Abstract

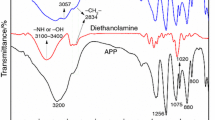

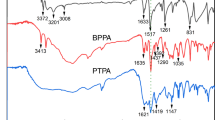

A novel char-forming agent (PETAP) containing aliphatic–aromatic polyamide and phosphoramide structure was successfully prepared via the high-temperature and high-pressure solution reaction of terephthalic acid, ethylenediamine and phosphorous acid. Meanwhile, polypropylene (PP) composites were prepared by using different proportions of PP, ammonium polyphosphate (APP) and PETAP, and the total load of PETAP and APP was 30%. According to the results of limit oxygen index (LOI), vertical burning test (UL-94) and thermogravimetric analysis, PETAP/APP system can greatly improve the thermal stability and flame retardancy of PP. For the mass ratio of (9 mass%/21 mass%/70 mass%) APP/PETAP/PP sample (PP-4), the LOI value achieved the highest, which is 28.8%. It achieved the UL-94 V-0 rating. Then, the Fourier transform infrared spectroscopy analyzed the thermal degradation mechanism of PP composite’s carbon residue at different temperatures, and the potential relationship between microstructure and flame retardancy was also evaluated and discussed. Moreover, the scanning electron microscopy of residual carbon showed that PETAP and APP were helpful to form denser char layer. This char layer has a compact structure which can effectively prevent heat transfer and plays an important role in flame retardant. Finally, the mechanical properties of PP composites were tested, which indicated the mechanical properties of PP composites have not changed much.

Similar content being viewed by others

References

Green J. The flame retardation of polyolefins. New York: Springer; 1982. p. 1–37.

Zheng L, Wu T, Kong QH, Zhang JH, Liu H. Improving flame retardancy of PP/MH/RP composites through the synergistic effect of organic CoAl-layered double hydroxide. J Therm Anal Calorim. 2017;129:1039–46.

Long J, Li S, Liang J. Preparation and characterization of graphene oxide and its application as a reinforcement in polypropylene composites. Polym Compos. 2019;40(2):723–9.

Ah YS, Ha YC, Eun SL. Development of anti-insect microencapsulated polypropylene films using a large scale film coating system. J Food Sci. 2018;83(4):1011–6.

Yi J, Yin H, Cai X. Effects of common synergistic agents on intumescent flame retardant polypropylene with a novel charring agent. J Therm Anal Calorim. 2013;111(1):725–34.

Xiao D, Li Z, De Juan S. Preparation, fire behavior and thermal stability of a novel flame retardant polypropylene system. J Therm Anal Calorim. 2016;125(1):321–9.

Xu JL, Liu XQ, Yang WL. Flame retardant performance of nano-Sb2O3/BEO/PP composites. J Mater Eng Perform. 2019;47(1):84–90.

Zhang J, Kong Q, Yang L, et al. Few layered Co(OH)2 ultrathin nanosheets based polyurethane nanocomposites with reduced fire hazard: from eco-friendly flame retardance to sustainable recycling. Green Chem. 2016;18(10):3066–74.

Zhang J, Kong Q, Wang D. Simultaneously improving the fire safety and mechanical properties of epoxy resin with Fe–CNTs via large-scale preparation. J Mater Chem A. 2018. https://doi.org/10.1039/C7TA10961J.

Zhang J, Kong Q, Sun Y, Wang D, et al. Ultrathin iron phenyl phosphonate nanosheets with appropriate thermal stability for improving fire safety in epoxy. Compos Sci Technol. 2019;182:107748.

Nie SB, Peng C, Yuan SJ, Zhang MX. Thermal and flame retardant properties of novel intumescent flame retardant polypropylene composites. J Therm Anal Calorim. 2013;1:865–71.

Qian Y, Wei P, Jiang P. Synthesis of a novel hybrid synergistic flame retardant and its application in PP/IFR. Polym Degrad Stab. 2011;96(6):1134–40.

Wang M, Wang N. Influence of PA6 as a charring agent on flame retardancy, thermal and mechanical properties of LGFR PP composites. Int Polym Process. 2018;33(4):535–42.

Subasinghe A, Bhattacharyya D. Performance of different intumescent ammonium polyphosphate flame retardants in PP/kenaf fibre composites. Compos Part A Appl Sci. 2014;6:91–9.

Shao ZB, Deng C, Tan Y. An efficient mono-component polymeric intumescent flame retardant for polypropylene: preparation and application. ACS Appl Mater Interfaces. 2014;6(10):7363–70.

Yang B, Liu H, He BB, Leng JH, Chen X. Effect of novel copolyamide charring agents on flame-retarded polypropylene. Polym Compos. 2013;3:634–40.

Chen X, Jiang Y, Jiao C. Synergistic effects between hollow glass microsphere and ammonium polyphosphate on flame-retardant thermoplastic polyurethane. J Therm Anal Calorim. 2014;117(2):857–66.

Chen X, Ma C, Jiao C. Synergistic effects between iron–graphene and ammonium polyphosphate in flame-retardant thermoplastic polyurethane. J Therm Anal Calorim. 2016;126(2):633–42.

Xu Z, Chu Z, Yan L. Enhancing the flame-retardant and smoke suppression properties of transparent intumescent fire-retardant coatings by introducing boric acid as synergistic agent. J Therm Anal Calorim. 2018;13:1241–52.

Bras ML, Bourbigot S, Delporte C, Siat C, Tallec YL. New intumescent formulations of fire-retardant polypropylene—discussion of the free radical mechanism of the formation of carbonaceous protective material during the thermo-oxidative treatment of the additives. Fire Mater. 1996;20(4):191–203.

Bras ML, Bourbigot S, Tallec YL. Laureyns J Synergy in intumescence application to b-cyclodextrin carbonisation agent in intumescent additives for fire retardant polyethylene formulations. Polym Degrad Stab. 1997;56:11–2.

Wang W, Wen PY, Zhan J, Hong NN. Synthesis of a novel charring agent containing pentaerythritol and triazine structure and its intumescent flame retardant performance for polypropylene. Polym Degrad Stab. 2017;144:454–63.

Yang R, Ma B, Zhao H. Preparation, thermal degradation, and fire behaviors of intumescent flame retardant polypropylene with a charring agent containing pentaerythritol and triazine. Ind Eng Chem Res. 2016;55(18):5298–305.

Fu H, Cui Y, Lv J. Fire retardant mechanism of PA66 modified by a “trinity” reactive flame retardant. J Appl Polym Sci. 2020. https://doi.org/10.1002/app.47488.

Dong X, Yang J, Hua X, Nie SB. Synthesis of a novel char-forming agent (PEIC): improvement in flame retardancy, thermal stability, and smoke suppression for intumescent flame-retardant polypropylene composites. J Appl Polym Sci. 2020. https://doi.org/10.1002/app.48296.

Ke C, Li J, Fang K. Enhancement of a hyperbranched charring and foaming agent on flame retardancy of polyamide 6. Polym Adv Technol. 2011;22(12):2237–43.

Lu XD, Jun Z, Gu HM. Influences of different char-forming agents on the combustion behavior and fire retardancy of polypropylene/intumescent systems. Plastics. 2006;1:18–22.

Lu C, Gao XP, Yang D. Flame retardancy of polystyrene/nylon-6 blends with dispersion of clay at the interface. Polym Degrad Stab. 2014;107:10–20.

Yi J, Liu Y, Pan D, Cai XF. Synthesis, thermal degradation, and flame retardancy of a novel charring agent aliphatic–aromatic polyamide for intumescent flame retardant polypropylene. J Appl Polym Sci. 2013;1:1061–8.

Xue Y, Yu T, Chen J, Wan X, Cai X, Guo X, Zhang F, Xiong W, Liu Y, Kong Q, Yuan A, Zhang J. Fabrication of GeO2 microspheres/hierarchical porous N-doped carbon with superior cyclic stability for Li-ion batteries. J Solid State Chem. 2020;286:121303.

Ren Y, Wei LF, Li WM, Cai XF. Synthesis of silicic poly carbonyl urea and its flame-retardant effect on polypropylene for char forming. J Therm Anal Calorim. 2019;137:1267–77.

Ke CH, Li J, Fang KY, Zhu QL, Zhu J, Yan Q, Wang YZ. Synergistic effect between a novel hyperbranched charring agent and ammonium polyphosphate on the flame retardant and anti-dripping properties of polylactide. Polym Degrad Stab. 2010;95:763–70.

Wang X, Song Y, Bao J. Synergistic effects of nanoc-Mn0.4Zn0.6Fe2O4 on intumescent flame-retarded polypropylene. J Vinyl Addit Technol. 2008;14(3):120–5.

Zhu S, Shi W. Thermal degradation of a new flame retardant phosphate methacrylate polymer. Polym Degrad Stab. 2003;80(2):217–22.

Acknowledgements

The work was financially supported by the Experiment Center of Polymer Science and Engineering Academy, Sichuan University and National Natural Sciences Foundation of China, Grant No. 50973066.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, J., He, L., Huang, L. et al. Synthesis of aliphatic–aromatic polyamide carbonized system with phosphoramide structure and study on its thermal degradation mechanism and flame retardancy in polypropylene system. J Therm Anal Calorim 145, 3041–3051 (2021). https://doi.org/10.1007/s10973-020-09879-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09879-2