operations & Rural Development’s (FLNRORD) compilations of annual allowable cut (AAC) projections and the fractions of realized AAC available in 2016. As a consequence of reduction in growing stocks from the impacts of the Mountain Pine Beetle and large-scale forest fires in recent years, BC is anticipating reduced roundwood harvest for the next few decades (BCFML 2010; BCFLNRORD 2018c). This study was part of the Forest Carbon Management (FCM) Project funded by the Pacific Institute of Climate Solutions (PICS), which has a broader objective and examined forest sector mitigation options and interactions with climate change. This paper specifically addresses the substitution effects of harvested wood products. More specifically, it focuses on the production, trade, and usage decisions along the post-harvest wood products supply chain. The chain begins when harvested biomass is removed from the forest. The ecosystem carbon dynamics, including intensified harvest, conservation, forest regrowth and decay of logging residues left on site, and carbon opportunity costs, are addressed in other analyses for BC (e.g., Smyth et al. 2014, 2020; Xu et al. 2018) or internationally (e.g., Pingoud et al. 2016; Soimakallio et al. 2022) but are outside the scope of this study. All scenarios analyzed here used the same harvest projections.

This study also did not explore alternative uses of bark as a feedstock for biofuel production and assumed that it can only be used as hog fuel, because published literature has indicated that high bark contamination in feedstocks can significantly reduce the yield of liquid biofuels (Ringsred 2018). Under bark, data were used for carbon allocations, in accordance with the industrial roundwood data published by FAOSTAT and BC’s mill surveys (FAO 2015; BCFLNRORD 2018b).

Interprovincial trade from BC to other Canadian provinces was considered to be domestic (Canadian) consumption and was not modeled as an export.

2.3 Substitution assumptions

BC harvested about 66 million cubic meters (m3) of logs in 2016 that contained roughly 60 mega tonnes of carbon dioxide equivalent per year (MtCO2e·year−1) (BCFLNRORD 2018b). The extreme scenario ALL_CONS assumed that all BC’s harvested biomass is manufactured — with losses in manufacturing and process energy use — into wood products that are used in the construction sector. However, in this context, it is important to consider whether all of these wood products would be used to displace concrete or steel constructions (Seppälä et al. 2019; Howard et al. 2021), because timber construction already has a share of over half of the total residential construction market in BC and the United States (US), and roughly a quarter for the rest of Canada (CISC 2013; McKeever and Elling 2014, 2015; Elling and McKeever 2015).

In this study, not all forest biomass used for construction or bioenergy is considered to contribute to substitution benefit. Some buildings may be predetermined by the market to be constructed with wood, and steel or concrete has never been considered an alternative. This substitution assumption can be illustrated with an example. If timber construction has a 50% market share, without other incentives, when 100 new buildings are constructed, 50 of them will be built with wood and the other 50 of them with other materials, although in BC it predominantly would be reinforced concrete. In this case, there is no wood-to-other-material substitution. If there is an incentive by the government encouraging the use of wood in the construction sector, for example with a subsidy, regulations of embodied energy, or changes in building codes, then the wood construction market share may increase, for example from 50 to 60%, and consequently shifting 10 buildings that would have been constructed with concrete to be constructed with wood. In this case, wood in these 10 buildings can be regarded as wood-replacing-concrete and counted towards substitution benefit. Therefore, this study assumed that a substitution is only justified when there is a change, such as policy or human behavior, that causes the buildings that would otherwise have been constructed with steel and concrete to be built with wood (principle 1).

The BASE, IN_POP, and OU_CN scenarios assumed that no market share changes occurred in the construction or bioenergy sectors, so these three scenarios did not have any additional substitutions. The substitution benefit of OU_CONS and OU_PLTS was excluded for three reasons. Firstly, it is uncertain how much of these exported wood products will contribute to substitution. For example, in the OU_CONS scenario, more BC wood is used in the US and other countries for construction purposes. However, this could simply be BC wood replacing US wood or wood harvested from other countries. It cannot be guaranteed that this increased consumption is caused by increased timber construction market share. Secondly, although the same DFs were used across Canada, larger variations exist among countries than within, and Canadian DFs may not be applicable in foreign countries.

Thirdly, according to the United Nations Framework Convention on Climate Change (UNFCCC), a Party is required to report emissions from HWPs that originated from its forests (i.e., the Production Approach and the Simple Decay Approach which include export but exclude import) (UNFCCC 2012; IPCC 2014a). The industrial processes and product use (IPPU) sector also accounts emissions using a production-based approach (IPCC 2006). However, emissions from the energy sector are accounted for differently using a consumption-based approach in which the energy emissions within the Parties’ jurisdictional boundary should be reported (i.e., the Sectoral Approach which includes import but excludes export) (IPCC 2006). Due to this discrepancy in accounting approaches, the beneficiaries of emission reduction depend on the origin and destination of the materials or fuels. For example, if wood pellets produced in BC were used to substitute coal for electricity generation in the United Kingdom (UK) — assuming that the coal being substituted is no longer consumed in the UK — then the substitution beneficiary would be the UK. However, the downstream emissions arising from burning these wood pellets in the UK and the upstream emissions associated with producing these wood pellets would all be reported as BC’s emissions. On the other hand, substitutions of timber constructions are treated differently. For example, consider CLT produced in BC, consumed in the US to substitute for a functionally equivalent amount of steel that would otherwise be imported from China. Assuming that this amount of steel was no longer produced due to the decreased demand, then China would achieve a substitution benefit in its IPPU sector even though the timber construction is built in the US; BC would report a foreign storage benefit in the AFOLU sector; the US may benefit from reduced energy emissions associated with material transportation as BC is closer to the US than China, and with erecting the structure due to the prefabricated nature of CLT and its rapid construction process. In these two examples, the reduced consumption of coal and the reduced production of steel have been assumed. In reality, such reduction may not be guaranteed without international cooperation on mitigating climate change. As a result, in both examples, the substitution benefit by exported HWPs will unlikely contribute to BC’s emission reductions.

For these reasons, this study took a conservative approach and only estimated the substitution benefits of the ALL_CONS, ALL_FUEL, IN_CONS, IN_FUEL, and IN_PCF scenarios. Table 1 summarizes the scenarios and whether substitution benefits were estimated in this study.

2.4 Substitution benefit calculations

The increased shares of timber constructions and biofuels (i.e., the amounts that contributed to justified substitution) were obtained from the modeling results in Xie et al. (2021). Equation 3 was used to calculate the substitution benefit.

where Eavoided is the avoided emissions, Csubstitution is the carbon contained in the end-uses of justified substitution, and DF is the corresponding displacement factor.

The DFs calculated in this study from the LCAs were used to determine a range and an expected value with which a triangular distribution of DFs was constructed. This type of distribution was chosen because it uses the 3-point estimation technique (i.e., best-case, most likely, and worst-case estimates) to construct a probability distribution for uncertainty analysis based on limited quantitative information. A set of 100,000 DF values was randomly sampled from the triangular distribution to conduct the uncertainty calculation of the substitution benefit, which was represented by a box plot with minimum, maximum, first quartile, second quantile (i.e., median), and third quartile values.

2.5 Mitigation indicators

The substitution benefits were then added to the scenario-based mitigation analysis with total mitigation benefit quantified using Eq. 4:

where the storage benefit refers to the reduced HWP biogenic emissions compared to the baseline scenario in Xie et al. (2021) (Eq. 5).

where EHWP, BASE and EHWP, SCEN are the biogenic emissions from HWPs under the baseline scenario and under each bioeconomy scenario, respectively.

It is worth noting that the storage benefit is different from the carbon storage in HWPs (Eq. 6).

where C StorageHWP, SCEN is the carbon storage in HWPs under a scenario. Charvest is the carbon contained in the harvested woody biomass and EHWP, SCEN is the biogenic emissions from HWPs under a scenario.

The net emissions were calculated using Eq. 7 to demonstrate the net GHG emission consequences of HWP utilization and substitution.

where EHWP is the biogenic emissions from HWPs and Eavoided is the avoided emissions.

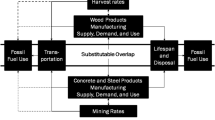

2.6 MitigAna model

A HWP C dynamics model — MitigAna — has been previously developed to conduct mitigation analyses in Xie et al. (2021). The model was designed to simulate the fate of wood carbon for scenario-based mitigation analysis. It was implemented using the Abstract Network Simulation Engine (ANSE) which is a software system developed by the Canadian Forest Service (NRCan 2022). The conceptual flow model started with harvested wood being taken out of the forest and undergoing manufacture and use by society and ended with carbon storage in landfills or an underground geological formation, or carbon emissions to the atmosphere. This study used MitigAna to track the fate of harvested carbon by its spatial origin and simulate carbon flows in annual time steps.

2.7 Calculating threshold service life

Under the condition that the demand from the domestic market is fulfilled, one of the goals of this study was to compare two utilization strategies for the remaining wood — either pursuing foreign carbon storage benefits or pursuing substitution benefits through domestic fuel switching. It was established in our previous study (Xie et al. 2021) that long-lived uses of exported HWPs may not be guaranteed. Therefore, there exists a threshold service life for the exported HWPs. If the weighted average service life of the exported products was lower than the threshold, the net emissions of domestic fuel switching (i.e., biofuel emissions minus substitution benefits) would be smaller than the emissions from exported HWPs, and BC would be better off, from the perspective of the reported GHG balance, using the remaining wood for domestic fuel switching rather than exporting to regions with short-lived uses. We estimated the threshold service life by progressively changing the service lives of exported HWPs in the MitigAna model until the emissions from exported HWPs were equal to the emissions from domestic fuel uses. Only if longer service lives are achieved does exporting HWPs perform better than using biomass to produce fuels for domestic consumption.

2.8 Model run for portfolio strategy

Because the domestic market is relatively small and its growth rate is constrained, BC would have to rely on access to foreign markets to achieve some of the mitigation potential. However, if the exported HWPs are not used for long-lived applications, from a domestic emission reduction perspective, BC may have to explore inward-focused biofuel substitution options. Therefore, there may exist a portfolio strategy that involves a suite of combined actions: prioritize construction uses, keep other long- and medium-lived material applications in the domestic and international markets, and shift short-lived export to domestic biofuel production.

The IN_PCF scenario was created to estimate the emission consequences of such inward-focused, construction-dominated, and biofuel-subordinated bioeconomy. Configurations in MitigAna were adjusted to rerun the IN_PCF scenario. Specifically, this scenario assumed that:

-

1.

The domestic HWPs demand for various end-uses increased in proportion to population growth.

-

2.

The domestic demand for residential and non-residential constructions increased in proportion to household growth and the domestic market share of timber constructions was doubled, predominantly replacing domestically produced reinforced concrete constructions. This implied that the timber construction market shares of residential dwellings and non-residential buildings were roughly 100% and 50% for BC, respectively, and 60% and 20% for the rest of Canada.

-

3.

The remaining sawnwood and plywood were exported with the allocation partitions the same as used by the BASE scenario. The remaining amounts of OSB, MDF, and particleboard were exported only if their end-uses had service lives longer than the threshold service life.

-

4.

The remaining pulp logs and milling residues were used to produce “drop-in” biofuels and displaced fossil fuels in the transportation sector.

3 Results

3.1 Displacement factors of timber construction

The calculated DFs of wood products replacing steel and concrete as construction materials based on the selected building LCAs are summarized in Table 2.

All DFs were positive but calculated DFs displayed a wide range — from 0.35 to 2.4. This was expected, because many factors can have significant impacts on the results including construction types, building year, building codes, transportation distance, energy mix of different jurisdictions, and whether the study used actual buildings. This range generally agrees with previously published DF reviews (Sathre and O’Connor 2010; Smyth et al. 2016; Leskinen et al. 2018). There did not appear to be a substantial difference between wood substitutions for reinforced concrete or for steel, based on the LCA data that were available to this research, and therefore for the remainder of this paper, these two building materials are discussed collectively.

Wherever functional equivalency is possible, lightweight wood frame, in theory, should have a higher DF than heavy timber construction because less wood mass is needed to replace the same amount of concrete or steel. The DFs of residential buildings in Table 2 generally followed this assertion, but the DFs of non-residential buildings did not, which is likely because of the small sample size and the influence of factors such as wood source, building design, and transportation distance. Non-residential buildings can be functionality-driven with large variability. For example, a theater, shopping mall, school, and gym will have very different designs and floor spaces.

3.2 Displacement factors of wood-derived biofuel

The calculated DFs of wood-derived biofuels are summarized in Table 3.

Despite the range of fuel types, pathways, and facility scenarios considered, the range of DFs in Table 3 was relatively narrow, ranging from 0.38 to 0.52 with an average of 0.45 and a standard deviation of 0.04.

3.3 Displacement factor distributions for uncertainty analysis

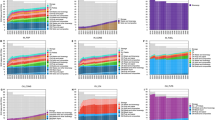

The DF distribution of timber constructions had a lower limit of 0.35, a mode of 1.03, and an upper limit of 1.22 (Fig. 1A). The value of 1.03 was chosen as the mode because it was calculated from comparable LCA studies of recently completed, actual, heavy timber and reinforced concrete buildings in BC (Bowick and O’Connor 2017; Bowick 2018a, b). The two highest values in Table 2 (i.e., 1.90 and 2.40) were based on structures built over a decade ago (i.e., 2004 and 1994, respectively (Lippke et al. 2004; Gustavsson et al. 2006)) and were excluded from the distribution. The sampling distribution also gave more weight to the heavy timber buildings with lower values, in accordance with their market growth opportunities (Fig. 1C). In addition, due to increased climate awareness and updated building codes influencing the material content of buildings, and the concrete building sector focusing on reducing their carbon footprint (Sabnis 2015), the DF will likely decrease with time. Therefore, the distribution is left skewed to provide a measure of future proofing.

The triangular probability density function (PDF) of the DF of A wood products replacing steel and concrete as construction materials, and B wood-derived biofuels replacing conventional fossil-based fuels, in the domestic market. C and D are the frequency and cumulative density diagram (CDF) of the 100,000 samples based on A and B, respectively

The DF distribution of wood-derived biofuels had a lower limit of 0.38, a mode of 0.45, and an upper limit of 0.52 (Fig. 1B). Unlike the DF for buildings, the DFs of biofuels were within a narrow range (Table 3). Therefore, this study selected the average value of 0.45 as the mode, and the upper and lower limit were the highest and lowest values, respectively.

3.4 Uncertainty ranges of avoided emissions

The uncertainty ranges of avoided emission under the ALL_CONS, ALL_FUEL, IN_CONS, IN_FUEL, and IN_PCF scenarios in 2020, 2030, and 2050 are summarized in Fig. 2.

The negative values on the y-axis indicate the amount of annual emissions avoided due to substitution. Compared to the other scenarios, the ALL_CONS scenario avoided more emissions but also had wider uncertainties, ranging from − 56.7 to − 18.0 MtCO2e·year−1 with a median of − 37.9 MtCO2e·year−1 and a mean of − 36.8 MtCO2e·year−1 in 2030. The median indicates larger avoided emissions than the mean because the determined DF distribution is left skewed (Fig. 1A and C). The ALL_FUEL scenario ranked second, with − 24.9 MtCO2e·year−1 as both the median and mean in 2030. The IN_PCF, IN_FUEL, and IN_CONS scenarios achieved median avoided emissions of − 14.3, − 12.7, and − 2.5 MtCO2e·year−1 in 2030, respectively.

3.5 Overall emission consequences

Using the 50th percentile (i.e., median) above, the magnitude of substitution benefits is placed into the mitigation context (Fig. 3). The HWP biogenic emissions were results from Xie et al. (2021). The contributions of forest ecosystem carbon sinks to the overall GHG balance are not assessed here because they are the same for all scenarios and do not alter the ranking of wood-use alternatives.

A comparison of the cumulative emission consequences from 2016 to 2050 of all mitigation scenarios (positive bars indicate emissions from HWPs and negative bars indicate avoided emissions in the other sectors. Lower value means better). The avoided emission results at 50th percentile were used to represent the substitution benefits

The storage, substitution, and overall mitigation benefits of all bioeconomy scenarios are summarized in Table 4.

In the BASE scenario, the cumulative biogenic emissions from HWPs were 1397 MtCO2e. In the ALL_FUEL scenario, the HWP biogenic emissions were approximately 1884 MtCO2e — an amount that is the same as BC’s projected harvest excluding bark between 2016 and 2050 — because all harvested wood was used as feedstock for biofuels. The BASE scenario achieved a cumulative HWP carbon storage of 487 MtCO2e (Eq. 6).

The ALL_CONS scenario had a carbon storage of 1493 MCO2e, all of which was stored in timber structures; whereas its storage and substitution benefits were 1007 MtCO2e (Eq. 5) and 1296 MtCO2e (Eq. 3), respectively. The mitigation benefit of the ALL_CONS scenario was 2303 MtCO2e or 66 MtCO2e·year−1 (Eq. 4). For comparison, BC’s GHG emissions in 2016 from all sectors excluding forest management were reported to be 62 MtCO2e·year−1 (BCECCS 2018).

The IN_CONS scenario also achieved its mitigation benefit through shifting to more longer-lived uses, except that the magnitude — 231 MtCO2e — was substantially lower.

The ALL_FUEL scenario had no HWP carbon storage and increased the biogenic emissions from HWPs by 486 MtCO2e compared to the BASE scenario. However, biofuel displacement cumulatively avoided emissions from fossil fuel production and consumption of 851 MtCO2e.

The IN_FUEL scenario achieved a biogenic emission reduction from HWPs of 4.7 MtCO2e and avoided 434 MtCO2e through fuel switching. The overall mitigation benefit of the IN_FUEL scenario was greater than the ALL_FUEL scenario.

The difference in overall mitigation benefits between the two theoretical ALL_CONS and ALL_FUEL scenarios was substantial, at approximately 1938 MtCO2e, even though their substitution benefits alone were similar. On the other hand, even in the absence of substitution benefit, the OU_CONS scenario resulted in the second largest mitigation benefit at 953 MtCO2e, solely due to large C storage in HWPs abroad. However, achieving the ALL_CONS or OU_CONS scenario would require that BC’s HWPs were used to construct buildings with floor areas of 154 million m2 year−1 or 140 million m2 year−1, respectively. Among BC’s trading partners, only the US and China could accommodate that amount of construction (Xie et al. 2021). The respective sizes of the US and Chinese residential construction markets in floor area are approximately 177 million m2 year−1 (US Census 2019) and 2 billion m2 year−1 (StatsChina 2017). However, the share of BC’s wood in the US timber construction market has decreased from approximately 20% in 2006 to 15% in 2016 (FPInnovations 2016), and with decades of effort on market penetration, the floor area of wood constructions built in China in 2018 using Canadian wood was merely 0.8 million m2 year−1 (Canada Wood 2019). In addition, the Canada-US softwood lumber dispute and the Sino-Canada trade tensions can further hinder the realization of this timber construction-focused bioeconomy plan. Furthermore, like any wood exporting region, BC has limited influence over the use of wood in long-lived applications in the foreign market. If wood is used for products with shorter retention times, the resulting emissions can be as much as threefold higher as observed from the results of the OU_CN and OU_PLTS scenarios.

3.6 Threshold service life

If the average service life of exported HWPs in the destination markets drops below a certain level (i.e., the threshold service life), the domestic substitution benefit of biofuels may be higher than the foreign storage benefit. This can have important implications for BC’s mitigation efforts, especially when the destination jurisdiction does not use wood as a substitute for emission-intensive alternatives. In addition, the international accounting rules do not attribute foreign substitution benefits to the wood exporting country.

Using the MitigAna model (Xie et al. 2021), the threshold service life was estimated to be approximately 32 years. As observed from Fig. 3 and Table 4, the overall mitigation benefit of the IN_FUEL scenario is larger than those of the OU_CN and OU_PLTS scenarios because the mass-based average service life of HWPs exported to China is 5.7 years in the OU_CN scenario and that of pellets exported to the EU is 0 years in the OU_PLTS scenario. It is important to note that these values only apply to the bioeconomy scenarios in this study and would change depending on the carbon contained in the exported HWPs, the amount of justified substitution, and the length of the study period.

3.7 Portfolio strategy

The results of the IN_PCF scenario are presented in Fig. 3 and Table 4. The IN_PCF scenario ranked the third lowest net emissions among all scenarios and only resulted in higher net emissions than the theoretical and unachievable ALL_CONS and OU_CONS scenarios. The net emissions of the IN_PCF scenario were 44% less than the BASE scenario and approximately midway between the IN_CONS and OU_CONS scenarios. The overall mitigation benefit was approximately 610 MtCO2e compared to the BASE scenario, or an average of 17.4 MtCO2e·year−1 between 2016 and 2050, which is equivalent to about 30% of BC’s 2050 GHG emission reduction target.

4 Discussion

4.1 Interpretation of uncertainty analysis results

Two factors contributed to the magnitudes of substitution benefits and their uncertainties, as demonstrated by Eq. 3. The first factor is the DF. The sampling distribution in Fig. 1 demonstrated that 98% of the cases in which timber construction displacing concrete buildings provided a higher DF than wood-derived biofuels replacing fossil fuels. As a result, in 90% of the circumstances, the avoided emissions of the ALL_CONS scenario were larger than the ALL_FUEL scenario (Fig. 2).

The second factor is the amount of wood involved in the substitution, of which the market size is an important determinant. In this study, market constraints were intentionally not set for the ALL_CONS scenario to illustrate the largest theoretical substitution benefit that BC can achieve through incentivizing timber construction (i.e., on average 37 MtCO2e·year−1). It has also been established in the previous study that the domestic transportation sector has the potential demand to consume all BC’s harvest for biofuels (Xie et al. 2021). In particular, biofuels produced in the theoretical ALL_FUEL scenario could supply 99% of BC’s or 13% of Canada’s energy demand in the transportation sector in 2016. On the other hand, although the IN_CONS scenario doubled the share of the timber constructions in the domestic market, the Canadian market itself was still relatively small and the amount of wood contributed to the substitution was only 2.9 MtCO2e·year−1. For comparison, the amount of wood contributed to the substitution in the unconstrained ALL_CONS scenario was 42 MtCO2e·year−1. Therefore, in the ALL_CONS, ALL_FUEL, and IN_FUEL scenarios, the mitigation constraint was the available amount of biomass input, whereas in the IN_CONS scenario, the constraint was the market demand. The IN_PCF scenario was constrained both by construction market demand and feedstock availability.

Several observations resulted from these market settings:

-

1.

The uncertainty spread of the IN_CONS was narrower than those of the ALL_CONS, ALL_FUEL, IN_FUEL and IN_PCF scenarios (Fig. 2).

-

2.

The ALL_FUEL and IN_FUEL scenarios had higher biogenic emissions than the IN_CONS scenario, but the substitution benefits of the former outweighed the combined storage and substitution benefit of latter (Fig. 3, Table 4), which demonstrates that the inclusion of substitution benefits can alter the overall mitigation outcome.

-

3.

The avoided emissions of the ALL_CONS, ALL_FUEL, IN_FUEL, and IN_PCF scenarios were declining overtime, because the harvest in BC was projected to decline over the study period, whereas the avoided emissions of the IN_CONS scenario were increasing, because the domestic construction market was set to be aligned with the household growth which was projected to increase (Fig. 2).

4.2 Challenges regarding the quantification of substitution benefits

The challenges of accurately quantifying the substitution benefit of wood products are usually due to the lack of context-specific data and information, such as geographical locations, building designs, and future technological advancements that alter the emission intensity of wood and non-wood products and whether material or fuel switching will result in substitution or contribute to energy rebound (i.e., increased demand following price reduction triggered by reduced demand from substitution) or leakage (i.e., substituted materials are used elsewhere) (IPCC 2014b). The results in this research are limited by the data available to us. The estimation was conducted from a BC-centric viewpoint, and while the results showed global carbon storage of wood harvested in BC, the substitution benefit analysis was limited to domestic product uses. Greater substitution could be achieved at the global level from exported HWP but that was not examined in detail.

In terms of the uncertainty analysis of substitution benefits conducted in this research, we are fully aware that technology advances, and as more data become available, these could widen or narrow the DF uncertainty ranges in the future. Future decarbonization will also decrease or increase the values of the DF and may even affect the validity of harvested wood products’ substitution benefits. As the society decarbonizes over time, the DF value may slowly decrease from the upper bound or mode to the lower bound (Fig. 1). The uncertainty ranges in Fig. 2 show the upper and lower bounds of substitution benefits, and in the event of continuous decarbonization over time, the overall substitution benefits fall within these uncertainty ranges. A left skewed DF distribution for timber construction (Fig. 1A) represents a more conservative substitution estimation range, giving higher likelihood to values lower than the mode. However, it is also worth noting that phasing out fossil fuels and technology improvements such as carbon capture and storage decarbonize the forest industry as well. Depending on the decarbonization rates in different industrial sectors, the DF values of HWPs may increase over time. For example, over 98.5% of the emissions in the forest industry can be reduced by switching to lower carbon fuels, while over 60% of emissions in the cement industry are from calcination of carbonates which cannot be lowered by phasing out fossil fuels (NRCan 2018a). The target of the uncertainty analysis was to quantify the impact of DF and market under various scenarios. In other words, this analysis did not adopt a simple decline model to represent the effect of future decarbonization, nor quantify the likelihood or uncertainties of the entire scenarios.

4.3 Implications of the bioeconomy scenarios

The bioeconomy scenarios in this study were not projection of future market conditions. Nonetheless, they indicate that wood-derived biofuels may have a promising potential in helping achieve the emission reduction goals set by BC, provided that the construction market is saturated, as demonstrated by the IN_PCF scenario. The achievability of this construction-dominated and biofuel-subordinated bioeconomy is relatively high compared to the theoretical extreme construction- or biofuel-focused scenarios. This strategy did not require building beyond feasible future market demand — only the domestic market share of timber construction needed to increase from the present value of 3 million m2·year−1 to 7 million m2·year−1 at the expense of concrete and steel (CISC 2013; McKeever and Elling 2014, 2015; Elling and McKeever 2015; NRCan 2018b). The floor areas of timber construction in the export markets remained at the present value of 27 million m2·year−1. This strategy also produced 4.4 billion liters (L) year−1 biofuel sourced from pulp logs and milling residues that are presently used to produce exported pulp and wood pellets. This volume was sufficient to displace 50% of BC’s total transportation fuel consumption in 2016 (StatCan 2019b), which may be a promising pathway for BC to reduce carbon intensity in the transportation sector, especially for heavy-load long-range road transportation that may be difficult to electrify.

While such restructuring of BC’s economy would achieve meaningful mitigation benefits, the social and economic impacts would also be substantial. The pulp and paper industry has traditionally been very important to BC’s financial and social prosperity, and in 2016, contributed 1.5 billion dollars to the province’s GDP, employed over 8000 people, and supported several rural communities (PwC 2007; BCFLNRORD 2018a; StatCan 2019a, c). However, environmental groups and workers’ unions have raised concerns regarding the increased wood pellets production (CBC and Watson 2021). In 2019, BC exported 2.14 Mt of pellets to Europe and Japan (BCFLNRORD 2020) and the number is still increasing, but the entire pellet industry with 14 mills only generates around 300 jobs (CCPA 2021). By exporting pellets to be directly used as heat and power generation in other countries, BC and Canada may miss a great domestic mitigation and development opportunity. Pellets may be better suited to replace coal and natural gas in the Canadian market (Smyth et al. 2017) or as an intermediate product for easier transportation to domestic biorefineries.

It is also worth noting that even if the social and economic implications were ignored, there could be leakage. If the world demands wood fiber for paper and pellets, it is going to manufacture that product somewhere. Restricting pulp and pellets production and exports in BC will not eliminate emissions on a global scale. This research did not consider a detailed quantification of carbon leakage or energy rebound because, at the moment, there is no justifiable approach to quantify and estimate the effects of leakage and rebound far into the future. However, the potential impacts were acknowledged, and as a first step, this study aimed to avoid relocating emissions arising from domestic market demand to other regions. In the design of mitigation scenarios, domestic demand for various wood end-uses — long-lived, short-lived, or energy — was required to be fulfilled first before the remaining biomass can be used to explore utilization and trade options for climate mitigation.

The production facilities and market demand are yet to be developed for BC to convert from an industry that is traditionally focused on the production and export of lumber and pulp to a construction-dominated, biofuel-subordinated bioeconomy. In addition, the full commercial deployment of drop-in biofuels still faces major technical and economic challenges. However, BC’s forest industry experienced large-scale sawmill and pulp mill production curtailments and shutdowns caused by the reduction in wood supply and difficult market conditions in 2019 (Kane 2019; Meissner 2019). The province has since announced millions of dollars of funding through the Forest Enhancement Society of BC grant, Forest Employment Program, skill training, and rural community recovery initiative to support fiber mobilization, industry innovation, rural infrastructure, and economic development (BC 2021; BCFLNRORD 2021). The growing global demand for the advanced bioproducts requires a structural transformation of BC’s traditional forest industry and the wood products value-adding chain needs to be diversified and extended to enhance BC’s economic and social competitiveness and resilience in international markets. Such transformations, for example, from kraft pulp mills to next-generation integrated forest biorefineries, may be able to rejuvenate rural communities and achieve both socio-economic benefits and contribute to clean energy targets (van Heiningen 2006; Bajpai 2012; Wilke et al. 2021).

4.4 From a global mitigation context

Lastly, it is important to point out the potential conflict between BC-specific benefits and maximizing the global GHG mitigation outcome. By using less biomass for long-lived high-displacement applications, the world achieves less GHG mitigation per unit of roundwood harvested in BC. The construction-dominated and biofuel-subordinated bioeconomy (IN_PCF) examined in this study is a suboptimal solution from a global mitigation perspective compared to an internationally coordinated construction-focused bioeconomy, although the latter is challenging to achieve due to constrained access to foreign construction markets. Figure 3 shows an important observation that among all the scenarios analyzed, only the extreme all-construction scenario (ALL_CONS) achieved a substitution benefit that is larger than the biogenic emissions from HWPs during the study period between 2016 and 2050, even if the minimum value from the uncertainty analysis (561 MtCO2e, Table 4) was used. While the substitution benefits by exported HWPs may not contribute to BC’s emission reductions, as demonstrated in Section 2.3, if international consensus on future use of wood buildings as a global mitigation strategy were in place, timber construction has been demonstrated to be the most climate-efficient use of harvested biomass (Churkina et al. 2020). The development of such a globally coordinated bioeconomy would need more engineered wood products to be created for the construction sector, which means that more finger-jointing facilities, cross-laminated timber plants, and other value-added facilities need to be built. The technology to manufacture engineered wood products is relatively mature, the risk is lower, and the required capital investment may be less than building biorefineries. These value-added downstream facilities can create jobs in addition to the existing lumber- and pulp-dominated bioeconomy in BC.

5 Conclusions

Substitution benefits can contribute substantial emission reductions and need to be considered when developing mitigation strategies to recognize the total mitigation effort across sectors. The efficiency of the substitution effect (i.e., the displacement factor) and the market size (i.e., the amount of wood involved in the substitution) are the two important factors that contribute to the magnitude of substitution benefits and their uncertainties. The quantitative analysis in this study shows that, when market constraints exists, the inclusion of substitution effect in mitigation strategic design can result in different policy recommendations compared to analysis that is conducted only from a direct carbon storage and emission perspective. In theory, the largest cumulative mitigation benefit from 2016 to 2050 that BC can create through the application of wood constructions under the current harvest projections is approximately 2303 MtCO2e (1568–2776 MtCO2e). However, with the current level of market access, even doubling the domestic market share of wood constructions would only achieve about 10% of this value. Conversely, a cumulative mitigation benefit of approximately 439 MtCO2e (373–501 MtCO2e) can be achieved through producing wood-derived biofuels to displace fossil fuels in the domestic transportation sector instead of exporting HWPs for short-lived material or energy uses. An inward-focused strategy portfolio (IN_PCF) that combines construction and biofuel uses can achieve an overall mitigation benefit of 610 MtCO2e (507–693 MtCO2e) by 2050, or on average 17.4 MtCO2e·year−1, which is 30% of BC’s 2050 GHG emission reduction target. Such transformations may also contribute to rejuvenation of rural communities, but the risk is that the technology and infrastructure to produce the required quantities of liquid transportation fuels from wood are not yet available in BC, and will require years and significant investments to develop.

From a global perspective, this inward-focused bioeconomy scenario is less climate-efficient than a construction-focused mitigation strategy. However, like all wood exporting regions, BC’s influence on ensuring long-lived applications of its exported wood is limited. Although BC has extensive infrastructure and knowledge of green building methodology, obtaining the requisite access to foreign construction markets is uncertain, and will require long-term effort and cooperation among countries. Potential conflict exists between BC-specific benefits and maximizing the global GHG mitigation outcome. How and where BC wood products will be used domestically and internationally can influence both the desired domestic and global mitigation outcomes.

Data availability

The datasets used in this study are publicly available and are cited in the manuscript.

Notes

“Drop-in” biofuels refer to renewable gasoline, diesel, and jet fuel that are functionally equivalent to conventional fuels and can be “dropped into” existing infrastructure.

Abbreviations

- ALL_CONS:

-

Scenario label: all forest biomass manufactured to construction materials

- ALL_FUEL:

-

Scenario label: all forest biomass as feedstock for renewable fuel

- BASE:

-

Scenario label: the business-as-usual baseline

- BC:

-

The province of British Columbia in Canada

- BCFLNRORD:

-

BC Ministry of Forests, Lands, Natural Resource Operations and Rural Development (since late 2022 BC Ministry of Forest [FOR])

- CLT:

-

Cross-laminated timber

- CMP:

-

Conference of the Parties serving as the meeting of the Parties to the Kyoto Protocol

- CISC:

-

Canadian Institute of Steel Construction

- DF:

-

Displacement factor

- EU:

-

European Union

- FPI:

-

FPInnovations

- GHG:

-

Greenhouse gas

- HTL:

-

Hydrothermal liquefaction

- HWPs:

-

Harvested wood products

- IN_CONS:

-

Scenario label: inward-focused, increase domestic market share of wood frame construction

- IN_FUEL:

-

Scenario label: inward-focused, prioritize renewable fuel feedstock

- IN_PCF:

-

Scenario label: inward-focused, population-driven, construction-dominated biofuel-subordinated

- IN_POP:

-

Scenario label: inward-focused, demand increase driven by population growth

- IPCC:

-

Intergovernmental Panel on Climate Change

- LCA:

-

Life cycle assessment

- MDF:

-

Medium density fiberboard

- Mt:

-

Mega tonnes

- MtCO2e:

-

Mega tonnes of carbon dioxide equivalent

- OSB:

-

Oriented strand board

- OU_CN:

-

Scenario label: outward-focused, prioritize export to China

- OU_CONS:

-

Scenario label: outward-focused, prioritize export to US and other markers for constructions

- OU_PLTS:

-

Scenario label: outward-focused, prioritize wood pellets export to EU and Japan for energy

- PICS:

-

Pacific Institute of Climate Solutions

- StatCan:

-

Statistics Canada

- UNFCCC:

-

United Nations Framework Convention on Climate Change

References

Achachlouei MA, Moberg Å (2015) Life cycle assessment of a magazine, Part II: A comparison of print and tablet editions: LCA of a magazine, Part II: Print vs. tablet. J Ind Ecol 19:590–606. https://doi.org/10.1111/jiec.12229

Anex RP, Aden A, Kazi FK et al (2010) Techno-economic comparison of biomass-to-transportation fuels via pyrolysis, gasification, and biochemical pathways. Fuel 89:S29–S35. https://doi.org/10.1016/j.fuel.2010.07.015

Athena (2016) User manual and transparency document - impact estimator for buildings v.5. Athena Sustainable Materials Institute. https://calculatelca.com/software/impact-estimator/user-manual/. Accessed 8 Jun 2018

Bajpai P (2012) Biotechnology for pulp and paper processing. Springer, New York. https://doi.org/10.1007/978-1-4614-1409-4

BC (2018) CleanBC: our nature. Our power. Our future. British Columbia. https://cleanbc.gov.bc.ca/app/uploads/sites/436/2018/12/CleanBC_Full_Report.pdf. Accessed 17 Jan 2019

BC (2021) Supports for forestry workers and rural communities. Government of British Columbia. Government Website, Province of British Columbia. https://www2.gov.bc.ca/gov/content/industry/forestry/supports-for-forestry-workers. Accessed 15 Jan 2022

BCECCS (2018) Provincial greenhouse gas emissions inventory 2016. British Columbia Ministry of Environment and Climate Change Strategy. https://www2.gov.bc.ca/gov/content/environment/climate-change/data/provincial-inventory. Accessed 19 Feb 2018

BCFLNRORD (2018a) 2017 economic state of the BC forest sector. British Columbia Ministry of Forests, Lands, Natural Resource Operations and Rural Development. https://www2.gov.bc.ca/assets/gov/farming-natural-resources-and-industry/forestry/forest-industry-economics/economic-state/2017_economic_state_of_bc_forest_sector-with_appendix.pdf. Accessed 30 Nov 2018a

BCFLNRORD (2018b) Major primary timber processing facilities in British Columbia 2016. British Columbia Ministry of Forests, Lands, Natural Resource Operations and Rural Development, Victoria, BC. https://www2.gov.bc.ca/assets/gov/farming-natural-resources-and-industry/forestry/fibre-mills/2016_mill_list_report_final1.pdf. Accessed 16 Dec 2018b

BCFLNRORD (2018c) Trends in timber harvest in BC. British Columbia Ministry of Forests, Lands, Natural Resource Operations and Rural Development. Government Website. https://catalogue.data.gov.bc.ca/dataset/18754165-1daa-42ea-8c43-fef0e8cf4598. Accessed 18 Feb 2019

BCFLNRORD (2020) 2019 economic state of British Columbia’s forest sector. British Columbia Ministry of Forests, Lands, Natural Resource Operations and Rural Development, Victoria, BC, Canada25. https://www2.gov.bc.ca/assets/gov/farming-natural-resources-and-industry/forestry/forest-industry-economics/economic-state/2019_economic_state_of_the_bc_forest_sector.pdf. Accessed 14 Oct 2021

BCFLNRORD (2021) New grants to help use more wood fibre | BC Gov News. Government of British Columbia. Government Website. https://news.gov.bc.ca/releases/2021FLNRO0007-000157. Accessed 15 Jan 2022

BCFML (2010) The state of British Columbia’s forests, 3. ed. British Columbia Ministry of Forests, Mines and Lands, Victoria, BC. https://www2.gov.bc.ca/assets/gov/environment/research-monitoring-and-reporting/reporting/envreportbc/archived-reports/sof_2010.pdf. Accessed 19 Feb 2019

BCMoE (2014) 2014 & 2015 BC Best Practices Methodology for Quantifying Greenhouse Gas Emissions. British Columbia Ministry of Environment. https://www2.gov.bc.ca/assets/gov/environment/climate-change/cng/methodology/2014-15-pso-methodology.pdf. Accessed 31 Jul 2018

Bowick M (2018a) Brock Commons Tallwood House, University of British Columbia: an environmental building declaration according to EN 15978 standard. Athena Sustainable Materials Institute. http://www.athenasmi.org/wp-content/uploads/2018a/08/Tallwood_House_Environmental_Declaration_20180608.pdf. Accessed 8 May 2018

Bowick M (2018b) Ponderosa commons cedar house, University of British Columbia: an environmental building declaration according to EN 15978 standard. Athena Sustainable Materials Institute. http://www.athenasmi.org/wp-content/uploads/2018b/08/Cedar_House_Environmenta_Declaration_20180608.pdf. Accessed 8 May 2018

Bowick M, O’Connor J (2017) Carbon footprint benchmarking of BC multi-unit residential buildings. Athena Sustainable Materials Institute. http://www.athenasmi.org/wp-content/uploads/2017/09/BC_MURB_carbon_benchmarking_final_report.pdf. Accessed 19 Oct 2017

Bull JG, Kozak RA (2014) Comparative life cycle assessments: the case of paper and digital media. Environ Impact Assess Rev 45:10–18. https://doi.org/10.1016/j.eiar.2013.10.001

Bullis K (2012) Amyris gives up making biofuels: update. MIT Technology Review. https://www.technologyreview.com/s/426866/amyris-gives-up-making-biofuels-update/. Accessed 4 Jul 2019

Canada Wood (2019) Canada wood released China tracking wood project report | Canada Wood Group. https://canadawood.org/blog/canada-wood-released-china-tracking-wood-project-report/. Accessed 1 May 2019

CARB (2018) Low carbon fuel standard pathway certified carbon intensities. California Air Resources Board. Government of {{California}}. https://www.arb.ca.gov/fuels/lcfs/fuelpathways/pathwaytable.htm. Accessed 20 Aug 2018

Carre A, Crossin E (2015) A comparative life cycle assessment of two multi storey residential apartment buildings. Forest and Wood Products Australia, Melbourne, Australia114. https://www.fwpa.com.au/images/marketaccess/PRA344-1415-Australand.pdf. Accessed 28 Apr 2016

CBC, Watson B (2021) B.C. Trees are being turned into wood pellets and that’s bad for the climate and workforce, critics say | CBC News. CBC. https://www.cbc.ca/news/canada/british-columbia/ccpa-report-wood-pellets-1.5979498. Accessed 15 Jan 2022

CCPA (2021) Suspend approvals of new wood pellet mills in BC, environmental groups and union urge government. Canadian Centre for Policy Alternatives. https://www.policyalternatives.ca/newsroom/news-releases/suspend-approvals-new-wood-pellet-mills-bc-environmental-groups-and-union. Accessed 15 Jan 2022

Chen R, Qin Z, Han J et al (2018) Life cycle energy and greenhouse gas emission effects of biodiesel in the United States with induced land use change impacts. Biores Technol 251:249–258. https://doi.org/10.1016/j.biortech.2017.12.031

Churkina G, Organschi A, Reyer CPO et al (2020) Buildings as a global carbon sink. Nat Sustain. https://doi.org/10.1038/s41893-019-0462-4

CISC (2013) National and regional market share summary report. Canadian Institute of Steel Construction. http://www.cisc-icca.ca/getmedia/4d5abdda-ebdb-49a3-87dd-de87c26bbb1f/CISC_National_and_Regional_Market_Share_Summary_Report.aspx. Accessed 28 Feb 2017

Cox K, Renouf M, Dargan A et al (2014) Environmental life cycle assessment (LCA) of aviation biofuel from microalgae, Pongamia pinnata, and sugarcane molasses. Biofuels, Bioprod Biorefin 8:579–593. https://doi.org/10.1002/bbb.1488

Elling J, McKeever DB (2015) Wood products and other building materials used in new residential construction in Canada 2013, With Comparison To Previous Studies. https://www.fpl.fs.fed.us/documnts/pdf2015/fpl_2015_elling001.pdf. Accessed 28 Feb 2017

FAO (2015) FAOSTAT forest products definitions. Food and Agriculture Organization of the United Nations. http://www.fao.org/forestry/statistics/80572/en/. Accessed 25 May 2016

FPInnovations (2016) BC trend analysis in export markets - all markets - fall 2016. FPInnovations, Vancouver BC86. http://www.bcfii.ca/download/file/fid/1913. Accessed 27 Feb 2017

Grann B (2014) Wood innovation and design centre whole building life cycle assessment. FPInnovations32. https://fpinnovations.ca/Extranet/Pages/AssetDetails.aspx?item=/Extranet/Assets/ResearchReportsWP/3126.pdf. Accessed 30 Jul 2018

Gustavsson L, Pingoud K, Sathre R (2006) Carbon dioxide balance of wood substitution: comparing concrete- and wood-framed buildings. Mitig Adapt Strat Glob Change 11:667–691. https://doi.org/10.1007/s11027-006-7207-1

Howard C, Dymond CC, Griess VC et al (2021) Wood product carbon substitution benefits: a critical review of assumptions. Carbon Balance Manag 16:9. https://doi.org/10.1186/s13021-021-00171-w

ICAO (2016) On board a sustainable future - ICAO environmental report 2016 - aviation and climate change. International Civil Aviation Organization, Montreal, QC, Canada. https://www.icao.int/environmental-protection/Documents/ICAO%20Environmental%20Report%202016.pdf. Accessed 31 Jul 2019

IPCC (2006) 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Intergovernmental Panel on Climate Change. http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html. Accessed 25 May 2016

IPCC (2014a) 2013 revised supplementary methods and good practice guidance arising from the Kyoto Protocol. Intergovernmental Panel on Climate Change. http://www.ipcc-nggip.iges.or.jp/public/kpsg/pdf/KP_Supplement_Entire_Report.pdf. Accessed 22 Feb 2016

IPCC (2014b) Climate change 2014b: mitigation of climate change: Working Group III contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Intergovernmental Panel on Climate Change, New York, NY. https://www.ipcc.ch/report/ar5/wg3/. Accessed 28 Nov 2019

Jensen CU, Rodriguez Guerrero JK, Karatzos S et al (2017) Fundamentals of hydrofaction: renewable crude oil from woody biomass. Biomass Convers Biorefin 7:495–509. https://doi.org/10.1007/s13399-017-0248-8

John S, Nebel B, Perez N, Buchanan A (2009) environmental impacts of multistorey buildings using different construction materials. Department of Civil and Natural Resources Engineering, University of Canterbury, Christchurch, New Zealand. https://ir.canterbury.ac.nz/bitstream/handle/10092/8359/12637413_JOHN%20STEPHEN%20ET%20AL%20Environmental%20Impacts%20of%20Multi-Storey%20Buildings%20Using%20Different%20Construction%20Materials%20MAF%20Report%202008.pdf?sequence=1&isAllowed=y. Accessed 29 Aug 2018

Johnson L, Lippke B, Oneil E (2012) Modeling biomass collection and woods processing life-cycle analysis. For Prod J 62:258–272. https://doi.org/10.13073/FPJ-D-12-00019.1

Kane L (2019) Can anything be done to stop the crisis in BC’s forestry industry? CTVNews. https://www.ctvnews.ca/business/can-anything-be-done-to-stop-the-crisis-in-b-c-s-forestry-industry-1.4593957. Accessed 9 Dec 2019

Karapetyan A, Yaqub W, Kirakosyan A, Sgouridis S (2015) A two-stage comparative life cycle assessment of paper-based and software-based business cards. Procedia Comput Sci 52:819–826. https://doi.org/10.1016/j.procs.2015.05.138

Karatzos S, McMillan JD, Saddler JN (2014) The potential and challenges of drop-in biofuels: a report by IEA Bioenergy Task 39. University of British Columbia, Vancouver. http://task39.sites.olt.ubc.ca/files/2014/01/Task-39-Drop-in-Biofuels-Report-FINAL-2-Oct-2014-ecopy.pdf. Accessed 17 Feb 2017

Kurz WA, Smyth C, Lemprière T (2016) Climate change mitigation through forest sector activities: principles, potential and priorities. Unasylva. http://www.fao.org/3/a-i6419e.pdf. Accessed 28 Dec 2018

Laganière J, Paré D, Thiffault E, Bernier PY (2017) Range and uncertainties in estimating delays in greenhouse gas mitigation potential of forest bioenergy sourced from Canadian forests. GCB Bioenergy 9:358–369. https://doi.org/10.1111/gcbb.12327

Leskinen P, Cardellini G, González-García S et al (2018) Substitution effects of wood-based products in climate change mitigation. European Forest Institute (EFI). https://www.efi.int/publications-bank/substitution-effects-wood-based-products-climate-change-mitigation. Accessed 17 Jan 2019

Lippke B, Wilson J, Perez-Garcia J, et al (2004) CORRIM: life-cycle environmental performance of renewable building materials. Forest Products Journal. https://corrim.org/wp-content/uploads/2017/12/FPJ_Environmental_Performance_of_Renewable_Building_Materials.pdf. Accessed 29 Aug 2018

Mahalle L, O’Connor J (2011) Chapter 11 environmental performance of cross-laminated timber. In: CLT handbook: cross-laminated timber. FPInnovations, Québec. https://library.fpinnovations.ca/media/WP/E4845.pdf. Accessed 12 Jun 2018

McKeever DB, Elling J (2014) Wood and other materials used to construct nonresidential buildings in Canada 2012. APA The Engineered Wood Association. https://www.fpl.fs.fed.us/documnts/pdf2014/fpl_2014_mckeever001.pdf. Accessed 28 Feb 2017

McKeever DB, Elling J (2015) Wood products and other building materials used in new residential construction in the United States 2012, with comparison to previous studies. https://www.fpl.fs.fed.us/documnts/pdf2015/fpl_2015_mckeever001.pdf. Accessed 28 Feb 2017

Meissner D (2019) BC forest industry facing uncertain future as mills close across province | CBC News. CBC. https://www.cbc.ca/news/canada/british-columbia/b-c-forest-industry-facing-uncertain-future-as-mills-close-across-province-1.5380138. Accessed 9 Dec 2019

Mitchell SR, Harmon ME, O’Connell KEB (2012) Carbon debt and carbon sequestration parity in forest bioenergy production. GCB Bioenergy 4:818–827. https://doi.org/10.1111/j.1757-1707.2012.01173.x

NEB (2017) Canada’s renewable power landscape - energy market analysis 2017. National Energy Board. https://www.neb-one.gc.ca/nrg/sttstc/lctrct/rprt/2017cndrnwblpwr/index-eng.html. Accessed 3 Jul 2019

NEB (2018) Canada’s energy future 2018: energy supply and demand projections to 2040, end - use demand. National Energy Board. Government Website. https://apps.neb-one.gc.ca/ftrppndc/dflt.aspx?GoCTemplateCulture=en-CA. Accessed 1 Nov 2018

Nie Y, Bi X (2018) Life-cycle assessment of transportation biofuels from hydrothermal liquefaction of forest residues in British Columbia. Biotechnol Biofuels 11:23. https://doi.org/10.1186/s13068-018-1019-x

NRCan (2018a) Fuel switching opportunities in Canadian industrial sectors. Natural Resources Canada. Government of Canada. https://www.nrcan.gc.ca/energy-efficiency/transportation-alternative-fuels/fuel-switching-opportunities-canadian-industrial-sectors/21266. Accessed 28 Oct 2022

NRCan (2018b) Residential sector British Columbia Table 18: floor space by building type and vintage. Natural Resources Canada. http://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.cfm?type=CP§or=res&juris=bc&rn=18&page=0. Accessed 7 Oct 2019

NRCan (2022) Forest carbon accounting tools. Natural Resources Canada. Government of Canada. https://www.nrcan.gc.ca/climate-change-adapting-impacts-and-reducing-emissions/climate-change-impacts-forests/carbon-accounting/forest-carbon-accounting-tools/24310. Accessed 3 Nov 2022

O’Connor J, Bowick M (2016) Embodied carbon of buildings. Athena Sustainable Materials Institute, Forestry Innovation Investment Ltd. (FII), Vancouver, BC. http://www.athenasmi.org/wp-content/uploads/2016/09/Embodied_Carbon_Policy_Review_August_2016.pdf. Accessed 1 Sep 2017

Pingoud K, Ekholm T, Soimakallio S, Helin T (2016) Carbon balance indicator for forest bioenergy scenarios. GCB Bioenergy 8:171–182. https://doi.org/10.1111/gcbb.12253

PwC (2007) Report on the economic impact of the BC Pulp and Paper Industry. Prepared for BC Pulp and Paper Industry Task Force. PricewaterhouseCoopers LLP, Canada. https://ppc2.sites.olt.ubc.ca/files/2015/02/final_pwc_report_to_task_force_nov_07.pdf. Accessed 30 Nov 2018

Ringsred A (2018) The potential of the aviation sector to reduce greenhouse gas emissions by using biojet fuels. {{MASc Thesis}}, University of British Columbia, Vancouver BC. https://open.library.ubc.ca/collections/ubctheses/24/items/1.0368545. Accessed 18 Jul 2018

Robertson AB, Lam FCF, Cole RJ (2012) A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: laminated timber or reinforced concrete. Buildings 2:245–270. https://doi.org/10.3390/buildings2030245

Sabnis GM (2015) Green building with concrete: sustainable design and construction, 2nd edn. CRC Press, Boca Raton

Sarkar S, Kumar A, Sultana A (2011) Biofuels and biochemicals production from forest biomass in Western Canada. Energy 36:6251–6262. https://doi.org/10.1016/j.energy.2011.07.024

Sathre R, O’Connor J (2010) Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ Sci Policy 13:104–114. https://doi.org/10.1016/j.envsci.2009.12.005

Schlamadinger B, Marland G (1996) The role of forest and bioenergy strategies in the global carbon cycle. Biomass Bioenerg 10:275–300. https://doi.org/10.1016/0961-9534(95)00113-1

Seppälä J, Heinonen T, Pukkala T et al (2019) Effect of increased wood harvesting and utilization on required greenhouse gas displacement factors of wood-based products and fuels. J Environ Manag 247:580–587. https://doi.org/10.1016/j.jenvman.2019.06.031

Smyth CE, Stinson G, Neilson E et al (2014) Quantifying the biophysical climate change mitigation potential of Canada’s forest sector. Biogeosci Discuss 11:441–480. https://doi.org/10.5194/bgd-11-441-2014

Smyth C, Rampley G, Lemprière TC et al (2016) Estimating product and energy substitution benefits in national-scale mitigation analyses for Canada. GCB Bioenergy. https://doi.org/10.1111/gcbb.12389

Smyth C, Kurz WA, Rampley G et al (2017) Climate change mitigation potential of local use of harvest residues for bioenergy in Canada. GCB Bioenergy 9:817–832. https://doi.org/10.1111/gcbb.12387

Smyth CE, Xu Z, Lemprière TC, Kurz WA (2020) Climate change mitigation in British Columbia’s forest sector: GHG reductions, costs, and environmental impacts. Carbon Balance Manag 15:21. https://doi.org/10.1186/s13021-020-00155-2

Soimakallio S, Böttcher H, Niemi J et al (2022) Closing an open balance: the impact of increased tree harvest on forest carbon. GCB Bioenergy 14:989–1000. https://doi.org/10.1111/gcbb.12981

StatCan (2019a) Table 14–10–0202–01 Employment by industry, annual (formerly CANSIM 281–0024). Statistics Canada. Government Website. https://www150.statcan.gc.ca/t1/tbl1/en/tv.action?pid=1410020201. Accessed 18 Jun 2019a

StatCan (2019b) Report on energy supply and demand in Canada 2016 revised. Statistics Canada135. https://www150.statcan.gc.ca/n1/en/pub/57-003-x/57-003-x2019b001-eng.pdf?st=vp6-Qndg. Accessed 5 Oct 2019b

StatCan (2019c) Table 36–10–0402–01 GDP by industry, provinces and territories (formerly CANSIM 379–0030). Statistics Canada. Government Website. https://www150.statcan.gc.ca/t1/tbl1/en/tv.action?pid=3610040201. Accessed 18 Jun 2019c

StatsChina (2017) China Statistical Yearbook-2017. National Bureau of Statistics of China. http://www.stats.gov.cn/tjsj/ndsj/2017/indexeh.htm. Accessed 4 Oct 2018