Abstract

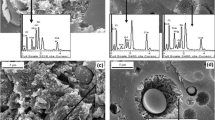

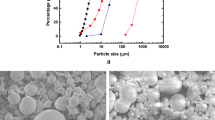

In this work, 50% of the Portland cement was replaced with fly ash and limestone powder by mass. Fly ash to limestone powder ratios of 50:0, 45:5, 40:10, and 30:20 were used. Thermogravimetric analysis (TGA), X-ray diffraction and scanning electron microscopy of the paste mixes were carried out after water curing for 7 and 28 days to determine the hydration and pozzolanic reaction that occurred during the early age and after the standard 28-day curing. In addition, the compressive strength and physical properties of the corresponding mortar mixes were also investigated. At 7 days, the use of limestone with fly ash led to an increase in compressive strength when compared to that for a fly ash mix without limestone (50% FA). This was attributed to the filler effect of the limestone rather than the reaction of the limestone powder with C3A as there was no hemicarboaluminate detected; this was possibly due to a decreased amount of C3A being available since 50% of the Portland cement was used. At 28 days, the 45% FA and 5% LS mixture showed an increased compressive strength, a decreased water absorption and a decreased number of voids. Again, this can be attributed to the filler effect of the limestone. Interestingly, at 28 days, monocarboaluminate was detected by TGA and XRD when the limestone powder was added.

Similar content being viewed by others

References

BS EN 197-1. Cement—part 1: composition, specifications and conformity criteria for common cements. European Committee for Standardization. 2000:1–29.

Dhir RK, Limbachiya MC, McCarthy MJ, Chaipanich A. Evaluation of Portland limestone cements for use in concrete construction. Mater Struct. 2007;40:459–73.

Elgalhud AA, Dhir RK, Ghataora G. Limestone addition effects on concrete porosity. Cem Concr Compos. 2016;72:222–34.

Hawkins P, Tennis P, Detwiler R. The use of limestone in Portland cement: a state-of-the-art review. EB227, Portland Cement Association, Skokie, Illinois, USA. 2003:1–44.

Kakali G, Tsivilis S, Aggeli E, Bati M. Hydration products of C3A, C3S and Portland cement in the presence of CaCO3. Cem Concr Res. 2000;30:1073–7.

Lothenbach B, Saout GL, Gallucci E, Scrivener K. Influence of limestone on the hydration of Portland cements. Cem Concr Res. 2008;33:848–60.

Tydlitát V, Matas T, Cerny R. Effect of w/c and temperature on the early-stage hydration heat development in Portland-limestone cement. Constr Build Mater. 2014;50:140–7.

Matschei T, Lothenbach B, Glasser FP. The role of calcium carbonate in cement hydration. Cem Concr Res. 2007;37(4):551–8.

Thongsanitgarn P, Wongkeo W, Chaipanich A, Poon CS. Heat of hydration of Portland high-calcium fly ash cement incorporating limestone powder: effect of limestone particle size. Constr Build Mater. 2014;66:410–7.

Thongsanitgarn P, Wongkeo W, Chaipanich A. Hydration and compressive strength of blended cement containing fly ash and limestone as cement replacement. J Mater Civ Eng. 2014;26:1–5.

Rong ZD, Sun W, Xiao HJ, Wang W. Effect of silica fume and fly ash on hydration and microstructure evolution of cement based composites at low water–binder ratios. Constr Build Mater. 2014;51:446–50.

Rashad AM. An investigation of high-volume fly ash concrete blended with slag subjected to elevated temperatures. J Clean Prod. 2015;93:47–55.

Kurda R, Silvestre JD, Brito J, Ahmed H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J Clean Prod. 2018;194:730–50.

Palou MT, Kuzielova´E, Radoslav Novotny R, Soukal F, Zemlicka M. Blended cements consisting of Portland cement–slag–silica fume–metakaolin system. J Therm Anal Calorim. 2016;125:1025–34.

Li Z, Ding Z. Property improvement of Portland cement by incorporating with metakaolin and slag. Cem Concr Res. 2003;33:579–84.

Maheswaran S, Iyer NR, Palani GS, Alagu Pandi R, Divina Dikar D, Kalaiselvam S. Effect of high temperature on the properties of ternary blended cement pastes and mortars. J Therm Anal Calorim. 2015;122:775–86.

Yilmaz B, Olgun A. Studies on cement and mortar containing low-calcium fly ash, limestone, and dolomitic limestone. Cem Concr Compos. 2008;30(3):194–201.

De Weerdt K, Justnes H, Kjellsen KO. Sellevold E Fly ash -limestone ternary composite cements: synergetic effect at 28 days. Nordic Concr Res. 2010;42(2):51–70.

De Weerdt K, Ben Haha M, Le Saout G, Kjellsen KO, Justnes H, Lothenbach B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem Concr Res. 2011;41(3):279–91.

De Weerdt K, Ben Haha M, Le Saout G, Kjellsen KO, Justnes H, Lothenbach B. The effect of temperature on the hydration of composite cements containing limestone powder and fly ash. Mater Struct. 2012;45:1101–14.

De Weerdt K, Kjellsen KO, Sellvold E, Justnes H. Fly ash–limestone ternary cements: effect of component fineness. Adv Cem Res. 2011;23(4):203–14.

ASTM Standard, 2005. Standard test method for compressive strength of hydraulic cement mortars (using 2-in. or [50-mm] cube specimens). ASTM International C 109/C109M, West Conshohocken.

Oliveira FT, Moreira C, Rego JH, Capuzzo VMS. Influence of the Limestone type on the Compressive strength of LC3 cements. In: Martirena-Hernandez JF, Alujas-Díaz A, Amador-Hernandez M (eds) Proceedings of the international conference of sustainable production and use of cement and concrete: ICSPCC 2019. Springer. https://doi.org/10.1007/978-3-030-22034-1.

Acknowledgements

The authors would like to thank Thailand Science Research and Innovation (TSRI) formerly known as the Thailand Research Fund (TRF) for the Research Scholar Award (RSA6280011) given to Associate Professor Dr. Arnon Chaipanich. This work was partially supported by Chiang Mai University and the Faculty of Science, Chiang Mai University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaipanich, A., Thongsomboon, S. & Chomyen, P. Thermogravimetric analysis and phase characterizations of Portland fly ash limestone cements. J Therm Anal Calorim 142, 183–190 (2020). https://doi.org/10.1007/s10973-020-10016-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10016-2