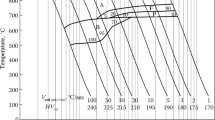

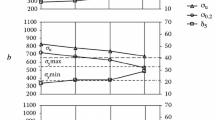

Results are given for an experimental study of steel manufacturing technology satisfying specifications for strength class not less than K60 for connecting pieces (fittings). Laboratory melts, rolling, and heat treatment by different regimes are performed for low-alloy steels of four composition versions containing 0.05–0.08% carbon. Steels containing about 1% copper, in contrast to steels with a lower content or without addition of copper after normalizing and tempering, demonstrate a level of properties corresponding to strength class K60. Research shows that additional strengthening occurs as a result of precipitation of fine particles enriched in copper after tempering. Steel impact strength KCV–40 and relative elongation of steels alloyed with copper are at a high level due to a low carbon content and addition of nickel, and also prior grain refinement during controlled rolling. During tempering after normalizing, a more balanced set of properties is provided with tempering at 600°C. The steel developed may be used for preparing fittings of strength class K60 by hot stamping without thermal improvement or of strength class K65 after additional quenching and tempering.

Similar content being viewed by others

References

F. B. Pickering, Physical Metallurgy and Steel Development [Russian translation], Metallurgiya, Moscow (1982).

Yu. R. Matrosov, A. A. Litvinenko, and S. A. Golovanenko, Steel for Main Gas Pipelines, Metallurgiya, Moscow (1989).

E. Gudremont, Special Steels [Russian translation], Metallurgiya, Moscow (1966).

S. R. Goodman, S. S. Brenner, and J. R. Low, Met. Trans., 4, 2363–2370 (1973).

P. J. Othen, M. L. Jenkins, G. D. W. Smith, and W. J. Phythian, “Transmission electron microscope investigations of the structure of copper precipitates in thermally-aged Fe–Cu and Fe–Cu–Ni,” Phil. Mag. Lett., 64, No. 6, 383–391 (1991).

D. Isheim, M. S. Gagliano, M. E. Fine, and D. N. Seidman, “Interfacial segregation at Cu-rich precipitates in a highstrength low carbon steel studied on a sub-nanometer scale,” Acta Mater., 54, 841–849 (2006).

E. J. Czyryca, “Advances in low carbon high strength ferrous alloys,” Proc. Int. Conf., Trans. Tech. Publication, Switzerland (1993), p. 491.

Y. Tomita, R. Yamaba, T. Haze, et al., “YP 450 N/mm2 class heavy plate steel for offshore structures produced by thermo-mechanical process,” OMAE-2, Tokyo, Japan, April 1986, p. 386.

K. Shibata, S. J. Seo, M. Kaga, et al., “Suppression of surface hot shortness due to Cu in recycled steels,” Mat. Trans., 43, No. 3, 292–300 (2002).

R. Hultgren and R. D. Desai, “Selected thermodynamic values and phase diagrams for copper and some of its binary alloys,” INCRA Monograph on the Metallurgy of Copper, Ser. I, Int. Copper Research Association, New York (1971), pp. 136–148.

J. Pavliska, Z. Jonita, F. Mazancova, and K. Mazanec, “Microstructure and metallurgy investigation of the hot ductility behaviour of steels,” Acta Metal. Slovakia, No. 4, 318–326 (2000).

N. Imai, N., M. Komatsubara, and N. Kunishige, “Effect of Cu and Ni on hot workability of hot-rolled mild steel,” ISIJ Int., 37, No. 3, 224–231 (1997).

A. Takemura, Yu. Ugawa, K. Kunishige, et al., “Surface hot shortness of copper containing steel in a compact strip production process,” Mat. Trans., 52, No. 10, 1905–1911 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 4, pp. 64–71, April, 2016.

Rights and permissions

About this article

Cite this article

Matrosov, M.Y., Martynov, P.G., Kichkina, A.A. et al. Development of Low-Carbon Steel Alloyed with Copper for Pipeline Fittings Prepared by Hot Stamping. Metallurgist 60, 413–421 (2016). https://doi.org/10.1007/s11015-016-0307-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0307-6