Results are presented for a study of the macro- and microstructure of ingots, granules, and experimental compacted specimens of a new nickel-base superalloy. Features are emphasized most strongly affecting mechanical properties of finished objects prepared from nickel-base superalloy granules, and in fact the size of a dendrite cell, morphology, carbide and γ′-phase size, and solid solution grain size.

Similar content being viewed by others

References

A. M. Volkov, A. V. Vostrikov, and M. M. Bakradze, “Principles of creation and features of alloying granular nickel-base superalloys for GTE disks,” Trudy VIAM: Elektron. Nauch. Tekhn. Zh., No. 8, Art. 02, www.viam-works.ru, acc. 11.30.2016, DOI: https://doi.org/10.18577/2307-6046-2016-0-8-2-2.

E. N. Kablov, O. G. Ospennikova, and B. S. Lomberg, “Comprehensive innovative technology for isothermal stamping in air in a superplasticity regime for disks made from superalloys,” Aviats. Mater. Tekhnol., Spec. Iss., 129–141 (2012).

E. N. Kablov, “VIAM materials and technology for aero engines,” in: IB Perm. Aviats. Dvig., Spec. Iss., 43–47 (2014)

E. N. Kablov, “Innovative development of FGUP VIAM GNTs RF for implementing strategic areas and processing technology in the period up to 2030,” Aviats. Mater. Tekhnol., No. 1, 3–33 (2015), DOI: 10.18577/2071-9140-2015-0-1-3-33.

D. E. Kablov, E. G. Shompolov, V. V. Sidorov, and A. V. Goryumov, “Vacuum indiction melting and teeming unit VIM 12 Sh NMS for preparing high quality nickel-base superalloys,” Trudy VIAM: Elektron. Nauch. Tekhn. Zh., No. 5, Art. 5 (2014), www.viam-works.ru, acc. 11.30.2016, DOI:https://doi.org/10.18577/2307-6046-2014-0-5-5-5.

A. G. Evgenov, S. V. Nerush, and S. A. Vasilenko, “Preparation and appraisal of finely-dispersed metal powder of high-chromium alloy,” Trudy VIAM: Elektron. Nauch. Tekhn. Zh., No. 5, Art. 4 (2014), www.viam-works.ru, acc.11.30.2016, DOI: https://doi.org/10.18577/2307-6046-2014-0-5-4-4.

A. F. Belov, N. F. Anoshkin, and O. Kh. Fatkullin, Structure and Properties of Granular Nickel Alloys, Metallurgiya, Moscow (1984).

C. T. Sims, N. S. Stolov, and U. K. Hagel, Superalloys II: Heat-Resistant Materials for Aerospace and Industrial Energy Installations [Russian translation], Metallurgiya, Moscow (1995), Vol. 1.

D. Rice, P. Kantzos, B. Hann, et al., “P/M alloy 10 – a 700°C capable nickel-based superalloy for turbine disk applications,” Superalloys 2008: Publ. of TMS, The Minerals, Metals, Materials Society, Warrendale, Pennsylvania, USA (2008), pp. 139–147.

G. S. Garibov, N. M. Grits, V. M. Volkov, et al., “Metallurgical aspects f producing disk workpieces from granulated nickel-base superalloy by HIP method,” Tekhnol. Legk. Splavov, No. 3, 54–59 (2014).

G. S. Garibov, B. A. Driyanov, A. R. Pirumov, et al., “Calculation of hot hydrostatic compaction parameters for granulated materials in a shell,” Poroshk. Metallurg., No. 7, 12–17 (1979).

S. S. Gorelik, Metal and Alloy Recrystallization, Metallurgiya, Moscow (1978).

M. M. Bakradze, S. V. Ovsepyan, S/ A. Shugaev, and M. N. Letnikov, “Effect of quenching regimes on structure and properties of stamped disks made from nickel-base superalloy EK151-ID,” Trudy VIAM: Elektron. Nauch. Tekhn. Zh., No. 9, Art. 1 (2013), www.viam-works.ru, acc. 11.30.2016.

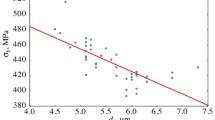

B. S. Lomberg, M. M. Bakradze, E. B. Chabina, and E. V. Filonova, “Correlation of structure and properties of nickel alloys for gas turbine engine disks,” Aviats. Mater. Tekhnol., No. 2, 25–30 (2011).

A. A. Buyakina, M. N. Letnikov, M. M. Bakradze, and S. A. Shugaev, “Effect of thermomechanical and heat treatment on the structure and properties of alloy VZh177,” Trudy VIAM: Elektron. Nauch. Tekhn. Zh., No. 10, Art. 02 (2016), www.viam-works.ru, acc. 11.30.2016, DOI: https://doi.org/10.18577/2307-6046-2016-0-10-2-2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 11, pp. 61–65, November, 2017.

Rights and permissions

About this article

Cite this article

Volkov, A.M., Buyakina, A.A. Features of Material Structure During Manufacture of Billets from Nickel-Base Superalloys Granules. Metallurgist 61, 982–987 (2018). https://doi.org/10.1007/s11015-018-0596-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0596-z