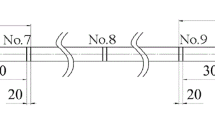

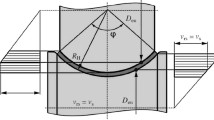

We describe the results of a study of the longitudinal and circumferential variation in pipe/tube wall thickness as a function of kinematic tension coefficient for pipe/tube passing through three stands of a reduction mill. The study was performed via computer modeling using the DEFORM software. The variation in pipe/tube wall thickness and the mean wall thickness were found to decrease as the kinematic tension coefficient increased, as evidenced by the calculated dispersions, root mean square deviations, and coefficients of variation.

Similar content being viewed by others

Notes

The rolling process is assumed to have reached a steady state when the pipe/tube is passing through all of the mill stands. In this case, the rolling speed at each stand approaches the appropriate constant value for each specific tension mode.

The DEFORM postprocessor has the capability to designate between 2 and 1000 nodal points on the inner or outer surface around the circumference of any transverse section through the pipe using the function SV Distribution Between 2 Points. The function State Variables is then used to select Thickness in the Analysis field, and the software calculates the wall thickness of the pipe/tube at the previously selected nodal points. The results can be saved in *.txt format and imported into Microsoft Office Excel, where a statistical analysis can easily be performed.

References

V. N. Danchenko, A. P. Kolikov, B. A. Romantsev, et al., Pipe Production Processes, Moscow, Intermet Inzhiniring (2002).

Yu. F. Shevakin, A. P. Kolikov, and Yu. N. Raikov, Pipe Manufacturing, Moscow, Intermet Inzhiniring (2005).

G. I. Gulyaev, P. N. Ivshin, I. N. Erokhin, et al., Process for Continuous Plugless Rolling of Pipe, Moscow, Metallurgiya (1975).

I. N. Potapov, A. P. Kolikov, and V. M. Druyan, Theory of Pipe Production: Textbook, Moscow, Metallurgiya (1991).

M. F. Stoletnii and E. D. Klempert, Accuracy of Pipe, Moscow, Metallurgiya (1975).

This work was performed with the support of Russian Federation Presidential Grant MK-3011.2017.8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 3, pp. 18–20, March, 2018.

Rights and permissions

About this article

Cite this article

Pavlov, D.A., Bogatov, A.A. & Pavlova, E.A. Effect of Kinematic Tension Coefficient on Wall Thickness Variation for Tube/Pipe Rolled in a Reducing Mill. Metallurgist 62, 203–206 (2018). https://doi.org/10.1007/s11015-018-0645-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0645-7