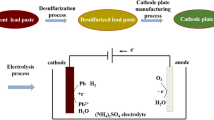

Electrochemical preparation of lead from lead-containing waste in molten alkali-carbonate is described. The dust studied forms during shaft smelting of lead battery scrap being a technogenic resource with a high lead content. An ecologically clean process is developed for electrochemical processing of technogenic lead-containing raw material in molten electrolyte consisting of 60–95% NaOH and 5–40% Na2CO3. A large laboratory electrolyzer is constructed and prepared and tested with a current strength of 200–600 A. The use of plant shaft furnace dust from lead battery treatment makes it possible to obtain molten lead at a cathode and oxygen at an anode. There is no rapid evaporation of lead metal, lead compounds, and molten alkali-carbonate with an electrolysis temperature of 490–550°C.

Similar content being viewed by others

References

N. M. Barbin, S. V. Mamyachenkov, and S. I. Kholod, Metallurgical Technology for Processing Technogenic and Secondary Resources. Part 1. Lead, UGTU–UPI, Ekaterinburg (2009).

I. F. Khudyakov, A. P. Doroshevkovich, and S. V. Karelov, Secondary Nonferrous Metal Metallurgy, Metallurgiya, Moscow (1987).

Yu. P. Romanteev and V. P. Bystrov, Heavy Nonferrous Metallurgy. Lead. Zinc. Cadmium, ID MISiS, Moscow (2010).

M. A. Kreusch, M. J. J. S. Ponte, H. A. Ponte, et al., “Technological improvements in automotive battery recycling,” Resour., Conserv. Recycl., 52, No. 2, 368–380 (2007).

A. Smaniotto, A. Antunes, I. N. Filho, et al., “Qualitative lead extraction from recycled lead–acid batteries slag,” J. Hazard. Mater., 172, No. 2–3, 1677–1680 (2009).

D. Lin and K. Qiu, “Recycling of waste lead storage battery by vacuum methods,” Waste Manag., 31, No. 7, 1547–1552 (2011).

M. K. Dyusebaev, V. A. Zavorin, and N. G. Sulaeva, “Determination of the physicochemical properties of dust during processing of battery scrap and development of a dust separation method,” Komp. Ispol. Mineral. Syrya, No. 1, 39–42 (1987).

J. E. Bowers, “Current technology and trends in the secondary lead refining,” Met. Mater. Technol., 13, No. 12, 621–622 (1981).

J. M. Bonnemason, “Captage des poussieres et sumecs en mettallurgie du Plomb,” Techn. Mod., 73, No. 1–2, 91–93 (1981).

G. J. G. Griffith, “Practical aspects of air pollution control in the lead industry,” Proc. Int. Conf. Air Pollution (1979), No. 2, pp. 1–10.

A. V. Klimov, S. G. Melamud, A. V. Poluyakhtov, and D. S. Binder, “Preparation of lead dust and cake for pyrometallurgical treatment,” Tsvet. Met., No. 10, 66–70 (2014).

Yu. K. Delimarskii, P. P. Turov, and E. B. Gitman, “Treatment of battery scrap in molten sodium hydroxide,” Ukr. Khim. Zh., 23, No. 6, 817–822 (1957).

A. G. Morachevskii, Z. I. Vaiskant, and A. I. Demidov, Treatment of Secondary Lead Resources, Khimiya, St. Petersburg (1993).

N. M. Barbin, G. F. Kazantsev, and N. A. Vatolin, Treatment of Secondary Lead Resources in Ionic Molten Salts, UrO RAN, Ekaterinburg (2002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 5, pp. 70–72, May, 2017.

Rights and permissions

About this article

Cite this article

Barbin, N.M., Barbina, T.M. Electrolytic Preparation of Lead from Lead Battery Recycling Plant Shaft Furnace Dust. Metallurgist 61, 414–417 (2017). https://doi.org/10.1007/s11015-017-0509-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0509-6