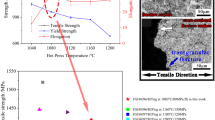

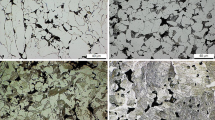

Fatigue test results are provided for hot-deformed powder steels with microadditions of Na, Ca, and Al. Microalloying promotes improvement of joining between particles and makes fatigue crack development difficult in its stable consolidation stage, and also during accelerated failure, which provides an improvement in fatigue strength properties compared with reference specimens.

Similar content being viewed by others

References

Ph. Gundermann, “Overview of the status and trends in the European PM Industry,” Plenary Presentation Euro PM2013, Gothenburg, Sweden, Sept. 15–18, 2013, Svenska Mässan, EPMA, www.epma.com/pm_2013/pdf/P_Gundermann_Plenary_final.pdf.

Yu. G. Dorofeev, B. G. Gasanov, V. Yu. Dorofeev, et al., Industrial Powder Object Hot Pressing Technology, Metallurgiya, Moscow (1990).

H. A.Kuhn and B. L. Ferguson, Powder Forging, MPIF, Princeton, NJ (1990).

G. A. Bagalyuk, “Production problems of hot stamping porous billets,” Visn. Nats. Tekhn. Univ. Ukraini Kiev. Politekh. Inst., Ser. Mashinobuduv., No. 56, 93–100 (2009).

V. Yu. Dorofeev and Yu. G. Dorofeev, “Hot stamping of powder billets: today and tomorrow,” Poroshk. Metall, No. 7/8, 27–36 (2013).

V. Yu. Dorofeev and Kh. S. Kochkarova, “Effect of heat and thermomechanical treatment on structure and properties of hot-deformed powder steels microalloyed with sodium and calcium,” Proc. 10th Int. Sci.-Tech. Conf. New Materials and Technology: Powder Metallurgy, Composite Materials, Protective Coatings, Welding, Minsk, Belarus, Sept. 12–14, 2012, Belarus Navuka, Minsk (2012), pp. 46–50.

V. Yu. Dorofeev and Kh. S. Kochkarova, “Hot stamping of powder materials based on iron with microadditions of sodium and calcium,” Proc. Sci.-Pract. Seminar New Materials and Objects of Metal Powders. Technology. Manufacture. Application (TPP-PM-2011), Ioshkar-Ola, June 28–30, 2011, Ioshkar-Ola (2011), pp. 109–114.

V. Yu. Dorofeev and Kh. S. Kochkarova, “Heat and thermomechanical treatment of hot-deformed carbon steels microalloyed with aluminum,” Surface Engineering. New Powder Composite Materials. Welding: Proc. Int. Symp. at 13th Int. Exhib. Powder Metallurgy – 2011, 9th Int. Exhib. Welding and Cutting – 2011, Int. Spec. Salon Protection from Corrosion. Coatings – 2011, Minsk, Belarus, March 22–25, 2011, IPM, Minsk (2011), Part 1, pp. 124–131.

V. Yu. Dorofeev and Kh. S. Kochkarova, “Effect of microalloying with sodium and calcium on defect formation during heat treatment of hot-deformed powder steels,” Proc. 8th Int. Symp. Powder Metallurgy: Surface Engineering, New Powder Composite Materials. Welding, Minsk, Belarus, April 10–12, 2013, Belarus Navuka (2013), Part 1, pp 170–181.

V. Yu. Dorofeev and Kh. S. Kochkarova, “Effect of mechanical activation of original charge components on quality of consolidation between particles of hot-deformed powder material based on iron microalloyed with aluminum,” Surface Engineering. New Powder Composite Materials. Welding: Proc. Int. Symp. at 12th Int. Exhib. Powder Metallurgy – 2009, 8th Int. Exhib. Welding and Cutting – 2009, Int. Spec. Salon Protection from Corrosion. Coatings – 2009, Minsk, Belarus, March 25–27, 2009, IPM, Minsk (2009), Part 2, pp. 56–65.

V. N. Antsiferov, N. N. Maslennikov, S. N. Peshcherenko, et al., Structural Inheritance of Powder Steels, RITTs PM, Perm (1996).

Fr. Chagnon, “ Effect of Ni addition route on static and dynamic properties of Fe–2Cu–1.8Ni–0.5Mo–0.65C and Fe–2Cu–1.8Ni–0.5Mo–0.85C PM steels,” Adv. Powder Metall. Part. Mater., 2, 10.73–10.84 (2012).

V. Yu. Dorofeev and Kh. S. Kochkarova, “Some features of structure formation and properties of hot-deformed powder materials based on nickel microalloyed with aluminum,” Proc. 8th Int. Sci.-Tech. Conf. New Materials and Technology: Powder Metallurgy, Composite Materials, Protective Coatings, Welding, Minsk, Belarus, May 27–28, 2008, IPM GNPO PM, Minsk (2008), pp. 22–24.

E. V. Zvonarev, L. N. D’yachkova, L. F. Kerzhentseva, and S. I. Shidlovskaya, “Microalloying with alkali elements of powder materials based on iron,” MiTOM, No. 8, 29–32 (1991).

Yu. G. Dorofeev, V. Yu. Dorofeev, and Kh. S. Kochkarova, “Features of microalloying element distribution in hot-deformed powder materials based on iron and their effect on quality of consolidation between particles,” MiTOM, No. 8, 35–39 (2013).

S. Saritas, W. B. James, and A. Lawley, “Fatigue properties of sintered steels: a critical review,” Proc. Europ. Congr. and Exhib. Powder Metallurgy EURO PM 2001, Nice, France, Oct. 22–24, 2001, EPMA (2001), Vol. 1, pp. 272–285.

Yu. Ya. Meshkov, Physical Bases of Steel Structure Failure, Naukova Dumka, Kiev (1981).

V. Yu. Dorofeev and V. I. Chumakov, “Ways of improving powder hot-pressed steel properties,” in: Studies in the Field of Hot Pressing in Powder Metallurgy, Novocherkassk (1984), pp. 34–39.

MPIF Standard 35, Materials Standards for PM Structural Parts, MPIF, Princeton, NJ (2012).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Metallurg, No. 11, pp. 102–107, November, 2014.

Rights and permissions

About this article

Cite this article

Dorofeev, Y.G., Dorofeev, V.Y. & Kochkarova, K.S. Fatigue Strength of Microalloyed Hot-Deformed Powder Steels. Metallurgist 58, 1032–1037 (2015). https://doi.org/10.1007/s11015-015-0036-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-015-0036-2