Abstract

An improved method has been developed to determine the sublimation enthalpies of solid organic compounds using thermogravimetric analysis and applying an isothermal methodology with a TA Instruments® SDTQ600 equipment. This was achieved by measuring the rate of mass loss as a function of the temperature from isothermal experiments in an interval of temperature of 10 to 20 K below the melting temperature of the sample. The resulting rates of mass loss were used by applying the Pieterse and Focke equation, then combined with the integrated Clausius–Clapeyron equation to calculate the heat of sublimation at the experimental temperature and it was corrected to T = 298.15 K. In order to demonstrate the reliability of this methodology, the results for benzoic acid, pyrene and phenanthrene are presented, which are respectively primary, secondary, and tertiary reference compounds in the measurement of enthalpies of sublimation, along with the sublimation enthalpies of picolinic acid, nicotinic acid and isonicotinic acid which are three pyridinecarboxylic acids isomers with the carboxyl group in the ortho, meta and para position, respectively, to the nitrogen of the pyridine.

Similar content being viewed by others

Introduction

The methods for measuring the enthalpy of sublimation are usually classified into two groups, direct and indirect methods. In direct methods, the enthalpy of sublimation is calorimetrically determined at a fixed temperature [1,2,3]. In indirect methods, a temperature-dependent variable is determined and is related to the enthalpy of sublimation. The most common in this category is the Knudsen effusion method [4,5,6]. Thermogravimetry (TG) is another indirect method that has become a widely used technique in the determination of enthalpies of sublimation [7, 8]. Compared with other techniques, thermogravimetry offers certain advantages such as the use of small amounts of sample, easy preparation and the relatively short duration of the experiments. However, in our laboratory this technique has been applied under dynamic conditions, which could lead to experimental errors due to the lack of actual equilibrium conditions in the system. In contrast, isothermal methodology ensures equilibria conditions which provides greater confidence in the results generated [9]. The Langmuir equation [10], which is valid in vacuum conditions, has extensively been applied to quantify the enthalpy of sublimation of a substance by TGA. However, the thermogravimetric experiments are carried out at atmospheric pressures, and under a constant flow of nitrogen gas, experimental conditions that can affect the accuracy of the enthalpies of sublimation determined by this methodology.

In this work, an improved technique for measuring enthalpies of sublimation has been developed by using an isothermal methodology with a TA Instruments SDTQ600® equipment. Such a methodology is based in the Pieterse and Focke assumption that the mass loss in the thermogravimetric device is limited by the diffusion of the vapor of the sample that sublimates toward the inert gas [11]. By applying the Pieterse and Focke equation and combining the loss mass rate to the vapor pressure and temperature through the Clausius–Clapeyron equation [12], high quality results of enthalpy of sublimation can be obtained when is applied to substances of reference in the measuring of the enthalpy of sublimation.

The methodology developed was then applied to the determination of the change of phase enthalpies of three pyridinecarboxylic acids isomers, namely picolinic acid, nicotinic acid and isonicotinic acid, because these molecules are characterized by structural variations that cause subtle differences in their enthalpies of sublimation which, if detected, could support the reliability and accuracy of the methodology proposed in this work. Furthermore, previous studies to determine the enthalpy of sublimation of nicotinic acid have shown discrepancy in the results at 298.15 K [13,14,15], so this work is a good opportunity to contribute to the study of the energetics of this pyridinecarboxylic acid with some reliable data.

Experimental methodology

Substances

Determination of the enthalpies of sublimation of benzoic acid, pyrene and phenanthrene was carried out in this work because these substances correspond to reference compounds for the measurement of sublimation enthalpies [16]. The benzoic acid analyzed was NIST SRM 39j calorimetric standard, while the phenanthrene and pyrene were supplied by Sigma-Aldrich and Supelco, respectively. On the other hand, the picolinic and nicotinic acids were supplied by Sigma-Aldrich, while the isonicotinic acid was supplied by Chem Service. The provenance information of each substance is summarized in Table 1.

A preliminary analysis by DSC of the commercial samples demonstrated that only phenanthrene had a substantial impurities concentration, then it was purified by sublimation under reduced pressure. The mole fraction of impurities contained in each compound was determined from analysis of the melting curve generated by DSC, and the results are shown in Table 1. The isonicotinic acid was not possible to study using differential calorimetry due to its high volatility, which makes the mass of the sample into the calorimetric pan to sublimate before to reach its melting temperature, then its purity was determined by using an HPLC-MS Agilent G6120B equipment. The resulting chromatogram shows a single signal with a 100% of area (see Supporting Information), evidencing that isonicotinic acid was pure enough for its thermochemical study.

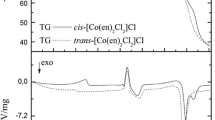

Heat capacities, temperatures and enthalpies of fusion by DSC

Melting determinations and heat capacities measurements were performed using a PerkinElmer DSC7 equipment. In each melting experiment, around 3.0 mg of sample were placed in a 0219-0062 PerkinElmer aluminum pan and located into the calorimeter. The sample was heated 20 K below its melting temperature; then, it was allowed to reach thermal equilibria and generates a baseline with a minima fluctuation in the heat flux signal. Once the calorimetric signal was stable, the scanning in temperature was started until the profile of the melting curve was complete. Each curve allowed computing the enthalpy and temperature of fusion, and the mole fraction of impurities in the sample was determined from graphical van’t Hoff method [17,18,19]. Heat capacities were measured by using the DSC7 device in continuous mode and carrying out three independent experiments—baseline, calibration and measurement—as described by Minas da Piedade and coworkers [19]. In the current work, the interval of Cp measurements was of 288.15–304.15 K in order to obtain accurate results at 298.15 K. For the melting measurements, DSC7 calorimeter was previously calibrated in heat flux and temperature using NIST® SRM® 2232 Indium, which has a certified melting enthalpy of (28.51 ± 0.19) J·g−1 at (429.75 ± 0.01) K. For the heat capacity measurements, NIST® SRM® 720 sapphire, with a Cp,m = 79.01 J·K−1·mol1 at 298.15 K [16], was utilized to determine the DSC7 calibration factor applied in these determinations. Melting as well as heat capacity measurements were performed with a heating rate of 5.0 K⋅min−1 and under a nitrogen gas flow of 25.0 cm3 min−1. Samples and aluminum pans were weighed using a Mettler-Toledo XP26 microbalance sensitive to 1.0 µg (repeatability ± 1.5 µg).

Sublimation enthalpies by isothermal thermogravimetry

Thermogravimetric mass loss measurements were done with a TA Instruments SDT Q600® equipment, which has an horizontal dual balance—sample capacity of 200 mg, sensitivity of ± 0.1 μg—and a furnace working in the range of room temperature to 1773 K. Temperature of the sample is followed by type B thermocouples—platinum/platinum–rhodium junction— located inside the ceramic beams of the balance and directly below of the crucibles containing the substance. This design of the device ensures to measure the temperature of the sample with an estimated uncertainty of only ± 0.1 K. Two cylindrical platinum crucibles with an internal diameter of 6.1 mm and a height of 3.5 mm are used in each experiment. Prior to use, the device was calibrated in mass, temperature and heat flux according to the user’s manual included in the software Thermal Advantage-QSeries® [20] which controls the SDTQ600® device. After calibration, to ensure a correct measurement in mass loss, a dynamic experiment for decomposition of calcium oxalate monohydrate was performed using a scanning rate of 10.0 K min−1 from room temperature to 1073 K. Three main mass losses were measured at different temperatures with the percentages of mass loss in agreement with those recommended [21, 22].

For determination of the sublimation enthalpies, the Pieterse and Focke equation [11] was applied. In isothermal conditions, this equation correlates the rate of mass loss of the substance with its vapor pressure and with the diffusion effect of the vapor phase through the inert gas:

where dm/dt is que rate of mass loss in kg·s−1; P is the vapor pressure in Pa; D is the diffusion coefficient of the sample toward the inert gas in m2⋅s−1; M is the molar mass of the compound in kg·mol−1; R is the universal gas constant in J·K−1 ⋅mol−1; T is the temperature in K; and S is a shape factor of the crucible equivalent to A/h, where A is the crucible area in m2 and h its height in m. Combining Eq. (1) with the integrated Clausius–Clapeyron equation leads to the equality:

where \({\Delta }_{{\text{cr}}}^\text{g}H\) is the sublimation enthalpy and the factor a includes all the constant terms in Eq. (1) as well as the constant of integration of Clausius–Clapeyron equation. From Eq. (2), it follows that plotting ln [(dm/dt)⋅T] vs 1/T provides a straight line whose slope is proportional to the enthalpy of sublimation.

For an accurate measurement of the mass loss rate (dm/dt) as a function of temperature, the following methodology was developed: around 10 mg of the compound to be studied are added to the sample crucible, while the reference crucible remains empty throughout the experiment. The equipment is programmed to increase the temperature of the furnace from room temperature to 5.0 K below the first isotherm, and then the sample is allowed to reach thermal equilibrium before increase its temperature again, at an scanning rate of 1.0 K·min−1, until the temperature of the first isothermal step, where it is maintained for 240 min to ensure thermal equilibrium and a constant rate of loss of mass at that temperature. Subsequently, the temperature is increased by 4.0 K again at a rate of 1.0 K·min−1, and the substance is kept in this second isothermal step by 70 min; the procedure is repeated until having the representative mass loss rate in each of six isothermal steps. To ensure mass loss rates measured in constant temperature conditions, just the last 60 min of each isothermal step were considered, and to ensure that (dm/dt) corresponded to the solid–gas phase change, all measurements were made far below the melting temperature of the substance. The entire heating and isothermal steps were done under a nitrogen gas flow of 100 cm3·min−1.

For phenanthrene, mass loss rate measurements for sublimation process were done above the temperature of its crystalline transition reported for this substance, to avoid loss of linearity in the results of ln [(dm/dt)⋅T] as function of 1/T. In the case of benzoic acid and pyridinecarboxylic acids, too much mass was lost during the stabilization interval prior to measurements, and the last points of the experiments deviate from linearity. Therefore, the temperature was lowered such that the rate of mass loss between the third and fourth isotherms was around 2 × 10–10 kg·s−1, which ensured enough mass in the pan for each isotherm and for the whole experiment.

Results and discussion

Heat capacity and melting data

Table 2 shows the results of the heat capacity and melting data for each compound. Each Cp,m datum in Table 2 refers to the mean of four independent measurements for each compound, and the assigned uncertainty is once the standard deviation of the mean. Among the compounds under study, and in the interval of temperature analyzed, solid–solid transitions for phenanthrene and the nicotinic acid were detected. On the other hand, the melting temperature was characterized as the onset temperature of the melting peak, whereas the melting enthalpy was determined by integrating the melting curves with a straight baseline. The reported uncertainty associated with each average value is the standard deviation of five independent measurements, which implies a standard uncertainty [23]. High volatility of the samples at the melting temperature—around 673 K—made impossible to determine the melting data of the isonicotinic acid. Comparison of Cp.m, solid–solid transition, melting temperature and melting enthalpy results, with some representative data previously reported in the literature, is shown in Table 2.

Considering the associated uncertainty, the results of heat capacity, melting enthalpy and melting temperature determined in this work for the reference substances are in good agreement with those reported in the literature. For benzoic acid, the difference in enthalpy of melting is barely 0.5 kJ mol−1 respect the value recommended by Sabbah et al. [16] and match with most of the data reported in works [24] to [27]. In the same way, the result of melting temperature is the same as the recommended in reference [16] and is in good agreement with those reported in references [24,25,26]. Similar trend is found in the heat capacity data determined in this work for benzoic acid; there is not a significant difference with regard the recommended one [16] and those reported by Roux et al. [24] and Aguilar [27]. For phenanthrene, the agreement for the heat capacity and melting data with regard to previous works [28,29,30,31,32] and the recommended values [33, 34] are also evident. However, there is some small discrepancy in the temperature and enthalpy of the crystalline transition determined by the different author for this aromatic polycyclic compound. This could be explained by the method applied in the preparation of the sample, different purification techniques could result in small changes in the structure of the crystalline arrangement. Concerning to pyrene, the results of melting temperature and enthalpy determined in this research agree with the recommended ones [33, 34] and are in the middle of the interval of the values reported in the literature [29, 30, 35]. Given the accuracy of the results of Cp,m found for benzoic acid and phenanthrene in the current work, the result of heat capacity here determined for pyrene must be also reliable.

With regard to the picolinic acid (Fig. 1), the result of Tfus of this work is identical to that of Sabbah and Ider [13] and just 1.0 K below of that of Allan et al. [36] whose measurements, in both cases, were performed by differential thermal analysis (DTA). However, the agreement is not so good in the case of the enthalpy of melting. The results of Sabbah and Ider is 10 kJ mol−1 below the results determined in this work and 15.0 kJ mol−1 below the result suggested by Allan et al. The underestimated result of enthalpy of melting, systematically obtained for the pyridinecarboxylic acids by Sabbah and Ider, could be caused by an inaccurate calibration of the DTA device utilized. Regarding the heat capacity results, those of Sabbah are systematically above of those reported in the literature, and in this work, such a disagreement could be explained by the differences in size of sample, operation and control of temperature of the drop calorimeter applied by Sabbah and the DSC applied in the current work. Despite these differences in the methodology and device utilized, in similar way to Sabbah and Ider, the measurement of the enthalpy and temperature of melting of the isonicotinic acid was found non-viable in this research, for the decomposition [13] or high volatility of the sample at the temperature of fusion. Then, the result of 135 kJ mol−1 proposed by Allan et al. [36] for the enthalpy of melting of isonicotinic acid seems to be excessively large and must be taken with caution. Regarding the nicotinic acid, an analysis as above developed for the other pyridinecarboxylic acids suggests that the reliable results of enthalpy of melting for this isomer must be those of Wang et al. [37], Minas da Piedade et al. [19, 38, 39] and this work. Similar agreement between these three authors results when Cp,m data for this acid are analyzed.

Sublimation enthalpies from isothermal TGA

Tables 3 and 4 show representative experimental data of temperature, T; mass, m and rate of loss mass, (dm/dt), in each isothermal step for each compound. Those tables also include the least squares fitting equation of ln[(dm/dt)⋅T] vs 1/T, for each series, with its respective uncertainties for the intercept u(a) and the slope u(b), calculated all them as described in [23]. The detailed experimental data and results for each series are provided in the Supporting Information. Figures 2 and 3 show a representative graph of the dependence of ln[(dm/dt)⋅T] with the inverse of the temperature for each of the compounds studied in this work.

In Tables 3 and 4, uncertainties involved in the measurements are u(T) = ± 0.1 K, u(m) = ± 0.1 µg and u(dm/dt) = 4 × 10–4 µg s−1, this last calculated in turn from an estimated uncertainty in the time of u(t) = ± 1.0 s. The uncertainty accompanying each result of enthalpy of sublimation at the experimental temperature is a combined uncertainty calculated applying Eq. (3), which was derived from the definitions and recommendations given in [23, 40] and [41]. The detailed procedure leading to Eq. (3) is given in the Supporting Information.

To apply Eq. 3, average values of dm, dt and [ln(dm/dt)⋅T–a] were computed from the data of each of the six isotherms involved in a series of measurements. The average mass of enthalpy of sublimation μ and its standard deviation u(µ) were calculated using \(\mu \text{=}\sum \left({\text{x}}_{\text{i}}/{u}_{\text{i}}^{2}\right)/\sum \left({1}/{\text{u}}_{\text{i}}^{2}\right)\) and \( u(\mu )^2 = [N/\sum \left( {1/u_{\text{i}}^2 } \right)] \), where xi is the sublimation enthalpy value for each of the N series of experiments and ui its respective combined uncertainty [23].

Calculation of the sublimation enthalpies of substances at 298.15 K was done from the results of the sublimation enthalpies at the experimental temperatures and applying the Kirchoff’s Law:

where \({\Delta }_{{\text{cr}}}^\text{g}\) Cp(s) represents the difference in heat capacity of the gas and solid phase. For all the substances included in this study \({\Delta }_{{\text{cr}}}^\text{g}C\) p,m was estimated by applying the approach proposed by Chickos et al. [42]:

where Cp,m(cr, 298.15 K) is the heat capacity of the solid phase at 298.15 K determined by DSC in this work. The uncertainty for the enthalpy of sublimation at 298.15 K was determined combining the uncertainty of the enthalpy of sublimation at the experimental temperature with that of the correction in temperature \({\int }_{298.15\mathrm{ K}}^{{T}_{{\text{exp}}}}{\Delta }_{{\text{cr}}}^\text{g}{C}_{{\text{p}},{\text{m}}}\text{d}T\), then multiplying the resulting combined uncertainty by a coverage factor k = 1.96 to have an expanded uncertainty with a confidence level of 95% [41].

Table 5 shows the results of enthalpy of sublimation at 298.15 for the three reference compounds benzoic acid, phenanthrene and pyrene, together with the values recommended in the literature. The results obtained in this work are in good agreement with those recommended.

Table 6 shows the sublimations enthalpies of the three pyridinecarboxylic acids resulted in this work and compared with the previously reported values. For the picolinic acid, the result here determined matches with that proposed by Ribeiro Da Silva et al. [14] but is, by around 5.0 kJ mol−1, above the calorimetric result of Sabbah [13]. For the nicotinic acid, the result of this research support that of Sabbah [13] and the results of Menon [50], this last estimated from data of TGA measurements with scanning in temperature. On the other hand, the enthalpy of sublimation here measured for nicotinic acid differs by about 20 kJ∙mol−1 of the results of Ribeiro da Silva [15] and Bickerton [51] and by around 7.0 kJ mol−1of the result of Minas da Piedade [38]. In opinion of the authors, the discrepancy in this result is not caused by the thermogravimetric methodology applied, given that results of the reference substances here determined are in very good agreement with the recommended ones. A plausible explanation to this difference could be found in the crystalline form of the substance included in the sample of the nicotinic acid sublimed in the experiments. Different methods of purification and preparation of the sample can lead to different crystal arrangements in the solid, then to different results of enthalpy of sublimation. Finally, for the isonicotinic acid, the results reported by Sabbah and Ider [13], Ribeiro da Silva et al. [14] and this work match considering the uncertainty accompanying each result.

To clarify the trend in the result of the enthalpy sublimation of the pyridinecarboxylic acids we need to resort to the crystalline structures previously reported. As it is shown in Table 6, picolinic acid has the lowest sublimation enthalpy of all three isomers which means it has the weakest intermolecular interactions. The crystalline structure of this acid confirms this assumption, because it shows an intramolecular hydrogen bond between the hydrogen of the carboxyl group and the nitrogen of the pyridine, as shown in Fig. 4; such intramolecular hydrogen bond decreases interactions between neighboring molecules [52]. In the case of nicotinic and isonicotinic acid, there is no intramolecular hydrogen bond, but in the crystalline lattice [53, 54], shown in Fig. 5, a different π stacking between isomers is evident. Regarding the nicotinic acid, the crystalline structure (Fig. 5a and b) shows a face-centered π stacking and an hydrogen bond between carboxyl groups and neighboring molecules; this kind of stacking is unfavorable energetically between the same molecules because electrostatic repulsion induced by the electronic density at the center of the aromatic ring [55,56,57]. In the case of isonicotinic acid, it also shows an hydrogen bond between carboxyl groups and the adjacent molecules, but it shows an parallel offset π stacking arrangement (Fig. 5c and d) which is favorable energetically between identical molecules because the electronic density of the center of the aromatic ring has a favorable electrostatic interaction with the hydrogens of the neighbor molecules with no repulsion between aromatic rings [55,56,57]. Is this difference between π stackings arrangements which explain why isonicotinic acid has a higher sublimation enthalpy in agreement with the results determined in this work.

Crystalline structure of the nicotinic acid —(a) top view and (b) side view—and crystalline structure of the isonicotinic acid—(c) top view and (d) side view. The four crystalline structure were generated by using DIAMOND 3.0-visual structure information system® software [58]

Conclusions

The results obtained for standards in enthalpy of sublimation measurements show good linear correlations, low uncertainties and an excellent agreement with the values reported in the literature, proving that the isothermal methodology developed using the SDTQ600 TA® equipment, working under the isothermal conditions described throughout this work, is adequate for the determination of enthalpies of sublimation. The accuracy in this methodology is enough to account differences in enthalpy of sublimation of isomers and its use seems adequate for a reliable determination of this thermochemical quantity in organic compounds containing C, H, O, and N.

The sublimation enthalpies results generated in this work for the pyridinecarboxylic acids establish that the sublimation enthalpy increases as the carboxyl functional group gets farther away from the nitrogen of the pyridine group, the crystalline structure analysis confirms that changing the position of the functional group around the pyridinic ring generates different π stackings, causing different intermolecular interactions and explaining the observed trend of the enthalpies of sublimation.

References

Calvet E, Prat H. Microcalorimetrie: applications physico chimiques et biologiques. Paris: Mason; 1956.

Sabbah R, Chastel R, Laffitte M. Mesures calorimetriques des enthalpies de vaporisation et de sublimation par effusion; mise au point de la technique. Thermochim Acta. 1972;5:117–27.

Sabbah R, Antipine I, Coten M, Davy L. Quelques reflexions a propos de la mesure calorimetrique de l’enthalpie de sublimation ou vaporisation. Thermochim Acta. 1987;115:153–65.

Ribeiro da Silva MAV, Monte MJS, Santos LMNBF. The design, construction, and testing of a new Knudsen effusion apparatus. J Chem Thermodyn. 2006;38:778–87.

Torres LA, Hernandez-Contreras I, Guardado JA. The problem of counting the number of molecules and calculating thermodynamic properties: an experimental approach. J Chem Educ. 1995;72:67–9.

Costa JC, Campos RM, Lima LM, da Silva MR, Santos LM. On the aromatic stabilization of fused polycyclic aromatic hydrocarbons. J Phys Chem. 2021;125:3696–709.

Martínez-Herrera M, Campos M, Torres LA, Rojas A. Enthalpies of sublimation of fullerenes by thermogravimetry. Thermochim Acta. 2015;622:72–81.

Sanchez-Bulas T, Cruz-Vásquez O, Hernández-Obregón J, Rojas A. Enthalpies of fusion, vaporisation and sublimation of crown ethers determined by thermogravimetry and differential scanning calorimetry. Thermochim Acta. 2017;650:123–33.

Galindo-García U, Torres LA. Crystal structure at the origin of the thermal stability and large enthalpy of fusion and sublimation values of calixarenes crystal growth and design. Cryst Growth Des. 2020;20:1302–10.

Langmuir I. The vapor pressure of metallic tungsten. Phys Rev. 1913;2:329–42.

Pieterse N, Focke W. Diffusion-controlled evaporation through a stagnant gas: estimating low vapour pressures from thermogravimetric data. Thermochim Acta. 2003;406:191–8.

Flores H, Ramos F, Camarillo EA, Santiago O, Perdomo G, Notario R, Cabrera S. Isothermal thermogravimetric study for determining sublimation enthalpies of some hydroxyflavones. J Chem Eng Data. 2018;63:1925–36.

Sabbah R, Ider S. Energétique des liaisons inter-et intramoléculaires dans les trois acides carboxypyridiniques (acides picolinique, nicotinique et isonicotinique). Can J Chem. 1999;77:249–57.

Ribeiro da Silva MDMC, Matos MAR, Vaz MC, Santos LMNBF, Pilcher G, Acree Jr. WE, Powell JR. Enthalpies of combustion of the pyridine N-oxide derivatives: 4-methyl-, 3-cyano-, 4-cyano-, 3-hydroxy-, 2-carboxy-, 4-carboxy-, and 3-methyl-4-nitro, and of the pyridine derivatives: 2-carboxy-, and 4-carboxy-.The dissociation enthalpies of the N-O bonds. J Chem Thermodyn. 1998;30: 869–78.

Ribeiro da Silva MDMC, Gonçalves JM, Acree Jr. WE. Standard molar enthalpy of sublimation of crystalline 3-pyridinecarboxylic acid. J Chem Thermodyn. 2000;32:1071–3.

Sabbah R, Xu-Wu A, Chickos JS, Leitão MP, Roux MV, Torres LA. Reference materials for calorimetry and differential thermal analysis. Thermochim Acta. 1999;331:93–204.

Brown ME. Determination of purity by differential scanning calorimetry (DSC). J Chem Educ. 1979;56:310–3.

McNaughton JL, Mortimer CT, Differential Scanning Calorimetry. Norwalk: Perkin Elmer Co; 1975.

Abhinav J, Bernardes CES, Minas da Piedade ME. Heat capacity and thermodynamics of solid and liquid pyridine-3-carboxylic acid (nicotinic acid) over the temperature range 296 K to 531 K. J Chem Thermodyn. 2012;55:23–8.

WatersTM. TA Instrumens®. Software sorted by instrument https://www.tainstruments.com/support/software-downloads-support/software-sorted-by-instruments/ Accessed 07 july 2023.

Davies P. Thermogravimetric analysis advanced techniques for better materials characterization. TA Instruments UK. 2017. https://tainstruments.com.cn/wp-content/uploads/8-Philip_Davies.pdf. Accessed 07 july 2023.

Lawson-Wood K, Robertson I. Study of the decomposition of calcium oxalate monohydrate using a hyphenated thermogravimetric analyser-FT-IR system (TG-IR). Application Note, PerkinElmer, Inc.® 2016. https://resources.perkinelmer.com/lab-solutions/resources/docs/app-DecompositionCalcium-oxalate-monohydrate-013078-01.pdf. Accessed 07 july 2023.

Bevington PR, Robinson DK. Data reduction and error analysis for the physical sciences. 3rd ed. New York: McGraw-Hill Higher Education; 2003.

Roux MV, Temprado M, Jimenez P, Guzman-Mejia R, Juaristi E, Chickos JS. Heat capacities of thiane sulfones and thiane sulfoxide. Refining of Cp group values for organosulfur compounds and their oxides. Thermochim Acta. 2003;406:9–16.

Andon RJL, Connett JE. Calibrants for thermal analysis. Measurement of their enthalpies of fusion by adiabatic calorimetry. Thermochim Acta. 1980;42:241–7.

Badea E, Della Gatta G, D’Angelo D, Brunetti B, Reckova Z. Odd even effect in melting properties of 12 alkane-a, x-diamides. J Chem Thermodyn. 2006;38:1546–52.

Aguilar AR, Guareño EO. Thermochemistry of methyl-D-glucopyranosides and methyl-D-galactopyranosides. J Chem Thermodyn. 2000;3:767–75.

Finke HL, Messerly JF, Lee SH, Osborn AG, Douslin DR. Comprehensive thermodynamic studies of seven aromatic hydrocarbons. J Chem Thermodyn. 1977;9:937–56.

Rojas A, Orozco E. Measurement of the enthalpies of vaporization and sublimation of solids aromatic hydrocarbons by differential scanning calorimetry. Thermochim Acta. 2003;405:93–107.

Casellato F, Vecchi C, Girelli A. Differential calorimetric study of polycyclic aromatic hydrocarbons. Thermochim Acta. 1973;6:361–8.

Sabbah R, El Watik L. New reference materials for the calibration (temperature and energy) of differential thermal analysers and scanning calorimeters. J Therm Anal. 1992;38:855–63.

Petropavlov NN, Tsygankova IG, Teslenko LA. Microcalorimetric investigation of polymorphic transitions in organic crystals. Sov Phys Crystallogr. 1988;33:853–5.

Domalski ES, Hearing EID. Heat Capacities and entropies of organic compounds in the condensed phase. Volume III. J Phys Chem Ref Data. 1996;25:1–525.

Roux MV, Temprado M, Chickos JS, Nagano Y. Critically evaluated thermochemical properties of polycyclic aromatic hydrocarbons. J Phys Chem Ref Data. 2008;37:1855–996.

Wong WK, Westrum EF. Thermodynamics of polynuclear aromatic molecules. 1. Heat Capacities and Enthalpies of Fusion of Pyrene, Fluoranthene, and Triphenylene. J Chem Thermodyn. 1971;3:105–24.

Allan JR, Geddes WC, Hindle CS, Orr AE. Thermal analysis studies on pyridine carboxylic acid complexes of zinc(II). Thermochim Acta. 1989;153:249–56.

Wang SX, Tan ZC, Di YY, Xu F, Wang MH, Sun LX, Zhang T. Calorimetric study and thermal analysis of crystalline nicotinic acid. J Therm Anal Calorimet. 2004;76:335–42.

Goncalves EM, Bernardes CES, Diogo HP, Minas da Piedade ME. Energetics and structure of nicotinic acid (Niacin). J Phys Chem B. 2010;114:5475–85.

Goncalves EM, Rego TS, Minas da Piedade ME. Thermochemistry of aqueous pyridine-3-carboxylic acid (nicotinic acid). J Chem Thermodyn. 2011;43:974–9.

Taylor BN, Kuyat CE. Guidelines for evaluating and expressing the uncertainty of NIST measurement results. Gaithersburg: NIST Technical Note 1297; 1994 Edition.

Chirico RD, Frenkel M, Diky VV, Marsh KN, Wilhoit RC. ThermoMLsAn XML-based approach for storage and exchange of experimental and critically evaluated thermophysical and thermochemical property data. 2. Uncertainties. J Chem Eng Data. 2003;48:1344–59.

Chickos JS, Hosseini S, Hesse DG, Liebman JF. Heat capacity corrections to a standard state: a comparison of new and some literature methods for organic liquids and solids. Struct Chem. 1993;4:271–8.

Rojas-Aguilar A, Orozco-Guareño E, Martínez-Herrera M. An experimental system for measurement of enthalpies of sublimation by d.s.c. J Chem Thermodyn. 2001;33:1405–18.

Malaspina L, Gigli R, Bardi G. Microcalorimetric determination of the enthalpy of sublimation of benzoic acid and anthracene. J Chem Phys. 1973;59:387–94.

Morawetz E. Enthalpies of vaporization for a number of aromatic compounds. J Chem Thermodyn. 1972;4:455–60.

Torres-Gomez LA, Barreiro-Rodríguez G, Galarza-Mondragón A. A new method for determination of enthalpies of sublimation by differential scanning calorimetry. Thermochim Acta. 1988;124:229–33.

De Kruif CG, Blok JG. The vapour pressure of benzoic acid. J Chem Thermodyn. 1982;14:201–6.

De Kruif CG. Enthalpies of sublimation and vapour pressures of 11 polycyclic hydrocarbons. J Chem Thermodyn. 1980;12:243–8.

Malaspina L, Bardi G, Gigli R. Simultaneous determination by Knudsen-effusion microcalorimetric technique of the vapor pressure and enthalpy of vaporization of pyrene and 1, 3, 5-triphenylbenzene. J Chem Thermodyn. 1974;6:1053–64.

Menon D, Dollimore D, Alexander KS. A TG–DTA study of the sublimation of nicotinic acid. Thermochim Acta. 2002;392:237–41.

Bickerton J, Pilcher G, Al TG. Enthalpies of combustion of the three aminopyridines and the three cyanopyridines. J Chem Thermodyn. 1984;16:373–8.

Takusagawa F, Shimada A. The crystal structure of picolinic acid. Chem Lett. 1973;2:1089–90.

Wright WB, King GSD. The crystal structure of nicotinic acid. Acta Crystallogr. 1953;6:305–17.

Takusagawa F, Shimada A. Isonicotinic acid. Acta Crystallogr Sect B Structu Crystallogr Cryst Chem. 1976;32:1925–7.

Martinez CR, Brent LI. Rethinking the term “pi-stacking.” Chem Sci. 2012;3:2191–201.

Cockroft SL, Hunter CA, Lawson KR, Perkins J, Urch CJ. Electrostatic control of aromatic stacking interactions. J Am Chem Soc. 2005;127:8594–5.

Hunter CA, Sanders JKM. The nature of. pi.-pi. interactions. J Am Chem Soc. 1990;112:5525–34.

DIAMOND 3.0-Visual crystal structure information system, CRYSTAL IMPACT, Postfach 1251, D-53002 Bonn, Germany, 2004.

Acknowledgements

The authors are grateful to Conahcyt (México) for financial support (grants 104299 CB-2008 and 286452 CB-2016) and the scholarship granted to M.A.T.K. (CVU 1046349) and D.E.R. (CVU 859391). Thanks to Aurora Vásquez-Badillo, Geiser Cuellar-Rivera and Marco A. Leyva-Ramírez (Cinvestav) for the valuable help in the spectral characterization of some of the samples involved in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Treviño-Kauffmann, M.A., Esparza-Rivera, D. & Rojas, A. Sublimation enthalpies of organic compounds by isothermal thermogravimetry. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-12897-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-12897-z

Benzoic Acid;

Benzoic Acid;  Phenanthrene;

Phenanthrene;  Pyrene

Pyrene

Picolinic Acid;

Picolinic Acid;  Nicotinic Acid;

Nicotinic Acid;  Isonicotinic Acid

Isonicotinic Acid