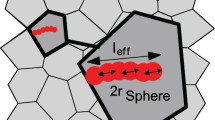

We propose a model of multiple cracking of specimens under the combined action of thermal and mechanical cyclic loads. In view of the complexity of computations required for the solution of the problems of interaction of stochastically arranged cracks, it is proposed to treat them as doubly periodic systems of branched cracks capable of modeling the intergranular damage as well as the intercrystalline and transcrystalline fracture. To determine the main direction of propagation of fracture, we introduce in the model cross-shaped cracklike defects, which can grow in two mutually perpendicular directions relative to the applied thermal and force loads. We also obtain the dependences of the formation of defects, the length of microcracks, and the distances between them on the number of cycles and the parameters of thermal and force loading.

Similar content being viewed by others

References

M. Mansoor, I. Islam, and A. Tauqir, “Restricted life of after burner manifold assemblies due to stress raisers,” Eng. Fail. Anal., 14, 1280–1285 (2007).

L. Rémy, M. Geuffrard, A. Alam, et al., “Effects of microstructure in high temperature fatigue: Lifetime to crack initiation of a single crystal superalloy in high temperature low cycle fatigue,” Int. J. Fatigue, Fatigue and Microstructure: A Special Issue on Recent Advances, 57, 37–49 (2013).

L. Rémy, A. Alam, N. Haddar, et al., “Growth of small cracks and prediction of lifetime in high-temperature alloys,” Mater. Sci. Eng., Ser. A, The McEvily Symp.: Fatigue and Fracture of Traditional and Advanced Materials (TMS 2006), 468–470, 40–50 (2007).

X. W. Liu and W. J. Plumbridge, “Damage produced in solder alloys during thermal cycling,” J. Electron. Mater., 36, 1111–1120 (2007).

R. L. J. M. Ubachs, P. J. G. Schreurs, and M. G. D. Geers, “Elasto-viscoplastic nonlocal damage modeling of thermal fatigue in anisotropic lead-free solder,” Mech. Mater., 39, 685–701 (2007).

T. Beck, D. Löhe, J. Luft, and I. Henne, “Damage mechanisms of cast Al–Si–Mg alloys under superimposed thermal-mechanical fatigue and high-cycle fatigue loading,” Mater. Sci. Eng., Ser. A, 468–470, 184–192 (2007).

V. Firouzdor, M. Rajabi, E. Nejati, and F. Khomamizadeh, “Effect of microstructural constituents on the thermal fatigue life of A319 aluminum alloy,” Mater. Sci. Eng., Ser. A, 454–455, 528–535 (2007).

S. Taheri, “Some advances on understanding of high cycle thermal fatigue crazing,” J. Press. Vessel Technol., 129, 400–410 (2007).

R. Ya. Kosarevych, O. Z. Student, Ya. D. Onyshchak, et al., “Estimation of damage to the collector of a water economizer by thermal fatigue cracks,” Fiz.-Khim. Mekh. Mater., 40, No. 1, 109–114 (2004); English translation: Mater. Sci., 40, No. 1, 132–138 (2004).

A. Fissolo, S. Amiable, O. Ancelet, et al., “Crack initiation under thermal fatigue: An overview of CEA experience. Part I: Thermal fatigue appears to be more damaging than uniaxial isothermal fatigue,” Int. J. Fatigue, 31, 587–600 (2009).

O. Ancelet, S. Chapuliot, G. Henaff, and S. Marie, “Development of a test for the analysis of the harmfulness of a 3D thermal fatigue loading in tubes,” Int. J. Fatigue, 29, 549–564 (2007).

R. Desmorat, A. Kane, M. Seyedi, and J. P. Sermage, “Two scale damage model and related numerical issues for thermomechanical high cycle fatigue,” Eur. J. Mech., Ser. A: Solids, 26, 909–935 (2007).

A. Ahmadi and H. Zenner, “Simulation of microcrack growth for different load sequences and comparison with experimental results,” Int. J. Fatigue, Cumulative Fatigue Damage Conf. (University of Seville, 2003), 27, 853–861 (2005).

M. Missirlian, F. Escourbiac, M. Merola, et al., “Damage evaluation under thermal fatigue of a vertical target full scale component for the ITER divertor,” J. Nucl. Mater., Proc. of the Twelfth Internat. Conf. on Fusion Reactor Materials (ICFRM-12), 367–370, Part B, 1330–1336 (2007).

V. Maillot, A. Fissolo, G. Degallaix, and S. Degallaix, “Thermal fatigue crack networks parameters and stability: an experimental study,” Int. J. Solids Struct., Micromechanics of Materials, 42, 759–769 (2005).

M. Kamaya and S. Taheri, “A study on the evolution of crack networks under thermal fatigue loading,” Nucl. Eng. Des., 238, 2147–2154 (2008).

N. Malésys, L. Vincent, and F. Hild, “A probabilistic model to predict the formation and propagation of crack networks in thermal fatigue,” Int. J. Fatigue, 31, 565–574 (2009).

K. Tohgo, H. Suzuki, Y. Shimamura, et al., “Monte Carlo simulation of stress corrosion cracking on a smooth surface of sensitized stainless steel type 304,” Corr. Sci., 51, 2208–2217 (2009).

N. Haddar and A. Fissolo, “2D simulation of the initiation and propagation of crack array under thermal fatigue,” Nucl. Eng. Des., 235, 945–964 ((2005).

N. Haddar, A. Fissolo, and V. Maillot, “Thermal fatigue crack networks: a computational study,” Int. J. Solids Struct., Micromechanics of Materials, 42, 771–788 (2005).

N. Kasahara, H. Takasho, and A. Yacumpai, “Structural response function approach for evaluation of thermal striping phenomena,” Nucl. Eng. Des., 212, 281–292 (2002).

O. Yasniy, Y. Lapusta, Y. Pyndus, et al., “Assessment of lifetime of railway axle,” Int. J. Fatigue, Recent Progress in the Understanding of Fatigue Crack Propagation, 50, 40–46 (2013).

P Paris and F. Erdogan, “A critical analysis of crack propagation laws,” J. Fluids Eng., 85, 528–533 (1963).

I. Pasternak, “Doubly periodic arrays of cracks and thin inhomogeneities in an infinite magnetoelectroelastic medium,” Eng. Anal. Bound. Elem., 36, 799–811 (2012).

P. Yasniy, P. Maruschak, I. Konovalenko, and R. Bishchak, “Diagnostics of thermal fatigue cracks on continuous caster rolls surface,” Mechanika, 17, No. 3, 251–254 (2011).

V. V. Klypachevs’kii and M. M. Teslyuk, “Graphic programming in thermal fatigue and fatigue strength tests,” Strength Mater., 43, 101–108 (2011).

O. Yasniy, P. Maruschak, and Y. Lapusta, “Probabilistic modeling of surface crack growth in a roll of continuous casting machine,” Int. J. Fract., 172, 113–120 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 51, No. 6, pp. 17–23, November–December, 2015.

Rights and permissions

About this article

Cite this article

Sulym, H.T., Yasnii, O.P. & Pasternak, Y.M. Modeling of Multiple Cracking Under the Conditions of Thermomechanical Fatigue. Mater Sci 51, 765–772 (2016). https://doi.org/10.1007/s11003-016-9901-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-016-9901-9