Abstract

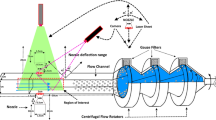

Steam gasification kinetics studies were conducted in a modified drop tube fixed bed reactor to approximate the injection of ambient temperature coal into a fluidized bed gasifier. Product gases were measured using a customized rapid response gas analysis system with a quadrupole mass spectrometer. Experiments were done within Regime I temperature range (no mass transfer restrictions), and effects of temperature and pressure on surface chemical reaction were analyzed using three different particle size ranges. The random pore model closely fits the experimental results and the fitting parameters are listed. Char characterizations are presented, including surface area measurements and scanning electron microscope images. Mass transfer resistances were analyzed by comparing experimental and theoretically predicted effectiveness factors using the Thiele modulus, based on particle sizes, temperature, total pressure, and steam partial pressure.

Similar content being viewed by others

References

Bell DA, Towler BF, Fan M. Coal gasification and its applications. Oxford, UK: Elsevier Inc.; 2011. https://doi.org/10.1016/B978-0-8155-2049-8.10003-8.

Kajitani S, Suzuki N, Ashizawa M, Hara S. CO2 gasification rate analysis of coal char in entrained flow coal gasifier. Fuel. 2006;85:163–9. https://doi.org/10.1016/j.fuel.2005.07.024.

Bryan Woodruff R, Weimer AW. A novel technique for measuring the kinetics of high-temperature gasification of biomass char with steam. Fuel. 2013;103:749–57. https://doi.org/10.1016/j.fuel.2012.09.035.

Lewis AD, Fletcher EG, Fletcher TH. CO2 gasification rates of petroleum coke in a pressurized flat-flame burner entrained-flow reactor. Energy Fuels. 2014;28:4447–57.

Huang S, Wu S, Wu Y, Liu Y, Gao J. Steam cogasification of petroleum coke and different rank coals for enhanced coke reactivity and hydrogen-rich gas production. Energy Fuels. 2014;28:3614–22.

Kajitani S, Tay H-L, Zhang S, Li C-Z. Mechanisms and kinetic modelling of steam gasification of brown coal in the presence of volatile–char interactions. Fuel. 2013;103:7–13. https://doi.org/10.1016/j.fuel.2011.09.059.

Ye DP, Agnew JB, Zhang DK. Gasification of a South Australian low-rank coal with carbon dioxide and steam: kinetics and reactivity studies. Fuel. 1998;77:1209–19. https://doi.org/10.1016/S0016-2361(98)00014-3.

Miura K, Hashimoto K, Silveston PL. Factors affecting the reactivity of coal chars during gasification, and indices representing reactivity. Fuel. 1989;68:1461–75. https://doi.org/10.1016/0016-2361(89)90046-X.

Tan S, Paglieri SN, Li D. Nano-scale sulfur-tolerant lanthanide oxysulfide/oxysulfate catalysts for water–gas-shift reaction in a novel reactor configuration. Catal Commun. 2016;73:16–21. https://doi.org/10.1016/j.catcom.2015.10.007.

Zhang F, Xu D, Wang Y, Wang Y, Gao Y, Popa T, et al. Catalytic CO2 gasification of a powder river basin coal. Fuel Process Technol. 2015;130:107–16. https://doi.org/10.1016/j.fuproc.2014.09.028.

Matveev IB, Messerle VE, Ustimenko AB. Investigation of plasma-aided bituminous coal gasification. IEEE Trans Plasma Sci. 2009;37:580–5. https://doi.org/10.1109/TPS.2009.2013710.

McLendon TR, Lui AP, Pineault RL, Beer SK, Richardson SW. High-pressure co-gasification of coal and biomass in a fluidized bed. Biomass Bioenergy. 2004;26:377–88. https://doi.org/10.1016/j.biombioe.2003.08.003.

Tremel A, Spliethoff H. Gasification kinetics during entrained flow gasification—Part III: modelling and optimisation of entrained flow gasifiers. Fuel. 2013a;107:170–82.

Messenböck R, Dugwell D, Kandiyoti R. Coal gasification in CO2 and steam: development of a steam injection facility for high-pressure wire-mesh reactors. Energy Fuels. 1999;13:122–9.

Zeng X, Wang F, Wang Y, Li A, Yu J, Xu G. Characterization of char gasification in a micro fluidized bed reaction analyzer. Energy Fuels. 2014;28:1838–45.

Harris D, Roberts D, Henderson D. Gasification behaviour of Australian coals at high temperature and pressure. Fuel. 2006;85:134–42. https://doi.org/10.1016/j.fuel.2005.07.022.

Wu H, Bryant G, Benfell K, Wall T. An experimental study on the effect of system pressure on char structure of an australian bituminous coal. Energy Fuels. 2000;14:282–90.

Weiland NT, Means NC, Morreale BD. Product distributions from isothermal co-pyrolysis of coal and biomass. Fuel. 2012;94:563–70. https://doi.org/10.1016/j.fuel.2011.10.046.

Silbermann R, Gomez A, Gates I, Mahinpey N. Kinetic studies of a Novel CO2 gasi fication method using coal from deep unmineable seams. Ind Eng Chem Res. 2013;52:14787–97. https://doi.org/10.1021/ie401918e.

Gomez A, Silbermann R, Mahinpey N. A comprehensive experimental procedure for CO2 coal gasification: Is there really a maximum reaction rate? Appl Energy. 2014;124:73–81. https://doi.org/10.1016/j.apenergy.2014.02.077.

Tremel A, Spliethoff H. Gasification kinetics during entrained flow gasification—Part II: intrinsic char reaction rate and surface area development. Fuel. 2013b;107:653–61. https://doi.org/10.1016/j.fuel.2012.10.053.

Kajitani S, Hara S, Matsuda H. Gasification rate analysis of coal char with a pressurized drop tube furnace. Fuel. 2002;81:539–46.

Wall TF, Liu GS, Wu HW, Roberts DG, Benfell KE, Gupta S, et al. The effects of pressure on coal reactions during pulverised coal combustion and gasification. Prog Energy Combust Sci. 2002;28:405–33. https://doi.org/10.1016/S0360-1285(02)00007-2.

Wang Y, Bell DA. Reaction kinetics of powder river basin coal gasification in carbon dioxide using a modified drop tube reactor. Fuel. 2015;140:616–25. https://doi.org/10.1016/j.fuel.2014.09.106.

Huo W, Zhou Z, Wang F, Wang Y, Yu G. Experimental study of pore diffusion effect on char gasification with CO2 and steam. Fuel. 2014;131:59–65. https://doi.org/10.1016/j.fuel.2014.04.058.

Popa T, Fan M, Argyle MD, Slimane RB, Bell DA, Towler BF. Catalytic gasification of a powder river basin coal. Fuel. 2013;103:161–70. https://doi.org/10.1016/j.fuel.2012.08.049.

Fletcher TH. Time-resolved temperature measurements of individual coal particles during devolatilization. Combust Sci Tech. 1989;63:89–105.

Walker PL, Rusinko F, Austin LG. Gas reactions of carbon. Adv Catal. 1959;11:133–221.

Roberts DG, Harris DJ. Char gasification with O2, CO2, and H2O: effects of pressure on intrinsic reaction kinetics. Energy Fuels. 2000;14:483–9. https://doi.org/10.1021/ef9901894.

Peng FF, Lee IC, Yang RYK. Reactivities of in situ and ex situ coal chars during gasification in steam at 1000–1400°C. Fuel Process Technol. 1995;41:233–51. https://doi.org/10.1016/0378-3820(94)00086-9.

Roberts D, Harris D, Wall T. Total pressure effects on chemical reaction rates of chars with O2, CO2 and H2O. Fuel. 2000;79:1997–8. https://doi.org/10.1016/S0016-2361(00)00070-3.

Zeng D. Effects of pressure on coal pyrolysis at high heating rates and char combustion. Provo: Brigham Young University; 2005.

Fogler HS. Elements of chemical reaction engineering, vol. 4. Upper Saddle River: Prentice Hall International Series; 2005.

Bird RB, Stewart WE, Lightfoot EN. Transport Phenomena. Edition 1. New York: John Wiley & Sons, Inc.; 1960.

Smith JM. Chemical engineering kinetics, vol. 3. New York: McGraw-Hill; 1981.

Acknowledgements

The authors would like to thank Kyle Winkelman for his assistance in building the experimental reactor. We thank our colleague, Dr. William Schaffers, for his helpful technical discussions and assistance. We also thank Dr. Joseph Holles and Dr. Qinghua Lai for providing the surface area apparatus. This research was supported by the University of Wyoming, School of Energy Resources, as part of the U.S.—China Clean Energy Research Center for Coal.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Tan, S. & Bell, D.A. Steam gasification of powder river basin coal: surface reaction kinetics and intraparticle mass transfer restrictions. J Therm Anal Calorim 146, 2209–2222 (2021). https://doi.org/10.1007/s10973-020-10407-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10407-5