Abstract

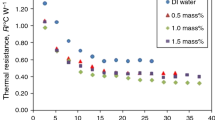

High heat generation from electronic devices needs to cool down properly to prevent overheating. Loop heat pipe (LHP) is one of the excellent cooling devices for high heat generation of electronic devices. Nanofluid is a working fluid which has nanoparticle dispersed in based fluid. Nanofluid is proven to have better thermal performance compared with conventional fluids. In this paper, we investigate on the thermal performance of loop heat pipes using different types of nanofluids. The desired nanofluids used in this study are diamond nanofluid, aluminium oxide (Al2O3) nanofluid and silica oxide nanofluid (SiO2) with 0–3% of mass concentrations. The results showed that as the mass concentration of nanofluids increased, the thermal resistance for diamond nanofluid and Al2O3 nanofluid decreased, but SiO2 nanofluid results show the opposite trend of thermal resistance with increasing mass concentration. The lowest thermal resistance is 3.0872 °C W−1, 3.1465 °C W−1 and 3.2816 °C W−1 for diamond, Al2O3 and SiO2, respectively. Moreover, all types of nanofluids show better heat transfer performance compared with water. Diamond nanofluid also had higher heat capacity than Al2O3 nanofluid as it had a lower vapour line temperature reading. Optimization result also shows that diamond nanofluid has better thermal enhancement than Al2O3 with 1.19% of mass concentration.

Similar content being viewed by others

Abbreviations

- Q :

-

Heat input, W

- R T :

-

Total thermal resistance, °C W−1

- R B :

-

Base thermal resistance, °C W−1

- R E :

-

Evaporator thermal resistance, °C W−1

- R V :

-

Vapour line thermal resistance, °C W−1

- R C :

-

Convective thermal resistance, °C W−1

- R L :

-

Liquid line thermal resistance, °C W−1

- T :

-

Temperature, °C

- T A :

-

Ambient temperature, °C

- T B :

-

Base plate temperature, °C

- T C :

-

Condenser temperature, °C

- T E :

-

Evaporator temperature, °C

- T V :

-

Vapour line temperature, °C

- T L :

-

Liquid line temperature, °C

- W nano :

-

Mass of nanoparticle, kg

- W base :

-

Mass of base fluid, kg

References

Lu X, et al. Thermal analysis of loop heat pipe used for high-power LED. Thermochim Acta. 2009;493(1–2):25–9.

Wang D, et al. Experimental study of the loop heat pipe with a flat disk-shaped evaporator. Exp Therm Fluid Sci. 2014;57:157–64.

Sarkar J, Ghosh P, Adil A. A review on hybrid nanofluids: recent research, development and applications. Renew Sustain Energy Rev. 2015;43:164–77.

Mahian O, et al. Recent advances in modeling and simulation of nanofluid flows-part I: fundamentals and theory. Phys Rep. 2019;790:1–48.

Mahian O, et al. Recent advances in modeling and simulation of nanofluid flows—part II: applications. Phys Rep. 2019;791:1–59.

Rashidi S, et al. Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. 2019;135(1):437–60.

Tharayil T, et al. Thermal performance of miniature loop heat pipe with graphene–water nanofluid. Int J Heat Mass Transf. 2016;93:957–68.

Heris SZ, Esfahany MN, Etemad SG. Experimental investigation of convective heat transfer of Al2O3/water nanofluid in circular tube. Int J Heat Fluid Flow. 2007;28(2):203–10.

Lee Y. The use of nanofluids in domestic water heat exchanger. J Adv Res Appl Mech. 2014;3(1):9–24.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2018;131(3):2027–39.

Ma H, et al. Effect of nanofluid on the heat transport capability in an oscillating heat pipe. Appl Phys Lett. 2006;88(14):143116.

Moraveji MK, Razvarz S. Experimental investigation of aluminum oxide nanofluid on heat pipe thermal performance. Int Commun Heat Mass Transf. 2012;39(9):1444–8.

Bezerra MA, et al. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta. 2008;76(5):965–77.

Esfe MH, Hajmohammad MH. Thermal conductivity and viscosity optimization of nanodiamond-Co3O4/EG (40: 60) aqueous nanofluid using NSGA-II coupled with RSM. J Mol Liq. 2017;238:545–52.

Rostamian H, Lotfollahi MN. New functionality for energy parameter of Redlich–Kwong equation of state for density calculation of pure carbon dioxide and ethane in liquid, vapor and supercritical phases. Period Polytech Chem Eng. 2016;60(2):93–7.

Taylor J. Introduction to error analysis, the study of uncertainties in physical measurements. Mill Valley: University Science Books; 1997.

Gunnasegaran P, et al. Optimization of SiO2 nanoparticle mass concentration and heat input on a loop heat pipe. Case Stud Therm Eng. 2015;6:238–50.

Gunnasegaran P, Abdullah MZ, Yusoff MZ. Heat transfer in a loop heat pipe using Fe2NiO4–H2O nanofluid. In: MATEC web of conferences. EDP Sciences; 2017.

Aun TS, Abdullah MZ, Gunnasegaran P. Influence of low concentration of diamond water nanofluid in loop heat pipe. Int J Heat Technol. 2017;35(3):539–48.

Shukla K, et al. Thermal performance of cylindrical heat pipe using nanofluids. J Thermophys Heat Transf. 2010;24(4):796–802.

Yu W, et al. Review and comparison of nanofluid thermal conductivity and heat transfer enhancements. Heat Transf Eng. 2008;29(5):432–60.

Chon CH, et al. Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl Phys Lett. 2005;87(15):153107.

Septiadi W, et al. Characteristics of screen mesh wick heat pipe with nano-fluid as passive cooling system. Atom Indones. 2013;39(1):24–31.

Keblinski P, et al. Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf. 2002;45(4):855–63.

Trisaksri V, Wongwises S. Critical review of heat transfer characteristics of nanofluids. Renew Sustain Energy Rev. 2007;11(3):512–23.

Montgomery DC. Design and analysis of experiments. New York: Wiley; 2017.

Gunabal S, Alagappan N. Performance of working fluids in a waste heat recovery system using heat pipes. Int J Eng Adv Technol. 2019;8:1–6.

Elnaggar MHA, Abdullah MZ, Mujeebu MA. Experimental investigation and optimization of heat input and coolant velocity of finned twin U-shaped heat pipe for CPU cooling. Exp Tech. 2013;37(6):34–40.

Kourkah FF, Mahd DK, Mirzaee M. Optimization of double pipe heat exchanger with response surface methodology using nanofluid and twisted tape. Fluid Mech. 2017;3(3):20.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Harun, M.A.B., Gunnasegaran, P.A., Sidik, N.A.C. et al. Experimental investigation and optimization of loop heat pipe performance with nanofluids. J Therm Anal Calorim 144, 1435–1449 (2021). https://doi.org/10.1007/s10973-020-09641-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09641-8