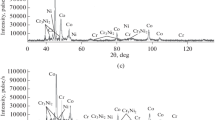

This article studies the composition, structure, and properties of electroerosive cobalt-chromium powder, as well as the additive products from it. The use of the obtained experimental data will enable the control of the formation process of the structure and properties of products obtained by means of additive technologies and ensure the technical requirements imposed on them.

Similar content being viewed by others

References

J. Karlsson, A. Snis, H. Engqvist, and J. Lausmaa, “Characterization and comparison of materials produced by Electron Beam Melting (EBM) of two different Ti-6Al-4V powder fractions,” J. Mater. Process. Technol., 213 (12), 2109–2118 (2013).

B. Song, S. Dong, B. Zhang, et al., “Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti–6Al–4V,” Mater. Des., 35, 120–125 (2012).

B. Song, S. Dong, P. Coddet, et al., “Fabrication and microstructure characterization of selective laser melted FeAl intermetallic parts,” Surf. Coat. Technol., 206, 4704–4709 (2012).

Z. Wang, K. Guana, and M. Gaoa, “The microstructure and mechanical properties of deposited IN718 by selective laser melting,” J. Alloys Compd., 513, 518–523 (2012).

A. Safdar, L.Y. Wei, A. Snis, and Z. Lai, “Evaluation of microstructural development in electron beam melted Ti-6Al-4V,” Mater. Charact., 65, 8–15 (2012).

A. Safdar, H. Z. He, L. Y. Wei, A. Snis, et al., “Effect of process parameters settings and thickness on surface roughness of EBM produced Ti–6Al–4V,” Rapid Prototyp. J., 18 (5), 401–408 (2012).

L. Loeber, S. Biamino, U. Ackelid, et al., “Comparison of selective laser and electron beam melted titanium aluminides,” in: Conf. paper of 22nd Intern. Symp. “Solid freeform fabrication proceedings” University of Texas, Austin (2011), pp. 547–556.

S. Biamino, A. Penna, U. Ackelid, et al., “Electron beam melting of Ti-48Al-2Cr-2Nb alloy: microstructure and mechanical properties investigation,” Intermetallics, 19, 776–781 (2011).

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe, “Laser additive manufacturing of metallic components: materials, processes and mechanisms,” Intern. Materials Rev., 57 (3), 133–164 (2012).

E. V. Ageeva, E. V. Ageev, S. V. Pikalov, E. A. Vorobiev, and A. N. Novikov, “X-ray analysis of the powder of micro- and nanometer fractions, obtained from wastes of alloy T15K6 in aqueous medium,” J. Nano Electron. Phys., 7 (4), 04058 (2015).

E. V. Ageeva, N. M. Khor’yakova, and E. V. Ageev, “Morphology of copper powder produced by electrospark dispersion from waste,” Russ. Eng. Res., 34 (11), 694–696 (2014).

E. V. Ageeva, N. M. Khor’yakova, and E. V. Ageev, “Morphology and composition of copper electrospark powder suitable for sintering,” Russ. Eng. Res., 35 (1), 33–35 (2015).

E. V. Ageev, A. Yu. Altukhov, E. V. Ageeva, and A. I. Pykhtin, “Structure and mechanical properties of powders obtained by electrodisperging cobalt-chromium alloy,” J. Appl. Eng. Sci., 19 (1), 230–236 (2021).

E. V. Ageeva, E. V. Ageev, and R. A. Latypov, “Properties of the VNZH pseudoalloy sintered from spark erosion powders fabricated in distilled water,” Russ. Metallurg. (Metally), 6, 119–123 (2021).

E. V. Ageev, E. V. Ageeva, and N. M. Khoryakova, “X-Ray methods for studying the surface of powder obtained by electroerosion dispersion of the waste of W-Ni-Fe 95 pseudoalloy in kerosene,” J. Surface Investig.: X-ray, Synchrotron Neutron Tech., 15, No. 4, 723–727 (2021).

E. V. Ageev and E. V. Ageeva, “Wear resistance of hardened components produced from electrospark cobalt-chromium powder by additive manufacturing,” Russ. Eng. Res., 41, No. 8, 731–733 (2021).

R. A. Latypov, A. V. Serov, N. V. Serov, and I. Yu. Ignatkin, “Recycling of wastes from mechanical engineering and metallurgy during the strengthening and restoration of machine parts,” Part 1, Part 2, Metallurg, No. 5, 81–87; No. 6, 87–92 (2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 10, pp. 78–81, October, 2021. Russian DOI 10.52351/00260827_2021_10_78.

Rights and permissions

About this article

Cite this article

Ageev, E.V., Ageeva, E.V. & Altukhov, A.Y. Additive Products from Electroerosion of Cobalt-Chromium Powder. Metallurgist 65, 1157–1162 (2022). https://doi.org/10.1007/s11015-022-01259-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01259-5