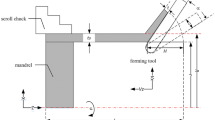

A new tube plugging process is described and studied on a lengthwise rolling mill installed on PRP-140 of the Sinara Pipe Plant. The deformation of a shell on a plug in a lengthwise rolling mill is studied using the finite-element method. The behavior of the dimensionless parameters characterizing the deformation of the metal in the groove tapers with variation in the elongation ratio of the shell is established. The effect of the ovality and kinematic tension of the shell on its deformation during plugging is analyzed through computer-aided simulation. It is established that applying kinematic tension and preovalization to the shell increases the elongation ratio by 37%, decreases the variation in wall thickness, and extends the range of tube grades produced with an automatic tube rolling mill.

Similar content being viewed by others

References

A. A. Bogatov, D. A. Pavlov, S. V. Lipnyagov, and V. N. Suvorov, “Simulation of the formation of a guide mark defect on the inside surface of tubes during lengthwise rolling,” Proizv. Prokata, No. 8, 37–39 (2012).

I. N. Potapov, A. P. Kolikov, and V. M. Druyan, Pipe and Tube Production Theory, Metallurgiya, Moscow (1991).

A. F. Danilov, A. Z. Gleiberg, and V. G. Balakin, Hot Rolling and Extrusion of Tubes, Metallurgiya, Moscow (1972).

A. A. Bogatov, D. A. Pavlov, and E. A. Dresvyankina, “Developing a mathematical model of a new lengthwise tube rolling process,” in: Proc. OMD 2014. Fundamental Problems. Innovative Materials and Technologies, Mo scow, April 4–17, 2014, MISiS, Moscow (2014), pp. 102–106.

A. A. Bogatov, D. A. Pavlov, S. V. Lipnyagov, et al., “Rolling hot deformed pipe on a stub mandrel,” Steel in Transl., 44, No. 12, 912–915 (2014).

A. A. Bogatov, D. A. Pavlov, and E. A. Pavlova, “Improvement of the tube plugging process,” in: Proc. Modern Metallic Materials and Technologies, SMMT’15, St. Petersburg, June 23–27, 2015, Izd. Politekhn. Univ., St. Petersburg (2015), pp. 46–57.

A. P. Karamyshev, I. I. Nekrasov, A. I. Pugin, et al., Deform-3D Software Manual, UrFU, Ekaterinburg (2010).

TK 161-T2-1602-2009, Process Sheet, Sinara Pipe Plant.

This study was carried out in the framework of State Assignment No. 11.1369.2014/K of 07.18.2014 in the field of scientific activitiy (State Reg. ID: 114122470051).

The study was supported by Program of 211 of the Government of the Russian Federation (Agreement No. 02.A03. 21.0006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 10, pp. 18–22, October, 2016.

Rights and permissions

About this article

Cite this article

Bogatov, A.A., Pavlov, D.A. & Pavlova, E.A. Intensification of Tube Plugging Based on Simulation Results. Metallurgist 60, 1016–1021 (2017). https://doi.org/10.1007/s11015-017-0401-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0401-4