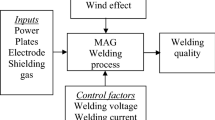

Low-carbon steel St37-2 is widely used in the bus-production industry. The gas-metal arc welding (GMAW) is strongly applied to join steel components due to its ease and low cost. Heat-affected zone (HAZ) is the area between the weld and the base metal, where the welded joint may have the lowest toughness and, hence, it has always been a matter of interest for numerous researchers. Our aim is to study the effects of GMAW parameters on the width of the HAZ. The Taguchi orthogonal array, signal-to-noise (S/N) ratios, and the analysis of variance (ANOVA) are used to investigate and analyze the effect of the welding parameters on the HAZ width.

Similar content being viewed by others

References

G. Hun, S. Yun, X. Cao, and J. Li, “Acquisition and pattern recognition of spectrum information of welding metal transfer,” Mater. Des., 24, 699–703 (2003).

S. C. Absi Alfaro, G. C. Carvalho, and S. A. de Melo Junior, “Stand offs indirect estimation in GMAW,” J. Mater. Proc. Technol., 157–158, 3–7 (2004).

M. Suban and J. Tusek, “Dependence of melting rate in MIG/MAG welding on the type of shielding gas used,” J. Mat. Proc. Technol., 119, 185–192 (2001).

R. Kacar and K. Kokemli, “Effect of controlled atmosphere on the MIG-MAG arc weldment properties,” J. Mater. Des., 26, 508–516 (2005).

R. W. Messler, Principles of Welding, Processes, Physics, Chemistry, and Metallurgy, Chapter 3, New York: Wiley & Sons (1999).

R. E. Dolby, Met. Const. Brit. Weld. J., 3, 99 (1971).

J. D. Harrison, Why Does Low Toughness in the HAZ Matter?, Welding Institute Seminar, Coventry, England, 1983.

D. P. Fairchild, “Local brittle zones in structural welds,” in: J. Y. Koo (editor), Welding Metallurgy of Structural Steels, TMS, CO, Denver (1987), pp. 303–318.

T. Haze and S. Aihar, Proc. of the 7th Conf. on the Offshore Mechanics and Arabic Engineering (OMAE), Houston (1988).

P. L. Harisson and P. H. M. Hant, Proc. of the Internat. Conf. on Weld Failures, Welding Institute, London (1988).

R. M. Denys, Proc. of the Internat. Conf. on Weld Failures, Welding Institute, London (1988).

T. Boniszewski and F. Watkinson, “Effect of weld microstructure on hydrogen-induced cracking in transformable steels,” Met. Mater., 7, 91–96/145–151 (1973).

S. D. Ambekar and S. R. Wadhokar, “Influence of process parameters on depth of penetration in GMAW process by using Taguchi method,” Int. J. Sci. Res., 4, 3065–3069 (2015).

A. Khalkhali, H. Noraie, and M. Sarmadi, “Sensitivity analysis and optimization of hot-stamping process of automotive components using analysis of variance and Taguchi technique,” in: Proc. of the Institution of Mechan. Eng., Part E, J. Process Mech. Eng. (2016).

M. Sailender, G. Chandra Mohan Reddy, and S. Venkatesh, “Influences of process parameters on heat affected zone in submerged arc welding of low carbon steel,” Amer. J. Mater. Sci., 6, 102–108 (2016).

R. Kumar and S. Kumar, “Study of mechanical properties in mild steel using metal inert gas welding,” Int. J. Res. Eng. Techn., 3, 751–756 (2014).

A. S. Jadon, N. S. Kushwah, Agrawal, and P. Mittal, “Parametric optimization of GTAW welding using Taguchi and ANOVA,” Int. J. Res. Appl. Sci. Eng. Technol., 5, 650–655 (2017).

H. Mohamed, M. H. Lee, M. Sarahintu, S. Salleh, and B. Sanugi, “The use of Taguchi method to determine factors affecting the performance of destination sequence distance vector routing protocol in mobile Ad Hoc networks,” J. Math. Stat., 4, 194–198 (2008).

A. Rajendran, M. Thirugnanam, and V. Thangavelu, “Statistical evaluation of medium components by Plackett-Burman experimental design and kinetic modeling of lipase production by Pseudomonas fluorescens,” Ind. J. Biotechnol., 6, 469–478 (2007).

S. A. Patil, F. Baratzadeh, and H. Lankarani, “Modeling of the weld strength in spot weld using regression analysis of the stress parameters based on the simulation study,” J. Mater. Sci. Res., 6, 51–61 (2017).

Design-Expert Software, Version 6, User’s Guide, Technical Manual, Stat-Ease, Minneapolis, MN– 2000.

H. R. Lindman, Analysis of Variance in Experimental Design, 1st Ed, Springer-Verlag, New York (1992).

Acknowledgements

The authors would like to thank the Managing Director of the Industrial and Manufacturing Company of Sava Sazeh Segal for all facilities and the financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 6, pp. 76–81, November–December, 2020.

Rights and permissions

About this article

Cite this article

Ghazvinloo, H.R., Honarbakhsh-Raouf, A. Numerical Modeling of Heat-Affected Zone in the GMAW Process. Mater Sci 56, 807–813 (2021). https://doi.org/10.1007/s11003-021-00498-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00498-2