Abstract

In this work development of structural and chemical properties of four nanoporous hybrid carbons has been presented. The carbons were synthesized by direct carbonization at 450, 600, 750 and 900 °C of the terpolymeric hybrid precursor composed of methacrylamide, divinylbenzene and trimethoxyvinylsilane and impregnated with sulfanilic acid (SA) as the surface modifier. The conditions of the carbonization process were set on the basis of the thermogravimetric analysis combined with FTIR analysis of the evolved gases (TGA-EGA). The use of SA contributed to the reduction of the carbonization temperature by about 100 °C and resulted in carbons with very uniform and bimodal porosity with the width range of about 1 and 14–28 nm. Spectral (ATR, Raman, XPS) and X-ray diffraction methods used to characterize the resulting carbon products allowed to define the gradual changes taking place in the morphological and chemical structure of the prepared materials. Cyclic and symmetrical structures of silicates species were gradually replaced by amorphous arrangements. At the same time, the increase in the sp2/sp3 carbon ratio from 1 to 65% proved progressive ordering and aromatization of the carbonized polymeric hybrid precursor. Some functional groups (e.g., N-containing) were built into carbon clusters forming pyridinic, pyrrolic and N-graphitic like structures, while others (e.g., carbonyls) were removed from the surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanoporous hybrid carbons are very attractive materials because in their biphasic structure they incorporate a number of desirable features. Typical of carbon materials, high thermal and chemical stability, electrical conductivity and good biocompatibility, in combination with characteristics of inorganic (e.g., silica, silicate) framework, such as high mechanical strength, hydrophilicity and non-flammability give a huge variety of new long-lasting materials with diverse porosity, ready for recycling and repeated use, including further chemical modifications [1]. Such properties provide great possibilities for potential applications in many fields including catalysis, sorption-based separation and purification techniques, storage and conversion of energy, biomedicine, microelectronics and other smart or intelligent systems [2,3,4]. The growing demand for hybrid carbons drives the development of methods for their production. In order to meet the task of producing carbons for a specific application, the morphological properties of the developed materials must be easily optimized. Due to the ability to control the physical and surface properties during synthesis, both synthetic and natural polymer nanoparticles, nanocarbon/or polymer blends and hybrids are gaining recognition as precursors of novel carbon materials.

There are many methods and chemical pathways available for the synthesis of organic–inorganic hybrid materials, of which the most popular are: template, sol–gel, hydrothermal, self-assembly, intercalation or nanobuilding blocks procedures. Each of these strategies offer a final product with specific chemical and morphological properties created by the strength of interactions between organic and inorganic structural elements [5]. Another approach is to perform polymerization, in which organic monomers are mixed with monomers having inorganic sites, and the sol–gel process can proceed along with the main reaction [6,7,8]. In such a case, organosiloxanes including alkoxyl derivatives react through a series of complex hydrolysis and condensation processes. As the result not only ordinary occurring structures like chains or cyclic units are formed but also more complex cross-linked frameworks resembling cages, ladders or sheets of different sizes tend to develop. Silicate frameworks can also generate many intermediate or defective structures depending on the used substrates and the reaction conditions [9,10,11,12].

The subsequent stage is thermal treatment of hybrid precursor realized by classical (e.g., pyrolysis, carbonization or graphitization) or modern methods (e.g., microwave, plasma, hydrothermal or pressure carbonization, laser ablation and arc discharge) to convert the organic matter of the substrate into carbon substance. In this step many different factors related to precursor structure and process conditions affect the properties of the final product [13]. Porosity, presence of heteroatoms, aromatic rings or functional groups in the molecule, degree of crosslinking of polymeric chains are the main attributes creating thermal behavior of the precursor. Temperature, heating time and atmosphere are the parameters which allow to control progress and depth of structural transformation during the process. Sometimes additionally activating or modifying agents are used to support the process and obtain more desirable features. Acids (H3PO4, H2SO4, HNO3) [14, 15], bases (NaOH, KOH) [16, 17] salts (KMnO4, AgNO3, FeCl3) [18] and aromatic substances [19,20,21] are commonly used for this purpose. Inorganic modifiers can be used before or after carbonization in order to modify the existing or introduce new functional groups on the carbon surface. The organic modifiers generally are applied during thermal treatment. For example, in chemical vapor deposition (CVD) method the carrier gas is enriched with vapors of organic substances which, deposited on the pore walls, lead to the formation of a homogeneous porous texture of the resulting carbon product [22,23,24].

Among many organic compounds sulfanilic acid is very useful as activating or modifying agent. Its ability to form ionic crystals results in a high melting point (288 °C) followed by a decomposition. The products of its decomposition are aniline and sulfur dioxide. The former by accumulation on the pore walls should behave the same as in the CVD method, leading to homogenization of pore sizes. The latter, having oxidizing potential, can act as an in situ activator of the carbon surface. Thus in one carbonization step both, homogenization and activation process could be possible. Additionally, it should be emphasized, that since in the impregnation technique only the porous structure of the precursor is filled with the modifying reagent, a significant reduction in chemical quantities is achieved and beneficial compared to the CVD method.

Although the development of carbon structure under the influence of heat treatment for various precursors has already been well investigated [13, 14, 25,26,27], the details of a formation of hybrid carbons by carbonization of polymeric hybrid precursors, especially doped with heteroatoms, seem to be still insufficiently understood. The same is the case with siloxane base composites and nanohybrids. Among them, polyhedral oligomeric silsesquioxanes (POSS) are the most widely and comprehensively described in literature, while the characteristics of those with a less regular or amorphous framework are not so frequent in scientific reports, despite their common occurrence in many materials.

In order to better control the process of formation of hybrid carbons, it is necessary to explore and understand better the thermochemical changes that occur during carbonization of the precursor. In these studies, we investigate gradual structural transitions proceeding in porous hybrid terpolymer composed of methacrylamide, divinylbenzene and trimethoxyvinylsilane, impregnated with sulfanilic acid as surface modifier. At first, based on thermogravimetry coupled with analysis of evolved gases, comparison of thermal behavior of sulfanilic acid, the hybrid precursor and the impregnated precursor was performed to demonstrate the effect of modifier on the hybrid precursor. Analysis of the TGA results has led to the choice of carbonization temperatures required for detailed examination of the process. Four temperatures with an interval of 150 °C were selected to show subsequent stages of structural transformations. As a starting point 450 °C was taken, at which the decomposition of the polymer should have been already completed, and charring process has just started. 600 °C—the middle of the charring process. 750 °C corresponding to the end of the charring and 900 °C as the typically applied carbonization temperature.

Carbonization of the impregnated polymer at selected temperatures resulted in 4 products with different degrees of carbonization, corresponding to the subsequent stages of carbon structure formation.

The final hybrid carbons were characterized using ATR, XPS, Raman and XRD techniques to reveal structural and chemical differences between them. Changes in porosity were evaluated using standard BET method based on nitrogen sorption experiments.

Experimental

Materials and samples preparation

Nanoporous hybrid carbons were prepared by thermal treatment of the terpolymeric hybrid precursor (P2) composed of divinylbenzene, methacrylamide and trimethoxyl(vinyl)silane at the molar ratio of 1:1:1. The monomers mixed with pore forming diluents (toluene and decan-1-ol) at 1:1 volumetric ratio and with addition of 1% of α,α′-azoiso-bis-butyronitrile as initiation were poured to 1% aqueous solution of bis(2-ethylhexyl)sulfosuccinate sodium salt as suspension stabilizer. The polymerization was carried out at 80 °C for 18 h under continuous mechanical stirring. The polymer product was obtained in the form of porous microspheres with diameters ranging from 15 to 30 µm. Detailed description of the way of the precursor synthesis was given by Podkościelna et al. [28]. Before heat treatment the polymer was impregnated (P2 impr) with saturated aqueous solution of sulfanilic acid (analytical grade, POCH, Gliwice, Poland) (SA), which acted as the surface modifier supporting thermal treatment and formation of uniform porosity. For every 1 g of the pristine polymer, 10 mL of ambient temperature SA solution was used. The mixture was places in vacuum chamber and the pressure was reduced to − 85 kPa for 15 min. in order to remove air from the polymer pores and completely fill them with the SA solution. The sample was heated to 50 °C to gently evaporate excess water and then allowed to dry in the open air at room temperature until a constant mass was obtained. Typically, after impregnation the mass of polymer increased by 10%.

Carbonization was performed under nitrogen atmosphere at four temperatures: 450, 600, 750 and 900 °C. These were designated as C2-450, C2-600, C2-750 and C2-900, according to their carbonization temperature. The obtained carbon materials were washed with methanol (pure grade, POCH, Gliwice, Poland) in Soxhlet apparatus for at least 8 h and left to dry.

Measurements

TG/DTG analyses were performed by means of an STA 449 F1 Jupiter thermal analyzer (Netzsch, Selb, Germany). Samples (about 7 mg) were weighed into a Al2O3 crucible. Measurements were performed under helium atmosphere (40 mL min−1) in the temperature range of 30 to 1000 °C with the heating rate set to 10 °C min−1. The gaseous products released from the sample were simultaneously analyzed (EGA) by the online coupled Fourier transform infrared spectrometer FTIR Tensor 27 (Bruker, Ettlingen, Germany). The spectra were acquired in the frequency range of 4000 to 600 cm−1 at a resolution 4 cm−1, performing 16 scans per sample scan time. The recorded spectra were shown in absorbance units (A.U.) Spectral analysis was performed by comparing the obtained spectra with those available in the NIST database [29], selecting the spectra of standards in the gas state.

Porous structure parameters were determined by low temperature nitrogen sorption experiments with an ASAP 2405 analyzer (Accelerated Surface Area and Porosimetry system, Micromeritics Inc., Norcross, GA, USA). Before analysis, the samples were outgassed at 110 °C for 1 h. The isotherms were measured at -196 °C. The specific surface area (SBET) was calculated using the standard BET method assuming N2 molecular cross-sectional area 0.162 nm. The total pore volume was calculated as the volume of liquid adsorbate at a relative pressure of 0.99. The total pore volume (Vtot), mesopore (Vme) and micropore (Vmi) volumes and pore size distributions (PSD) were calculated using the carbon N2-2D-NLDFT, standard slit model implemented in the SAIEUS software (Micromeritics), free version, www.nldft.com. The calculations were performed based on adsorption branch of the isotherms and the slit pore model.

Elemental analysis results (CHN) were obtained using Perkin Elmer CHN 2400 analyzer (Palo Alto, CA, USA).

Infrared spectra were collected in Attenuated Total Reflectance mode (ATR-FTIR) using a TENSOR 27 spectrophotometer (Bruker, Ettlingen, Germany). The spectra were recorded in the same frequency range and the resolution as above, performing 32 scans per measurement. To distinguish ATR spectra from those of EGA, the former were shown as a function of transmittance.

A photoelectron spectroscopy data (XPS) was recorded by Prevac multi-chamber UHV analytical system (Rogów, Poland) using hemispherical Scienta R4000 electron analyzer with Scienta SAX-100 x-ray source (Al Kα, 1486.6 eV, 0.8 eV band) equipped in the XM 650 X-Ray Monochromator (0.2 eV band). The pass energy of the analyzer was set to 200 eV for survey spectra (with 500 meV step), and 50 eV for high resolution regions: Ni2p, O1s and Si2p (with 50–100 meV step). The base pressure in the chamber was 5·10–9 mbar and during the spectra collection it was not higher than 3·10–8 mbar. The spectra were analyzed and processed with the use of CasaXPS 2.3.10 software. The background was approximated by Shirley algorithm and the detailed spectra were fitted with Voigt function.

The powder X-ray diffraction (PXRD) data were collected with the Panalytical Empyrean diffractometer with Ni-filtered Cu Kα radiation (Malvern Panalytical, Malvern, UK). The intensity data were captured with the PIXcel3D detector over the 2θ range of 5–50◦ with the step ∆θ = 0.013°. All the measurements were performed at room temperature. The overlays of diffraction patterns were generated using Highscore software.

Raman spectra were measured using Renishaw inVia Reflex Raman microscope, with the laser power about 1.4 mW. The excitation laser wavelength was 514 nm. The spectra were acquired in the frequency range of 3200–100 cm−1 at a resolution 1 cm−1, performing 1 scan per measurement.

Results and discussion

Carbonization of the precursor—details of thermal degradation

TG/DTG coupled with evolved gas analysis (EGA) enables a detailed description of the carbonization process. In order to accurately assess the influence of the surface modifier on the course of the carbonization, both the pristine (P2) and the impregnated terpolymeric hybrid precursor (P2 impr) were tested. The decomposition process of the modifier—sulfanilic acid (SA) has been studied as well. The obtained TG/DTG results are presented in Fig. 1 and Table 1. While the spectra of the compounds released during decomposition are shown in Fig. 2.

FTIR spectra of gases evolved during TG analyses obtained for a, the pristine polymeric precursor (P2), b the modifier—sulfanilic acid (SA) with evolution profiles of individual decomposition products depending on the heating temperature and c the impregnated polymeric precursor (P2 impr). For the latter the right panel presents zoom of the marked region

Comparing the course of the TG plots (Fig. 1a) and the characteristic parameters of the TG analysis collected in Table 1, it is apparent the significant influence the modifier exerts on the course of carbonization. The initial decomposition temperature was assumed to be the first change occurring in the sample, related to 1% of the sample mass loss (T1%). For the pristine polymeric precursor and the modifier T1% values are 294 and 309 °C, respectively. Decomposition of these materials occurs rapidly as a single stage process which can be observed on DTG plot (Fig. 1b) as single, sharp peak located at 448 (Tmax P2) and 369 °C (Tmax SA). The mass loss that accompanies these processes is 72 and 79% for the precursor and SA, respectively. It should be emphasized that high thermal stability of the pristine precursor is a consequence of its spatially cross-linked polymeric structure reinforced by interpenetrating silicate framework. In turn, the high melting point (288 °C) and high thermal resistance of SA is related to the fact that, being in the form of a zwitterion, it creates ionic crystal structures stabilized by numerous hydrogen bonds [30]. For this reason, both of them require high temperature to initiate decomposition process.

In case of the polymer impregnated with modifier the decomposition behavior is quite different. Thermal decomposition begins at a temperature almost 100 °C lower than T1% of P2. The observed decrease in thermal stability can be explained by the fact that in narrow pores SA is spread on the pore walls, but the available space is too small to allow the formation of larger crystal structures. In this situation, no energy is needed to melt the crystal, therefore SA decomposition occurs at a lower temperature. Thermal destruction of P2 impr comprises of three slowly progressing stages with the Tmax values at 336, 418 and 609 °C, respectively. In each of the subsequent decomposition phases, the mass loss is greater and amounts to approximately 21, 30 and 37%. This indicates a considerable extension of the decomposition temperatures range (300–670°). Such fundamental changes in the thermal behavior of the hybrid polymer precursor suggest a strong influence of the modifier on its chemical structure.

Furthermore, comparing temperatures corresponding to 25% and 50% of sample mass loss (T25% and T50%) for the P2 and P2 impr polymers it can be stated that P2 has higher thermally stability than P2 impr. This means that impregnation process caused deep changes in the polymer (related to the oxidation of its structure) manifested by a significant loss of the thermal stability. For this reason, percent of mass loss (Δm) of P2 impr during carbonization was in most cases higher than that for the pristine P2 (Table 1).

The analysis of evolved gaseous products of decomposition sheds even more light on the studied phenomena and allows to better explain the described carbonization process. As it was mentioned above, DTG plot revealed that P2 impr decomposed in three stages. Each of them is accompanied by the emission of gaseous products, which is confirmed by the Gram Schmidt plot presented in Fig. 1b. It is worth noting, that none of these steps coincide with those observed for P2 or SA, which excludes the independent decomposition of the polymeric precursor and the modifier. This conclusion is also confirmed by the analysis of the FTIR spectra presented in Fig. 2.

Figure 2a presents FTIR spectra recorded at 392 and 462 °C that is just before and at the peak of gaseous products emission from P2 sample. According to the data collected in Table 2, in the spectrum taken at the lower temperature among evolved gases CO2 (2380–2300 cm−1), CO (2200–2100 cm−1) and small amounts of unsaturated and aromatic compounds (3100–2880 and 909 cm−1) can be distinguished. The main components of mixture of these organic compounds can be ethylene, ethylbenzene, styrene or its aliphatic derivatives. When temperature increases the share of aromatic compounds in released gases increases significantly. Among them aliphatic styrene derivatives seem to dominate what is indicated by a broad band in the range of 3100–2880 and four characteristic bands in the range of 1000–700 cm−1 with one dominant at 906 cm−1. Such product can be evolved as a result of partial unzipping reaction or detachment of pendant DVB molecules. The release of CO and CO2 remains on unchanged levels, proving gradual decomposition of oxygen containing functional groups like, e.g., methoxylic of silicate framework. A weak bands of ammonia especially in spectrum collected at 450 °C may indicate the ongoing conversion process of amide (from methacrylamide unit) to imide [39].

In the left panel of Fig. 2b, the spectra depicting the decomposition products of SA were placed. Although thermal analysis has shown that sulfanilic acid decomposes between 300 and 400 °C and charring occurs above this range, the detailed spectral analysis of evolved gases (the right panel of Fig. 2b) revealed that the process has more complex course. It starts with the SO2 emission, which indicates degradation of sulfonic moieties. Then the emission of aniline increases. In the final stage, mainly CO2 and H2O are released from charred residue, as a result of pyrolysis of its surface functional groups.

Thermal degradation of the polymer impregnated with modifier runs in quite a different way. Figure 2c presents spectra of evolved gases at temperatures around determined Tmax values to show differences at each stage of decomposition. In the first phase of the process (352 °C) a dominating product is SO2, which can be identified by all its characteristic bands. Another one is CO2 but its amount is not as high as the former substance. There are also not very intense bands of aniline (at 1606 and 1506 cm−1) and CO proving their presence, but weak intensity means low concentration of these compounds. Such small amounts of released aniline may come from the decomposition of sulfanilic acid deposited (physically adsorbed) on the outer surface of the precursor beads. The SA molecules in the porous structure still remain trapped inside as if they were chemisorbed.

When temperature reaches 414 °C the main decomposition product is CO2. Small amounts of aniline and CO are still evolved. Additionally, residual water and CH4 appear in the spectrum. The composition of gases at final stage (600 °C) is very similar to previous one. However, the bands from water and methane have almost completely disappeared, meaning that the process of their releasing is over. This observation suggests that at about 400 °C surface of the polymer is already charred and further structural changes occur in this newly formed carbonized matter.

The differences in decomposition of the studied materials are evident. And the presented results allow to conclude that SA undoubtedly actively participates in modification process under carbonization conditions. During impregnation, the modifier penetrates deep into the porous structure of the polymer. In this limited space SA is not able to produce crystal structures, which definitely reduces its thermal stability and can lead to increased reactivity especially at elevated temperatures.

Assuming such a pathway, it can also be explained why decomposition of P2 impr started at lower temperature. The modifier without forming a crystalline phase, as less thermally stable, decomposes more easily and the evolved gases/SO2 immediately react with the polymer, initiating its oxidation by formation of oxygen functional groups on its surface. Consequently, in the products of thermal decomposition of P2 impr, small amounts of SO2 are released only at the first stage, and then CO2 becomes the main product as the result of degradation of the oxidized polymer. Additionally, a significant mass loss during the carbonization of this sample also confirm that strong oxidation of the polymer has occurred.

Another important aspect worth mentioning, is very low concentration of aniline in the evolved products of P2 impr decomposition. To explain this phenomenon, the possibility of interactions or even chemical reactions, between, e.g., the polymer and the modifier, should be taken into account as it was mentioned above. This approach allows to justify the entrapment of aniline in the porous structure of the polymer. Moreover, such an aromatic compound remaining in the porous structure of the carbonized precursor, on the one hand, contributes to the restriction of the pore width and reduction of the porosity of the material, but on the other hand, it allows to obtain pores of a more uniform size. This effect has been described for different aromatics by Kawabuchi [20, 40, 41].

Porosity

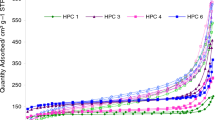

To confirm the above assumption more extended studies of porous structure of the prepared materials were performed. The obtained results are collected in Fig. 3 and in Table 3.

According to the presented data specific surface area (ABET) of the carbons prepared at different temperatures changes in the range of 380–495 m2 g−1. Their values initially increase to the highest obtained for C2-600 and then decrease. It is mainly related to the formation and transformation of microporous structures, as similar relation is observed for micropore volumes (Vmi). In case of the mesopore volumes (Vme) gradual reduction of their values takes place. Since mesopores account for about 70% of the total pore volume (Vtot), this parameter also shows the identical tendency.

The nitrogen adsorption–desorption isotherms of all the studied materials (Fig. 3a and S1) have the same shapes which proves the structural similarity of both polymeric hybrid precursor (P2) and the carbonized materials. The presence of hysteresis loops confirm occurrence of the capillary condensation in mesopores with width exceeding 4 nm [42]. More accurate information on porosity development can be obtained from the pore size distribution plots shown in Fig. 3b and c. Generally, for all the materials two regions can be distinguished. One covering the range of micropores and the other including mesopores with widths from 6 to 30 nm.

When comparing the pore size distributions of the samples carbonized gradually increasing temperatures, some changes in porous structure become visible. In case of C2-450, peak representing micropores is wide with maximum at about 1 nm. Whereas for the sample prepared at 600 °C it is more narrow and its maximum is shifted to 0.76 nm. The carbons C2-750 and C2-900 have even narrower micropore size distributions, but maxima remain almost unchanged, confirming the mechanism of carbon deposition described in previous section. Mesopore size distributions are very uniform and almost identical for all the carbonized samples. In their bimodal curves dominate pores of 14–28 nm width with maximum about 22 nm while those of 6–14 nm make a much smaller contribution to the volume of the mesopore.

The extent of changes becomes clear when the comparison also takes PSD of P2 into account (Figure S2). It can be seen that for mesopores in the size range of 15–30 nm, only minor modifications occur and they mainly concern the volume of pores, whereas their widths do not change significantly. A much greater difference refers to the range covering sizes up to ca 3 nm. It is clearly visible that the transformation of P2 porosity during carbonization affects just this area since precursor possesses micro-and mesopores approximately 0.7 nm wider than materials after carbonization. Subsequent alterations happen gradually, and therefore, micropore size distribution of C2-450 is wider but it narrows for the other carbons (C2-600 and C2-750).

Surface chemical heterogeneity

Chemical heterogeneity of the surfaces was studied with the use of elemental analysis, FTIR and Raman spectrophotometry and XPS technique to ensure a possibly complementary interpretation of the obtained data.

Results of elemental and XP analysis (Table 4 and Fig. 4) show that in the structure of the nanoporous hybrid materials: carbon, hydrogen, nitrogen, oxygen and silicon can be found. Interestingly sulfur was not detected which proves that sulphonyl groups were thoroughly decomposed under heat treatment. Contents of the individual elements depend on carbonization temperature. The percentage of C, H and N slightly decreases with increasing temperature due to the thermal decomposition of the polymer precursor. The process is accompanied by the formation of a charred product. An inverse relationship is observed for oxygen and silicon, which is the result of converting units derived from trimethoxyl(vinyl)silane into silica and silicate moieties. These transformations are confirmed by ATR-FTIR spectra (Fig. 5) described below. Some differences between the data from classical elemental analysis and the results of high resolution X-ray photoelectron can be explained by the fact that the former method reflects composition of the bulk material while the latter only the composition of the outer surface layer.

The most intense band in the ATR spectra of all the studied hybrid carbons is that of silicon derivatives. Its considerable width (1210–1000 cm−1) is characteristic of silica and silicate species (Table 5). In this range both symmetric (at about 1030 cm−1) and asymmetric (at 1108 and 1062 cm−1) stretching vibrations of Si–O–Si can be observed. Among them the latter (at ~ 1060 cm−1) is the strongest which proves random and disordered structure of silicate network [9,10,11, 43, 44]. Very detailed studies in this matter, performed by Park et al. [11], revealed that relative intensity of the band at about 1050 cm−1 reflected a local symmetry around Si–O–Si bonding and an increase in its intensity indicated a lower symmetry typical for networks with random structure. Moreover, they observed significant increase in this band for the samples heat treated in temperature range up to 450 °C. The observation was explained by the secondary condensation of alkoxyl and hydroxyl species and the volatilization of highly symmetric cage-like structures of a low molecular weight.

In this study, we also observe a gradual increase in the intensity of the band located at 1050 cm−1 for carbons prepared at 450–750 °C, while its decrease is registered only for the sample carbonized at 900 °C. Additionally, the other bands overlap the most intense one, causing its asymmetry, and therefore they are visible only as a convexity on its slopes. From the right shoulder of this band a small peak gradually emerges. Its position shifts from 967 to 955 cm−1 suggesting structural change in Si–O–C bonding as former value is typical for linkages to aliphatic carbons while the latter to aromatic rings [44]. Such transformation could be possible when methyl group in Si–O–CH3 would be substituted by aromatic ring of carbonized material, what is schematically shown in Fig. 6 beneath.

This course of the reaction is confirmed by the presence of methane in evolved gaseous products revealed during TG analysis especially at higher temperature. Tissot et al. studied possible mechanisms of Si–O–C linkages dissociation and showed that depending on surface structure and properties, both Si–O and O–C bonds can be broken [45].

The course of the transformation (Fig. 6) should take into account the possibility of the formation of an intermediate product, which are, e.g., silanol groups. In the largest amount, they were formed in the process of partial hydrolysis of trimethoxyl(vinyl)silane unit already at the stage of the polymeric precursor synthesis. As it was described in supplement file, silanol and methoxyl groups underwent condensations to form silicate species, but some of them did not participate in the reaction or were formed at a later stage. Their presence can be confirmed by a weak band in the range 830–905 cm−1 still visible for C2-450 and C2-600. In case of the carbons (C2-750 and C2-900) prepared at higher temperatures, this band becomes visible as a shoulder, indicating the disappearance of these species. The last band related to silicon derivatives is that of Si–C bond, which vibrations typically occurs in the range of 1250–1280 cm−1. Its location about 1272–1274 cm−1 is due to the presence of Si–C bonds next to Si–O–CH3 like, e.g., in silicate compounds. On the other hand, in case of siloxanes the Si–C band vibrates at a lower wave number value (1220–1265 cm−1). Thus, the shift and partial reduction of the intensity of described band confirms structural changes occurring in the material under carbonization conditions.

Other bands of medium intensities in the range of 1650–1450 and below 850 cm−1 are derived from polyaromatic compounds that are formed as a result of thermal treatment of the polymer precursor. These complex polycyclic aromatic structures give rise to small graphite-like carbon planes creating irregular clusters in the structure of the carbonized material. This structural reorganization will be described in more detail in the next paragraph.

The band at about 1700 cm−1 is due to a presence of carbonyl group. Its position is not the same as in P2 polymer where vibration of amide group of methacrylamide units is observed at 1671 cm−1 (Figure S3). The shift of the band toward higher wave number values confirms stretching of imide moieties (1670–1740 cm−1) in C2-450 and C2-600 samples. In case of C2-750 C=O band almost thoroughly disappears suggesting decomposition of imide species. While two very small peaks appearing at ~ 1740 and 1710 cm−1 can be caused by vibrations of aldehyde and carboxyl groups, respectively. In the last sample, the carbonyl band is located at 1717 cm−1. It may be assigned to carboxyl or ketone moieties which arose as a result of oxidation of residual aliphatic chains during the carbonization stage or later during the cooling process [46].

In order to get more details and better characterize the surface structure of the tested materials XPS analysis were performed. High resolution X-ray photoelectron (XP) spectra of C 1 s excitation revealed numerous carbon species on the surface of the studied hybrid materials. An exemplary deconvoluted XP spectra is presented in Fig. 7.

Deconvolution processes were carried out according to the recommendations and standards commonly used in the analysis of carbon materials [47,48,49,50,51,52,53]. Typical ranges of binding energies (B.E.) for C 1 s, O 1 s, N 1 s, and Si 2p species on carbonaceous materials adopted for the purposes of these studies as well as those reported in the literature [43, 45, 54,55,56,57,58,59,60] are collected in Table 6.

Figure 8 presents percentage contents of individual deconvoluted peaks in C 1 s envelopes of all the studied hybrid carbons. The results were divided into these related to carbon skeletal structure (left panel) and other species where carbon is present in an oxidized form (right panel).

Analysis of the obtained data allows to investigate the transformation that takes place under carbonization conditions. With the increase in temperature, initially a small and then sharp rise of primary C–C is observed, which proves formation of graphite-like structures. As the process is favored by high temperature, the top value (65%) was achieved for C2-900. The development of aromatic structures is also confirmed by a plot showing the sp2/sp3 ratio, which illustrates the relative content of aromatic moieties versus aliphatic/cycloaliphatic ones. For materials prepared at relatively low temperatures (C2-450, C2-600 and C2-750) its value increases from 0.02 to 0.20, indicating that non-aromatic forms dominate in the structure over aromatic. However, for the material carbonized at 900 °C, a rapid increase in sp2/sp3 ratio (exceeding 3) is observed, clearly demonstrating the favored formation of aromatic structures.

A significant reorganization of the precursor structure during carbonization is also indicated by changes observed for species described as C–C low and C–C high. Their content is initially high and changes significantly with increasing carbonization temperature, to drop dramatically in the case of the C2-900 sample. The C–C low and C–C high structures are derived from polymer chains, which in the precursor material form an irregular and tangled network of cross-linked chains. Under the influence of high temperature, they undergo further changes including processes such as: further cross-linking, dehydrogenation, cyclization and aromatization, creating a turbostratic structure typical of carbonized materials [13, 51,52,53,54,55,56,57,58,59,60].

Among oxidized carbon species those with the nature of C–O/Csp3–N/C–N=O connections are subject to the greatest fluctuations indicating their strong activity in changes taking place during carbonization. In case of carbonyl containing groups (C=O/N–(Csp2=O)/N–C(O)–C/Si–O–C) changes are very minor, which may confirm the stability of most of these species up to 750 °C. For C2-900 complete disappearance of these functionalities is observed. As it was described by Grassie et al. [39] polymers containing methacrylamide groups are easily converted to cyclic imide derivatives. Their characteristic feature is high thermal stability up to approx. 600 °C [71]. Further heating above this temperature leads to formation of aromatic structures like pyrrolic, pyridinic or pyridone and so called quaternary N species where nitrogen is incorporated in almost flat graphite-like fragments [56].

Similar thermal behavior is exhibited by C(O)–O/N–C(N)–N/N–C(O)–N, which include, among others, carboxylic/lactone groups. Their contents are about 4% and show a slightly increasing trend with rise of temperature.

It should be emphasized, that the unambiguous identification of specific groups and the changes they undergo, based only on the C 1 s region cannot be clearly performed due to the large variety of groups, with the same or very similar binding energies.

On the basis of the data presented in Fig. 9, it can be seen that singly bonded oxygens predominate in the structure of hybrid carbons. It also should be noted that for C2-450 the aliphatic and aromatic C–O species are present in very similar amounts. However, with the progress of carbonization their ratio changes, what can be observed in case of subsequent samples. The aliphatic forms begin to dominate over the aromatic ones. Additionally, it should be kept in mind that binding energies of ~ 532 and ~ 533 eV can be assigned not only to C–O species. Comparative values of B.E. are characteristic of Si–O bonds. Taking into account FTIR observation described above and combining them with the obtained XPS results it should be stated that the significant increase in functionalities of 532 eV is related to reorganization of Si–O–Si bonds.

These results are consistent with the data obtained from XPS Si 2p (Fig. 10 and S4). In the high resolution Si 2p spectrum, the peak is broad indicating the presence of different chemical states of this element. Since their assignment to specific binding energies is not unambiguously fixed as in the case of C or O, and often the same states are assigned to various B.E. values by different authors [45, 72, 73], we decided to separate only two peaks in the our deconvolution. The first, at 102.4 eV, includes lower oxidation states (Si2+ and Si3+) which can be found in compounds like silicones, siloxanes or silicates and are assigned to Si(–O–)2/Si(–O–)3 bindings where Si–O species form tetrahedrons with two or three bridging oxygens and two or one non-bridging oxygens, respectively. The second, at 103.2 eV comprise all states of Si4+ (Si(–O–)4/Silica), in which Si–O bonds form tetrahedrons with four bridging oxygens. Such species are present in orthosilicates or amorphous silica.

In Fig. 10a, one can see that the position of the second peak changes slightly and mildly in the narrow range of 103.0–103.3 eV approaching, but not reaching, the typical for SiO2 value of 103.5 eV, but ultimately no or only a small amount of crystalline silica is formed.

From Fig. 10b follows that amount of Si4+ species initially increases and then rapidly decreases to 2% in case of the C2-900 sample. According to this observation, it can be stated that only this marginal amount is silica, because the temperature as high as 900 °C does not change it. The rest must consist of moieties of other type (e.g., Si–O–Caliph/arom) which may undergo further transformation or reorganization during heat treatment not exceeding 900 °C.

In this instance, the large variation in the B.E. values of the first peak (Fig. 10a) becomes understandable. They just reflect the changes in the state of Si atom and its surroundings. For the hybrid carbons prepared at 450, 600 and 750 °C the observed changes in B.E. values are not very large and the gradual decrease in areas of the first peak is accompanied by the same increase in the second peak. However, in case of the C2-900 carbon a drastic change of this trend is visible. It should be emphasized that the same tendency is visible in the ATR spectra (Fig. 5) indicating that the peak at wavenumber ~ 1060 cm−1 corresponds to that of B.E. 103.2 eV confirming the correctness of the considerations regarding formation of low symmetry random network described there. In case of the compounds studied by Park et al. depending on the type of applied monomers, such process took place in the range of 280–500 °C [11]. In turn, Liu et al. [12] demonstrated that the presence of higher symmetry species like, e.g., polyhedral oligomeric silsesquioxanes in composites suppressed their thermal decomposition to ca. 700 °C. Moreover, they explained this phenomenon by a formation of “inorganic silica-like phase” on the surface of the sample, which acted as a protective barrier preventing further degradation processes. This last explanation seems to be in line with the results obtained in this study.

The smallest peak observed in XP spectra (Fig. 11) belongs to nitrogen species.

The origin of the nitrogen species remaining in the carbon structure is related to the presence of methacrylamide unit in the hybrid polymeric precursor. According to studies performed by Grassie et al. [39, 74] and Dyke et al. [75] under heat treatment most of amide groups decompose at relatively low temperature (ca 400 °C). Further heating leads to more complex processes including imidization, dehydration, cyclization, hydrogen transfer and so on [54,55,56, 75] which contribute to the incorporation of nitrogen into the structure of the carbon that is formed. For this reason, in C2-450 mainly pyridinic/–CN/imide and NH2/–C(O)N/pyridone type moieties are present, but their combined contents gradually decrease for carbons prepared at higher temperatures. The C2-600 hybrid carbon contains nitrogen bound mainly in form of five- or six-membered rings. In case of the next two samples significant increase in N-graphitic and N-oxide species is visible. Additionally, the share of these functionalities together with pyrrolic ones is on almost the same level for C2-750 and C2-900 proving their stability under the studied conditions. The major structural change involves a simultaneous decrease in –NH2/–C(O)N/pyridone groups and increase in pyridinic/imide ones by the same amount, suggesting that the former groups are being transformed into the latter, according to the mechanism described above.

Structural heterogeneity and its reorganization under thermal treatment

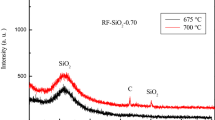

The PXRD analyses, presented in Fig. 12, confirm the structural rearrangement of silicone environment in the materials under investigation. Although all the recorded profiles exhibit only a halo pattern typical of amorphous phase, which dominates in the studied carbon structure, weak and broad diffraction peaks also can be distinguished. Their location is in one of three regions of 2Θ angles: below 8°, 14–30° and above 40°.

According to the literature [9, 10, 76], the peak in the first range can be attributed to fourfold siloxane rings, that may origin from cyclic structures arranged in a macromolecular network of silicates or silsesquioxanes, while that in the range 14–30° to amorphous silica. In PXRD patterns of heavily disordered carbonaceous materials peaks are observed at ca. 23° and 43° [77,78,79]. The former is attributed to a small number of almost parallel graphene–like layers with the stacking distances being greater than in graphite (3.35 Å), while the latter (43º) is related with the average dimension of the crystallite in the in-plane direction [79,80,81]. Therefore, they are assigned to (002), (100) planes of graphite, respectively. For carbons prepared below 1000 °C, the peaks are usually broad and their intensities are low, which indicates a very little crystallinity, created only by small carbon clusters arranged in two layers on average [80,81,82,83].

In the pattern of C2-450, the peak at 7.2° has higher intensity and that at 20.6° is flattened and less intense. In case of the C2-600 carbon, the first peak becomes asymmetric and more flat with top at 6.0°, while the intensity of the other is higher and shifted toward higher angles of 2Θ (21.7°). The diffraction patterns of the carbons prepared at 750 and 900 °C are almost identical. The peaks below 10° 2Θ are not observed, whereas those at 23.8° do not change their position, only the intensity of C2-900 peak is slightly lower than that of C2-750. The observed changes in the positions and intensities of the PXRD peaks, occurring under the influence of heat treatment, indicate the rearrangement of silica species in the complex structure of the hybrid carbon. The gradual disappearance of cyclic and more symmetrical moieties is accompanied by an increase in amorphous silica species and the formation of layers of carbon clusters. The peak in the third range rises gradually for the carbons obtained at temperature of 600 °C or higher. The increase in its intensity can be attributed to the enlargement of small condensed aromatic structures into an increasing number of clusters merging with each other and forming graphite-like layers.

The development of such structure of the carbons is also confirmed by Raman spectroscopy, which results are presented in Fig. 13.

For the C2-450 sample a series of small, not fully resolved peaks can be observed. Their positions (1591, 1469, 1366, 1244 and 1149 cm−1) correspond quite well with the peaks proposed by Smith et al. [84]: G, A, D, DS and S, respectively. The peak G is associated with the presence of sp2 carbon clusters in the carbonized precursor. Defective polyaromatic hydrocarbons (PAHs) of various sizes are often used as a model to represent their structure. The peak A origin from out of plane deformations caused by irregular structures (e.g., 5-membered rings) adjacent to 6-membered rings and heteroatoms. The peak D is a result of combined breathing and Kekule vibrations of PAHs. Its location is related to the size of aromatic system, for large and more symmetric ones it is close to 1350 cm−1, but for smaller ones with lower symmetry it is shifted toward 1400 cm−1. When small PAHs systems are present in the carbon structure also the DS peak can be distinguished as a consequence of their breathing modes. In turn, this type of vibration for 7-membered rings with Kekule modes in adjacent 6-membered systems or breathing vibration of benzene connected to heteroatom give rise to the peak S [84].

Very low intensity of the peaks in C2-450 spectrum indicates that the formation of these structures begins at a very early stage. With the increase in heat treatment temperature, a strongly pronounced rise in the D and G peaks, characteristic of carbons with amorphous structure, can be observed. The position of the G peak changes very slightly from 1591 (C2-450) to 1598 cm−1 (C2-900), i.e., toward the value of 1600 cm−1 typical of asymmetric stretching vibrations of the six-membered aromatic ring. In addition, the peak becomes narrower, indicating an increase in the size of carbon clusters and an improvement in their symmetry.

Of the three bands initially observed in the range of 1500–900 cm−1, the D band gradually becomes dominant. Its position also changes from 1368 to 1355 cm−1, indicating the formation of larger and more symmetrical/less defective aromatic systems. The obtained Raman results are consistent with those of ATR spectra and XRD patterns and, together, create a complete and coherent picture of structural changes taking place during the synthesis of hybrid porous carbons.

Conclusions

Four nanoporous hybrid carbons were synthesized by carbonization of the terpolymeric hybrid precursor impregnated with sulfanilic acid as the surface modifier. The thermal treatment was performed at 450, 600, 750 and 900 °C, what allowed to investigate the gradual changes taking place in the morphological and chemical structure of the prepared materials.

The TGA-EGA technique not only showed differences between the course of thermal degradation of pristine and impregnated precursor, but also revealed the significant decrease in thermal resistance of the latter which was due to the inability to crystallize the modifier in the porous structure of the precursor.

The prepared hybrid carbons were characterized by a very homogeneous bimodal porosity with micropores less than 1 nm wide and mesopores in the range of 14–28 nm. The homogeneity of mesopores was strongly related with the porosity of the hybrid polymeric precursor, but in case of the micropores, it was caused by the formation of the deposit from the decomposed modifier on the pore walls.

The comprehensive studies carried out using spectroscopic techniques (ATR, XPS, Raman, XRD) revealed the structural and chemical changes that occurred during the carbonization of the hybrid terpolymer precursor. It was demonstrated that transformation process was very complex and included not only charring of the polymer, but also reorganization of inorganic portion of the materials. In the studied range of temperatures from 450 to 900 °C, cyclic and more symmetrical structures of silicate derivatives were gradually lost, and in their place, amorphous silica-like structures were formed. At the same time, progressive aromatization and ordering of carbonized organic matter took place. This process involved also surface functional groups. N-containing moieties were partially removed (amides) and partially built into carbon clusters giving pyridinic, pyrrolic and graphitic-like structures which at higher temperature were further converted into oxidized derivatives, while O-containing functionalities, like, e.g., carboxyl and carbonyls, were mainly removed from the surface.

References

Wu T, Ke Q, Lu M, Pan P, Zhou Y, Gu Z, Cui G, Lu H. Recent advances in carbon-silica composites: preparation, properties, and applications. Catalysts. 2022;12:573. https://doi.org/10.3390/catal12050573.

Li H, Chen L, Li X, Sun D, Zhang H. Recent progress on asymmetric carbon- and silica-based nanomaterials: from synthetic strategies to their applications. Nano-Micro Lett. 2022;14:45. https://doi.org/10.1007/s40820-021-00789-y.

Gerasymenko N, Reyes RP, Espinosa MÁH, Mora ES, Petranovskii V. The adsorbing properties of mesoporous silica/carbon composites prepared by direct carbonization of the template as the sole source of the carbon phase. Adv Compos Lett. 2019;28:2633366X1989599. https://doi.org/10.1177/2633366X19895993.

Meunier V, Ania C, Bianco A, Chen Y, Choi GB, Kim YA, Koratkar N, Liu C, Tascon JMD, Terrones M. Carbon science perspective in 2022: current research and future challenges. Carbon N Y. 2022;195:272–91. https://doi.org/10.1016/j.carbon.2022.04.015.

Erigoni A, Diaz U. Porous silica-based organic-inorganic hybrid catalysts: a review. Catalysts. 2021;11:79. https://doi.org/10.3390/catal11010079.

Meier D, Huch V, Kickelbick G. Aryl-group substituted polysiloxanes with high-optical transmission, thermal stability, and refractive index. J Polym Sci. 2021;59:2265–83. https://doi.org/10.1002/pol.20210316.

Blanco I, Zaharescu T. The effect of polyhedral oligomeric silsesquioxanes (POSSs) incorporation in ethylene-propylene-diene-terpolymer (EPDM): a thermal study. J Therm Anal Calorim. 2022;147:5313–21. https://doi.org/10.1007/s10973-021-10994-x.

Laine RM. Nanobuilding blocks based on the [OSiO1.5]x (x= 6, 8, 10) octasilsesquioxanes. J Mater Chem. 2005;15:3725. https://doi.org/10.1039/b506815k.

Giasuddin ABM, Cartwright A, Britt DW. Silica nanoparticles synthesized from 3,3,3-Propyl(trifluoro)trimethoxysilane or n -propyltrimethoxysilane for creating superhydrophobic surfaces. ACS Appl Nano Mater. 2021;4:4092–102. https://doi.org/10.1021/acsanm.1c00398.

Rios X, Moriones P, Echeverría JC, Luquin A, Laguna M, Garrido JJ. Ethyl group as matrix modifier and inducer of ordered domains in hybrid xerogels synthesised in acidic media using ethyltriethoxysilane (ETEOS) and tetraethoxysilane (TEOS) as precursors. Mater Chem Phys. 2013;141:166–74. https://doi.org/10.1016/j.matchemphys.2013.04.042.

Park ES, Ro HW, Nguyen CV, Jaffe RL, Yoon DY. Infrared spectroscopy study of microstructures of poly(silsesquioxane)s. Chem Mater. 2008;20(4):1548–54. https://doi.org/10.1021/cm071575z.

Liu YR, Huang YD, Liu L. Thermal stability of POSS/methylsilicone nanocomposites. Compos Sci Technol. 2007;67:2864–76. https://doi.org/10.1016/j.compscitech.2007.01.023.

Inagaki M, Kang F. Fundamental science of carbon materials. In: Materials science and engineering of carbon: fundamentals. Elsevier; 2014. p. 17–217. https://doi.org/10.1016/B978-0-12-800858-4.00002-4.

Puziy AM, Poddubnaya OI, Sobiesiak M, Gawdzik B. Structural and surface heterogeneity of phosphorus-containing polyimide-derived carbons: effect of heat treatment temperature. Adsorption. 2013;19(2–4):717–22. https://doi.org/10.1007/s10450-013-9497-4.

Liu W, Xie H, Zhang J, Zhang C. Sorption removal of cephalexin by HNO3 and H2O2 oxidized activated carbons. Sci China Chem. 2012;55:1959–67. https://doi.org/10.1007/s11426-011-4488-3.

Jedynak K, Charmas B. Adsorption properties of biochars obtained by KOH activation. Adsorption. 2023. https://doi.org/10.1007/s10450-023-00399-7.

Ahmadpour A, Do D. The preparation of active carbons from coal by chemical and physical activation. Carbon N Y. 1996;34:471–9.

Sobiesiak M. Nanoporous carbons obtained by carbonization of copolymers impregnated by salts. Adsorption. 2012;19:349–56. https://doi.org/10.1007/s10450-012-9457-4.

Bernal V, Giraldo L, Moreno-Piraján JC. Thermodynamic study of the interactions of salicylic acid and granular activated carbon in solution at different pHs. Adsorpt Sci Technol. 2018;36:833–50. https://doi.org/10.1177/0263617417730463.

Kawabuchi Y, Sotowa C, Kuroda K, Kawano S, Whitehurst DD, Mochida I. Chemical vapor deposition of organic compounds over active carbon fiber to control its porosity and surface function. ACS Symp Ser. 1997;681:61–70.

Moreira RFP, José H, Rodrigues A. Modification of pore size in activated carbon by polymer deposition and its effects on molecular sieve selectivity. Carbon N Y. 2001;39:2269–76. https://doi.org/10.1016/S0008-6223(01)00046-X.

Wang Z, Li F, Ergang N, Stein A. Effects of hierarchical architecture on electronic and mechanical properties of nanocast monolithic porous carbons and carbon-carbon nanocomposites. Chem Mater. 2006;18:5543–53.

Chen L, Singh RK, Webley P. Synthesis, characterization and hydrogen storage properties of microporous carbons templated by cation exchanged forms of zeolite Y with propylene and butylene as carbon precursors. Microporous Mesoporous Mater. 2007;102:159–70. https://doi.org/10.1016/j.micromeso.2006.12.033.

Liang C, Li Z, Dai S. Mesoporous carbon materials: synthesis and modification. Angew Chem Int Ed Engl. 2008;47:3696–717. https://doi.org/10.1002/anie.200702046.

Puech P, Dabrowska A, Ratel-Ramond N, Vignoles GL, Monthioux M. New insight on carbonisation and graphitisation mechanisms as obtained from a bottom-up analytical approach of X-ray diffraction patterns. Carbon N Y. 2019;147:602–11. https://doi.org/10.1016/j.carbon.2019.03.013.

Seredych M, Bandosz TJ. Surface properties of porous carbons obtained from polystyrene-based polymers within inorganic templates: role of polymer chemistry and inorganic template pore structure. Microporous Mesoporous Mater. 2007;100:45–54. https://doi.org/10.1016/j.micromeso.2006.10.013.

Inagaki M, Park KC, Endo M. Carbonization under pressure. New Carbon Mater. 2010;25:409–20. https://doi.org/10.1016/S1872-5805(09)60042-1.

Podkościelna B, Fila K, Gil M, Nowak J. Synthesis and characterization of new hybrid microspheres with amide functionalization. Adsorpt Sci Technol. 2017;35:422–31. https://doi.org/10.1177/0263617417694364.

NIST database Available online: https://webbook.nist.gov/chemistry/

Low JN, Glidewell C. A quasi-diamondoid hydrogen-bonded framework in anhydrous sulfanilic acid. Acta Crystallogr Sect C Cryst Struct Commun. 2002;58(4):o209–11. https://doi.org/10.1107/S0108270102003025.

Bassilakis R, Carangelo R, Wojtowicz M. TG-FTIR analysis of biomass pyrolysis. Fuel. 2001;80:1765–86.

Herrera M, Wilhelm M, Matuschek G, Kettrup A. Thermoanalytical and pyrolysis studies of nitrogen containing polymers. J Anal Appl Pyrolysis. 2001;58–59:173–88. https://doi.org/10.1016/S0165-2370(00)00193-5.

Wang S, Wang Q, Hu YM, Xu SN, He ZX, Ji HS. Study on the synergistic co-pyrolysis behaviors of mixed rice husk and two types of seaweed by a combined TG-FTIR technique. J Anal Appl Pyrolysis. 2015;114:109–18. https://doi.org/10.1016/j.jaap.2015.05.008.

Sobiesiak M, Podkościelna B, Mazur L. Investigations of the carbonization process of hybrid polymer microspheres using the TGA-EGA method: assessment of the impact of sulphanilic acid on the process. J Therm Anal Calorim. 2024. https://doi.org/10.1007/s10973-024-13236-y.

Zhu HM, Yan JH, Jiang XG, Lai YE, Cen KF. Study on pyrolysis of typical medical waste materials by using TG-FTIR analysis. J Hazard Mater. 2008;153:670–6. https://doi.org/10.1016/j.jhazmat.2007.09.011.

Tudorachi N, Bunia I. Synthesis and thermal investigation by TG-FTIR-MS analysis of some functionalized acrylic copolymers and magnetic composites with Fe3O4. J Anal Appl Pyrolysis. 2015;116:190–201. https://doi.org/10.1016/j.jaap.2015.09.010.

Cuthbertson AA, Lincoln C, Miscall J, Stanley LM, Maurya AK, Asundi AS, Tassone CJ, Rorrer NA, Beckham GT. Characterization of polymer properties and identification of additives in commercially available research plastics. Green Chem. 2024. https://doi.org/10.1039/d4gc00659c.

Fernández-Berridi MJ, González N, Mugica A, Bernicot C. Pyrolysis-FTIR and TGA techniques as tools in the characterization of blends of natural rubber and SBR. Thermochim Acta. 2006;444:65–70. https://doi.org/10.1016/j.tca.2006.02.027.

Grassie N, McNeill IC, Samson JNR. The thermal degradation of polymethacrylamide and copolymers of methacrylamide and methyl methacrylate. Eur Polym J. 1978;14:931–7. https://doi.org/10.1016/0014-3057(78)90092-7.

Kawabuchi Y, Kishino M, Kawano S, Whitehurst DD, Mochida I. Carbon deposition from benzene and cyclohexane onto active carbon fiber to control its pore size. Langmuir. 1996;12:4281–5. https://doi.org/10.1021/la960292a.

Kyotani T. Control of pore structure in carbon. Carbon N Y. 2000;38:269–86. https://doi.org/10.1016/S0008-6223(99)00142-6.

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem. 2015;87:1051–69. https://doi.org/10.1515/pac-2014-1117.

Simonsen ME, Sønderby C, Li Z, Søgaard EG. XPS and FT-IR investigation of silicate polymers. J Mater Sci. 2009;44:2079–88. https://doi.org/10.1007/s10853-009-3270-9.

Socrates, G. In Infrared and Raman Frequencies Characteristic Group; George Socrates, The University of West London, Middlesex, U.K., Ed.; Third Edit.; John Wiley & Sons LTD: Chichester, 2001; ISBN 0-471-85298-8

Tissot H, Gallet J-J, Bournel F, Pierucci D, Silly M, Sirotti F, Rochet F. Dissociation of ethoxysilane and methoxysilane on Si(001)-2 × 1 and Si(111)-7 × 7 at room temperature: a comparative study using synchrotron radiation photoemission. J Phys Chem C. 2014;118:24397–406. https://doi.org/10.1021/jp5050767.

Boehm H. Surface oxides on carbon and their analysis: a critical assessment. Carbon N Y. 2002;40:145–9. https://doi.org/10.1016/S0008-6223(01)00165-8.

Gengenbach TR, Major GH, Linford MR, Easton CD. Practical guides for x-ray photoelectron spectroscopy (XPS): Interpreting the carbon 1s spectrum. J Vac Sci Technol A. 2021;39: 013204. https://doi.org/10.1116/6.0000682.

Morgan DJ. Comments on the XPS analysis of carbon materials. C. 2021;7(3):51. https://doi.org/10.3390/c7030051.

Greczynski G, Hultman L. The same chemical state of carbon gives rise to two peaks in X-ray photoelectron spectroscopy. Sci Rep. 2021;11:1–5. https://doi.org/10.1038/s41598-021-90780-9.

Smith M, Scudiero L, Espinal J, McEwen JS, Garcia-Perez M. Improving the deconvolution and interpretation of XPS spectra from chars by ab initio calculations. Carbon N Y. 2016;110:155–71. https://doi.org/10.1016/j.carbon.2016.09.012.

Seredych M, Tamashausky AV, Bandosz TJ. Graphite oxides obtained from porous graphite: the role of surface chemistry and texture in ammonia retention at ambient conditions. Adv Funct Mater. 2010;20:1670–9. https://doi.org/10.1002/adfm.201000061.

Puziy AM, Poddubnaya OI, Socha RP, Gurgul J, Wisniewski M. XPS and NMR studies of phosphoric acid activated carbons. Carbon N Y. 2008;46:2113–23. https://doi.org/10.1016/j.carbon.2008.09.010.

Huang C, Puziy AM, Poddubnaya OI, Hulicova-Jurcakova D, Sobiesiak M, Gawdzik B. Phosphorus, nitrogen and oxygen co-doped polymer-based core-shell carbon sphere for high-performance hybrid supercapacitors. Electrochim Acta. 2018;270:339–51. https://doi.org/10.1016/j.electacta.2018.02.115.

Ayiania M, Smith M, Hensley AJR, Scudiero L, McEwen J-S, Garcia-Perez M. Deconvoluting the XPS spectra for nitrogen-doped chars: an analysis from first principles. Carbon N Y. 2020;162:528–44. https://doi.org/10.1016/j.carbon.2020.02.065.

Zhu X, Yang S, Wang L, Liu Y, Qian F, Yao W, Zhang S, Chen J. Tracking the conversion of nitrogen during pyrolysis of antibiotic mycelial fermentation residues using XPS and TG-FTIR-MS technology. Environ Pollut. 2016;211:20–7. https://doi.org/10.1016/j.envpol.2015.12.032.

Pels J, Kapteijn F, Moulijn J, Zhu Q, Thomas K. Evolution of nitrogen functionalities in carbonaceous materials during pyrolysis. Carbon N Y. 1995;33:1641–53.

Chen W, Yang H, Chen Y, Chen X, Fang Y, Chen H. Biomass pyrolysis for nitrogen-containing liquid chemicals and nitrogen-doped carbon materials. J Anal Appl Pyrolysis. 2016;120:186–93. https://doi.org/10.1016/j.jaap.2016.05.004.

Shircliff RA, Stradins P, Moutinho H, Fennell J, Ghirardi ML, Cowley SW, Branz HM, Martin IT. Angle-resolved XPS analysis and characterization of monolayer and multilayer silane films for DNA coupling to silica. Langmuir. 2013;29:4057–67. https://doi.org/10.1021/la304719y.

Yang SY, Liu L, Jia ZX, Fu WW, Jia DM, Luo YF. Study on the structure-properties relationship of natural rubber/SiO2 composites modified by a novel multi-functional rubber agent. Express Polym Lett. 2014;8:425–35. https://doi.org/10.3144/expresspolymlett.2014.46.

Guruvenket S, Hoey JM, Anderson KJ, Frohlich MT, Krishnan R, Sivaguru J, Sibi MP, Boudjouk P. Synthesis of silicon quantum dots using cyclohexasilane (Si6H12). J Mater Chem C. 2016;4:8206–13. https://doi.org/10.1039/c6tc01435f.

Schulte-Fischedick, J., FrieB, M., Krenkel, W. Crack Microstructures During the Carbonizing of Carbon Fiber Reinforced Plastics to Carbon/Carbon Composites. In Conference: 12Int. Conf. on Composite Materials-ICCM12; Paris/F, 5–9 July 1999; 1999

Kiciński W, Dyjak S. Nitrogen-doped carbons derived from imidazole-based cross-linked porous organic polymers. Molecules. 2021;26:668. https://doi.org/10.3390/molecules26030668.

Wen-Chao L, Bao-Rong W, Ting L, Rui G, Guang-Yue L, Jie-Ping W. Theoretical insight into tar carbonization mechanism. Chem Phys Lett. 2020;747:137373. https://doi.org/10.1016/j.cplett.2020.137373.

Kiciński W, Dyjak S, Gratzke M. Pyrolysis of porous organic polymers under a chlorine atmosphere to produce heteroatom-doped microporous carbons. Molecules. 2021;26:3656. https://doi.org/10.3390/molecules26123656.

Wang L, Su Y, Gu C. Solution processing of cross-linked porous organic polymers. Accounts Mater Res. 2022;3:1049–60. https://doi.org/10.1021/accountsmr.2c00130.

Gottlieb E, Matyjaszewski K, Kowalewski T. Polymer-based synthetic routes to carbon-based metal-free catalysts. Adv Mater. 2019;31:1804626. https://doi.org/10.1002/adma.201804626.

Grundy M, Ye Z. Cross-linked polymers of diethynylbenzene and phenylacetylene as new polymer precursors for high-yield synthesis of high-performance nanoporous activated carbons for supercapacitors, hydrogen storage, and CO 2 capture. J Mater Chem A. 2014;2:20316–30. https://doi.org/10.1039/C4TA04038D.

Hu B, Kong L-B, Kang L, Yan K, Zhang T, Li K, Luo Y-C. Synthesis of a hierarchical nanoporous carbon material with controllable pore size and effective surface area for high-performance electrochemical capacitors. RSC Adv. 2017;7:14516–27. https://doi.org/10.1039/C7RA01151B.

Zhang B, Jiang Y, Balasubramanian R. Synthesis, formation mechanisms and applications of biomass-derived carbonaceous materials: a critical review. J Mater Chem A. 2021;9:24759–802. https://doi.org/10.1039/D1TA06874A.

Zhao L, Kaiser RI, Lu W, Xu B, Ahmed M, Morozov AN, Mebel AM, Howlader AH, Wnuk SF. Molecular mass growth through ring expansion in polycyclic aromatic hydrocarbons via radical–radical reactions. Nat Commun. 2019;10:3689. https://doi.org/10.1038/s41467-019-11652-5.

Matsumoto T, Nishimura K, Kurosaki T. Ladder-type polyimides based on diaminodibenzofurane. Eur Polym J. 1999;35:1529–35. https://doi.org/10.1016/S0014-3057(98)00236-5.

Bai Z, Tu W, Zhu J, Li J, Deng Z, Li D, Tang H. POSS-derived synthesis and full life structural analysis of Si@C as anode material in lithium ion battery. Polymers (Basel). 2019;11:576. https://doi.org/10.3390/polym11040576.

NIST X-ray Photoelectron spectroscopy database Available online: https://srdata.nist.gov/xps/

Grassie N. Recent work on the thermal degradation of acrylate and methacrylate homopolymers and copolymers. Pure Appl Chem. 1972;30:119–34. https://doi.org/10.1351/pac197230010119.

Van Dyke JD, Kasperski KL. Thermogravimetric study of polyacrylamide with evolved gas analysis. J Polym Sci Part A Polym Chem. 1993;31(7):1807–23. https://doi.org/10.1002/pola.1993.080310720.

Mantz RA, Jones PF, Chaffee KP, Lichtenhan JD, Gilman JW, Ismail IMK, Burmeister MJ. Thermolysis of polyhedral oligomeric silsesquioxane (POSS) macromers and POSS−siloxane copolymers. Chem Mater. 1996;8:1250–9. https://doi.org/10.1021/cm950536x.

Abdulsalam J, Mulopo J, Oboirien B, Bada S, Falcon R. Experimental evaluation of activated carbon derived from South Africa discard coal for natural gas storage. Int J Coal Sci Technol. 2019;6:459–77. https://doi.org/10.1007/s40789-019-0262-5.

Itoi H, Suzuki R, Miyaji M, Matsuura M, Takagi K, Tanabe Y, Goto Y, Kameoka S, Kugimiya S, Iwata H, et al. Hybridization of a polymer inside the pores of activated carbon and pore structural characterization. ACS Appl Polym Mater. 2021;3:3603–11. https://doi.org/10.1021/acsapm.1c00498.

An Z, Wang H, Zhu C, Cao H, Xue J. Synthesis and formation mechanism of porous silicon carbide stacked by nanoparticles from precipitated silica/glucose composites. J Mater Sci. 2019;54:2787–95. https://doi.org/10.1007/s10853-018-3039-0.

Zickler GA, Smarsly B, Gierlinger N, Peterlik H, Paris O. A reconsideration of the relationship between the crystallite size La of carbons determined by X-ray diffraction and Raman spectroscopy. Carbon N Y. 2006;44:3239–46. https://doi.org/10.1016/j.carbon.2006.06.029.

Mubari PK, Beguerie T, Monthioux M, Weiss-Hortala E, Nzihou A, Puech P. The X-ray, Raman and TEM signatures of cellulose-derived carbons explained. C. 2022;8(1):4. https://doi.org/10.3390/c8010004.

Hung C-H, Singh B, Landowski MG, Ibrahim M, Miles AJ, Jensen DS, Vail MA, Dadson AE, Smith SJ, Linford MR. Multi-instrument characterization of poly(divinylbenzene) microspheres for use in liquid chromatography: as received, air oxidized, carbonized, and acid treated. Surf Interface Anal. 2015;47:815–23. https://doi.org/10.1002/sia.5778.

Putman KJ, Rowles MR, Marks NA, de Tomas C, Martin JW, Suarez-Martinez I. Defining graphenic crystallites in disordered carbon: Moving beyond the platelet model. Carbon N Y. 2023;209:117965. https://doi.org/10.1016/j.carbon.2023.03.040.

Smith MW, Dallmeyer I, Johnson TJ, Brauer CS, McEwen JS, Espinal JF, Garcia-Perez M. Structural analysis of char by Raman spectroscopy: improving band assignments through computational calculations from first principles. Carbon N Y. 2016;100:678–92. https://doi.org/10.1016/j.carbon.2016.01.031.

Funding

Horizon-MSCA-2022-SE-01 Project: 101131382—Clean water.

Author information

Authors and Affiliations

Contributions

MS contributed to conceptualization, methodology, synthesis of hybrid carbons, data curation, writing—original draft, visualization, resources, methodology and software, formal analysis and supervision—reviewing and editing. AMP and OIP involved in processing and visualization of XPS and porosity data. MP involved in reviewing and editing manuscript. MS, OIP and MS discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflicts of interest/competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sobiesiak, M., Puziy, A.M., Poddubnaya, O.I. et al. Thermal degradation of nanoporous Si-containing hybrid terpolymer. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13420-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13420-0