Abstract

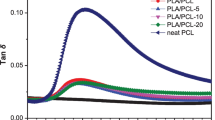

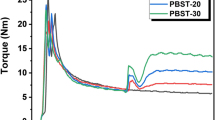

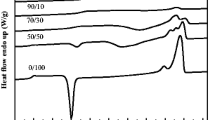

A low-temperature melt blending method was adopted to prepare ternary blends of poly(L-lactide) (PLLA), poly(butylene carbonate) (PBC), and poly(D-lactide) (PDLA), aiming to obtain fully biodegradable blends with well-balanced properties. The in situ formation of stereocomplex polylactide (SC-PLA) crystals was confirmed by torque changes, differential scanning calorimetry results, and wide-angle X-ray diffraction measurements. At a PDLA concentration of 5 mass%, SC-PLA crystals formed a percolating network structure, and the rheological behavior of the blend melts transformed from liquid-like to solid-like. The viscosity ratio between PLLA and PBC melts increased due to the presence of SC-PLA crystals, resulting in an enlargement of the PBC domain size. SC-PLA crystals exhibited an excellent nucleation effect, significantly accelerating the crystallization rate of PLLA. Compared to neat PLLA with elongation at break of 5.2%, PLLA/PBC/PDLA ternary blends containing 2 mass% PDLA with elongation at break of 247.2% presented excellent toughness. This work provided a facile method to prepare PLLA-based material with outstanding crystallization ability and tailored rheological behavior as well as mechanical properties, which had the potential to replace conventional plastic products.

Similar content being viewed by others

References

Zhou ZY, LaPointe AM, Shaffer TD, Coates GW. Nature-inspired methylated polyhydroxybutyrates from C1 and C4 feedstocks. Nat Chem. 2023;15(6):856–61. https://doi.org/10.1038/s41557-023-01187-0.

Castro-Aguirre E, Iñiguez-Franco F, Samsudin H, Fang X, Auras R. Poly(lactic acid)-mass production, processing, industrial applications, and end of life. Adv Drug Deliv Rev. 2016;107:333–66. https://doi.org/10.1016/j.addr.2016.03.010.

Nofar M, Sacligil D, Carreau PJ, Kamal MR, Heuzey MC. Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol. 2019;125:307–60. https://doi.org/10.1016/j.ijbiomac.2018.12.002.

Hamad K, Kaseem M, Yang HW, Deri F, Ko YG. Properties and medical applications of polylactic acid: a review. Express Polym Lett. 2015;9(5):435–55. https://doi.org/10.3144/expresspolymlett.2015.42.

Yi L, Luo S, Cui L, Budai-Szűcs M, Móczó J, Pukánszky B. Processes taking place during the preparation and use of electrospun PLA fibers and their effect on controlled drug release. J Therm Anal Calorim. 2022;147(23):13191–9. https://doi.org/10.1007/s10973-022-11554-7.

Nofar M, Park CB. Poly (lactic acid) foaming. Prog Polym Sci. 2014;39(10):1721–41. https://doi.org/10.1016/j.progpolymsci.2014.04.001.

Menossi M, Salcedo F, Rivilli N, Nicolini AT, Alvarez VA, Ludueña LN. Biodegradable mulch films based on starch/poly (lactic acid)/poly (ε-caprolactone) ternary blends. J Polym Environ. 2023;31:2114–37. https://doi.org/10.1007/s10924-022-02721-w.

Terroba-Delicado E, Fiori S, Gomez-Caturla J, Montanes N, Sanchez-Nacher L, Torres-Giner S. Valorization of liquor waste derived spent coffee grains for the development of injection-molded polylactide pieces of interest as disposable food packaging and serving materials. Foods. 2022;11(8):1162. https://doi.org/10.3390/foods11081162.

Moldovan A, Cuc S, Prodan D, Rusu M, Popa D, Taut AC, Petean I, Bombos D, Doukeh R, Nemes O. Development and characterization of polylactic acid (PLA)-based nanocomposites used for food packaging. Polymers. 2023;15(13):2885. https://doi.org/10.3390/polym15132855.

Tümer EH, Erbil HY. Extrusion-based 3D printing applications of PLA composites: a review. Coatings. 2021;11(4):309. https://doi.org/10.3390/coatings11040390.

Huang WJ, Zhang XZ, Zheng X, Zhang Z, Ding BA, Zhang Y, Wang XH. Synergistic enhancement of modified sericite on rheological and foaming properties of poly (lactic acid). Int J Biol Macromol. 2023;253: 127235. https://doi.org/10.1016/j.ijbiomac.2023.127235.

Li ZK, Song SX, Lv X, Sun SL. Enhanced the melt strength, toughness and stiffness balance of the reactive PB-g-SAG core–shell particles modified polylactide blends with the aid of a multifunctional epoxy-based chain extender. J Polym Res. 2021;28(5):151. https://doi.org/10.1007/s10965-021-02511-3.

Zhou YH, Lei L, Yang B, Li JB, Ren J. Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polym Test. 2018;68:34–8. https://doi.org/10.1016/j.polymertesting.2018.03.044.

Saeidlou S, Huneault MA, Li HB, Park CB. Poly(lactic acid) crystallization. Prog Polym Sci. 2012;37(12):1657–77. https://doi.org/10.1016/j.progpolymsci.2012.07.005.

Wang SY, Jiang C, Xie HH, Zeng JB, Li YD. Compatibilization of polylactide/poly(butylene adipate-co-terephthalate) blends with epoxidized natural rubber as a reactive compatibilizer. Ind Crop Prod. 2023;205: 117447. https://doi.org/10.1016/j.indcrop.2023.117447.

Zhao XP, Yu JJ, Wang X, Huang ZP, Zhou WY, Peng SX. Strong synergistic toughening and compatibilization enhancement of carbon nanotubes and multi-functional epoxy compatibilizer in high toughened polylactic acid (PLA)/poly (butylene adipate-co-terephthalate) (PBAT) blends. Int J Biol Macromol. 2023;250: 126204. https://doi.org/10.1016/j.ijbiomac.2023.126204.

Fernández-Tena A, Otaegi I, Irusta L, Sebastián V, Guerrica-Echevarria G, Müller AJ, Aranburu N. High-impact PLA in compatibilized PLA/PCL blends: optimization of blend composition and type and content of compatibilizer. Macromol Mater Eng. 2023;308(12):2300213. https://doi.org/10.1002/mame.202300213.

Aliotta L, Gigante V, Geerinck R, Coltelli MB, Lazzeri A. Micromechanical analysis and fracture mechanics of poly(lactic acid) (PLA)/polycaprolactone (PCL) binary blends. Polym Test. 2023;121: 107984. https://doi.org/10.1016/j.polymertesting.2023.107984.

Ge QY, Dou Q. Preparation of supertough polylactide/polybutylene succinate/epoxidized soybean oil bio-blends by chain extension. ACS Sustain Chem Eng. 2023;11(26):9620–9. https://doi.org/10.1021/acssuschemeng.3c01042.

Zhang XZ, Zhang Y. Reinforcement effect of poly(butylene succinate) (PBS)-grafted cellulose nanocrystal on toughened PBS/polylactic acid blends. Carbohydr Polym. 2016;140:374–82. https://doi.org/10.1016/j.carbpol.2015.12.073.

Loureiro NC, Esteves JL, Viana JC, Ghosh S. Mechanical characterization of polyhydroxyalkanoate and poly(lactic acid) blends. J Thermoplast Compos Mater. 2015;28(2):195–213. https://doi.org/10.1177/0892705712475020.

Wang XM, Zhuang YG, Dong LS. Study of biodegradable polylactide/poly(butylene carbonate) blend. J Appl Polym Sci. 2013;127(1):471–7. https://doi.org/10.1002/app.37735.

Wang XM, Zhuang YG, Dong LS. Properties of biodegradable poly(butylene carbonate) (PBC) composites with fumed silica nanoparticles. J Therm Anal Calorim. 2013;114(1):77–84. https://doi.org/10.1007/s10973-012-2862-9.

Ge F, Wang XM, Ran XH. Effect of annealing on the properties of polylactide/poly(butylene carbonate) blend. Adv Polym Technol. 2018;37(5):1335–44. https://doi.org/10.1002/adv.21792.

Refaa Z, Boutaous MH, Xin SH, Siginer DA. Thermophysical analysis and modeling of the crystallization and melting behavior of PLA with talc. J Therm Anal Calorim. 2017;128(2):687–98. https://doi.org/10.1007/s10973-016-5961-1.

Zou GX, Zhang X, Zhao CX, Li JC. The crystalline and mechanical properties of PLA/layered silicate degradable composites. Polym Sci Ser A. 2012;54(5):393–400. https://doi.org/10.1134/S0965545X12050148.

Pan HW, Cao ZW, Chen YJ, Wang XY, Jia SL, Yang HL, Zhang HL, Dong LS. Effect of molecular stereoregularity on the transcrystallinization properties of poly(L-lactide)/basalt fiber composites. Int J Biol Macromol. 2019;137:238–46. https://doi.org/10.1016/j.ijbiomac.2019.06.147.

Pan HW, Wang XY, Jia SL, Lu ZF, Bian JJ, Yang HL, Han LJ, Zhang HL. Fiber-induced crystallization in polymer composites: a comparative study on poly(lactic acid) composites filled with basalt fiber and fiber powder. Int J Biol Macromol. 2021;183:45–54. https://doi.org/10.1016/j.ijbiomac.2021.04.104.

Guo S, Zhou Z, Yu SL, Chen ZB, Xiang HX, Zhu MF. The synergistic effect of heterogeneous nucleation and stress-induced crystallization on supramolecular structure and performances of poly(lactic acid) melt-spun fibers. Int J Biol Macromol. 2023;226:1579–87. https://doi.org/10.1016/j.ijbiomac.2022.11.270.

He DR, Wang YM, Shao CG, Zheng GQ, Li Q, Shen CY. Effect of phthalimide as an efficient nucleating agent on the crystallization kinetics of poly(lactic acid). Polym Test. 2013;32(6):1088–93. https://doi.org/10.1016/j.polymertesting.2013.06.005.

Schmidt SC, Hillmyer MA. Polylactide stereocomplex crystallites as nucleating agents for isotactic polylactide. J Polym Sci Pol Phys. 2001;39(3):300–13. https://doi.org/10.1002/1099-0488(20010201)39:3%3c300::AID-POLB1002%3e3.0.CO;2-M.

Anderson KS, Hillmyer MA. Melt preparation and nucleation efficiency of polylactide stereocomplex crystallites. Polymer. 2006;47(6):2030–5. https://doi.org/10.1016/j.polymer.2006.01.062.

Saeidlou S, Huneault MA, Li H, Park CB. Poly(lactic acid) stereocomplex formation: application to PLA rheological property modification. J Appl Polym Sci. 2014;131(22):41073. https://doi.org/10.1002/app.41073.

Yan C, Hou DF, Zhang K, Yang MB. Effects of PDLA molecular weight on the crystallization behaviors and rheological properties of asymmetric PDLA/PLLA blends. Polymer. 2023;270: 125764. https://doi.org/10.1016/j.polymer.2023.125764.

Park HS, Hong CK. Relationship between the stereocomplex crystallization behavior and mechanical properties of PLLA/PDLA blends. Polymers. 2021;13(11):1851. https://doi.org/10.3390/polym13111851.

Su XL, Feng LH, Yu DM. Formation of stereocomplex crystal and its effect on the morphology and property of PDLA/PLLA blends. Polymers. 2020;12(11):2515. https://doi.org/10.3390/polym12112515.

Frone AN, Baciu DD, Popa MS, Nicolae CA, Gabor AR, Raduly MF, Fierascu RC, Panaitescu DM. Thermal behavior and thermo-mechanical properties of biocompatible poly(lactic acid)/allyl-POSS nanohybrids. J Therm Anal Calorim. 2023;148(20):10465–79. https://doi.org/10.1007/s10973-023-12196-z.

Boruvka M, Behalek L, Lenfeld P, Brdlik P, Habr J, Wongmanee S, Bobek J, Pechociakova M. Solid and microcellular polylactide nucleated with PLA stereocomplex and cellulose nanocrystals. J Therm Anal Calorim. 2020;142(2):695–713. https://doi.org/10.1007/s10973-020-09477-2.

Sun JR, Yu HY, Zhuang XL, Chen XS, Jing XB. Crystallization behavior of asymmetric PLLA/PDLA blends. J Phys Chem B. 2011;115(12):2864–9. https://doi.org/10.1021/jp111894m.

Tsuji H. Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci. 2005;5(7):569–97. https://doi.org/10.1002/mabi.200500062.

Wu DF, Wu L, Zhang M, Zhao YL. Viscoelasticity and thermal stability of polylactide composites with various functionalized carbon nanotubes. Polym Degrad Stab. 2008;93(8):1577–84. https://doi.org/10.1016/j.polymdegradstab.2008.05.001.

Sabzi M, Jiang L, Liu F, Ghasemi I, Atai M. Graphene nanoplatelets as poly(lactic acid) modifier: linear rheological behavior and electrical conductivity. J Mater Chem A. 2013;1(28):8253–61. https://doi.org/10.1039/c3ta11021d.

Bärwinkel S, Seidel A, Hobeika S, Hufen R, Mörl M, Altstädt V. Morphology formation in PC/ABS blends during thermal processing and the effect of the viscosity ratio of blend partners. Materials. 2016;9(8):659. https://doi.org/10.3390/ma9080659.

Everaert V, Aerts L, Groeninckx G. Phase morphology development in immiscible PP/(PS/PPE) blends influence of the melt-viscosity ratio and blend composition. Polymer. 1999;40(24):6627–44. https://doi.org/10.1016/S0032-3861(99)00048-8.

Huang HX. Macro, micro and nanostructured morphologies of multiphase polymer systems. In: Boudenne A, Ibos L, Candau Y, Thomas S, editors. Handbook of multiphase polymer systems. New Jersey: Wiley; 2011. p. 161–249.

Wu X, Liu YX, Wu HP, Wu H, Wang HJ, Duan YX, Zhang JM. Cellulose nanocrystals-mediated phase morphology of PLLA/TPU blends for 3D printing. Chin J Polym Sci. 2022;40(3):299–309. https://doi.org/10.1007/s10118-022-2665-9.

Vainio TP, Seppala JV. The effect of mixer type and processing conditions on the morphology of polyamide/polypropylene blend. Polym Polym Compos. 1993;1(6):427–37. https://doi.org/10.1177/096739119300100604.

Sakai F, Nishikawa K, Inoue Y, Yazawa K. Nucleation enhancement effect in poly(L-lactide) (PLLA)/poly(ε-caprolactone) (PCL) blend induced by locally activated chain mobility resulting from limited miscibility. Macromolecules. 2009;42(21):8335–42. https://doi.org/10.1021/ma901547a.

He Y, Fan ZY, Hu YF, Wu T, Jia W, Li SM. DSC analysis of isothermal melt-crystallization, glass transition and melting behavior of poly(L-lactide) with different molecular weights. Eur Polym J. 2007;43(10):4431–9. https://doi.org/10.1016/j.eurpolymj.2007.07.007.

Li JN, Qiu ZB. Effect of low loadings of cellulose nanocrystals on the significantly enhanced crystallization of biodegradable poly(butylene succinate-co-butylene adipate). Carbohydr Polym. 2019;205:211–6. https://doi.org/10.1016/j.carbpol.2018.10.035.

Avrami M. Kinetics of phase change. I general theory. J Chem Phys. 1939;7(12):1103–12. https://doi.org/10.1063/1.1750380.

Avrami M. Kinetics of phase change. II transformation-time relations for random distribution of nuclei. J Chem Phys. 1940;8(2):212–24. https://doi.org/10.1063/1.1750631.

Tsuji H, Takai H, Saha SK. Isothermal and non-isothermal crystallization behavior of poly(L-lactic acid): effects of stereocomplex as nucleating agent. Polymer. 2006;47(11):3826–37. https://doi.org/10.1016/j.polymer.2006.03.074.

Liang R, Chen YC, Zhang CQ, Yin J, Liu XL, Wang LK, Kong R, Feng X, Yang JJ. Crystallization behavior of biodegradable poly(ethylene adipate) modulated by a benign nucleating agent: zinc phenylphosphonate. Chin J Polym Sci. 2017;35(4):558–68. https://doi.org/10.1007/s10118-017-1917-6.

Xu ZH, Niu YH, Yang L, Xie WY, Li H, Gan ZH, Wang ZG. Morphology, rheology and crystallization behavior of polylactide composites prepared through addition of five-armed star polylactide grafted multiwalled carbon nanotubes. Polymer. 2010;51(3):730–7. https://doi.org/10.1016/j.polymer.2009.12.017.

Harnkarnsujarit N, Li Y. Structure-property modification of microcrystalline cellulose film using agar and propylene glycol alginate. J Appl Polym Sci. 2017;134(47):45533. https://doi.org/10.1002/app.45533.

Acknowledgements

This work was supported by the Science and Technology Department of Jilin Province (20230402067GH).

Author information

Authors and Affiliations

Contributions

Hongda Cheng contributed to conceptualization, methodology, data curation, writing—original draft, visualization, resources, methodology, and software. Mengdie Yu contributed to data curation, software, formal analysis, and conceptualization. Ye Zhang and Yanchun Yu contributed to software, data curation, and formal analysis. Hechang Shi contributed to data curation and software. Lijuan Wang contributed to conceptualization, resources, writing—reviewing and editing, investigation, and funding acquisition. Changyu Han contributed to conceptualization, resources, writing—reviewing and editing, investigation, and supervision. All authors discussed the results and contributed to the final manuscript; all authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest/competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, H., Yu, M., Zhang, Y. et al. Enhancement of the properties of biodegradable poly(L-lactide)/poly(butylene carbonate) blends by introducing stereocomplex polylactide crystals. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13245-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13245-x