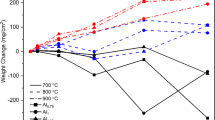

Temperatures of critical points for a new Russian intermetallic TiAl-alloy Ti–44.5Al–2V–1Nb–Zr/Cr–0.1Gd (at.%) are determined theoretically (using Thermo-Calc software) and experimentally taking account of Zr content variation from 0.5 to 1.5 at.% (1.2–3.5 wt.%) and Cr content from 1.5 to 2.5 at.% (2.0–3.5 wt.%). It is shown that alloy solidification proceeds through β-phase and ends within the single β-phase field. Differential scanning calorimetry curves show four peaks corresponding to high-temperature transformations (L)/(L + β)/(β), (β)/(α + β)/(α), (α)/(α + γ), and low-temperature transformations (α + γ)/(α2 + α + γ) and (α2 + α + γ)/(α2 + γ) in Zr-containing compositions, or (α + γ)/(α + γ + β), (α + γ + β)/(α2 + α + γ + β), and (α2 + α + γ + β)/(α2 + γ + β) in Cr-containing compositions. The predicted sequence of phase fields on phase diagram polythermal sections is confirmed by experiment and it is found that critical point temperatures for the alloy studied do not change with the introduction of up to 0.1 at.% Gd.

Similar content being viewed by others

References

N. A. Nochovnaya, O. A. Bazyleva, D. E. Kablov, and P. V. Panin, Intermetallic Alloys Based on Titanium and Nickel [in Russian], E. N. Kablov, (editor), VIAM, Moscow (2019); ISBN: 978-5-905217-46-3.

Y.-W. Kim and S.-L. Kim, “Advances in gamma alloy materials–processes–application technology: successes, dilemmas, and future,” J. of Metals, 70, 553–560 (2018); https://doi.org/10.1007/s11837-018-2747-x.

E. N. Kablov, Yu. A. Bondarenko, and A. B. Echin, “Development of directional crystallization technology for cast high-strength alloys with variable control of the temperature gradient,” Aviats. Mater. Tekhnol., No. S, 24-38 (2017); https://doi.org/10.18577/2071-91402017-0-S-24-38.

E. N. Kablov, V. V. Sidorov, D. E. Kablov, and P. G. Min, “Metallurgical bases for provision of high quality microcrystalline nickel superalloys,” Aviats. Mater. Tekhnol., No. S, 55–71 (2017); https://doi.org/10.18577/2071-9140-2017-0-S-55-71.

N. A. Nochovnaya, P. V. Panin, A. S. Kochetov, and K.A. Bokov, “Modern refractory alloys based on titanium gamma aluminide: prospects of development and application,” Metal Science and Heat Treatment, 56, Nos. 7–8, 364–367 (2014).

V. D. Belov, S. P. Pavlinich, and A. V. Fadeev, “Ti-Al-intermetallic material for tomorrow for Russian engine building,” Liteishchik Rossii, No, 11, 12–14 (2013).

K. Kothari, R. Radhakrishnan, and N. M. Wereley, “Advances in gamma titanium aluminides and their manufacturing techniques,” Progress in Aerospace Sciences, 55, 1–16 (2012); DOI: https://doi.org/10.1016/j.paerosci.2012.04.001.

F. Appel, J. D. H. Paul, and M. Oehring, Gamma Titanium Aluminide Alloys: Science and Technology, Wiley VCH Verlag & Co. KGaA, Weinheim (2011).

A. A. Il’in, B. A. Kolachev, and I. S. Pol’kin, Titanium Alloys. Composition, Structure, Properties: Handbook [in Russian], VILS MATI, Moscow (2009).

P. V. Panin, N. A. Nochovnaya, D. E. Kablov, E. B. Alekseev, A. A. Shiryaev, and A. V. Novak, Practical Handbook for Metallography of Titanium-Based Alloys and Intermetallics [in Russian], E. N. Kablov (editor), VIAM, Moscow (2020); ISBN: 978-5-905217-61-6

E. N. Kablov, E. A. Novochnaya, D. E. Kablov, V. V. Antipov, P. V. Panin, and A. S. Kochetkov, RF Patent 2606368. МPК C22C 14/00, C22C 30/00. Alloy Based on Titanium Intermetallic and Objects Made from it, Claim 10.15.2015, Publ. 01.10.2017. Bull. No. 1.

P. V. Panin, N. A. Novochnaya, E. A. Lukina, and A. S. Kochetkov, “Determinationof critical points for a new β-hardening Ti-Al alloy with Gd micro-additions,” in: G. A. Salishchev, M. S. Tikhonova, and E. F. Shcheigolevaya (editors), Structure and Properties of High-Entropy Alloys and Coatings. Technical Program and Theses of the Young scientist School (NIU BelGU, 9–11 October 2019), OO Épitsentr, Belgorod (2009).

P. V. Panin, N. A. Nochovnaya, E. A. Lukina, and A. S. Kochetkov, “Effect of chemical composition variability on phase composition and structure of beta-solidifying TiAl-alloy in as-cast condition,” Inorganic Materials: Applied Research, 10, No. 2, 316–321 (2019); https://doi.org/10.1134/S2075113319020333.

E. N. Kablov, N. A. Nochovnaya, P. V. Panin, E. B. Alekseev, and A. V. Novak, “Study of the structure and properties of heat-resistant alloys based on titanium aluminides with gadolinium micro-additives,” Inorganic Materials: Applied Research, 8, No. 4, 634–641 (2017); DOI: https://doi.org/10.1134/S2075113317040116.

E. B. Alekseev, N. A. Novochnaya, P. V. Panin, and A. V. Novak, “Technological ductility, structure and phase composition of test titanium ortho-alloy containing 13 wt.% aluminum,” Trudy VIAM Élektron. Nauch.-Tekhn. Zh., No. 12, 61–71 (2015); URL: http://www.viamworks.ru (access date 24.02.2021); https://doi.org/10.18577/23076046-2015-0-12-8-8.

Q. Wang, R. Chen, Y. Yang, et al., “Effects of V and B, Y additions on the microstructure and creep behaviour of high-Nb TiAl alloys,” J. of Alloys and Compounds, 747, 640–647 (2018); https://doi.org/10.1016/j.jallcom.2018.03.055.

T. He, W. Luo, J. Lei, et al., “Effect of non-metallic elements Si, C and O on mechanical properties of high temperature titanium alloys,” Proc. of 12th World Conf. on Titanium, II, 1240–1243 (2011)

Y. Xin, X. Zhengping, L.Yong. et al., “Microstructure refinement and improvement of mechanical properties of as-cast TiAl based intermetallics with yttrium and boron addition,” Proc. of 12th World Conf. on Titanium, II, 1571–1574 (2011).

U. Hecht, V. Witusiewicz, A. Drevermann, and J. Zollinger, “Grain refinement by low boron additions in niobium-rich TiAl-based alloys,” Intermetallics, 16, 969–978 (2008); https://doi.org/10.1016/j.intermet.2008.04.019.

R. M. Imayev, V. M. Imayev, M. Oehring, and F. Appel, “Alloy design concepts for refined gamma titanium aluminide based alloys,” Intermetallics, 15, 451–460 (2007); https://doi.org/10.1016/j.intermet.2006.05.003.

V. S. Sokolovsky, N. D. Stepanov, S. V. Zherebtsov, et al., “Hot deformation behavior and processing maps of B and Gd containing β-solidified TiAl based alloy,” Intermetallics, 94, 138–151 (2018); https://doi.org/10.1016/j.intermet.2018.01.004.

N. A. Nochovnaya, P. V. Panin, E. B. Alekseev, and A. B. Novak, “Features of structure and phase state formation for alloys based on ortho- and gamma-titanium aluminides during thermomechanical treatment,” Vestn. RFFI, No. 1(85), 18–26 (2015).

E. N. Kablov, “Innovative dveleopment of FGUP VIAM GNTs RF for implementing strategic areas for development of materials and preparation technology in the period up to 2030,” Aviats. Mater., Tekhnol., No. 1(34) 3–33 (2015); https://doi.org/10.18577/2071-9140-2015-0-1-3-33.

E. N. Kablov, “Strategic areas for development of materials and their processing technology in the period up to 2030,” Aviats. Mater., Tekhnol., No. S, 7–17 (2012).

N. A. Belov, V. D. Belov, and N. I. Dashkevich, Phase Composition of Multicomponent Gamma-Alloys Based on Titanium-Aluminide: Handbook [in Russian], E. N. Kablov (editor), VIAM, Moscow (2018); ISBN: 978-5-905217-21-0.

N. Saunders and A. P. Miodownik, CALPHAD – Calculation of Phase Diagrams. Pergamon Materials Series, R.W. Cahn (editor), Vol. 1, Elsevier Science. UK (1998).

N. Saunders and A. P. Miodownik, CALPHAD (Calculation of Phase Diagrams): A Comprehensive Guide, Pergamon Materials Series 1, New York (1998)..

N. Saunders, “Modelling of phase equilibria in Ti-alloys,” in: Proc. of 8th World Conf. on Titanium (1995).

N. Saunders, “Phase equilibria in multi-component γ-TiAl based alloys,” Proc. of Int. Symp. on Gamma Titanium Aluminides (ISGTA–1999), TMS, Warrendale, PA (1999).

V. Güther, M. Allen, J. Klose, and H. Clemens, “Metallurgical processing of titanium aluminides on industrial scale,” Intermetallics, 103, 12–22 (2018); https://doi.org/10.1016/j.intermet.2018.09.006.

V. Güther, A. Chatterjee, and H. Kettner, “Status and prospects of γ-TiAl ingot production,” in: Proc. of Int. Symp. on Gamma Titanium Aluminides (ISGTA–2003), TMS, San Diego CA (2003).

A. S. Kochetkov, P. V. Panin, N. A. Nochovnaya, and M. A. Makushina, “Study of chemical inhomogeneity in beta solidifying TiAl alloys of various composition,” Metallurgist, 64, Nos. 9–10, 962–973 (2021); https://doi.org/10.1007/s11015-02101077-1.

GOST R 55134–2012 (ISО 11357-1:2009). Plastics. Differential Scanning Colorimetry (DSC), Part 1. General Principles.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 4, pp. 74–82, April, 2021. Russian DOI: 10.52351/00260827_2021_04_74.

Rights and permissions

About this article

Cite this article

Panin, P.V., Lukina, E.A., Kochetkov, A.S. et al. Determination of Critical Points of Variable Composition Beta-Solidifying TiAl-Alloy. Metallurgist 65, 454–464 (2021). https://doi.org/10.1007/s11015-021-01176-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01176-z