Abstract

In this paper we present a semi-multiscale methodology, where a micrograph is split into multiple independent numerical model subdomains. The purpose of this approach is to enable a controlled reduction in model fidelity at the microscale, while providing more detailed material data for component level- or more advanced finite element models. The effective anisotropic elastic properties of each subdomain are computed using periodic boundary conditions, and are subsequently mapped back to a reduced mesh of the original micrograph. Alternatively, effective isotropic properties are generated using a semi-analytical method, based on averaged Hashin–Shtrikman bounds with fractions determined via pixel summation. The chosen discretization strategy (pixelwise or partially smoothed) is shown to introduce an uncertainty in effective properties lower than 2% for the edge-case of a finite plate containing a circular hole. The methodology is applied to a aluminium alloy micrograph. It is shown that the number of elements in the aluminium model can be reduced by \(99.89\%\) while not deviating from the reference model effective material properties by more than \(0.65\%\), while also retaining some of the characteristics of the stress-field. The computational time of the semi-analytical method is shown to be several orders of magnitude lower than the numerical one.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

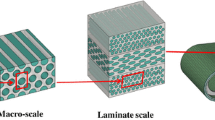

As the computational power of modern hardware continues to increase, multi-scale modeling of materials inevitably becomes more appealing even in engineering problems of industrial scale. The academic literature on such methods is massive and in some sense also multi-disciplinary, combining efforts from fields like model reduction, high performance computing and machine learning with material modelling, just to name a few [1,2,3]. Many books are available on related topics such as multiscale modelling, homogenization methods, and micromechanics related to heterogeneous materials [4,5,6,7,8]. Of particular interest is the area of computational homogenization, where knowledge about the microscopic constituents are used in order to predict material properties at the scale of engineering products [9]. In this paper, we focus on the specific task of estimating effective mechanical properties of heterogeneous engineering materials via computational homogenization, using an uncoupled multiscale approach which we denote semi-multiscale. A real, or artificial micrograph is used as input in this methodology, which is split into multiple subdomains that are evaluated independently from each other. The effective material properties are then mapped back to a reduced mesh, decreasing the level of detail in the model. This approach generates a reduced model for further analys, but also allows the evaluation of models which would otherwise be impossible to run on one machine to be evaluated in separate parts sequentially, or on multiple threads/machines in parallel.

A large amount of time and effort is spent both in academia and industry studying the microstructure of manufactured materials. In this process, micrographs are typically generated which are used in everything from microstructural characterization, process-structure-property modelling, defect identification and failure analysis to building numerical models [10, 11]. Such numerical models inherently contain multiple layers of approximations. Firstly, the micrograph itself is an approximation of the real physical microstructure. Secondly, image processing operations such as segmentation only approximates the actual material distribution of individual phases. Thirdly, discretization of the segmented material description introduces a more or less jagged approximation of phase boundaries, depending on which discretization strategy that is used [10, 12]. Lastly, such models might also need to be reduced depending on the available computational resources. In this paper we deal with model reduction by splitting the micrograph into multiple subdomains which are evaluated independently, meaning that regions of the same phase which were originally connected might become disconnected, and separated regions which are actually interacting might become unaware of each other. By generating artificial micrographs for shapes which have known analytical solutions for their constitutive behavior and stress under given loading conditions, the discrepancies from the first two approximations can be eliminated, and the errors introduced by discretization and model subdomain reduction can be isolated and quantified.

The paper is structured as follows; a short theoretical background on analytical expressions for effective mechanical properties, and analytical stress concentrations are given in Sect. 2. Section 3 covers implementation details, as well as the methodology used to investigate the influence of both discretization strategy and subdomain splitting. Section 4 presents results and analysis from applying the proposed subdomain methodology to the edge case of a finite plate containing a circular hole, as well as a more realistic case of a complex aluminium electron micrograph idealized as containing three interacting phases.

2 Theory

2.1 Analytical material properties

Hashin and Shtrikman [13] developed material property bounds for isotropic materials with arbitrary internal geometry, in terms of the bulk (K) and shear (G) modulus

where \(K_2 > K_1\), \(G_2 > G_1\). Here, \(f_1, f_2\) represent the phase volume fractions, and \(\nu _1\), \(\nu _2\) Poisson’s ratio for each phase. The upper bounds \(K_U\) and \(G_U\) can be used together with the lower bounds \(K_L\) and \(G_L\) as well as the well known relationships between K, G, E and \(\nu \)

to form the averages

which can be used to semi-analytically compute the effective stiffness E, and Poisson’s ratio \(\nu \), without any explicit information regarding the microstructural geometry.

Kachanov et al. developed expressions for the effective stiffness and Poisson’s ratio for a plate containing k elliptical holes, via the elastic potential of a solid with cavities of various shapes [14]. The porosity p and the hole density tensor \(\beta \) are given as

where A is the area of the plate, a, b are the elliptical hole half-axes and n, m are the unit normals of the global coordinate system. For a circular hole the effective properties \(E_{11}\) and \(\nu _{12}\) are functions of the plate material properties \(E_0\), \(\nu _0\) as well as p and \(\beta \) according to

where e.g. \(\beta _{11}\) is the first component of the hole density tensor.

2.2 Analytical stress

Kirsch derived analytical expressions for the stress in a plate containing a circular hole [15]. For general 2D loading of an infinite plate, the hoop stress \(\sigma ^{i}_{\theta \theta ,c}\) at the hole periphery is given by

where \(\sigma _{xx}\), \(\sigma _{yy}\), \(\sigma _{xy}\) are the remotely applied stresses, and the angle \(\theta \) represents the polar coordinate along the circle periphery. Inglis [16] developed expressions for the maximum stress \(\sigma ^i_{\theta \theta ,e}\) at an elliptical hole in an infinite plate

with the ellipse half-axes a and b. The case of a rectangular notch can be modelled using an equivalent ellipse of length a with edge curvature \(c=b^2/a\). By using this definition together with Eq. 16, the maximum stress \(\sigma ^i_{\theta \theta ,n}\) can be expressed as

For a finite plate of width w, containing a circular hole of radius r, the maximum hoop stress \(\sigma ^{f}_{\theta \theta ,c}\) becomes

where \(\sigma _\infty \) is the remotely applied uniaxial stress and \(K_t\) is an empirical stress concentration factor [15].

3 Method

3.1 Implementation

A Julia v1.5.2 [17] code denoted numerical_subdomain.jl was developed, which splits a provided micrograph into multiple individual subdomains. See Fig. 1 for an illustration of this operation. Each pixel is given one rectangular or two triangular elements, with material assignment based on the local intensity of the micrograph. Abaqus models with periodic boundary conditions (PBC) are built from each such subdomain, whose effective elastic anisotropic properties are evaluated from uniaxial- and pure shear loading using EasyPBC v1.4 [18]. Once all subdomain evaluations have been performed, the effective properties are gathered and mapped onto a reduced mesh of the same physical dimensions as the initial micrograph, by replacing each subdomain with a new element. See Fig. 2 for an illustration of this process.

The input micrograph dimensions should, if possible, be chosen such that the number of pixels along each dimension is a highly composite number. Alternatively, if the number of required subdomains is known in advance, the number of pixels should have the amount of subdomains as a divisor. The overall data-flow of the numerical code is illustrated in Fig. 3. Another Julia code denoted analytical_subdomain.jl was developed, which functions in the same way, but which instead determines the effective elastic isotropic properties of each subdomain using a semi-analytical method. The method is based on the average Hashin-Shtrikman bounds given by Eqs. 9 and 10, where the fractions are determined by summation over the pixels in each subdomain. It should be noted that the numerical approach operates on a finite element model of each subdomain, providing anisotropic properties, while the semi-analytical one only provides isotropic material data based on fractions. However, the effective properties of the reduced model may still become anisotropic using both methods. Given that the application we consider later in the paper consists of three idealized phases, and the applied analytical theory only considers two phases, the following conditional logic was implemented for the three phases i, j and k:

Implementation flowchart for the numerical homogenization method. The input is a micrograph together with phase properties. The micrograph is split into n subdomains which are meshed using either Julia, OOF2 or ANSA. Effective anisotropic properties of each subdomain are computed using EasyPBC/Abaqus, which are mapped back to a reduced mesh of the same physical dimensions as the original micrograph

This means that only the two largest (by fraction) phases are used to determine the effective isotropic properties, neglecting the third. In other words, the phase with the largest fraction is treated as phase 1, i.e. the “matrix”, while the phase with the second largest fraction is treated as phase 2, i.e. the “reinforcing phase”, while the phase with the lowest fraction is neglected altogether. In practice, this becomes an increasingly good approximation for larger numbers of subdomains, since the number of pixels, and therefore also the probability of finding multiple phases in each subdomain, decreases. Using this approach, both the numerical and the semi-analytical approaches described above will converge to the same model in the limit, where each pixel would be represented by one individual subdomain.

3.2 Discretization strategy

The influence of different discretization strategies was investigated. A series of artificial micrographs were generated describing a homogeneous material with a circular hole. The aspect ratio of these micrographs was chosen such that a finite element model accurately reproduces the analytical stress concentration for a circular central hole using Eqs. 15 and 18, resulting in \(400 \times 200\) pixels for tensile loads, and \(200 \times 200\) pixels for shear loads. The radius of the circular hole was chosen such that 0–90% of the total cross-sectional area was reduced in the center of each micrograph. Two imperfect discretization strategies were investigated relative to an explicit description of the circular hole. The first strategy yields a structured mesh with two first order plane stress right triangles (CPS3) per pixel of the micrograph, denoted “1px” because each catheti length is the same as one pixel. While rational, this results in a jagged and non-physical description of any circular phase boundaries. The second strategy produces an unstructured mesh with two first order plane stress triangles (CPS3) per three pixels, denoted “3px”. This approach yields some smoothening, but still produces jagged edges every other pixel. A Julia code was used to generate the 1px mesh, while the open source code OOF2 v2.1.19 [10] and the commercial pre-processor ANSA was used to generate and reshape the 3px mesh, ensuring that the aspect ratio and element density was approximately the same using both strategies. The main difference between these approaches is illustrated in a simplified way in Fig. 4.

3.2.1 Stress error

To quantify the error in stress caused by an imperfect discretization, the analytical stress at the circular hole was evaluated using finite plate theory as described in Sect. 2.2. For uni-axial loading, the micrographs were modelled as thin elastic rectangular plates of width \(w = 2\), height \(h = 1\) mm, thickness \(t = 0.01\) mm, stiffness \(E = 1\) GPa and Poisson’s ratio \(\nu = 0.3\). A traction load was applied to the boundary of each plate such that the remote stress \(\sigma _{\infty } = 1\) MPa. A circular hole with radius r mm was introduced in the center of each plate, whereby the finite plate hoop stress \(\sigma _{\theta \theta }^{f}\) was calculated using Eq. 18. For pure shear loading, a square elastic plate of width \(w = 1\) mm and height \(h=1\) mm was used. Displacement controlled periodic boundary conditions (PBC) was applied to the plate using EasyPBC, with otherwise identical parameters to the uniaxial case. The maximum hoop stress due to a state of pure shear was calculated using Eq. 18. For both uniaxial and shear loading, an explicitly modelled circle was verified to reproduce the analytical solutions. The maximum principal stresses in all models were then compared to this numerical model. To circumvent the unavoidable pointwise stress singularities caused by using a jagged description of the circular hole, the principal stresses were averaged around the element with the highest principal stress. The averaged maximum principal stress \({\bar{\sigma }}_1\) from each model was defined as

where e.g. \(\sigma _1^n\) are the first principal stresses for the n neighbouring elements of the same material, around the element with the highest principal stress. The relative stress error for each model \({\hat{\sigma }}_1^{1px} \), \({\hat{\sigma }}_1^{3px} \) was then defined based on these averages as

where e.g. \({\bar{\sigma }}^e_1\) is the averaged maximum principal stress of the explicitly modelled hole, i.e. the numerical solution is taken as reference. The same relative error definition is used throughout the paper with different reference models, i.e. for the quantity \(\bullet \)

3.2.2 Effective property error

The deviation in effective material properties was studied using several plates of width \(w = 1\), height \(h = 1\) mm, thickness \(t = 0.01\) mm, stiffness \(E = 1\) GPa and Poisson’s ratio \(\nu = 0.3\). A circular hole with various choices of radius r mm was introduced in the center of each plate. The numerical solution for stiffness and Poisson’s ratio was first validated using the analytical expressions in Eqs. 13 and 14. These properties are accurate when the ratio between the circle diameter d, and the plate width w, is \(d/w < 0.6\). For larger d/w-ratios the numerical model starts to deviate from the analytical solution. While keeping the just mentioned accuracy criteria in mind, the error was computed using Eq. 22, with the effective material properties from the model containing an explicitly discretized hole as the reference solution.

3.3 Subdomain split

The influence of dividing a micrograph into individual subdomains was investigated. A 1px discretization strategy was used, since the edge case of one subdomain per pixel will reproduce the same model without any reduction. Also, while the explicit discretization strategy is applicable to the simple case of a circular hole where there exists a known analytical solution, it is not so in general for micrographs containing complex microstructures. For this reason, the reference solution will be different in this case, when compared to the investigation described in Sect. 3.2. The effective material behavior of each subdomain was evaluated using both the numerical and semi-analytical approaches described in Figs. 3 and 5, and the resulting effective elastic properties were mapped back to a geometrically homogeneous solid plate of the same dimensions. In the semi-analytical case the subdomains are isotropic, while for the numerical case they may become anisotropic. However, the resulting reduced model may still become anisotropic using both methods due to the locally heterogeneous material distribution. The effective properties of this plate were then re-evaluated using EasyPBC, and the relative error in these were computed using Eq. 22. In the numerical case, the reference solution was taken as the model with no subdomain reduction. In the semi-analytical case, the model with pixelwise reduction. Both of which are identical.

Implementation flowchart for the analytical homogenization method. The input is a micrograph together with phase properties. The micrograph is split into n subdomains which are meshed using Julia. Effective isotropic properties of each subdomain are computed via phase fractions using averaged Hashin-Shtrikman bounds, which are mapped back to a reduced mesh of the same physical dimensions as the original micrograph

3.3.1 Finite plate

The artificial micrographs from Sect. 3.2 were considered in order to emulate a worst-case scenario, i.e. finite plates with central circular holes covering 10-90% of the plate width. A micrograph resolution of \(200\cdot 200=40000\) pixels was considered. The solid was modelled using E = 1 GPa, \(\nu \) = 0.3, while the hole was modelled using E = 0.000001 GPa and \(\nu \) = 0.3.

3.3.2 Aluminium micrograph

A complex aluminium microstructure was studied, where the real structure was idealized into a system of three numerical phases A, B and C. The initial model contains 30 million triangular plane stress elements (CPS3) based on a input micrograph of 15 million pixels, with a physical pixel side length of 0.2447 \(\upmu \)m. The micrograph describes a square physical area of approximately 1 \(\hbox {mm}^2\) and was constructed by stitching \(7\cdot 8=56\) individual electron micrographs together. The stitching operation results in local contrast fluctuations, which were normalized using the normalize local contrast plugin of ImageJ [19]. A histogram-based segmentation was performed, defining three numerical phases using the following ranges of grayscale values; \(A \in [7501,34999]\), \(B \in [35000,65535]\) and \(C \in [0,7500]\). The original micrograph as well as the segmented result are given in Fig. 6. The phase specific material data used were \(E_A = 68\) GPa, \(E_B = 175\) GPa, \(E_C = 0.000001\) GPa and \(\nu _A = \nu _B = \nu _C = 0.3\), where the numerical phase A represents \(\upalpha \)-aluminium, C represents porosity and B represents all other metallurgical phases present in the microstructure. Once all subdomain evaluations were completed, the effective material properties were mapped back to a 1 \(\hbox {mm}^2\) square plate for re-evaluation and analysis.

Left: input micrograph with 15,000,129 pixels of side-length 0.2447 \(\upmu \)m, covering a physical area of approximately 1 \(\hbox {mm}^2\), constructed by stitching of 56 electron micrographs. Before local contrast normalization. Right: idealized and segmented micrograph with the numerical phases A, B and C in black, grey and white respectively

4 Results and discussion

4.1 Discretization strategy

4.1.1 Stress error

Both the jagged “1px” and the smoother “3px” meshing strategies lead to incorrect stress predictions as seen in Fig. 7, especially for the case of small circles (\(d/w = 0.01\)) where the error is on the order of 76%. However a large error is to be expected here, since the circle goes towards a square when limited by the image resolution. In fact, at the data point with the highest error in Fig. 7, the circle is represented by a perfect square which has been rotated \(\uppi /4\) radians around its center. For larger circles which are more accurately represented, i.e. \(d/w > 0.3\) with the considered pixel-density, the shear stress deviation stays below 30%. The error in uniaxial stress is in general lower than that of shear, and stays below \(15\%\) for the considered geometry. It is noteworthy that the shear stress error is 5–10% lower in the case of a jagged 1px mesh, when compared to the partially smooth 3px mesh. In general, the errors due to 1px or 3px discretization strategies become unpredictable for \(d/w > 0.6\). It can also be noted that stresses are underestimated in general when compared to the explicit circular hole. This could potentially be explained by the analytical expression for a rectangular notch in Eq. 17, where for a more square representation of the hole \(c\rightarrow \infty \) which leads to a reduction in the stress concentration.

Relative error in averaged maximum principal stress \({\hat{\sigma }}^{npx}_1\) from different discretization strategies “1px” and “3px”, for both uniaxial (solid) and shear (dashed) loading. The reference solution \({\bar{\sigma }}^e_1\) is the averaged maximum principal stress of the explicitly modelled hole in a finite plate. The 1px models have pixelwise elements, while 3px are partially smoothed

4.1.2 Effective property error

As can be seen in Fig. 8, a jagged mesh tends to underestimate all measured material properties. The smoother mesh tends to over-estimate stiffness, but under-estimates Poisson’s ratio. The errors are in general low for both cases; below \(0.5\%\) for the isotropic stiffness E, and below \(0.25\%\) for Poisson’s ratio \(\nu \) regardless of discretization strategy. The shear modulus \(G=\frac{E}{2(1+\nu )}\) which depends on both properties only deviates at most \(2\%\) from the reference model. It should be highlighted once again that the error measure is taken in relation to the numerical solution, where for \(d/w > 0.6\) the analytical model results are no longer retained.

Relative error in effective material properties E, G and \(\nu \) from different discretization strategies, for both uniaxial (solid) and shear (dashed) loading. The reference solution (\(\bullet _r\)) is the explicitly modelled hole in a finite plate. The 1px models have pixelwise elements, while 3px are partially smoothed

4.2 Subdomain split

4.2.1 Finite plate: numerical method

The relative error in effective material properties determined from the numerical approach is illustrated in Figs. 9 and 10, with dashed lines representing the threshold of \(d/w > 0.6\). While the error is one order of magnitude higher than that coming from the choice of discretization strategy for higher d/w ratios, the error in effective stiffness is lower than 6% for \(d/w < 0.6\). Errors in Poisson’s ratio are below 25% for the same interval. With the exception of the large deviation at d/w = 0.9, when the circle is split into four quarters at the center, Poisson’s ratio is always underestimated by the subdomain split.

Finite plate with circular hole, numerical approach: Relative error in effective stiffness \(E_{11}\) once mapped back to a homogeneous solid plate, as a function of subdomains. The dashed lines represent d/w ratios where the analytical properties no longer hold. The reference cases (\(\bullet _r\)) of no subdomain reduction, or one subdomain per pixel overlap

Finite plate with circular hole, numerical approach: Relative error in effective Poisson’s ratio \(\nu \) once mapped back to a homogeneous solid plate, as a function of the number of subdomains. The dashed lines represent d/w ratios where the analytical properties no longer hold. The reference cases (\(\bullet _r\)) of no subdomain reduction, or alternatively one subdomain per pixel overlap

4.2.2 Finite plate: semi-analytical method

The relative error in effective material properties determined from the semi-analytical approach is illustrated in Figs. 11 and 12, with dashed lines representing the threshold of \(d/w > 0.6\). In contrast to the numerical method, the errors start off high and decreases for an increasing number of subdomains. The large initial error could be thought of as the shape-discrepancy, since no consideration of geometry is taken here. As an increasing number of subdomains are introduced, the shape is indirectly resolved. Once again, the plates with large hole fractions, i.e. \(d/w > 0.6\) are more unpredictable. As expected, it can also be noted that the errors are higher in general than for the numerical approach.

Finite plate with circular hole, semi-analytical approach: Relative error in \(E_{11}\) once mapped back to a homogeneous solid plate, as a function of the number of subdomains. The dashed lines represent \(d/w > 0.6\). The reference solution (\(\bullet _r\)) is the edge case of one subdomain per pixel, where the numerical and semi-analytical approaches overlap

Finite plate with circular hole, semi-analytical approach: Relative error in effective Poisson’s ratio \(\nu \) once mapped back to a homogeneous solid plate, as a function of the number of subdomains. The dashed lines represent \(d/w > 0.6\). The reference solution (\(\bullet _r\)) is the edge case of one subdomain per pixel, where the numerical and semi-analytical approaches overlap

4.3 Aluminium micrograph: numerical method

Reducing the aluminium micrograph using any investigated number of subdomains does not lead to a significant error in homogenized effective material properties, as can be seen in Fig. 13. The slight increase in error for larger numbers of subdomains can be explained by the fact that the micrograph dimensions are not divisible by all investigated numbers of subdomains. The stress-field visualized in Fig. 14 should be compared to the reference stress field in figure 15, where it can be seen that a certain level of detail can still be retained while reducing the number of elements by 99.89%. For an increasing number of subdomains, the reduced stress field tends towards the reference stress field. Like for the finite plate containing a circular hole, stresses around holes are in general underestimated in the reduced model, which becomes clear by comparing the maximum values in the legends of Figs. 14 and 15. The maximum vonMises stress is one order of magnitude higher in the reference model than in the reduced one. The computational times required for several values of subdomains are given in Fig. 19.

4.4 Aluminium micrograph: semi-analytical method

Reducing the aluminium micrograph using the semi-analytical approach also does not introduce any significant error, as can be seen in Fig. 16. With the exception of the initial shape-discrepancy, the reason for the slight error fluctuation can once again be explained by the micrograph dimensions, which are not divisible by all investigated numbers of subdomains. The stress-field visualized in Fig. 17 also captures the characteristics of the reference plate for the same level of reduction. The maximum vonMises stress is still higher in the reference model than in the reduced one, however the difference is smaller using the semi-analytical method, when compared to the numerical approach. The numerical and the semi-analytical stress fields are similar, with slight local deviations. This deviation shrinks when considering even higher numbers of subdomains. By comparing the computational time of the numerical and the semi-analytical methods in Figs. 18 and 19, it is clear that the semi-analytical method is several orders of magnitude faster than the numerical one.

Numerical computational time as a function of subdomains. Analysis performed on a 64-threaded Intel Xeon Gold 6130 CPU with 128 GB RAM. The evaluation time of the reduced model is the same as for the semi-analytical case, i.e. 30–150 s for 1-\(64^2\) subdomains, thus it is not possible to distinguish in the figure

5 Conclusions

While some of the investigated situations are unlikely to occur by choice in any numerical analysis, they are unavoidable when dealing with large micrographs of real microstructures. Features which are circular/elliptical in reality will be represented in a more “blocky” way regardless of discretization strategy, as they fail to be completely resolved by the imaging technique used. Some microstructural features will inevitably take up large parts of certain subdomains, introducing large local errors in the analysis. However, the above results indicate that the edge-case of a circular hole in a finite plate represents a worst-case situation. The deviation in effective material properties for the applied case of an aluminium micrograph is several orders of magnitude lower than that of the finite plate. The numerical approach, while more computationally intensive than the semi-analytical one, provides effective anisotropic subdomain-level properties, as well as an explicit model of the microstructure which can be used for a more sophisticated analysis. To summarize, the major findings from this work are:

5.1 Discretization strategy

-

Regardless of the chosen discretization strategy (pixelwise or smoothed), local averaged shear stress deviations of \(-76\%\), and uniaxial averaged stress errors of \(-55\%\) were found, in finite plates containing circular holes of various sizes

-

Deviations in effective stiffness are on the order of \(0.5\%\), Poisson’s ratio \(0.4\%\) and shear modulus \(2\%\), regardless of discretization strategy, and regardless of the high local stress errors

-

The numerical results indicate that stresses are under-estimated in image-based elastic analyses, regardless of discretization strategy

5.2 Subdomain split of finite plate

-

Numerically determined stiffness deviates by less than \(25\%\), and Poisson’s ratio by less than \(75\%\) for the case of finite plates containing circular holes of various sizes

-

Semi-analytically determined stiffness deviates by less than \(60\%\), and Poisson’s ratio between \(-60\%\) and \(175\%\) when determining fractions by counting pixels. The error decreases with an increasing number of subdomains

5.3 Subdomain split of aluminium micrograph

-

The numerically determined errors in effective material properties were found to be \(\varDelta E_{ii} \in [0,0.2] \%, \varDelta \nu _{12} \in [-0.5,0]\%\) and \(\varDelta G_{12} \in [-0.2, 0]\%\) for all investigated levels of subdomain reduction

-

The semi-analytically determined errors in effective material properties were found to be \(\varDelta E \in [-0.2, 0.65] \%\) and \(\varDelta \nu \in [-0.4,0]\%\) for all investigated levels of subdomain reduction

-

The numerical approach underestimates the maximum vonMises stress the most, followed by a slightly more accurate semi-analytical approach.

-

Both the numerical and semi-analytical approaches are able to reproduce the characteristics of the uniaxial reference stress field, while reducing the original mesh size by 99.89%

-

The computational time can be reduced by several orders of magnitude by using the semi-analytical approach

References

Elliott JA (2011) Novel approaches to multiscale modelling in materials science. Int Mater Rev 56(4):207–225. https://doi.org/10.1179/1743280410Y.0000000002

Gooneie A, Schuschnigg S, Holzer C (2017) A review of multiscale computational methods in polymeric materials. Polymers. https://doi.org/10.3390/polym9010016

Matouš K, Geers MG, Kouznetsova VG, Gillman A (2017) A review of predictive nonlinear theories for multiscale modeling of heterogeneous materials. J Comput Phys 330:192–220. https://doi.org/10.1016/j.jcp.2016.10.070

Ghosh S, Dimiduk D (2011) Computational methods for microstructure-property relationships. Springer, Berlin

Dvorak GJ (2013) Micromechanics of composite materials. Springer, Berlin

Fish J (2014) Practical multiscaling. Wiley, Hoboken

Trovalusci P (2016) Materials with internal structure: multiscale and multifield modeling and simulation. Springer, Berlin

Sorić J, Wriggers P, Allix O (2018) Multiscale modeling of heterogeneous structures. Springer, Berlin

Yvonnet J (2019) Computational homogenization of heterogeneous materials with finite elements. Springer, Berlin

Langer S, Fuller E, Carter W (2001) OOF2: Image-based finite-element analysis of material microstructures. Comput Sci Eng 3:15–23. https://doi.org/10.1109/5992.919261

Coffman VR, Reid AC, Langer SA, Dogan G (2012) OOF3D: an image-based finite element solver for materials science. Math Comput Simul 82(12):2951–2961. https://doi.org/10.1016/j.matcom.2012.03.003

Reid AC, Langer SA, Lua RC, Coffman VR, Haan SI, García RE (2008) Image-based finite element mesh construction for material microstructures. Comput Mater Sci 43(4):989–999. https://doi.org/10.1016/j.commatsci.2008.02.016

Hashin Z, Shtrikman S (1963) A variational approach to the theory of the elastic behaviour of multiphase materials. J Mech Phys Solids 11(2):127–140. https://doi.org/10.1016/0022-5096(63)90060-7

Kachanov M, Tsukrov I, Shafiro B (1994) Effective moduli of solids with cavities of various shapes. Appl Mech Rev 47(1):151–174. https://doi.org/10.1115/1.3122810

Ernst Gustav Kirsch (1898) Die Theorie der Elastizität und die Bedürfnisse der Festigkeitslehre. Zeitschrift des Vereines deutscher Ingenieure 42:797–807

Inglis C (1913) Stresses in plates due to the presence of cracks and sharp corners. Trans Inst Naval Archit 55:219–241

Bezanson J, Edelman A, Karpinski S, Shah VB (2017) Julia: a fresh approach to numerical computing. SIAM Rev 59(1):65–98

Omairey SL, Dunning PD, Sriramula S (2019) Development of an ABAQUS plugin tool for periodic RVE homogenisation. Eng Comput 35(2):567–577. https://doi.org/10.1007/s00366-018-0616-4

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH image to imagej: 25 years of image analysis. Nat Methods 9(7):671–675. https://doi.org/10.1038/nmeth.2089

Acknowledgements

The Swedish Knowledge Foundation (’KK-stiftelsen’) is greatly acknowledged for financing the research projects CompCAST+ and ODISSEE2 at Jönköping University. Mohammadreza Zamani is acknowledged for providing the stitched aluminium electron micrograph.

Funding

Open access funding provided by Jönköping University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jansson, J., Salomonsson, K. & Olofsson, J. Image-based semi-multiscale finite element analysis using elastic subdomain homogenization. Meccanica 56, 2799–2811 (2021). https://doi.org/10.1007/s11012-021-01378-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-021-01378-4