Abstract

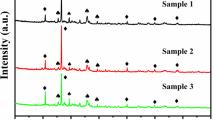

Electroplating sludge is a water purification waste containing multiple valuable metals which demand recycling with efficiency mostly associated with its thermal behavior. In this study, the thermal stability of a typical chromium-rich electroplating sludge (CRES) was assessed based on the analyses of thermogravimetric and differential scanning calorimetry, X-ray diffraction, Fourier transform infrared spectrometry, scanning electron microscopy, and electron probe micro-analysis, with a focus on phase transformations of chromium, iron, and sulfur-bearing components in the sludge within the temperature range up to 1600 °C. The results showed that the thermal stability of CRES in the temperature range could be divided into five stages. Initially, CRES had rapid mass loss below 450 °C (mostly from 196 to 393 °C), accompanied by the dehydration of metal hydroxides (CrO(OH), Fe(OH)2, and Fe(OH)3) to produce corresponding oxides, namely Cr2O3 (eskolaite), Fe3O4 (magnetite), Fe2O3 (hematite), and oxidation of CaSO3 to CaSO4 and partial Fe3O4 to Fe2O3. From 450 to 1000 °C, it remained relatively stable, with continuous minor oxidation of Fe3O4. Between 1000 and 1400 °C, CaSO4 decomposed. In the temperature range from 1400 to 1500 °C, there were decomposition of Fe2O3 and formation of (Fe,Mg)(Cr,Fe)2O4. When the temperature further increased to 1600 °C, partial replacement of Cr3+ by Fe3+ in Cr2O3 was identified.

Similar content being viewed by others

Abbreviations

- CRES:

-

Chromium-rich electroplating sludge

References

Yan K, Liu Z, Li Z, Yue R, Guo F, Xu Z. Selective separation of chromium from sulphuric acid leaching solutions of mixed electroplating sludge using phosphate precipitation. Hydrometallurgy. 2019;186:42–9.

Chen M, Zhou J, Zhang J, Zhang J, Chen Z, Ding J, Kong F, Qian G, Chen J. Ferrite catalysts derived from electroplating sludge for high-calorie synthetic natural gas production. Appl Catal A Gen. 2017;534:94–100.

Weng C, Sun X, Han B, Ye X, Zhong Z, Li W, Liu W, Deng H, Lin Z. Targeted conversion of Ni in electroplating sludge to nickel ferrite nanomaterial with stable lithium storage performance. J Hazard Mater. 2020;393:122296.

Chen H, Yuan H, Mao L, Hashmi MZ, Xu F, Tang X. Stabilization/solidification of chromium-bearing electroplating sludge with alkali-activated slag binders. Chemosphere. 2020;240:124885.

Zhang C, Song J, Zhang J, Zhang J, Xing J, Hu D, Peng Y, Zhou J, Liu Q, Gu H, Qian G. Understanding and application of an electroplating sludge-derived catalyst with an active texture for improved NO reduction. Sci Total Environ. 2018;631–632:308–16.

Matović L, Vujasin R, Kumrić K, Krstić S, Wu Y, Kabtamu DM, Devečerski A. Designing of technological scheme for conversion of Cr-rich electroplating sludge into the black ceramic pigments of consistent composition, following the principles of circular economy. J Environ Chem Eng. 2021;9(1):105038.

Wang M, Gong X, Wang Z. Sustainable electrochemical recovery of high-purity Cu powders from multi-metal acid solution by a centrifuge electrode. J Clean Prod. 2018;204:41–9.

Zhang L, Zhou W, Liu Y, Jia H, Zhou J, Wei P, Zhou H. Bioleaching of dewatered electroplating sludge for the extraction of base metals using an adapted microbial consortium: process optimization and kinetics. Hydrometallurgy. 2020;191:105227.

Nikfar S, Parsa A, Bahaloo-Horeh N, Mousavi SM. Enhanced bioleaching of Cr and Ni from a chromium-rich electroplating sludge using the filtrated culture of Aspergillus niger. J Clean Prod. 2020;264:121622.

Dai Z, Wu Y, Hu L, Zhang W, Mao L. Evaluating physical-mechanical properties and long periods environmental risk of fired clay bricks incorporated with electroplating sludge. Constr Build Mater. 2019;227:116716.

Kalola V, Desai C. Biosorption of Cr(VI) by halomonassp. DK4, a halotolerant bacterium isolated from chrome electroplating sludge. Environ Sci Pollut Res. 2020;27(22):27330–44.

Li J, Wang Y, Wang Y, Gao Y, Yang Y, Wang R. Selective complex precipitation for ferro-chrome separation from electroplating sludge leaching solution. Front Chem. 2021;9:592407.

Wu J, Yang L, Zhan J, Zhang C. Research on separation of chromium and iron in waste ferrochromium alloy. Hydrometallurgy China. 2011;30(1):51–6.

Wang H, Jiao S, Zhang G. Preparation of ferrosilicochromium by silicothermic reduction of Cr-bearing electroplating sludge. J Sustain Metall. 2023;9:303–13.

Duan G. Technical manual for electroplating wastewater reuse and treatment. Beijing: China Machine Press; 2010.

Tian L, Chen L, Gong A, Wu X, Cao C, Liu M, Chen Z, Xu Z, Liu Y. Separation and extraction of valuable metals from electroplating sludge by carbothermal reduction and low-carbon reduction refining. JOM. 2020;72(2):782–9.

Huang Z, Chen C, Xie J, Wang Z. The evolution of dehydration and thermal decomposition of nanocrystalline and amorphous chromium hydroxide. J Anal Appl Pyrol. 2016;118:225–30.

Snyder RG, Clavell-Grunbaum D, Strauss HL. Spinodal phase separation of unstable solid-state binary n-alkane mixtures. J Phys Chem B. 2007;111(50):13957–66.

Böke H, Akkurt S, Özdemir S, Göktürk EH, Saltik ENC. Quantification of CaCO3-CaSO3∙0.5H2O-CaSO4∙2H2O mixtures by FTIR analysis and its ANN model. Mater Lett. 2004;58(5):723–6.

Frost RL, Scholz R, Wang L. A Raman and infrared spectroscopic study of the phosphate mineral pseudolaueite and in comparison with strunzite and ferrostrunzite. J Chem Crystallogr. 2015;45:391–400.

Frost RL, Dickfos MJ. Raman and infrared spectroscopic study of the anhydrous carbonate minerals shortite and barytocalcite. Spectrochim Acta A. 2008;71(1):143–6.

Yang X, Roonasi P, Holmgren A. A study of sodium silicate in aqueous solution and sorbed by synthetic magnetite using in situ ATR-FTIR spectroscopy. J Colloid Interf Sci. 2008;328:41–7.

Yang J, Martens WN, Frost RL. Transition of chromium oxyhydroxide nanomaterials to chromium oxide: a hot-stage Raman spectroscopic study. J Raman Spectrosc. 2010;42(5):1142–11423.

Mallikarjuna NN, Govindaraj B, Lagashetty A, Venkataraman A. Combustion derived ultrafine Υ-Fe2O3 structure, morphology and thermal studies. J Thermal Anal Calorim. 2003;71:915–26.

Wang X, Li X, Liu S, Zhou H, Li Q, Yang J. Cis-9-Octadecenylamine modified ferric oxide and ferric hydroxide for catalytic viscosity reduction of heavy crude oil. Fuel. 2022;322: 124159.

Mao L, Gao B, Deng N, Liu L, Cui H. Oxidation behavior of Cr(III) during thermal treatment of chromium hydroxide in the presence of alkali and alkaline earth metal chlorides. Chemosphere. 2016;145:1–9.

Ingo GM, Riccucci C, Chiozzini G. Origin of gas porosity in gold-based alloys cast in calcium sulfate-bonded investment and influence of metal oxide acid-base properties on calcium sulfate thermal stability. J Am Ceram Soc. 2001;84(8):1839–43.

Zhang J, Peng Z, Luo G, Tian R, Rao M. Microwave drying kinetics of chromium-rich electroplating sludge. Metals. 2023;13(1):87.

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China under Grant 52111530046, the Natural Science Fund for Distinguished Young Scholars of Hunan Province, China under Grant 2023JJ10073, and the Science and Technology Planning Project of Hunan Province, China under Grant 2019RS2008.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, J., Peng, Z., Tian, R. et al. Assessment of thermal stability of chromium-rich electroplating sludge. J Therm Anal Calorim 148, 10335–10344 (2023). https://doi.org/10.1007/s10973-023-12400-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12400-0