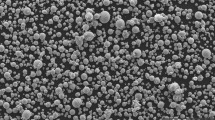

The paper described the structure and mechanical properties of nickel aluminide (Ni3Al) obtained by spark plasma sintering of the two compositions of nickel and aluminum powder mixtures with and without the addition of 0.1 wt.% boron, as well as with and without mechanical activation of such mixtures. It was found that by introducing a small amount of boron, it becomes possible to achieve a more beneficial effect on the relative density (98.8%) and strength properties of sintered nickel aluminide compared to the mechanical activation of the initial powders. The addition of boron to a mechanically activated powder mixture of nickel and aluminum (composition: 3Ni + Al) contributes to the formation of a work-piece with the highest complex of strength properties. The ultimate flexural strength (2,200 MPa) of the obtained material is 2.8 times higher than that of the material having the same composition, but without boron additives. The tensile strength (970 MPa) increases by 2.4 times. The level of impact toughness of the sintered nickel aluminide with boron additive increases by a factor of 5.

Similar content being viewed by others

References

B. A. Grinberg and M. A. Ivanov, Intermetallic Ni3Al and TiAl Compounds: Microstructure and Deformation Behavior [in Russian], Ural Branch of the Russian Academy of Sciences, Yekaterinburg (2002).

Ye. N. Kablov, O. G. Ospennikova, and O. A. Bazyleva, “Materials for highly heat-loaded parts of gas turbine engines,” Vestn. MGTU im. N. E. Baumana, Ser. “Machine building,” No. SP2, 13–19 (2011).

P. Jozwik, W. Polkowski, and Z. Bojar, “Applications of Ni3Al-based intermetallic alloys — current stage and potential perceptivities,” Materials, 8, 2537–2568 (2015); https://doi.org/10.3390/ma8052537.

N. Frage, S. Kalabukhov, A. Wagner, et al., “High temperature dynamic response of SPS-processed Ni3Al,” Intermetallics, 102, 26–33 (2018); https://doi.org/10.1016/j.intermet.2018.08.010.

J. R. Groza and A. Zavaliangos, “Nanostructured bulk solids by field activated sintering,” Rev. Adv. Mater. Sci., 5, 1, 24–33 (2003).

L. Shevtsova, V. Mali, A. Bataev, et al., “Microstructure and mechanical properties of materials obtained by spark plasma sintering of Ni3Al–Ni powder mixtures,” Materials Science and Engineering A, 773, Art. 138882 (2020); https://doi.org/10.1016/j.msea.2019.138882.

V. N. Chuvildeev, D. V. Panov, and M. S. Boldin, “Structure and properties of advanced materials obtained by Spark Plasma Sintering,” Acta Astronautica, 109, 172–176 (2015); https://doi.org/10.1016/j.actaastro.2014.11.008.

I. M. Makena, M. B. Shongwe, M. M. Ramakokovhu, and M. L. Lethabane, “A review on sintered nickel based alloys,” Proc. of the World Congress on Eng. WCE-2017, 922–927 (2017).

L. I. Shevtsova, “Structure and mechanical properties of intermetallic Ni3Al compound obtained using spark plasma sintering technology of mechanically activated Ni–Al powder mixture,” Obrabotka Metallov (Tekhnol., Oborud., Tools), No. 3 (64), 21–27 (2014).

J. Meng, C. Jia, and Q. He, “Effect of mechanical alloying on structure and property of Ni3Al by spark plasma sintering,” Powder Metall., 51, 227–230 (2008); https://doi.org/10.1179/174329007X223910.

M. H. Enayati, Z. Sadeghian, M. Salehi, et al., “The effect of milling parameters on the synthesis of Ni3Al intermetallic compound by mechanical alloying,” Mater. Science and Eng. A., 375–377, 809–811 (2004); https://doi.org/10.1016/j.msea.2003.10.060.

Y. Yu, J. Zhou, J. Chen, et al., “Synthesis of nanocrystalline Ni3Al by mechanical alloying and its microstructural characterization,” J. Alloys and Compounds, 498, 107–112 (2010); https://doi.org/10.1016/j.jallcom.2010.03.123.

M. Takeyama and C. T. Liu, “Effects of grain size and test temperature on ductility and fracture behavior of a B-doped Ni3Al alloy,” Acta Metall., 36, 1241–1249 (1988); https://doi.org/10.1016/0001-6160(88)90276-3.

J. T. Guo, L. Y. Sheng, Y. Xie, et al., “Microstructure and mechanical properties of Ni3Al and Ni3Al-1B alloys fabricated by SHS/HE,” Intermetallics, 19, 2, 137–142 (2011); https://doi.org/10.1016/j.intermet.2010.08.027.

M. L. Huang and C. Y. Wang, “Effects of boron and carbon on the ideal strength of Ni solution and Ni3Al intermetallics: a firstprinciples study of tensile deformation, Computational Mater. Science, 140, 140–147 (2017), https://doi.org/10.1016/J.COMMATSCI.2017.08.041.

N. Masahashi, “Physical and mechanical properties in Ni3Al with and without boron,” Mater Science and Engineering A, 223, 42–53 (1997); https://doi.org/10.1016/S0921-5093(96)10470-6.

A. Mohammadnejad, A. Bahrami, M. Sajadi, et. al., “Microstructure and mechanical properties of spark plasma sintered nanocrystalline Ni3Al–xB (0.0<x<1.5 at.%) alloy,” Materials Today Communications, 17, 161–168 (2018); https://doi.org/10.1016/j.mtcomm.2018.09.002.

N. A. Koneva, N. A. Popova, M. P. Kalashnikov, et al., “Effect of boron doping on the phase composition and defect structure of intermetallic Ni3Al compound,” Izv. RAN, Ser. Fizicheskaya, No. 7, 828–831 (2012).

M. A. Korchagin, V. Yu. Filimonov, Ye. V. Smirnov, et al., “Thermal explosion in a mechanically activated 3Ni + Al mixture,” Fizika Goreniya i Vzryva, 46, 1, 48–53 (2010).

L. I. Shevtsova, I. A. Bataev, V. I. Mali, et al., “Effect of heating temperature on the structure and mechanical properties of the material obtained by spark plasma sintering of PN85Yu15 powder,” Obrabotka Metallov (Tekhnol., Oborud., Tools), No. 4 (61), 35–42 (2013).

P. L. Potapov, S. Y. Song, V. A. Udovenko, et al., “Effect of LI0 + Ni5Al3 reordering on properties of martensitic Ni–Al Alloys,” J. de Physique IV (Proc.), 245–250 (1997); https://hal.archives-ouvertes.fr/jpa-00255635.

N. A. Nochevnaya, O. A. Bazyleva, D. Ye. Kablov, and P. V. Panin, Intermetallide Alloys based on Titanium and Nickel [in Russian], Izd. VIAM, Moscow (2018).

Acknowledgment

This study was sponsored by grant No. 21-79-00154 from the Russian Science Foundation; https://rscf.ru/project/21-79-00154/. The studies were carried out using the equipment of the Research Equipment Sharing Center “Structure, Mechanical, and Physical Properties of Materials” of the Novosibirsk State Technical University (NSTU).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 11, pp. 56–61, November, 2021. Russian DOI: https://doi.org/10.52351/00260827_2021_11_56.

Rights and permissions

About this article

Cite this article

Shevtsova, L.I., Korchagin, M.A., Esikov, M.A. et al. Structure and Properties of an Ni3Al Intermetallic Compound Formed as a Result of Spark Plasma Sintering of the Powder Mixtures Prepared by Various Methods. Metallurgist 65, 1273–1280 (2022). https://doi.org/10.1007/s11015-022-01273-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01273-7