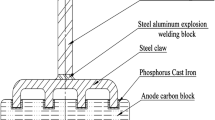

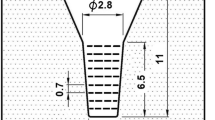

Physicomechanical and casting properties are studied for high-phosphorus irons used in the assembly of aluminum electrolyzer baked anodes in RUSAL enterprises compared with gray cast iron containing a minimum amount of phosphorus and sulfur. It is shown that iron primary crystallization under conditions approaching pouring production parameters and iron cooling in the nipple – cast iron – carbon anode contact assembly proceeds with significant supercooling that causes the formation of a pearlite matrix in the cast iron structure with increased hardness. Iron with a lower carbon equivalent exhibiting high hardness has a better elasticity modulus and strength values. The presence of ternary phosphide eutectic within the iron structure with a high phosphorus content reduces the breaking strength considerably at high anode operating temperatures and this may be a reason for cast iron loss of strength and anode separation at the end of an operating cycle leading the electrolyzer stoppage. Iron with the minimum phosphorus content exhibits strength exceeding by more than a factor of two that of high-phosphorus cast iron and also the least electrical resistance in the range up to 500–600°C. In addition, iron with a high phosphorus content has an anomalous change in linear thermal expansion coeffi cient (LTEC) in the range 600–810°C that may also lead to degradation of “soft” metal (anode at the end of an operating cycle). The results obtained are explained drawing on thermal analysis data and metallographic studies.

Similar content being viewed by others

References

Yu. V. Bogdanov, B. I. Zel’berg, A. V. Knizhnik, et al., “Industrial experience of test electrolyzers with baked anodes with increased current strength from 300 to 300 kA,” Tsvet. Met., No. 2, 47–50 (2009).

O. Trempe, D. Larouche, and D. Ziegler, “Real time temperature distribution during sealing process and room temperature air gap measurements of a Hall-Heroult cell anode,” Light Metals, 991–996 (2011).

O. Trempe, Étude expérimentale et modélisation du scellement d’un ensemble anodique d’une cuve Hall-Héroult: Master Thesis, University of Quebec, Canada (2011).

Nonferrous Metallurgy Handbook. Aluminum Production, Metallurgiya, Moscow (1971).

A. Nofal, M. Waly, Sh. Mohamed, and M. Agour, “New solutions for stub-anode connection at Egyptalum,” Light Metals, 1073–1078 (2009).

B. Оye, M. I. Onsоien, E. Haugland, et al., “Optimization of the anode-stub contact: material properties of cast iron,” Light Metals, 1073–1078 (2010).

V. V. Kondrat’ev, A. O. Mekhnin, N. A. Ivanov, et al., “Study and development of a recipe for cast iron nanomodification for aluminum electrolyzer anode nipples,” Metallurg, No. 1, 69–71 (2012).

V. V. Kondrat’ev, A. E. Balanovskii, N. A. Ivanov, et al., “Evaluation of the effect of the modifier composition with nanostructured additives on the properties of gray cast iron,” Metallurg, No. 5, 48–56 (2014).

A. N. Malen’kikh, A. A. Arnol’d, V. A. Gorbuov, and A. N. Matveichev, Patent 1712447 RF, IPC С22С37/10, “Cast iron preparation method for casting current conductors in carbon blocks of an aluminum electrolyzer,” subm. 01.03.1990, publ. 02.15.92, Byull., No. 8.

A. Nodal, M. M. Ali, A. Kandil, and M. Agour, “Characterization of new cast iron alloys for the stub-anode connection in the aluminium reduction cells,” J. Eng. Res. Applic., 3, No. 5, 414–419 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 4, pp. 71–77, April, 2017.

Rights and permissions

About this article

Cite this article

Babkin, V.G., Kukartsev, V.A., Cherepanov, A.I. et al. Effect of Cast Iron Structure and Properties on Contact Quality with an Aluminum Electrolyzer Carbon Anode. Metallurgist 61, 318–324 (2017). https://doi.org/10.1007/s11015-017-0495-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0495-8