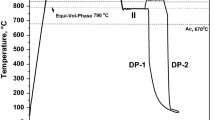

The effect of structural characteristics (ferrite, ferrite + pearlite, sorbite) including morphology, size and distribution of nonmetallic inclusions of different morphology, sizes and distribution, on ductile–brittle transition in structural steels is considered. It is shown that an elementary ductile microcrack is initiated by particles of critical size. For steels with ferrite-pearlite and sorbite microstructure, the particle size (carbide, nitride and nonmetallic inclusions) is almost the same. The ductile–brittle transition is caused by competition of the size of the brittle and ductile (pits) microcracks. As a result, the critical brittleness temperature T c in simplified form looks like \( {T}_c={T}_c^0+B{\Lambda}_d^{1/2}/{\Lambda}_b, \) where elementary microcracks Λ b and Λ d correspond to the size of a brittle crack of transcrystalline cleavage (Λ b ) and the size of ductile crack (Λ d ), Т c 0 reflects the contribution of different strengthening mechanisms to metal yield strength: dislocation, solid solution, grain size, precipitation hardening, and others, and B is a coefficient taking into account the stress-strain state in the fracture zone. As part of this model of failure, it becomes clear why for hardened steel the grain size does not change up to the recrystallization temperature, and yield strength and the value of T c have a complex dependence on the tempering temperature. Since the steel has particles of different sizes, they initiate the occurrence of pits of different sizes. The larger the particle, the sooner a micropore originates around it and pit growth is faster. A wide range of pit sizes arises that causes a wide range of T c values. A close connection is demonstrated for the width of the ΔT c ductile–brittle transition temperature range with a change in the distance between particles, including between pearlite colonies. This relationship can be positive and negative, which is confirmed by experiment.

Similar content being viewed by others

Notes

A situation considered typical for specimens with a notch.

Probably, this is the size of a barrier limiting dislocation sliding and forming their flat accumulation.

References

V. M. Goritskii, G. R. Shneiderov, and I. A. Guseva, “Effect of chemical composition and structure on the mechanical properties of low-alloy weldable steels after thermomechanical rolling,” Metallurg. No. 5, 49–55 (2016).

N. J. Petch, “Transition from a ductile state to brittle in α-iron,” in: Atomic Mechanism of Failure [Russian translation], Metallurgiya, Moscow (1963), pp. 69–83.

A. H. Cottrell, “Theoretical aspects of failure,” ibid., pp 30–68.

V. I. Trefilov, Yu. V. Mil’man, and S. A. Firstov, Physical Bases of Refractory Metal Strength, Naukova Dumka, Kiev (1974).

V. M. Gridnev, V. G. Gavrilyuk, and Yu. Ya. Meshkov, Strength and Ductility of Cold-Worked Steel, Naukova Dumka, Kiev (1974).

V. M. Goritskii, “Ductile–brittle transition and nonmetallic inclusions in materials with a BCC-lattice,” Probl. Prochn., No. 1, 89–97 (1981).

V. M. Goritskii, “Connection of structural parameters with critical brittleness temperature for polycrystalline materials with a BCC lattice,” FMM, 49, No. 2, 319–326 (1980).

V. M. Goritskii, Thermal Brittleness of Steels, Metallurgizdat, Moscow (2007).

J. Khan, B. L. Averbuch, V. S. Owen, and M. Cohen, in: Atomic Mechanism of Failure, Metallurgiya, Moscow (1963), pp. 109–134.

Yu. Ya. Meshkov and T. N. Serditova, “Ductile failure criteria with uniaxial tension of low-carbon steel,” Metallofizika, 5, No. 6, 75–80 (1983).

L. I. Gladshtein, V. M. Goritskii, N. P. Larionova, et al., “Methods fort accelerated determination of brittle failure resistance for structural steels,” Zavod. Lab., No. 1, 78–81 (1985).

M. I. Gol’dshtein, “Precipitation hardening of structural steels,” MiTOM, No. 11, 50–58 (1975).

F. B. Pickering, Steel Physical Metallurgy and Development [Russian translation], Metallurgiya, Moscow (1982).

V. M. Goritskii and D. P. Khromov, “Structure and quantitative fractography of brittle fractures of low-carbon and low-alloy steels,” FMM, 55, No. 6, 1169–1178 (1983).

V. M. Gortiskii and I. A. Guseva, “Connection of pitted fracture parameters with thermally improved structure characteristics,” FMM, 56, No. 1, 192–194 (1983).

V. M. Goritskii and I. A. Guseva, “Effect of dispersed phase particle size on cupped fracture microstructure,” FMM, 45, No. 5, 1095–1103 (1978).

V. I. Bogdanov, L. I. Gladhstein, and V. M. Gorityskii, “Effect of phosphorus, vanadium, and molybdenum on tendency towards thermal embrittlement of thermally improved steel 0.1% С–1% Сr–1% Si–1% Ni–0.4% Cu,” MiTOM, No. 9, 16–18 (1979).

C. T. Liu and J. Gurland, “Relations between the size of cementite particles and the subgrain size in quenched – and tempered steels,” Trans. Metal. Soc. AIME, 242, No. 6, 1542–1551 (1968).

S. A. Saltykov, Stereometric Metallography, Metallurgiya, Moscow (1970).

V. M. Goritskii, “Ductile pitted failure and width of ductile–brittle transition in structural steels with a BCC-lattice,” Probl. Prochn., No. 3, 78–84 (1985).

V. A. Surovova, B. M. Ovsyannikov, and A. G. Ivanov, “Effect of sulfur content on failure resistance of low-alloy pipe steel,” MiTOM, No. 9, 77–78 (1968).

V. M. Goritskii, Use of Impact Toughness Characteristics in Engineering Practice, Metallurgizdat, Moscow (2016).

A. P. Gulyaev, Clean Steel, Metallurgiya, Moscow (1975).

A. V. Taran, V. N. Zikeev, A. P. Gulyaev, and L. A. Evdukimov, “Effect of degree of steel cleanliness on structural steel micro-fractography,” MiTOM, No. 1, 455–457 (1971).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 2, pp. 46–55, February, 2018.

Rights and permissions

About this article

Cite this article

Goritskii, V.M. Effect of Structure on Ductile–Brittle Transition in Steels with BCC-Lattice. Metallurgist 62, 138–149 (2018). https://doi.org/10.1007/s11015-018-0636-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0636-8