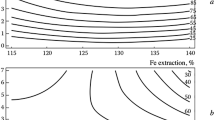

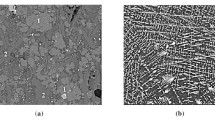

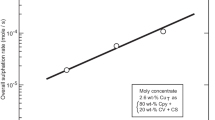

Results of studying combined pyrometallurgical processing of relatively high-sulfur, low-copper and high-copper, high-silica sulfide concentrates are presented. Experimental melting of a mixture of highsulfur Aktogai and high-silica Zhezkazgan copper concentrates in the ratio of 1:1 in the range 1310–1400°С with a weakly reducing gas atmosphere and a weakly oxidizing gas atmosphere are provided. The possibility of preparing matte containing from 40 to 50% copper is demonstrated. Copper-richer mattes (49.75–52.74% Cu) are obtained at 1400°C in a weakly oxidizing atmosphere. Production parameters are obtained for smelting Aktogai and Zhezkazgan copper concentrates demonstrating the possibility of preparing matte suitable for subsequent conversion.

Similar content being viewed by others

References

V. P. Zhukov, G. V. Skopov, and S. I. Kholod, Pyrometallurgy of Copper (Theory, Practice, Applied Statistics, Economics): Handbook [in Russian], UrO RAN, Ekaterinburg (2016).

A. V. Tarasov, “Increase in the efficiency of producing heavy nonferrous metals,” Tsvet. Met., No. 3, 24–32 (2016).

A. A. Gal’nbek, I. N. Beloglazov, E. O. Golubev, and E. V. Kalyukina, Electromelting of Briquetted Sulfide Copper-Nickel Raw Material [in Russian], ID Ruda Metally, St. Petersburg (2002).

L. B. Tsymbulov, D. A. Lapshin, A. B. Portov, et al., “Pyrometallurgical methods for treating sulfide copper concentrates of the Ukdokan deposit,” Tsvet. Met., No. 9, 29–37 (2014).

K. V. Bulatov, G. V. Skopov, D. Yu. Skopin, and S. A. Yakornov, “Processing of polymetallic concentrates in a Pobeda OOO Copper Mining Copper-Sulfur Combine smelting unit,” Tsvet. Met., No. 10, 39–44 (10214).

M. R. Rusakov, “Processes of high-intensity electromelting and high-intensity impoverishment of slag,” Proc. AO Institute Pironikel’ “New processes in metallurgy of nickel, copper, and cobalt,” Moscow (2000).

E. N. Selivanov, R. I. Gulyaeva, and A. M. Klyushnikov, “Technical and economic evaluation of direct metallurgical processing of sulfide ores,” Tsvet. Met., No. 3, 15–21 (2015).

C. Martinez, U. C. Martinez, P. B. Medel, et al., “General maintenance of electric furnace,” Proc. of Copper (Santiago, Chile, 2013), Vol. III (2013), pp. 945–950.

P. R. Moskalyk and A. M. Alfantazi, “Review of copper pyrometallurgical practice: today and tomorrow,” Minerals Engineering, 16, 893–919 (2003).

A. G. Bulaev, E. V. Pershina, and I. V. Ukraintsev, “State of development of contemporary bio-hydrometallurgical technology and prospects of their use in Russia,” Tsvet. Met., No. 10, 29–35 (2016).

M. Purévdash, “Prospects of hydrometallurgical treatment of oxide copper ores and sulfide copper concentrates as a component part of new technology for comprehensive treatment of Érdenetiin Ovoo deposits,” Zapiski Gorn. Inst.,189, 313–316 (2011).

K. A. Karimov, D. A. Rogozhnikov, S. S. Naboichenko, et al., “Autoclave ammonia leaching of silver from low-content copper concentrates,” Metallurg., No. 8, 53–57 (2018).

A. S. Shamgunov, S. A. Kvyatkovskii, A. S. Semenova, et al., “Melting of copper-containing oxide ores of the Aktogai and Boshchekul’ deposits with Nikolaev concentrate,” Kompleks. Ispol. Mineral. Syr’ya, No. 3, 48–52 (2016).

S. M. Kozhakhmetov, Research in the Field of Theory and Technology of Autogenic Process, Coll. Work, Almaty (2015).

S. M. Kozhakhmetov, New Effective Processes in Pyrometallurgy of Copper, Nickel, and Gold, Coll. Work, Almaty (2015).

S. Vaisburd, D. G. Brandon, S. Kozhakhmetov, and E. Kenzhaliev, “Physicochemical properties of matte-slag melts taken from Vanyukov’s furnace for copper extraction,” Metal. and Mater. Trans. B, 33, No. 4, 561–564 (2002).

S. Vaisburd, D. G. Brandon, S. Kozhakhmetov, et al., “Slags and mattes in Vanyukov’s process for the extraction of copper,” Metal. and Mater. Trans. B, 33, No. 4, 551–559 (2002).

S. M. Kozhakhmetov, S. A. Kvyatkovskii, M. K. Sultanov, et al., Treatment of oxide copper ores and sulfide copper concentrates of the Aktogai deposit by pyrometallurgical methods,” Kolpleks. Ispol. Mineral. Syr’ya., No. 3, 44–62 (2018).

Work was conducted with financial support of KN MON RK by grant No. AR05130400.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 63, No. 9, pp. 90–96, September, 2019.

Rights and permissions

About this article

Cite this article

Kozhakhmetov, S.M., Kvyatkovskii, S.A., Kenzhaliev, É.B. et al. Pyrometallurgical Technology for Treatment of High-Sulfur Concentrate Lean with Respect to Copper. Metallurgist 63, 984–992 (2020). https://doi.org/10.1007/s11015-020-00916-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00916-x