Abstract

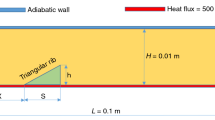

Configuration improvements are greatly important in heat transfer enhancement. In this study, TiO2/water nanofluid was used in combination with ribbed tubes for this purpose. Namely, this article presents a numerical investigation on the effect of rib geometries (trapezoidal and triangular rib shapes), number of ribs (4, 6, and 8 ribs) on heat transfer using TiO2 nanofluid in turbulent flow with Reynolds numbers of 5000–40,000. The thermal and hydraulic behavior of nanofluids was simulated utilizing single-phase approach with the assumption that the fluid properties are constant with temperature, and the flow is under uniform heat flux. The average size of the nanoparticles used in this work was 50 nm, and the nanofluid was considered at concentrations of 0.25–1.0%. The investigations were performed with the aim of establishing the impact of rib numbers and shapes on friction factor and heat transfer employing TiO2/water nanofluid as the working fluid. The results show that the helical-ribbed tube significantly improves heat transfer compared to the plain tube taking into account the shape and number of ribs. Further, by means of performance evaluation criteria, the tubes with trapezoidal ribs provide better thermal performance followed by the ones with triangular ribs compared to the plain tubes. Ultimately, the nonlinear models of Nusselt number and friction factor in the foregoing configurations were proposed with maximum deviations of ± 7.0% and ± 5.0%, respectively.

Similar content being viewed by others

Abbreviations

- \(b\) :

-

Rib average width (m)

- \(C\) :

-

Specific heat (J kg−1 K−1)

- \(C_{1}\), \(C_{2}\), \(C_{\mu }\) :

- \(d\) :

-

Diameter (m)

- \(E\) :

-

Energy (J)

- \(e\) :

-

Rib’s height (m)

- \(f\) :

-

Friction factor (\(=\Delta pd_{\text{h}} /2L\rho u^{2}\))

- \(G_{\text{k}}\) :

-

Generated turbulent kinetic energy (J)

- \(g\) :

-

Tube wall thickness (m)

- \(h\) :

-

Heat transfer coefficient (W m−2 K−1)

- \(k\) :

-

Thermal conductivity (W m−1 K−1)

- \(L\) :

-

Tube length (m)

- \(N\) :

-

Number of ribs

- \({\text{Nu}}\) :

-

Nusselt number (\(= hd_{\text{h}} /k\))

- \(P\) :

-

Pitch (m)

- \({ \Pr }\) :

-

Prandtl number (\(= \mu C /k\))

- \({\text{PEC}}\) :

-

Performance evaluation criteria

- \(p\) :

-

Pressure (Pa)

- \(q\) :

-

Heat flux (W m−2)

- \({\text{Re}}\) :

-

Reynolds number (\(= \rho ud_{\text{h}} /\mu\))

- \(T\) :

-

Temperature (°C or K)

- Trap:

-

Trapezoidal ribbed tube

- Tri:

-

Triangular ribbed tube

- \(u\) :

-

Velocity (m s−1)

- \(x\) :

-

Axial direction (m)

- y + :

-

Dimensionless wall distance (\(= \rho yu_{\tau } /\mu\))

- \(\alpha_{\text{k}} , \alpha_{\varepsilon }\) :

- \(\beta\) :

-

Helix angle (°)

- \(\delta_{\text{ij}}\) :

-

Kronecker delta function

- \(\varepsilon\) :

-

Turbulent kinetic energy dissipation rate (m2 s−3)

- \(\eta\) :

-

Variable in Eq. (4)

- \(\kappa\) :

-

Thermal conductivity ratio

- \(\mu\) :

-

Viscosity (kg m−1 s−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\phi\) :

-

Volume fraction (concentration)

- eff:

-

Effective

- f :

-

Fluid

- h :

-

Hydraulic

- i :

-

Internal

- in:

-

Inlet

- min:

-

Minimal

- nf:

-

Nanofluid

- o :

-

Reference value (plain tube)

- p :

-

Nanoparticle

- t :

-

Turbulent

References

Al-Sammarraie AT, Vafai K. Heat transfer augmentation through convergence angles in a pipe. Numer Heat Transf Part A Appl. 2017;72(3):197–214.

Al-Sammarraie AT, Vafai K. Thermal–hydraulic performance analysis of a convergent double pipe heat exchanger. J Heat Transf 2019;141(5):051001. https://doi.org/10.1115/1.4042487.

Shadlaghani A, Farzaneh M, Shahabadi M, Tavakoli MR, Safaei MR, Mazinani I. Numerical investigation of serrated fins on natural convection from concentric and eccentric annuli with different cross sections. J Therm Anal Calorim. 2019;135(2):1429–42.

Samruaisin P, Wongcharee K, Chuwattanakul V, Eiamsa-ard S. Silver–water nanofluid flow and convective heat transfer in a microfin tube equipped with loose-fit twisted tapes. J Therm Anal Calorim. 2019;8:1–4.

Khodabandeh E, Rozati SA, Joshaghani M, Akbari OA, Akbari S, Toghraie D. Thermal performance improvement in water nanofluid/GNP–SDBS in novel design of double-layer microchannel heat sink with sinusoidal cavities and rectangular ribs. J Therm Anal Calorim. 2019;136(3):1333–45.

Al-Sammarraie AT, Al-Jethelah M, Salimpour MR, Vafai K. Nanofluids transport through a novel concave/convex convergent pipe. Numer Heat Transf Part A Appl. 2019;75(2):91–109.

Maxwell JC. A treatise on electricity and magnetism. Oxford: Clarendon Press; 1881.

Sidik NA, Mohammed HA, Alawi OA, Samion S. A review on preparation methods and challenges of nanofluids. Int Commun Heat Mass Transf. 2014;1(54):115–25.

Zaidan MH, Alkumait AA, Ibrahim TK. Assessment of heat transfer and fluid flow characteristics within finned flat tube. Case Stud Therm Eng. 2018;1(12):557–62.

Al-Sammarraie AT, Jassem RR, Ibrahim TK. Mixed convection heat transfer in inclined tubes with constant heat flux. Eur J Sci Res. 2013;97(1):144–58.

Salimpour MR, Al-Sammarraie AT, Forouzandeh A, Farzaneh M. Constructal design of circular multilayer microchannel heat sinks. J Therm Sci Eng Appl. 2019;11(1):011001. https://doi.org/10.1115/1.4041196.

Elghool A, Basrawi F, Ibrahim TK, Habib K, Ibrahim H, Idris DM. A review on heat sink for thermo-electric power generation: classifications and parameters affecting performance. Energy Convers Manag. 2017;15(134):260–77.

Ibrahim TK, Mohammed MN, Mohammed MK, Najafi G, Sidik NA, Basrawi F, Abdalla AN, Hoseini SS. Experimental study on the effect of perforations shapes on vertical heated fins performance under forced convection heat transfer. Int J Heat Mass Transf. 2018;1(118):832–46.

Sundar LS, Ramana EV, Singh MK, Sousa AC. Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids for heat transfer applications: an experimental study. Int Commun Heat Mass Transf. 2014;1(56):86–95.

Ibrahim TK, Basrawi F, Mohammed MN, Ibrahim H. Effect of perforation area on temperature distribution of the rectangular fins under natural convection. ARPN J Eng Appl Sci. 2016;11(10):6371–5.

Al-Jethelah MS, Al-Sammarraie AT, Dheyab HS. Air space impact on the performance of a solar air heater. In: Proceedings of the 2019 COMSOL conference in Boston. 2019.

Bhuiyan MH, Saidur R, Mostafizur RM, Mahbubul IM, Amalina MA. Experimental investigation on surface tension of metal oxide–water nanofluids. Int Commun Heat Mass Transf. 2015;1(65):82–8.

Al-Sammarraie AT, Mahdi MS. Theoretical study of heat transfer through a sun space filled with a porous medium. Tikrit J Eng Sci. 2016;23(2):10–20.

Ahmed AT. Experimental study on natural convection heat transfer from two parallel horizontal cylinders in horizontal cylindrical enclosure. Tikrit J Eng Sci. 2010;17(1):38–58.

Masuda H, Ebata A, Teramae K. Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles. Dispersion of Al2O3, SiO2 and TiO2 ultra-fine particles. Netsu Bussei. 1993;4(4):227–33.

Murshed SM, Leong KC, Yang C. Investigations of thermal conductivity and viscosity of nanofluids. Int J Therm Sci. 2008;47(5):560–8.

Choi SU, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Lemont: Argonne National Lab; 1995.

Khoshvaght-Aliabadi M, Hosseini Rad SE, Hormozi F. Al2O3–water nanofluid inside wavy minichannel with different cross-sections. J Taiwan Inst Chem Eng. 2016;1(58):8–18.

Hosseinirad E, Hormozi F. New correlations to predict the thermal and hydraulic performance of different longitudinal pin fins as vortex generator in miniature channel: utilizing MWCNT–water and Al2O3–water nanofluids. Appl Therm Eng. 2017;25(118):199–213.

Hosseinirad E, Hormozi F. Influence of shape, number, and position of horizontal minifins on thermal-hydraulic performance of minichannel heat sink using nanofluid. Heat Transf Eng. 2017;38(9):892–903.

Hosseinirad E, Hormozi F. Performance intensification of miniature channel using wavy vortex generator and optimization by response surface methodology: MWCNT–H2O and Al2O3–H2O nanofluids as coolant fluids. Chem Eng Proces-Process Intensif. 2018;1(124):83–96.

Hosseinirad E, Khoshvaght-Aliabadi M, Hormozi F. Three-dimensional numerical study on thermal-hydraulic performance of twisted mini-channel using Al2O3–H2O nanofluid. Heat Transf Eng 2019;41(3):271–87. https://doi.org/10.1080/01457632.2018.1528063.

Bahiraei M, Hosseinalipour SM, Zabihi K, Taheran E. Using neural network for determination of viscosity in water–TiO2 nanofluid. Adv Mech Eng. 2012;4:742680.

Eiamsa-Ard S, Kiatkittipong K, Jedsadaratanachai W. Heat transfer enhancement of TiO2/water nanofluid in a heat exchanger tube equipped with overlapped dual twisted-tapes. Eng Sci Technol Int J. 2015;18(3):336–50.

Mohammed MK, Awad OI, Rahman MM, Najafi G, Basrawi F, Abd Alla AN, Mamat R. The optimum performance of the combined cycle power plant: a comprehensive review. Renew Sustain Energy Rev. 2017;1(79):459–74.

Arani AA, Amani J. Experimental study on the effect of TiO2–water nanofluid on heat transfer and pressure drop. Exp Therm Fluid Sci. 2012;1(42):107–15.

Reddy M, Rao VV, Reddy B, Sarada SN, Ramesh L. Thermal conductivity measurements of ethylene glycol water based TiO2 nanofluids. Nanosci Nanotechnol Lett. 2012;4(1):105–9.

Bozorgan N, Bozorgan N. Evaluation of the using Al2O3/EG and TiO2/EG nanofluids as coolants in the double-tube heat exchanger. Int J Adv Des Manuf Technol 2012;5(2):27–34.

Duangthongsuk W, Wongwises S. An experimental study on the heat transfer performance and pressure drop of TiO2–water nanofluids flowing under a turbulent flow regime. Int J Heat Mass Transf. 2010;53(1–3):334–44.

Khdher AM, Sidik NA, Mamat R, Hamzah WA. Experimental and numerical study of thermo-hydraulic performance of circumferentially ribbed tube with Al2O3 nanofluid. Int Commun Heat Mass Transf. 2015;1(69):34–40.

Malvandi A, Safaei MR, Kaffash MH, Ganji DD. MHD mixed convection in a vertical annulus filled with Al2O3–water nanofluid considering nanoparticle migration. J Magn Magn Mater. 2015;15(382):296–306.

Esfe MH, Wongwises S, Naderi A, Asadi A, Safaei MR, Rostamian H, Dahari M, Karimipour A. Thermal conductivity of Cu/TiO2–water/EG hybrid nanofluid: experimental data and modeling using artificial neural network and correlation. Int Commun Heat Mass Transf. 2015;1(66):100–4.

Goodarzi M, Amiri A, Goodarzi MS, Safaei MR, Karimipour A, Languri EM, Dahari M. Investigation of heat transfer and pressure drop of a counter flow corrugated plate heat exchanger using MWCNT based nanofluids. Int Commun Heat Mass Transf. 2015;1(66):172–9.

Jeng TM, Tzeng SC, Lin CH. Heat transfer enhancement of Taylor–Couette–Poiseuille flow in an annulus by mounting longitudinal ribs on the rotating inner cylinder. Int J Heat Mass Transf. 2007;50(1–2):381–90.

Wang Y, Zhou B, Liu Z, Tu Z, Liu W. Numerical study and performance analyses of the mini-channel with discrete double-inclined ribs. Int J Heat Mass Transf. 2014;1(78):498–505.

Pal S, Saha SK. Laminar fluid flow and heat transfer through a circular tube having spiral ribs and twisted tapes. Exp Thermal Fluid Sci. 2015;1(60):173–81.

Esen EB, Obot NT, Rabas TJ. Enhancement: part I. Heat transfer and pressure drop results for air flow through passages with spirally-shaped roughness. J Enhanc Heat Transf 1994;1(2):145–56.

Al-Fahed S, Chamra LM, Chakroun W. Pressure drop and heat transfer comparison for both microfin tube and twisted-tape inserts in laminar flow. Exp Therm Fluid Sci. 1998;18(4):323–33.

Xu W, Wang S, Liu G, Zhang Q, Hassan M, Lu H. Experimental and numerical investigation on heat transfer of Therminol heat transfer fluid in an internally four-head ribbed tube. Int J Therm Sci. 2017;1(116):32–44.

Mohebbi K, Rafee R, Talebi F. Effects of rib shapes on heat transfer characteristics of turbulent flow of Al2O3–water nanofluid inside ribbed tubes. Iran J Chem Chem Eng (IJCCE). 2015;34(3):61–77.

Mohebbi K, Rafee R, Talebi F. Effects of the rectangular groove dimensions on the thermal features of the turbulent Al2O3–water nanofluid flow in the grooved tubes. J Heat Mass Transf Res. 2015;2(1):59–70.

Zheng N, Liu P, Shan F, Liu Z, Liu W. Effects of rib arrangements on the flow pattern and heat transfer in an internally ribbed heat exchanger tube. Int J Therm Sci. 2016;1(101):93–105.

Zheng N, Liu P, Shan F, Liu J, Liu Z, Liu W. Numerical studies on thermo-hydraulic characteristics of laminar flow in a heat exchanger tube fitted with vortex rods. Int J Therm Sci. 2016;1(100):448–56.

Li Z, Wu Y, Tang G, Lu J, Wang H. Numerical analysis of buoyancy effect and heat transfer enhancement in flow of supercritical water through internally ribbed tubes. Appl Therm Eng. 2016;5(98):1080–90.

Varga S, Soares J, Lima R, Oliveira AC. On the selection of a turbulence model for the simulation of steam ejectors using CFD. Int J Low-Carbon Technol. 2017;12(3):233–43.

Ackerman J. Pseudoboiling heat transfer to supercritical pressure water in smooth and ribbed tubes. J Heat Transf Trans ASME. 1970;92:490–8.

Suhara S, Takahashi T, Ishikawa H, Abe T, Kitamura S. Heat transfer characteristics to supercritical water in ribbed tubes. Tokyo: Central Research Institute of Electric Power Industry; 1982.

Wang L, Sundén B. Experimental investigation of local heat transfer in a square duct with continuous and truncated ribs. Exp Heat Transf. 2005;18(3):179–97.

Zhang Q, Li H, Zhang W, Li L, Lei X. Experimental study on heat transfer to the supercritical water upward flow in a vertical tube with internal helical ribs. Int J Heat Mass Transf. 2015;1(89):1044–53.

Yang D, Pan J, Zhou CQ, Zhu X, Bi Q, Chen T. Experimental investigation on heat transfer and frictional characteristics of vertical upward rifled tube in supercritical CFB boiler. Exp Therm Fluid Sci. 2011;35(2):291–300.

Chen XD, Xu XY, Nguang SK, Bergles AE. Characterization of the effect of corrugation angles on hydrodynamic and heat transfer performance of four-start spiral tubes. J Heat Transf. 2001;123(6):1149–58.

Kareem ZS, Abdullah S, Lazim TM, Jaafar MM, Wahid AF. Heat transfer enhancement in three-start spirally corrugated tube: experimental and numerical study. Chem Eng Sci. 2015;29(134):746–57.

Zimparov V. Enhancement of heat transfer by a combination of three-start spirally corrugated tubes with a twisted tape. Int J Heat Mass Transf. 2001;44(3):551–74.

Srinivasan V, Christensen RN. Experimental investigation of heat transfer and pressure drop characteristics of flow through spirally fluted tubes. Exp Therm Fluid Sci. 1992;5(6):820–7.

Haitao ZH. Experimental study of TiO2-distilled-water nanofluids surface heat transfer in internally ribbed copper tube. J Mech Eng. 2012;12.

Sundar LS, Sharma KV. Laminar convective heat transfer and friction factor of Al2O3 nanofluid in circular tube fitted with twisted tape inserts. Int J Autom Mech Eng. 2011;3(2):65–278.

Al-Jethelah M, Tasnim SH, Mahmud S, Dutta A. Melting of nano-PCM in an enclosed space: scale analysis and heatline tracking. Int J Heat Mass Transf. 2018;1(119):841–59.

ANSYS Fluent Theory Guide. ANSYS, Inc. Nov 2013; 13. p. 1–814.

Shih TH, Liou WW, Shabbir A, Yang Z, Zhu J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput Fluids. 1995;24(3):227–38.

Speziale CG, Thangam S. Analysis of an RNG based turbulence model for separated flows. Int J Eng Sci. 1992;30(10):1379-IN4.

Tiwari AK, Ghosh P, Sarkar J, Dahiya H, Parekh J. Numerical investigation of heat transfer and fluid flow in plate heat exchanger using nanofluids. Int J Therm Sci. 2014;1(85):93–103.

Abdolbaqi MK, Azwadi CS, Mamat R. Heat transfer augmentation in the straight channel by using nanofluids. Case Stud Therm Eng. 2014;1(3):59–67.

Yu W, France DM, Timofeeva EV, Singh D, Routbort JL. Comparative review of turbulent heat transfer of nanofluids. Int J Heat Mass Transf. 2012;55(21–22):5380–96.

Myers SH, Walters DK. A one-dimensional subgrid near wall treatment for turbulent flow CFD simulation. In: ASME international mechanical engineering congress and exposition, vol. 42193; 2005. p. 577–85.

Brogna C, Pucciarelli A, Ambrosini W, Razumovskiy V, Pis’ Mennyi E. Capabilities of high y + wall approaches in predicting heat transfer to supercritical fluids in rod bundle geometries. Ann Nucl Energy. 2018;1(120):272–8.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf Int J. 1998;11(2):151–70.

Dittus FW. Heat transfer in automobile radiators of the tubler type. Univ Calif Pubs Eng. 1930;2:443.

Blasius H. Das aehnlichkeitsgesetz bei reibungsvorgängen in flüssigkeiten. In: Mitteilungen über Forschungsarbeiten auf dem Gebiete des Ingenieurwesens. Berlin: Springer; 1913. p. 1–41.

Petukhov BS. Heat transfer and friction in turbulent pipe flow with variable physical properties. Adv Heat Transf. 1970;6(503):i565.

Promvonge P, Pethkool S, Pimsarn M, Thianpong C. Heat transfer augmentation in a helical-ribbed tube with double twisted tape inserts. Int Commun Heat Mass Transf. 2012;39(7):953–9.

Webb RL, Kim NY. Enhanced heat transfer. New York: Taylor and Francis; 2005.

Sen R, Swaminathan T. Response surface modeling and optimization to elucidate and analyze the effects of inoculum age and size on surfactin production. Biochem Eng J. 2004;21(2):141–8.

Acknowledgements

The authors of this work would like to thank Tikrit University for providing facilities and technical support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alkumait, A.A.R., Ibrahim, T.K., Zaidan, M.H. et al. Thermal and hydraulic characteristics of TiO2/water nanofluid flow in tubes possessing internal trapezoidal and triangular rib shapes. J Therm Anal Calorim 147, 379–392 (2022). https://doi.org/10.1007/s10973-020-10289-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10289-7