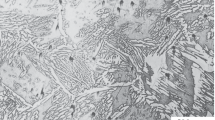

The impact toughness, microstructure and break features of low-alloy steel weld samples produced by automatic submerged arc welding have been compared. It has been established that when a notch is applied along the weld axis, fracture occurs along large grains of grain-boundary ferrite 80–140 μm in size with an unfavorable cleavage planes orientation {001}. The combination of such grains with non-metallic inclusions 3–5 μm in size facilitates the transcrystalline cleavage initiation. The effect of austenite grain size, crystallographic texture, and intergranular fracture on the impact toughness value is shown. Continuous chains of grain-boundary ferrite at the front of the main crack line up along the notch-parallel boundaries of columnar grains of axial orientation, which increases the tendency to transcrystalline cleavage. At the same time, with the lateral orientation of the columnar grains of the former austenite, the front line of the main crack intersects only certain separate areas of the grain-boundary ferrite. Offset notch results in an increase in both impact toughness and plasticity of weld metal.

Similar content being viewed by others

References

K. Easterling, Introduction to the Physical Metallurgy of Welding. Second Edition, Butterworth-Heinemann, Oxford (1992).

S. Kou, Welding Metallurgy. 3rd Ed., John Wiley & Sons, Hoboken (2020).

J. C. Lippold, Welding Metallurgy and Weldability, John Wiley & Sons, Hoboken (2014).

S. V. Zharkov, P. P. Stepanov, A. V. Chastukhin, et al., “Patterns (research) of effect of microstructure on impact strength of welded joints of large diameter pipes,” Metallurg, No. 9, 13–22 (2022).

J. C. F. Jorge, L. F. G. de Souza, M. C. Mendes, et al., “Microstructure characterization and its relationship with impact toughness of C-Mn and high strength low alloy steel weld metals: A review,” J. Mater. Res. Technol., 10, 471–501 (2021).

O. A. Bagmet, P. P. Stepanov, S. V. Zharkov, et al., “Features of formation of the structure of a welded joint made by automatic submerged arc welding,” Probl. Chern. Metallurg. Materialoved., No. 2, 52–65 (2022).

M. Diaz-Fuentes, A. Iza-Mendia, and I. Gutierrez, “Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Study of their toughness behavior,” Metall. Mater. Trans. A, 34, 2505–2516 (2003).

L. Cho, A. Tselikova, K. Holtgrewe, et al., “Critical assessment 42: acicular ferrite formation and its influence on weld metal and heat-affected zone properties of steels,” Mater. Sci. Technol., 38, No. 17, 1425–1433 (2022).

Y. Shao, C. Liu, Z. Yan, et al., “Formation mechanism and control methods of acicular ferrite in HSLA steels: A review,” J. Mater. Sci. Technol., 34, No. 5, 737–744 (2018).

D. Loder, S. K. Michelic, and C. Bernhard, “Acicular ferrite formation and its influencing factors: A review,” J. Mater. Sci. Res., 6, No. 1, 24–43 (2016).

F. J. Barbaro, P. Krauklis, and K. E. Easterling, “Formation of acicular ferrite at oxide particles in steels,” Mater. Sci. Technol., 5, No. 11, 1057–1068 (1989).

H. K. D. H. Bhadeshia and L. E. Svensson, “Modelling the evolution of microstructure in steel weld metal,” in: H. Cerjak and K. E. Easterling (eds.), Mathematical Modelling of Welding Phenomena, Institute of Materials, London (1993).

J. S. Seo, H. J. Kim, and H. S. Ryoo, “Effect of grain boundary ferrite on susceptibility to cold cracking in high-strength weld metal,” Met. Mater. Int., 14, No. 4, 515–522 (2008).

Z. Shi, T. Pan, Y. Li, et al., “Mechanism of BN-promoting acicular ferrite nucleation to improve heat-affected zone toughness of VN–Timicroalloyed offshore steel,” Materials, 15, No. 4, 1420 (2022).

F. Tankoua, J. Crépin, P. Thibaux, et al., “Quantification and microstructural origin of the anisotropic nature of the sensitivity to brittle cleavage fracture propagation for hot-rolled pipeline steels,” Int. J. Fracture, 212, 143–166 (2018).

A. Gervasyev, I. Pyshmintsev, R. Petrov, et al., “Splitting susceptibility in modern X80 pipeline steels,” Mater. Sci. Eng. A, 772, No. 2, 138746 (2020).

M. M. Kantor, K. G. Vorkachev, and K. A. Solntsev, “Nature of the scatter in the impact toughness of low-carbon low-alloy steel during fracture under ductile-brittle transition conditions,” Neorgan. Mater., 56, No. 11, 1271–1276 (2020).

M. M. Kantor, K. G. Vorkachev, V. A. Bozhenov, and K. A. Solntsev, “The role of splitting phenomenon under fracture of low-carbon microalloyed X80 pipeline steels during multiple Charpy impact tests,” Appl. Mech., 3, No. 3, 740–756 (2022).

A. O. Kluken, Ø. Grong, and J. Hjelen, “The origin of transformation textures in steel weld metals containing acicular ferrite,” Metall. Trans. A, 22, 657–663 (1991).

H. Nako, H. Hatano, Y. Okazaki, et al., “Crystal orientation relationships between acicular ferrite, oxide, and the austenite matrix,” ISIJ Int., 54, No. 7, 1690–1696 (2014).

M. Shi, M. Di, J. Zhang, et al., “Effect of initial microstructure on the toughness of coarse-grained heat-affected zone in a microalloyed steel,” Materials, 14, No. 16, 4760 (2021).

X. Li, G. Lu, Q. Wang, et al., “The effects of prior austenite grain refinement on strength and toughness of high-strength low-alloy steel,” Metals, 12, No. 1, 28 (2021).

J. Yin, M. Hillert, and A. Borgenstam, “Morphology of proeutectoid ferrite,” Metall. Mater. Trans. A, 48, 1425–1443 (2017).

H. Herø, J. Evensen, and J. D. Embury, “The occurrence of delamination in a control rolled HSLA steel,” Can. Metall. Quart., 14, No. 2, 117–122 (1975).

H. L. Haskel, E. Pauletti, J. D. P. Martins, and A. L. M. de Carvalho, “Microstructure and microtexture assessment of delamination phenomena in Charpy impact tested specimens,” Mater. Res., 17, No. 5, 1238–1250 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 6, pp. 5–15, June, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kantor, M.M., Vorkachev, K.G., Stepanov, P.P. et al. Impact Toughness and Microstructure of Low-Alloy Steel Weld Produced by Automatic Submerged Arc Welding. Metallurgist 67, 717–731 (2023). https://doi.org/10.1007/s11015-023-01561-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01561-w