Abstract

Rubber stress relaxation models are the main material input data for numerical and analytical conveyor belt indentation rolling resistance calculations. Stress relaxation data for rubbers, such as those used in the construction of conveyor belts, are difficult to measure directly due to their fast relaxation times and, as such, they are usually derived via a dynamic mechanical analysis; unfortunately, relaxation data for the strain levels reached in conveyor belting cannot be produced with typical dynamic mechanical analysis machines. This paper utilizes high strain level data produced on a high capacity dynamic mechanical analysis machine and compares the indentation rolling resistance predictions derived from the measured high strain relaxation moduli with other high strain relaxation moduli extrapolated from low strain level measurements that can be measured on dynamic mechanical analysers with smaller capacities. Jonker’s equation and a two dimensional finite element analysis model are used to compare the different sets of relaxation moduli and these are compared with results from large scale indentation rolling resistance experiments.

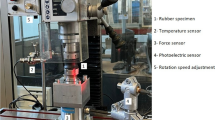

Reproduced with permission from Munzenberger and Wheeler (2016)

Similar content being viewed by others

References

AS1334.13: Australian Standard: Methods of Testing Conveyor and Elevator Belting Method 13: Determination of Indentation Rolling Resistance of Conveyor Belting. Standards Australia. ISBN: 978-1-76035-814-9 (2017)

Berer, M., Major, Z.: Characterization of the global deformation behaviour of engineering plasitc rolls. Int. J. Mech. Mater. Des. 6(1), 1–9 (2010)

Cho, J.R., et al.: Finite element estimation of hysteretic loss and rolling resistance of 3-D pattered tire. Int. J. Mech. Mater. Des. 9(4), 355–366 (2013)

Conveyor Equipment Manufacturers Association (CEMA): Belt Conveyors for Bulk Materials, 6th edn. Conveyor Equipment Manufacturers Association, Naples, FL (2005)

Hager, M., Hintz, A.: The energy-saving design of belts for long conveyor systems. Bulk Solids Handl. 13(4), 749–758 (1993)

Jonkers, C.: The indentation rolling resistance of belt conveyors. Fordern und Heben 30(4), 312–318 (1980)

Kraus, G.: Mechanical losses in carbon-black filled rubbers. Appl. Polym. Symp. 39, 75–92 (1984)

Lynch, F.D.: A finite element method of viscoelastic stress analysis with application to rolling contact problems. Int. J. Numer. Methods Eng. 1, 379–394 (1969)

Munzenberger, P., Wheeler, C.:. Advances in predicting the indentation rolling resistance using the finite element method. In: International Materials Handling Conference Beltcon, Johanesburg, vol. 17 (2013)

Munzenberger, P., Wheeler, C.: Laboratory measurement of indentation rolling resistance of conveyor belts. Measurement 94, 909–918 (2016)

O’Shea, J., Wheeler, C.: Dielectric relaxation studies of conveyor belt compounds to determine indentation rolling resistance. Int. J. Mech. Mater. Des. 13(4), 553–567 (2017)

O’Shea, J.I., Wheeler, C.A., Munzenberger, P.J., Ausling, D.A.: The influences of viscoelastic property measurements on the predicted rolling resistance of belt conveyors. J. Appl. Polym. Sci. 131(18), 9170–9178 (2014)

Payne, A.: the dynamic properties of carbon black loaded natural rubber vulcanisates part 1. J. Appl. Polym. Sci. 6(19), 57–63 (1962)

Qiu, X., Chai, C.: Estimation of energy loss in conveyor systems due to idler indentation. J. Energy Eng. 137, 36–43 (2011)

Reicks, A.V., Rudolphi, T.J., Wheeler, C.A.: A comparison of calculated and measured indentation losses in rubber belt covers. Bulk Solids Handling 32(3), 52–57 (2012)

Rudolphi, T.: Applied rubber belt cover loss prediction from indentation. SME Annual Meeting and Exhibit, Salt Lake City (2008)

Schwarzl, F., Struik, L.: Analysis of relaxation measurements. Adv. Mol. Relax. Process. 1(3), 201–255 (1968)

Shaw, M.T., MacKnight, W.J.: Introduction to Polymer Viscoelasticity. Wiley, Hoboken (2005)

Ward, I.M., Sweeney, J.: The Mechanical Properties of Solid Polymers, 2nd edn. Wiley, West Sussex (2008)

Wheeler, C.: Analysis of the Main Resistances of Belt Conveyors. The University of Newcastle, Newcastle (2003)

Wheeler, C.A., Munzenberger, P.J.: A Pseudo 3D Analysis of the Indentation Rolling Resistance Problem. BELTCON 15, Roodepoort (2009)

Wheeler, C.A., Munzenberger, P.J.: Prediction of conveyor belt indentation rolling resistance using the finite element method. In: International Conference for Conveying and Handling Particulate Solids, Friedrichshafen (2012)

Acknowledgements

Funding was provided by Australian Research Council (Grant No. LP0884106).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Munzenberger, P.J., O’Shea, J.I. & Wheeler, C.A. A comparison of rubber stress relaxation models for conveyor belt indentation rolling resistance calculations. Int J Mech Mater Des 15, 213–224 (2019). https://doi.org/10.1007/s10999-018-9412-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-018-9412-y