Abstract

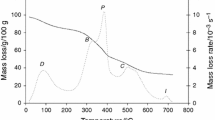

The thermal conversion of oil sludge has been presented as a promising alternative for treating this residue in the petroleum industry. The chemical and energetic characterization of residues is essential in determining the most suitable thermochemical conversion process for their treatment and the appropriate operational parameters for the process. In this sense, this study focuses on a non-isothermal thermo-kinetic analysis of oil sludge to determine the influence of temperature and heating rate on the composition of the evolved gases produced during pyrolysis. Using the thermogravimetric analysis coupled with a Fourier-Transform Infrared Spectroscopy (FTIR), the kinetic and thermodynamic analysis of oil sludge were carried out by applying the Kissinger, Friedman, Ozawa-Flynn-Wall, and the Coats-Redfern methods, leading to the determination of oil sludge activation energy (Ea) consonant with its pyrolysis. In a dry nitrogen atmosphere, four different heating rates were used (5, 10, 20, and 50 K min−1). The active region occurs between 373 and 873 K. The overall pyrolysis process was considered a two-step process with two conversion stages. The first one ranges from 5 to 55% conversion, with the Ea ranging from 44.10 to 45.83 kJmol−1 and the pre-exponential factor (A) ranging from 1.95 × 105 to 1.05 × 10−3 min−1. The second stage presents an Ea range from 107.38 to 134.04 kJ mol−1 and a ranging from 7.93 × 1013 to 2.91 × 10–3 min−1. The FTIR results and thermogravimetric data indicate the generation of mainly H2O, CO2, and aliphatic hydrocarbons such as –CH3, –CH2, and CH4. At 10 and 20 K min−1, the results present higher quantities of hydrocarbons and lower amounts of H2O. The results show that by increasing the process temperature and heating rate, pyrolysis can be an efficient method for treatment and simultaneous energy recovery, bio-char, and bio-oil from oil sludge.

Similar content being viewed by others

Data availability

Due to confidentiality agreements, supporting data can only be made available to bona fide researchers subject to a non-disclosure agreement. Details of the data are available from the corresponding author on reasonable request.

References

BP. Energy Outlook 2020 edition explores the forces shaping the global energy transition out to 2050 and the surrounding that. BP Energy Outlook 2030, Stat Rev London Br Pet. 2020;81. Available from: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/energy-outlook/bp-energy-outlook-2020.pdf

Johnson OA, Affam AC. Petroleum sludge treatment and disposal: a review. Environ Eng Res. 2019;24:191–201.

Wang AY, Sun K, Wu L, Wu P, Zeng W, Tian Z, et al. Co-carbonization of biomass and oily sludge to prepare sulfamethoxazole super-adsorbent materials. Sci Total Environ. 2020;698:134238. https://doi.org/10.1016/j.scitotenv.2019.134238.

Gong Z, Wang Z, Wang Z, Du A, Fang P, Sun Z, et al. Study on pyrolysis of oil sludge with microalgae residue additive. Can J Chem Eng. 2018;96:1919–25.

ANP. Anuário estatístico brasileiro do petróleo, gás natural e biocumbustíveis: 2021. Avaliable on: https://www.gov.br/anp/pt-br/centrais-de-conteudo/publicacoes/anuarioestatistico/arquivos-anuario-estatistico-2021/anuario-2021.pdf

Hu G, Li J, Zeng G. Recent development in the treatment of oily sludge from petroleum industry: a review. J Hazard Mater. 2013;261:470–90. https://doi.org/10.1016/j.jhazmat.2013.07.069.

Li Q, Gao Y, Ji G, Chen C, Li A. Evaluation of pyrolysis residue of oil sludge for recycling as bed material. Can J Chem Eng. 2020;98:465–74.

Hui K, Tang J, Lu H, Xi B, Qu C, Li J. Status and prospect of oil recovery from oily sludge: a review. Arab J Chem. 2020;13:6523–43. https://doi.org/10.1016/j.arabjc.2020.06.009.

Teng Q, Zhang D, Yang C. A review of the application of different treatment processes for oily sludge. Environ Sci Pollut Res. 2021;28:121–32.

Da Silva LJ, Alves FC, De França FP. A review of the technological solutions for the treatment of oily sludges from petroleum refineries. Waste Manag Res. 2012;30:1016–30.

Thong O, Ibrahim A, Rahim HA, Jun YW, Ismail N. A review of crude oil recovery methods from petroleum sludge. Int J Eng Technol Sci. 2021;8:40–50. https://doi.org/10.15282/ijets.8.1.2021.1006.

Niu A, Sun X, Lin C. Trend in research on characterization, environmental impacts and treatment of oily sludge: a systematic review. Molecules. 2022;27:1–23.

Zhao M, Wang X, Liu D, Li Z, Guo S, Zhu W, et al. Insight into essential channel effect of pore structures and hydrogen bonds on the solvent extraction of oily sludge. J Hazard Mater. 2020;389:121826. https://doi.org/10.1016/j.jhazmat.2019.121826.

Nezhdbahadori F, Abdoli MA, Baghdadi M, Ghazban F. A comparative study on the efficiency of polar and non-polar solvents in oil sludge recovery using solvent extraction. Environ Monit Assess. 2018;190:1–9.

He X, Li G, Mo W, Yuan J, Wei X, Wu Y. Investigation on the composition and extraction mechanism of the soluble species from oily sludge by solvent extraction. ACS Omega. 2023;8:18472–8.

Li W, Ma Y, Feng X, Alheshibri M, Bu X, Ma G, et al. Optimization of an oil recovery process from oily sludge using a combined technique of froth flotation and centrifugal treatment. J Clean Prod. 2023;400:136752. https://doi.org/10.1016/j.jclepro.2023.136752.

Liu B, Chen B, Ling J, Matchinski EJ, Dong G, Ye X, et al. Development of advanced oil/water separation technologies to enhance the effectiveness of mechanical oil recovery operations at sea: potential and challenges. J Hazard Mater. 2022;437:129340. https://doi.org/10.1016/j.jhazmat.2022.129340.

Rao B, Wang G, Xu P. Recent advances in sludge dewatering and drying technology. Dry Technol [Internet]. 2022;40:3049–63. https://doi.org/10.1080/07373937.2022.2043355.

Chen G, Cheng C, Zhang J, Sun Y, Hu Q, Qu C, et al. Synergistic effect of surfactant and alkali on the treatment of oil sludge. J Pet Sci Eng. 2019;183:106420.

Huang H, Li Z, Ma Y, Yao M, Yao S, Zhang Z, et al. High-performance arabinoglucuronoxylan-based biosurfactants for oily sludge separation. Carbohydr Polym. 2023;303:120461. https://doi.org/10.1016/j.carbpol.2022.120461.

Humadi JI, Jafar SA, Ali NS, Ahmed MA, Mzeed MJ, Al-Salhi RJ, et al. Recovery of fuel from real waste oily sludge via a new eco-friendly surfactant material used in a digital baffle batch extraction unit. Sci Rep. 2023;13:1–14. https://doi.org/10.1038/s41598-023-37188-9.

Torres-García E, Ramírez-Verduzco LF, Aburto J. Pyrolytic degradation of peanut shell: activation energy dependence on the conversion. Waste Manag. 2020;106:203–12.

Fu P, Yang H, Zhang Q, Li X. Preparation of carbonaceous adsorption composite with refinery sludge for butyl xanthate and diethyldithiocarbamate removal in flotation wastewater. Int J Environ Sci Technol. 2023;20:5035–42.

Wang C, Lü Y, Song C, Zhang D, Rong F, He L. Separation of emulsified crude oil from produced water by gas flotation: a review. Sci Total Environ. 2022;845:157304. https://doi.org/10.1016/j.scitotenv.2022.157304.

Abdulqawi M, Ibrahim A, Embong R, Ismail N. Development of a hybrid technique of solvent extraction and freeze-thaw for oil recovery from petroleum sludge. Mater Today Proc. 2023. https://doi.org/10.1016/j.matpr.2023.04.661.

Feng W, Yin Y, de Lourdes MM, Wang L, Chen X, Liu Y, et al. Freeze-thaw method for oil recovery from waste cutting fluid without chemical additions. J Clean Prod. 2017;148:84–9. https://doi.org/10.1016/j.jclepro.2017.01.156.

Milato JV, França RJ, Marques Calderari MRC. Co-pyrolysis of oil sludge with polyolefins: evaluation of different y zeolites to obtain paraffinic products. J Environ Chem Eng. 2020;8:103805.

Duan Y, Ning Y, Gao N, Quan C, Grammelis P, Boutikos P. Effect of hydrothermal process on the pyrolysis of oily sludge: characterization and analysis of pyrolysis products. Fuel. 2023;338:127347. https://doi.org/10.1016/j.fuel.2022.127347.

Wang Z, Gong Z, Wang Z, Li X, Chu Z. Application and development of pyrolysis technology in petroleum oily sludge treatment. Environ Eng Res. 2021;26:1–15.

Su B, Huang L, Li S, Ding L, Liu B, Zhang A. Chemical–microwave–ultrasonic compound conditioning treatment of highly-emulsified oily sludge in gas fields. Nat Gas Ind B. 2019;6:412–8. https://doi.org/10.1016/j.ngib.2018.12.006.

Gou X, Zheng G, Tang J, Tao C, Liu R, Liu Z. Electric field efficiently enhanced thermochemical cleaning for oil recovery from oily sludge. Chem Eng Process-Process Intensif. 2023;185:109314. https://doi.org/10.1016/j.cep.2023.109314.

Taslimi Taleghani S, Fellah Jahromi A, Elektorowicz M. Electro-demulsification of water-in-oil suspensions enhanced with implementing various additives. Chemosphere. 2019;233:157–63. https://doi.org/10.1016/j.chemosphere.2019.05.161.

Luo X, Gong H, He Z, Zhang P, He L. Research on mechanism and characteristics of oil recovery from oily sludge in ultrasonic fields. J Hazard Mater. 2020;399:123137. https://doi.org/10.1016/j.jhazmat.2020.123137.

Hochberg SY, Tansel B, Laha S. Materials and energy recovery from oily sludges removed from crude oil storage tanks (tank bottoms): a review of technologies. J Environ Manag. 2022;305:114428. https://doi.org/10.1016/j.jenvman.2022.114428.

Hu G, Feng H, He P, Li J, Hewage K, Sadiq R. Comparative life-cycle assessment of traditional and emerging oily sludge treatment approaches. J Clean Prod. 2020;251:119594. https://doi.org/10.1016/j.jclepro.2019.119594.

Aydin ES, Yucel O, Sadikoglu H. Numerical and experimental investigation of hydrogen-rich syngas production via biomass gasification. Int J Hydrogen Energy. 2018;43:1105–15. https://doi.org/10.1016/j.ijhydene.2017.11.013.

EPA. EPA3051A-Microwave assisted acid digestion of sediments, sludges, soils, and oils [Internet]. 2007. Available from: https://www.epa.gov/sites/production/files/2015-12/documents/3051a.pdf

Deng S, Wang X, Tan H, Mikulčić H, Yang F, Li Z, et al. Thermogravimetric study on the co-combustion characteristics of oily sludge with plant biomass. Thermochim Acta. 2016;633:69–76.

Cheng S, Chang F, Zhang F, Huang T, Yoshikawa K, Zhang H. Progress in thermal analysis studies on the pyrolysis process of oil sludge. Thermochim Acta. 2018;663:125–36. https://doi.org/10.1016/j.tca.2018.01.006.

Liu H, Hong R, Xiang C, Wang H, Li Y, Xu G, et al. Thermal decomposition kinetics analysis of the oil sludge using model-based method and model-free method. Process Saf Environ Prot. 2020;141:167–77. https://doi.org/10.1016/j.psep.2020.05.021.

Barneto AG, Moltó J, Ariza J, Conesa JA. Thermogravimetric monitoring of oil refinery sludge. J Anal Appl Pyrolysis. 2014;105:8–13. https://doi.org/10.1016/j.jaap.2013.09.007.

Kok MV, Gundogar AS. DSC study on combustion and pyrolysis behaviors of Turkish crude oils. Fuel Process Technol. 2013;116:110–5.

Martínez-Alonso A, Bermejo J, Granda M, Tascón JMD. Suitability of thermogravimetry and differential thermal analysis techniques for characterization of pitches. Fuel. 1992;71:611–7.

Ciajolo A, Barbella R. Pyrolysis and oxidation of heavy fuel oils and their fractions in a thermogravimetric apparatus. Fuel. 1984;63:657–61.

Vodyanitskii YN. Standards for the contents of heavy metals in soils of some states. Ann Agrar Sci. 2016;14:257–63. https://doi.org/10.1016/j.aasci.2016.08.011.

Silaen A, Wang T. Effects of turbulence and devolatilization models on gasification simulation. In: 25th Annu Int Pittsburgh Coal Conf PCC-Proc 2008;1–16

Egazar’yants SV, Vinokurov VA, Vutolkina AV, Talanova MY, Frolov VI, Karakhanov EA. Oil sludge treatment processes. Chem Technol Fuels Oils. 2015;51:506–15.

Chan WP, Wang JY. Formation of synthetic sludge as a representative tool for thermochemical conversion modelling and performance analysis of sewage sludge–Based on a TG-FTIR study. J Anal Appl Pyrolysis. 2018;133:97–106. https://doi.org/10.1016/j.jaap.2018.04.015.

Sokrates G. Infrared and Raman characteristic group frequencies: tables and charts. Wiley. 2004

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Vyazovkin S, Chrissafis K, Di Lorenzo ML, Koga N, Pijolat M, Roduit B, et al. ICTAC kinetics committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta. 2014;590:1–23.

Blaine RL, Kissinger HE. Homer kissinger and the kissinger equation. Thermochim Acta. 2012;540:1–6. https://doi.org/10.1016/j.tca.2012.04.008.

Standard A. E1641-07, standard test method for decomposition kinetics by thermogravimetry. ASTM Int West Conshohocken, PA. 2007;i:1–6

Cheng S, Wang Y, Gao N, Takahashi F, Li A, Yoshikawa K. Pyrolysis of oil sludge with oil sludge ash additive employing a stirred tank reactor. J Anal Appl Pyrolysis. 2016;120:511–20.

Acknowledgements

The authors wish to express their gratitude to the Brazilian Petroleum Corporation (Petrobras), the Brazilian Electricity Regulatory Agency (ANEEL), the Research Support Foundation of the state of Minas Gerais (FAPEMIG), to the National Council for Scientific and the Technological Development (CNPq), the Coordination for the Improvement of Higher Level Personnel (CAPES), FAPERJ and the Human Resources Program of ANP (PRH-ANP 51.1).

Funding

The authors acknowledge Petrobras S.A., Fapemig, CAPES, CNPq, FAPERJ, and the National Agency of Petroleum, Natural Gas and Biofuels (PRH-ANP No 51.1).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by LOSDC, ARAA, KPB, and YCS. The first draft of the manuscript was written by LOSDC and KPB. All authors contributed to previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Colletta, L.d.O.S.D., Venturini, O.J., Andrade, R.V. et al. Oil sludge pyrolysis kinetic evaluation based on TG-FTIR coupled techniques aiming at energy recovery. J Therm Anal Calorim 148, 12795–12809 (2023). https://doi.org/10.1007/s10973-023-12555-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12555-w