Abstract

Spray freeze-drying (SFD) is an effective method for reducing the size of thermosensitive organic substances that are sparingly soluble in water. Despite the advantages of the method, its use has not yet become widespread. We aimed at studying SFD technique for metronidazole as a heat-sensitive active pharmaceutical ingredient for reducing its particle size and investigated the morphological and physical parameters of the modified drug.

The obtained particles were crystalline in all cases and their sizes were two and one order of magnitude smaller using water or dimethyl sulphoxide solutions, respectively, as compared to the initial reference metronidazole. The particle size varied depending on the experimental parameters (atomization pressure, peristaltic pump speed), although, the operating parameters had a smaller effect on the size of the materials than the applied concentration of starting solution, regardless of the solvent. The as-prepared samples had a microcrystalline structure that is retained for a long time.

Similar content being viewed by others

Introduction

The inherently low bioavailability of purely soluble drug products makes its medical application troublesome in cream, gel, and other formulations. Bioavailability can be improved by reducing the particle size [1] because of the increased surface area of the micron- or nanosized materials. Hence, there is a growing demand in the pharmaceutical industry for micronization or nanonization of poorly soluble drugs. There are plenty of methods known for preparing micron or nanosized amorphous particles such as melting, milling, solvent change, pH-shift method, supercritical fluid method, spray-drying (SD), freeze-drying (FD), and spray freeze-drying [2,3,4,5,6,7,8,9,10]. An overview is available about the most frequently applied methods in [11]. In many cases, amorphous material is formed, which exhibit much better solubility than the original crystalline material [12, 13]. However, amorphous materials are less stable in thermodynamic point of view and tend to transform to crystalline, a more stable form during storage, resulting in changes in their solubility and absorption.

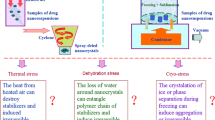

SFD is a relatively new method being useful among many others for the production of mainly amorphous drug particles, especially for thermosensitive organic materials with low solubility [9, 14, 15]. With decreasing size, the particles’ solubility increases according to the Kelvin equation [16]. The yield is generally high and good quality of active ingredients can be obtained by this method [9, 17,18,19,20]. SFD is a multi-step method, including atomization, freezing, and drying. For atomization and freezing, there are several different techniques available [16]. SFD method offers the synthesis of micron- or even nanosized particles having amorphous phase. It could be a good choice for the preparation of micro- or nanoparticles that have several favourable characteristics, nevertheless, its use is still not widespread. The oxidation of the compound modified by the SFD process is less as compared to other methods, e.g. the oxidation of docosahexaenoic acid was 13% by microencapsulation with SFD, while it was 31% with FD and 33% with SD [21].

Metronidazole is a widely applied drug against infections caused by anaerobic protozoa and most anaerobic bacteria [22, 23]. It can be used in the form of either as a solution, gel, or ointment (treatment of the skin, mucous membranes, oral cavity, and vagina), tablets or suspensions for oral treatment, and infusion preparation [24,25,26,27]. Nonetheless, the application of metronidazole is limited on account of its rather poor solubility. For increasing bioavailability, and in order to reduce the possible side effects including gastrointestinal problems (e.g. gastrointestinal disturbances, nausea, abdominal pain, and diarrhoea), neurotoxicity, etc. [22, 28], the drug needs to be used in the lowest possible dose which can be reached, for example by some kind of particle size reduction [4].

To best of our knowledge, not any study is available yet about the size reduction of metronidazole by SFD technique. For this reason, we aimed at this work studying the application of the SFD method for producing a stable, nanometric particle-sized thermosensitive organic drug agent, metronidazole. We characterized the morphology and the most important physical parameters of the materials obtained and its stability in time.

Materials and methods

Materials

Metronidazole was obtained with European Pharmacopoeia specifications from Aarti Drugs Limited, Mumbai, India. This compound is indicated as reference material in the article. Liquid nitrogen was obtained from Linde Gas Magyarország Zrt. with a purity of 99.999% (Budapest, Hungary). Dimethyl sulphoxide (DMSO) of analytical grade was purchased from Reanal Ltd. (Budapest, Hungary). High purity water (18.3 MΩ/cm) was made by Millipore equipment (Merck Ltd).

Preparation of spray freeze-drying materials

The equipment for spray freeze-drying can be divided into two separate units, the freeze granulator and freeze dryer. The freeze granulator (LS2-PowderProAB–freeze granulator, Gothenburg, www.powderpro.se) is similar to the device used by Lumia and co-authors [29]. Freeze granulation consists of two main steps, atomization and spraying by spray freezing into vapour over liquid (SFV/L technique) [19]. The freeze granulator includes a metering pump (peristaltic pump, Watson Marlow 323 pump) and a mixer, as well as a spray head. The pump speed can be set between 3 and 40 L min−1, while the atomizing gas pressure can be varied between 0.1 and 0.4 bar. The stirrer is an IKA RCT basic magnetic stirrer with a power of 600 Watts and a speed set between 280 and 300 L min−1. Since the physical properties of produced particles are determined by the atomization step in the SFV/L technique, we used different settings in the experiments shown in Table 1. The dissolved active ingredient (1–4 g in 100 mL of solution) was sprayed into 1.0 L of liquid nitrogen at − 196 °C, and the frozen material was freeze-dried in a vacuum. The lyophilizer was a Scanvac Coolsafe 55–9 Pro Control type 5-tray freeze dryer. The per cent yield is defined as the ratio of the actual yield to the theoretical yield, expressed as a percentage. The non-gap-free bulk density of the resulting material was measured in a measuring cylinder by determining the material's volume and mass and then it was referred to as 100 mL.

Scanning electron microscopic measurement

The morphology of the samples was studied with a Zeiss EVO40 scanning electron microscope (SEM). Tungsten hairpin filament was used and operated at 10 and 20 kV. To obtain information about the morphology, grain size and distribution, secondary electron images were acquired at different magnification.

Measurement of particle size

The particle size and distribution were determined by the laser diffraction method. For the calculation, the material refractive index 1.6 and the absorption coefficient 0.1 were used because they provided eligible fit between the calculated and measured data (residual shows the measured scattering data and the data predicted by the scattering model were under 1% according to the Malvern Instruments Operators Guide [30]. The particle size was reported as a volume equivalent sphere diameter marked as d (4,3). The measurements were carried out in wet dispersion in 100 mL cyclohexane containing 0.1% soy lecithin by a Malvern Mastersizer 2000 instruments (Malvern Instruments, Malvern, UK) using the SM dispersion unit with a stirring rate of 2500 rpm. The samples were prepared for the analysis as followed: 12 mg sample was dispersed in 3 mL cyclohexane containing 0.1% soy lecithin using ultrasonic 6 mm probe during 60 s with 50% power (Sonics VCX 130 instrument).

X-ray diffraction measurement

The X-ray powder diffraction measurements were performed using a Philips PW-1050 diffractometer, equipped with a Bragg–Brentano parafocusing goniometer, a Cu tube operated at 40 kV and 35 mA power using secondary beam graphite monochromator and a proportional counter. The scans were recorded in step mode with 0, 04° step size for 1 s between 10° and 70° 2θ.

Thermogravimetric and differential scanning calorimetric (TG-DSC) measurement

The thermal behaviour of samples was investigated by a Setaram LabsysEvo (Lyon, France) TG-DSC system in a flowing (50 mL min–1) high purity (99.999%) argon atmosphere. Samples, without any sample preparation, were weighed directly into 100 μL Al crucibles (the reference cell was empty) and where heated from 25 to 250 °C temperature interval, with a heating rate of 10 °C min–1. The obtained data were baseline corrected and further processed with the thermo-analyser's processing software (Calisto Processing, ver. 2.06), in which the melting point (extrapolated onset temperature), peak maximum, and enthalpy were determined by the baseline integration method. At the same time, the degree of crystallinity was calculated based on comparing the melting enthalpies of samples with the melting enthalpy of fully crystalline starting metronidazole reference material. The thermal analyser (both the temperature scale and calorimetric sensitivity) was calibrated by a multipoint calibration method. Seven different certified reference materials were used to cover the thermal analyser's entire operating temperature range.

Stability measurements

The physical stability of the drug was examined by repeating the analytical examinations in different times (four months, one year, and two years). The samples were stored in an airtight plastic container in a dark, cool place (in a refrigerator at 9 °C).

Results and discussion

Morphology

In experiments 1–5 metronidazole, aqueous solutions were spray freeze-dried with five different sets of experimental conditions (Table 1). A common feature was that all product materials were very light, loose-textured, flying powders with a bulk density of approximately 0.015 g mL−1.

The SEM images (Fig. 1.) reveal that the particles size of the product materials was significantly reduced by SFD processing as compared to the reference material.

The morphology of the particles obtained in tests No. 1 to 5 seems very similar despite of the different settings (atomizer gas pressure, peristaltic pump speed). However, images at higher magnification (Fig. 2) show that the size of the particles in experiments 4 and 5 are significantly smaller. Considering the operating conditions, these two samples differed only in the applied lower speed of the peristaltic pump. Thus, the liquid droplets can freeze faster and smaller ice crystals are formed, which ultimately yield smaller particle size after lyophilization. The lower pump speed results in a higher atomization efficiency, with smaller aerosol particles that gets frozen in the liquid nitrogen. Consequently, during lyophilization, there are a lower number of molecules available in the individual droplets that can coalesce during recrystallization. As a result, particles get smaller.

Since the solubility of metronidazole in water is rather limited (10.5 mg mL−1 at 25 °C) [31], we also used DMSO as a solvent to study the effect of the concentration and to increase the efficacy of the process. By virtue of the higher solubility of metronidazole in DMSO (Santa Cruz Biotechnology Ltd.), we could apply a twofold (2 g in 100 mL for sample 6) and a fourfold (4 g in100 mL for sample 7) concentration with respect to the aqueous solution (1 g in 100 mL). However, the SEM images (Fig. 3) show that the recrystallized particles are larger comparing with aqueous solution tests. The higher concentration resulted in larger crystals, and in turn larger particles after lyophilization. This tendency is clearly independent from the solvent and the concentration of the stock solution largely determines the size of the materials obtained by the SFD method. The difference in the particle size can be observed not only between the aqueous and DMSO solution tests but also between the two DMSO tests. The particles of sample 7 with twice as much starting concentration as sample 6 resulted in larger particles. A similar observation was found by Hu and co-authors [32].

Structure of particles

X-ray diffraction measurements were used to determine the crystalline or amorphous form of the materials, furthermore, Scherrer eq. was applied to calculate the crystallite size of the samples. The XRD measurements show that the reprecipitated materials in the samples are all crystalline, while amorphous phase is not detectable as it is also seen in Fig. 4. The crystallite size seemingly varied a little bit in different settings, indicated by the change in the width and intensity of the XRD peaks. The crystallite size was over 1 µm for the reference material and also for the samples 6 and 7, but the exact value cannot be determined by the Scherrer eq. in this size range. The smallest crystallite size was measured as 141 nm for sample 3, 247 nm for sample 5 and 987 nm for sample 4. The particle size of the products are affected by the operating parameters including the spraying speed and the concentration of the solution. The slower spraying results in stronger atomization that ultimately leads to smaller particle size. The larger crystallite sizes of samples 6 and 7 could be attributed to the higher concentration of starting solutions, while the materials obtained from lower concentrations of aqueous solutions were of a submicrometer size range. The results, however, are not perfectly consistent with electron microscopic images. The electron microscopy shows a larger particle size for sample 3 than for sample 4 and 5, while the crystal size calculated from XRD is the smallest for sample 3. Although based on the microscopic images, the sample 3 is larger in size, the crystallite size can be smaller, since the crystallite size is not equivalent to the particle size. This is supported by the recorded intensity values of the XRD pattern, according to which the smallest crystals were formed in samples 4 and 5, as well. In addition, presumably, the crystallite sizes are underestimated, and the calculations are limited because of the uncertainty of the Scherrer constant due to the presence of polydisperse or polycrystalline particles [33].

The thermal analysis was also conducted to confirm the crystalline structure of the samples (Fig. 5) irrespectively of the applied solvent material. The degree of crystallinity was calculated from the results of DSC measurements considering 100% crystalline in the starting metronidazole, which was proved by XRD measurements. The DSC results (Table 2) also confirm the fully crystalline state of the SFD-metronidazole samples. Minor deviations from 100% presumably stem from measurement uncertainties and the moisture content of the samples. Although the crystalline state was a little bit less than 100% for sample 7, but no sign for any amorphous fraction can be observed on the XRD image.

The completely crystalline structure of the products could be expected considering that from a thermodynamical point of view the crystalline structure is more favourable and stable [4]. Crystalline products were reported in earlier papers, too. For instance, Alam et al. [34] increased the solubility of metronidazole prepared by effervescence assisted solid dispersion (EASD) technique also resulted in a crystalline material. Although the SFD method could be suitable to prepare amorphous powders [19], in our experiments we obtained only crystalline metronidazole.

Particle size

In Fig. 6 we compared the particle size distribution of product particles crystallized from water (sample 5) and DMSO (sample 6) with the reference powder analysing by the laser diffraction method. The results are seemingly in agreement with SEM images (Figs. 1 and 2), although the latter method alone is not appropriate for gaining exact values. The smallest size was reached for sample 5, where 90% of the particles were under 2.41 µm. Quite similar d90 values were measured for sample 3 and 4 (3.63 and 3.65, respectively), which shows that the size did not change significantly when water was used as a solvent. The particle size of sample 6 (obtained from DMSO) was one order of magnitude higher (10.67 µm), while the particle size of the reference metronidazole was two orders of magnitude higher (182 µm) than sample 5 (1.81 µm). We assume that the larger particle size of the material obtained from DMSO could be attributed to the higher concentration of the drug in the solution, which was also supported by others [32]. The particle size analysis clearly shows that the SFD method is a highly efficient way of the size reduction in crystalline drug materials. The concentration of the solution had a significant effect on the particle size, while the operating parameters showed less significant contribution in this aspect.

Maa et al. produced protein powder by SD and SFD methods, and the obtained materials were very light and porous with a particle size of 3 µm for SD and 8–10 µm for SFD [35] which is similar to the results we obtained in this experiment. The obtained particle size is favourable in several aspects because the absorption is faster below 5 µm and it is not affected by the hydrodynamics in the gastrointestinal tract [36, 37].

Reproducibility

The reproducibility of the preparation was examined by repeating the experiments several times. SEM images show that the spray freeze-dried materials under the same conditions (experimental parameters: 0.4 bar gas pressure, 10l min–1 peristaltic pump speed) but at different time points have similar morphological properties as sample 4 previously. The measurement of particle size showed similar mean size and size distribution. The X-ray diffraction curves of the repeated experiment 4 represent characteristic features of the crystalline metronidazole and the DSC curves also show the thermal behaviour of crystalline metronidazole.

Stability of particles

Due to the applicability and use of metronidazole, its long-term stability is very important in the pharmaceutical and cosmetic industries. Therefore, the physical stability of the drug was also examined by repeating the analytical examinations several times in a given period. After four months, the size of the material hardly increased as compared to the size of the freshly produced sample (sample 4; experimental parameters: 0.4 bar gas pressure, 101 min–1 peristaltic pump speed), although it preserved its nanomorphological characteristics for a long time. It was stored in an airtight plastic container in a dark and cool place (in a refrigerator at 9 °C). After one year, no significant particle size increase was observed for any spray freeze-dried material by SEM. The materials still show well-crystallized characteristics after one year according to XRD (Fig. 7) and DSC (Fig. 8) measurements. No significant size increase occurred, and the XRD peak intensities are quite similar to the newly prepared sample, which means nanogranulated metronidazole proves its morphological stability. Based on these examinations, it can be said that no significant change in the material can be assumed over time (Fig. 7 and 8).

The applied SFD is a very simple and gentle procedure, which results in stable and long-term shelf life particles, where the undesirable chemical changes are minimal. The long-stability of these materials can be ascribed to the well-crystallized structure, which allows the structure to be stable for more than two years according to the XRD and DSC findings.

Conclusions

Spray freeze-drying (SFD) is a relatively new method for obtaining mainly amorphous materials under micrometer size range; however, in this research, the SFD using SFV/L technique resulted in smaller-sized, crystalline metronidazole.

Our investigation showed that using aqueous or DMSO solutions during the preparation process, the obtained particle size of the crystalline metronidazole samples was two and one order of magnitude smaller, than the initial reference sample, respectively. Based on our studies so far, differences were observed in the morphology and size of the metronidazole according to the applied experimental parameters (such as atomizer gas pressure, peristaltic pump speed). Considering the results, the particle size is more affected by the concentration of the starting solution than the parameters used in the atomization or the solvent itself. To clarify the exact correlations between the particle size and morphology as well as the experimental setting needs further experiments to be done.

However, our ingestions indicate that the applied SFD method enabled to synthesize reproducible and long-time stable crystalline materials.

References

Chaumeil JC. Micronization: a method of improving the bioavailability of poorly soluble drugs. Methods Finds Exp Clin Pharmacol. 1998;20:211–6.

Minakov A, Morikawa J, Ryu M, Zhuravlev E, Schick C. Variations of interfacial thermal conductance at melting and crystallization of an indium micro-particle in contact with a solid. Mater Des. 2021;201:109475.

Carling CJ, Brülls M. Milling of poorly soluble crystalline drug compounds to generate appropriate particle sizes for inhaled sustained drug delivery. Int J Pharm. 2021;593:120116.

Rasenack N, Steckel H, Müller BW. Preparation of microcrystals by in situ micronization. Powder Technol Elsevier. 2004;143–144:291–6.

Vandana KR, Prasanna Raju Y, Harini Chowdary V, Sushma M, Vijay KN. An overview on in situ micronization technique – An emerging novel concept in advanced drug delivery. Saudi Pharm J. 2014;22:283–9.

Sarrate R, Ticó JR, Miñarro M, Carrillo C, Fàbregas A, García-Montoya E, et al. Modification of the morphology and particle size of pharmaceutical excipients by spray drying technique. Powder Technol. 2015;270:244–55.

Jakubowska E, Lulek J. The application of freeze-drying as a production method of drug nanocrystals and solid dispersions – A review. J Drug Deliv Sci Technol. 2021;62:102357.

Mumenthaler M, Leuenberger H. Atmospheric spray-freeze drying: a suitable alternative in freeze-drying technology. Int J Pharm. 1991;72:97–110.

Wanning S, Süverkrüp R, Lamprecht A. Pharmaceutical spray freeze drying. Int J Pharm. 2015;488:136–53.

Bahrami M, Ranjbarian S. Production of micro- and nano-composite particles by supercritical carbon dioxide. J Supercrit Fluids. 2007;40:263–83.

Agarwal A, Singh BK, Trivedi N, Keshari KJ. Approaches for enhancement of solubility to improve the absorption and bioavailability of poorly soluble drugs. Pharma Res. 2014;11:18–28.

Hancock BC, Parks M. What is the True Solubility Advantage for Amorphous Pharmaceuticals? Pharm Res. 2000;17:397–404.

Vemula VR, Lagishetty V, Lingala S. Solubility enhancement techniques. Int J Pharm Sci Rev Res. 2010;5:41–51.

Rogers T-L, Hu J, Yu Z, Johnston K-P, Williams R-O III. A novel particle engineering technology: spray-freezing into liquid. Int J Pharm. 2002;242:93–100.

Rogers T-L, Nelsen A-C, Hu J, Brown J-N, Sarkari M, Young T-J, Johnston K-P, Williams R-O III. A novel particle engineering technology to enhance dissolution of poorly water soluble drugs: spray-freezing into liquid. Eur J Pharm Biopharm. 2022;54:271–80.

Leuenberger H. Spray freeze-drying – the process of choice for low water soluble drugs? J Nanoparticle Res. 2002;4:111–9.

Vishali DA, Monisha J, Sivakamasundari SK, Moses JA, Anandharamakrishnan C. Spray freeze drying: emerging applications in drug delivery. J Control Release. 2019;300:93–101.

Me A, Lamprecht A. Spray freeze drying as an alternative technique for lyophilization of polymeric and lipid-based nanoparticles. Int J Pharm. 2017;516:170–7.

Ishwarya SP, Anandharamakrishnan C, Stapley AGF. Spray-freeze-drying: A novel process for the drying of foods and bioproducts. Trends Food Sci Technol. 2015;41:161–81.

Dutta S, Moses JA, Anandharamakrishnan C. Modern frontiers and applications of spray-freeze-drying in design of food and biological supplements. J Food Process Eng. 2018;41(8):e12881.

Karthik P, Anandharamakrishnan C. Microencapsulation of docosahexaenoic acid by spray-freeze-drying method and comparison of its stability with spray-drying and freeze-drying methods. Food Bioprocess Technol. 2012;6:2780–90.

Tally FP, Sutter VL, Finegold SM. Treatment of anaerobic infections with metronidazole. Antimicrob Agents Chemother. 1975;7:672–5.

Löfmark S, Edlund C, Nord CE. Metronidazole is still the drug of choice for treatment of anaerobic infections. Clin Infect Dis. 2010;50:S16-23.

Goolsby TA, Jakeman B, Gaynes RP. Clinical relevance of metronidazole and peripheral neuropathy: a systematic review of the literature. Int J Antimicrob Agents. 2018;51:319–25.

Eiding J. Metronidazole-containing gels and creams for external use in the treatment of rosacea. Deutsche Apotheker Zeitung. 2004;144:52–3.

Reimann H. Metronidazole gels and creams. Pharm Ztg. 2001;146(48):44.

Jafarzadeh H, Ivanbagha R, Hasanzadeh D, Barhaghi MHS, Melli MS, Poorasl AM. Comparsion of the effect of lactobacillus acidophilus suppository and metronidazol vaginal tablet on bacterial vaginosis metronidazol vaginal tablet on bacterial vaginosis. HAYAT. 2011;17:5–14.

Gutiérrez-Soto B, García-Martín M, Gutiérrez-Soto M, Sosa Romero S, Morales Núñez MI. Cerebellar toxicity after prolonged use of metronidazole. SEMERGEN. 2021;47:133–4.

La Lumia F, Ramond L, Pagnoux C, Bernard-Granger G. Fabrication of homogenous pellets by freeze granulation of optimized TiO2-Y2O3 suspensions. J Eur Ceram Soc. 2019;39:2168–78.

Malvern Instruments Ltd., Operators Guide, 1999. Operators Guide, MAN 0247, Issue 2.0, Worcestershire. WR14 1XZ, United Kingdom.

Mahfouz NM, Hassan MA. Synthesis, chemical and enzymatic hydrolysis, and bioavailability evaluation in rabbits of metronidazole amino acid ester prodrugs with enhanced water solubility. J Pharm Pharmacol. 2010;53:841–8.

Hu Y, Ma C, Sun M, Guo C, Shen J, Wang J, Nie F, Gao B. Preparation and characterization of nano amitriptyline hydrochloride particles by spray freeze drying. Future Medicine. 2019;14:1521–31.

Jeong HY, Lee JH, Hayes KF. Characterization of synthetic nanocrystalline mackinawite: crystal structure, particle size, and specific surface area. Geochim Cosmochim Acta. 2008;72:493–505.

Alam MA, Al-Jenoobi FI, Al-Mohizea AM, Ali R. Effervescence assisted fusion technique to enhance the solubility of drugs. AAPS Pharm Sc iTech. 2015;16:1487–94.

Maa Y-F, Nguyen P-A, Sweeney T, Shire SJ, Hsu CC. Protein inhalation powders: spray drying vs spray freeze drying. Pharm Res. 1999;16:249–54.

Bisrat M, Nyström C. Physicochemical aspects of drug release. VIII. The relation between particle size and surface specific dissolution rate in agitated suspensions. Int J Pharm. 1988;47:223–31.

Scholz A, Abrahamsson B, Diebold SM, Kostewicz E, Polentarutti BI, Ungell A-L, et al. Influence of hydrodynamics and particle size on the absorption of felodipine in labradors. Pharm Res. 2002;19:42–6.

Acknowledgements

This work was supported by the Economic Development and Innovation Operation Program [Grant No. GINOP-2.2.1-15-2016-00023]. The authors are especially grateful to the EGIS Pharmaceuticals PLC for their partnership.

Funding

Open access funding provided by ELKH Research Centre for Natural Sciences.

Author information

Authors and Affiliations

Contributions

KS contributed to conceptualization, methodology, formal analysis, investigation, project administration, writing; ZM contributed to methodology, review; EB contributed to formal analysis, visualization and interpretation, review; JT contributed to formal analysis, visualization, review; LT contributed to thermal analysis, visualization, review and editing; SK contributed to formal analysis, review; TF contributed to project manager, adviser, project administration, review; ZK contributed to conceptualization, project administration, review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no interest in the content of the article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Szentmihályi, K., May, Z., Bódis, E. et al. Morphology transformation of thermosensitive metronidazol by spray freeze-drying. J Therm Anal Calorim 147, 11777–11786 (2022). https://doi.org/10.1007/s10973-022-11441-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11441-1