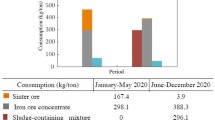

We describe the results for full-scale experimental test production of high-basicity sinter (basicity 2.0–5.0) at the Enakievo Metallurgical Plant Sinter Shop. As sinter basicity increased from 2.0 to 5.0, the iron content of the sinter decreased from 53.05% to 32.24%, and the ferrous oxide concentration decreased from 17.55% to 9.29%. However, the strength specifications of the sinter were improved: The concentration of 0–5-mm fines decreased from 19.32% to 15.89%, and the yield of +5 mm size class in a drum test increased from 65.9% to 72.3% through optimization of the sintering process parameters. The use of high basicity sinter in blast-furnace smelting reduced the specific consumption of lime in the blast-furnace charge from 233.9 kg/metric ton of cast iron (at sinter basicity 2.0) to 103.5 kg/metric ton (at basicity 4.5) and, correspondingly, the specific feed rate for coke during castiron production decreased from 538.1 kg/metric ton to 476.6 kg/metric ton.

Similar content being viewed by others

References

V. A. Utkov, High-Basicity Sinter, Metallurgiya [in Russian], Moscow (1977).

V. I. Korotich, Yu. A. Frolov, and G. N. Bezdenezhnyi, Sintering of Ore Materials [in Russian], UGTU-UPI, Ekaterinburg (2003).

T. Ya. Malysheva and O. A. Dolitskaya, Petrography and Mineralogy of Iron-Ore Raw Materials [in Russian], MISIS, Moscow (2004).

S. V. Krivenko and G. G. Bozhkov, “Structure of sinters with various basicities,” Vestnik Pryazovskoho Derzhavnoho Tekhnichnoho universytetu. Seriya Tekhnіchnі Nauki, No. 28, pp. 31–37 (2014).

R. Mežibrický and M. Fröhlichová, “Silico-ferrite of calcium and aluminum characterization by crystal morphology in iron ore sinter microstructure,” ISIJ International, 56, No. 6, 1111–1113 (2016).

S. Nicol, J. Chen, M. I. Pownceby, and N. A. Webster, “A review of the chemistry, structure and formation conditions of silicoferrite of calcium and aluminum (‘SFCA’) phases,” ISIJ International, 58, No. 12, 2157–2172 (2018).

N. A. Webster, M. I. Pownceby, R. Pattel, J. R. Manuel, and J. A. Kimpton, “Fundamentals of silico-ferrite of calcium and aluminium (SFCA) iron ore sinter bonding phase formation: effects of basicity and magnesium on crystallisation during cooling,” ISIJ International, 59, No. 2, 263–267 (2019).

V. Ya. Lyadova, V. P. Lekin, V. I. Gubanov, et al., USSR Inventor’s Certificate 1386668, IPC C22B 1/16, A Method for Producing Fluxed Iron-Ore Sinter, Appl. No. 4097269; application date 17 July 1986, publication date 07 April 1988, Byull. Izobr., No. 13 (1988).

V. Ya. Lyadova and L. Z. Khodak, Russian Federation Patent 2048548, IPC C22B 1/16, A Method for Producing Fluxed Iron-Ore Sinter, Appl. No. 5048431/02; application date 19 June 1992, publication date 20 November 1995, Byull. Izobr., No. 32 (1995).

Yu. S. Karabasov and V. S. Valavin, Fuel Usage in Sintering [in Russian], Metallurgiya, Moscow (1976).

I. M. Mishchenko, Theory of Raw Material Preparation Processes [in Russian], GVUZ DonNTU, Donetsk (2013).

T. Ya. Malysheva, Petrography of Iron-Ore Sinter [in Russian], Nauka, Moscow (1969).

E. F. Vegman, B. N. Zherebin, A. N. Pokhvisnev, et al, Metallurgy of Cast Iron [in Russian], 3rd ed., revised and enlarged, IKTs Akademkniga, Moscow (2004).

V. N. Andronov, Ferrous-Metal Extraction from Natural and Artificial Raw Materials. Blast-Furnace Process [in Russian], Nord- Press, Donetsk (2009).

I. G. Tovarovskii, Blast-Furnace Smelting [in Russian], Porogy, Dnepropetrovsk (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 8, pp. 14–20, August, 2020.

Rights and permissions

About this article

Cite this article

Bobylev, G.S., Kovalenko, A.G., Padalka, V.P. et al. Full-Scale Experimental Test Production of High-Basicity Sinter in the Enakievo Metallurgical Plant Sinter Shop. Metallurgist 64, 741–749 (2020). https://doi.org/10.1007/s11015-020-01063-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01063-z