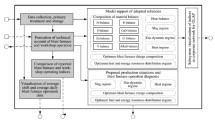

A general description of an algorithm for predicting the silicon content in the iron of a blast furnace is given. It is based on the knowledge of the processes occurring in the furnace and the general laws of transient processes. The algorithm allows real-time and 10 hour prediction of the silicon content. A linearized model of the blast furnace process and a combined full-scale/mathematical approach are used. They allow customize the model to the blast furnace conditions, taking into account changes in the composition and properties of iron ore raw materials and coke and in the blast and smelting parameters. The information/modeling system developed based on the algorithm is integrated into the information system of the MMK blast furnace shop. The architecture of the software is described and its operation is illustrated. The accuracy of predicting the silicon content in iron is assessed.

Similar content being viewed by others

References

A. A. Eremin, Magnitka 4.0: (Magnitogorsk Iron and Steel Works) Interviewed about What Has Been Digitized at the MMK and How to Make Steel Without Human Intervention [in Russian]; http://www.mashportal.ru/interview-49200.aspx (access date: 4/29/2019).

The NLMK Group Combines Digital Transformation and Information Technology [in Russian]; http://www.metalinfo.ru/ru/news/108069 (access date: 4/29/2019).

The Metalloinvest Has Transformed Business Processes Based on the Industry 4.0 Principles [in Russian]; http://www.metalinfo.ru/ru/news/103230 (access date: 4/29/2019).

I. G. Tovarovskii, Blast-Furnace Smelting [in Ukrainian], Porogi, Dnepropetrovsk (2009).

M. Geerdes, R. Chaigneau, I. Kurunov, O. Lingiardi, and J. Ricketts, Modern Blast Furnace Ironmaking. An Introduction, IOS Press, Amsterdam (2015).

S. Taguchi, H. Kubo, N. Tsuchiya, et al., “Development of a mathematical model of silicon transfer via SiO in the blast furnace,” Tetsu-To-Hagane. J. of the Iron and Steel Institute of Japan,68, No. 15, 2303–2310 (1982).

Xu Jian, Sheng-li Wu, Xin-ying Guo, and Kai-ping Du, “Numerical simulation on dynamic and static holdups of powder inside prereduction shaft furnace,” in: Proc. 6th Int. Congr. on the Science and Technology of Ironmaking, Rio de Janeiro, RJ, Brazil, October 14-18 (2012), pp. 414-424.

N. A. Spirin (ed.), V. V. Lavrov, V. Yu. Rybolovlev, et al., Mathematical Simulation of Metallurgical Processes in a Process Automation System [in Russian], OOO “UIPTs,” Ekaterinburg (2014).

O. P. Onorin, N. A. Spirin (ed.), V. L. Terent’ev, et al., Computer-Based Methods for the Simulation of the Blast-Furnace Process [in Russian], UGTU-UPI, Ekaterinburg (2005).

N. A. Spirin, V. V. Lavrov, I. E. Kosachenko, et al., “Software for the raw-materials management system in blast-furnace smelting,” Metallurgist,59, No. 1–2, 104–112 (2015).

N. A. Spirin, V. V. Lavrov, V. Y. Rybolovlev, et al., “Use of contemporary information technology for analyzing the blast furnace process,” Metallurgist,60, No. 5-6, 471–477 (2016).

A. V. Pavlov, A. A. Polinov, N. А. Spirin, et al., “Use of model systems for solving new technological problems in blast-furnace production,” Metallurgist,61, No. 5–6, 448–454 (2017).

V. I. Moikin, N. M. Babushkin, and B. A. Bokovikov, “Dynamic characteristics of a blast furnace found by mathematical simulation,” in: Issues of Iron Making in Blast Furnaces [in Russian], Metallurgiya, Moscow (1984), pp. 46–52.

Yu. N. Ovchinnikov, V. I. Moikin, N. A. Spirin, and B. A. Bokovikov, Nonstationary Processes and Improvement of the Effectiveness of Blast-Furnace Smelting [in Russian], Metallurgiya, Chelyabinsk (1989).

S. V. Emel’yanov, S. K. Korovin, L. P. Myshlyaev, et al., Theory and Practice of Prediction in Control Systems [in Russian], Rossiiskie Universitety, Kuzbassvuzizdat-ASTSh, Kemerovo–Moscow (2008).

O. P. Onorin, N. A. Spirin, A. S. Istomin, et al., “Features of blast furnace transient processes,” Metallurgist,61, No. 1-2, 121–126 (2017).

N. A. Spirin, O. P. Onorin, A. S. Istomin, et al., “Study of transition processes of blast-furnace smelting by the mathematical model method,” IOP Conf. Series: Mater. Sci. and Eng.,411, No. 1, 012–073 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 63, No. 9, pp. 22–28, September, 2019.

Rights and permissions

About this article

Cite this article

Spirin, N.A., Polinov, A.A., Gurin, I.A. et al. Information System for Real-Time Prediction of the Silicon Content of Iron in a Blast Furnace. Metallurgist 63, 898–905 (2020). https://doi.org/10.1007/s11015-020-00907-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00907-y