Abstract

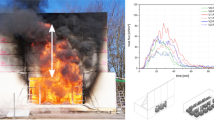

Multi-scale experiments including thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), fire propagation analysis (FPA), and fire resistance test were carried out to study thermal insulation of glass fiber. Temperature range of pyrolysis and combustion, heat of reaction and mass loss were measured by TGA and DSC. The percentage of mass loss measured by TGA and FPA is almost the same. The melting of glass fiber lead to the morphological changes of glass fiber under high radiation heat flux in FPA. The fire resistance test shows that glass fiber has excellent thermal insulation in two structures at low temperatures, but the melting of glass fiber has become a deadly destruction to structural failure at high temperatures. Simulation has been done to the fire resistance of a typical high-speed floor structure containing glass fiber. The simulation results are in good agreement with the experimental results, revealing the importance of considering pyrolysis and melting of glass fiber in predicting its thermal insulation behavior.

Similar content being viewed by others

References

Kinsella K, et al. Thermal decomposition products of fiberglass composites: a Fourier transform infrared analysis. J Fire Sci. 1997;15(2):108–25.

Frangi A, Schleifer V. A new fire resistant light mineral wool. Fire Technol. 2012;48(3):733–52.

Just A. Post protection behaviour of wooden wall and floor structures completely filled with glass fiber. Struct Fire. 2010;2010:584–92.

Tilioua A, et al. Characterization of the thermal properties of fibrous insulation materials made from recycled textile fibers for building applications: theoretical and experimental analyses. Appl Therm Eng. 2018;142:56–67.

Leppänen P, Malaska M. Experimental study on the smouldering combustion of mineral wool insulation in chimney penetrations. Fire Technol. 2019;55(6):2171–94.

Steen-Hansen A, et al. Smouldering combustion in loose-fill wood fibre thermal insulation: An Experimental Study. Fire Technol. 2018;54(6):1585–608.

Bijen J, Jacobs M. Properties of glass fibre-reinforced polymer-modified cement. Matériaux et Constructions. 1982;15:445–52.

Černý R, Poděbradská J, Totová M, et al. Hygrothermal properties of glass fiber reinforced cements subjected to elevated temperature. Mat Struct. 2004;37:597–607.

Lopes BJ, Silva G, D’Almeida JRM. Evaluation of the residual strength of a polyester/ e -glass composite tray after exposure to high temperatures due to a nearby fire event. Fire Technol. 2018;54:853.

Juan P, Hidalgo J, Torero L, et al. Experimental characterisation of the fire behaviour of thermal insulation materials for a performance-based design methodology. Fire Technol. 2016;53(3):1–32.

Weckman EJ, Didomizio MJ, Roos R. Determination of thermochemical properties of mineral wool insulation materials. Fire Mater. 2017.

Livkiss K, et al. Characterization of stone wool properties for fire safety engineering calculations. J Fire Sci. 2018;36(3):202–23.

Andres B, et al. Response of stone wool-insulated building barriers under severe heating exposures. J Fire Sci. 2018;36(4):315–41.

Karamanos A, et al. The impact of temperature and moisture on the thermal performance of stone wool. Energy Build. 2018;40(8):1402–11.

Keerthan P, Mahendran M. Thermal performance of composite panels under fire conditions using numerical studies: plasterboards, rockwool, glass fibre and cellulose insulations. Fire Technol. 2012;49(2):329–56.

Borodulin AS. Properties and peculiarities of glass fibre structures used for glass-reinforced resin production. Mater Sci. 2012;7:34–7.

Yang ZM, et al. active multi-component glass fiber. New York: IEEE; 2014.

Achchaq F, et al. Hydric, morphological and thermo-physical characterization of glass fibers: from macroscopic to microscopic approach. Constr Build Mater. 2009;23(10):3214–9.

Jones JC, Wade M. On the thermal diffusivity of insulating glass fiber. J Fire Sci. 2000;18(1):74–7.

Domínguez-Muñoz F, Anderson B, Cejudo-López JM, Carrillo-Andrés A. Uncertainty in the thermal conductivity of insulation materials. Energy Build. 2010;42(11):2159.

Kowatsch S. Mineral wool insulation binders. Phenolic Resins: A Century of Progress. 2010;209–242.

Zhang X, et al. Characterization of thermal decomposition and combustion for commercial flame-retardant rubber floor cloth in TG–FTIR and FPA. J Therm Anal Calorim. 2018;135(6):3453–61.

Kong D, Peng R, Sun X, Zhang J, Ping P, Du J. Study of the influence of crude oil on the spontaneous combustion risk of sulfurized rust in crude oil tanks. Fuel. 2019;255:115816.

Kong D, Liu P, Ping P, Chen G. Evaluation of the pyrophoric risk of sulfide mineral in storage. J Loss Prev Process Ind. 2016;44:487–94.

Marquis DM, et al. Modelling decomposition and fire behaviour of small samples of a glass-fibre-reinforced polyester/balsa-cored sandwich material. Fire Mater. 2013;37(6):413–39.

Mcgrattan KB, Mcdermott RJ, Weinschenk CG, et al. Fire dynamics simulator. User’s Guide: Nist Special Publication; 2013.

Yuan R, Lu S. Experimental and numerical study for effective thermal conductivity of metallic honeycomb sandwich structures. J Sandwich Struct Mater. 2020. https://doi.org/10.1177/1099636220933534.

Acknowledgements

This work was sponsored by the National Key Research and Development Program of China (2016YFB1200505).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation and data collection were performed by Rongnan Yuan, Yi Zhang and Tingting Qiu. Material analysis was performed by Rongnan Yuan. The first draft of the manuscript was written by Rongnan Yuan and Yi Zhang. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, R., Zhang, Y., Qiu, T. et al. Research on the effect of pyrolysis and melting on thermal insulation of glass fiber at multiple scales. J Therm Anal Calorim 147, 8009–8018 (2022). https://doi.org/10.1007/s10973-021-11068-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11068-8