Abstract

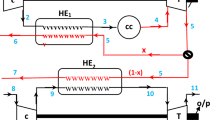

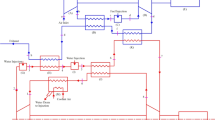

The present investigation is the comparative energy and exergy analysis of a proposed gas turbine (PGT) cycle with a simple gas turbine (SGT) cycle while maintaining the same mass flow rate of fuel in both cycles. In the PGT cycle, a bypass valve (BVP) connects the topping regenerative gas turbine cycle with the air bottoming cycle. It is found that with increase in pressure ratio (rp), turbine inlet temperature (TIT) of topping cycle of PGT cycle decreases continuously in the absence of the BPV, whereas in the PGT cycle with the BVP, the net output and thermal efficiency increased by 20% at rp = 12 and TIT = 900 K to 81% at rp = 4 and TIT = 1000 K. SFC of PGT cycle is reduced by 43–45% for TIT = 900 K and 1000 K, respectively, at rp = 4 as compared to SGT cycle. Also the total exergy destruction and exergetic efficiency of SGT cycle are 62.1–55% less and 26.5–49.7% more, respectively, in contrast to PGT cycle. In addition to this, the exhaust gas exergy losses decrease by 75.5% at the maximum output as compared to the SGT cycle.

Similar content being viewed by others

Abbreviations

- \(W\) :

-

Work output

- T :

-

Temperature (K)

- \(\varepsilon\) :

-

Heat exchanger effectiveness

- \(r_{\text{p}}\) :

-

Pressure ratio

- BPV:

-

Bypass valve

- SFC:

-

Specific fuel consumption

- PGT:

-

Proposed gas turbine

- TIT:

-

Topping gas turbine inlet temperature (K)

- \(\dot{Q}\) :

-

Heat supply rate

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(\eta\) :

-

Thermal efficiency

- LCV:

-

Lower calorific value of fuel

- \(PGT\) :

-

Proposed gas turbine

- HE:

-

Heat exchanger

- SGT:

-

Simple gas turbine

- t :

-

Topping cycle

- c :

-

Compressor

- b :

-

Bottoming cycle

- a :

-

Air

- T :

-

Turbine

- Comb.:

-

Combined

- net:

-

Net

- f :

-

Fuel

References

Kalina AI. Combined-cycle system with novel bottoming cycle. Trans ASME J Eng Gas Turbines Power. 1984;106(4):737–42.

Frost TH, Anderson A, Agnew B. A hybrid gas turbine cycle (Brayton/Ericsson): an alternative to conventional combined gas and steam turbine power plant. Proc Inst Mech Eng Part A (J Power Energy). 1997;211(A2):121–31.

Najjar YSH. Gas turbine cogeneration systems: a review of some novel cycles. Appl Therm Eng. 2000;20(2):179–97.

Kaviri AG, Jaafar MNM, Lazim TM. Modeling and multi-objective exergy based optimization of a combined cycle power plant using a genetic algorithm. Energ Convers Manag. 2012;58:94–103.

Khaliq A. Exergy analysis of gas turbine trigeneration system for combined production of power heat and refrigeration. Int J Refrig. 2009;32:534–45.

Khaliq A, Kaushik SC. Second-law based thermodynamic analysis of Brayton/Rankine combined power cycle with reheat. Appl Energ. 2004;78:179–97.

Sanjay. Investigation of effect of variation of cycle parameters on thermodynamic performance of gas-steam combined cycle. Energy. 2011;36:157–67.

Cafaro S, Napoli L, Alberto T, Massardo AF. Monitoring of the thermoeconomic performance in an actual combined cycle power plant bottoming cycle. Energy. 2010;35:902–10.

Dolz V, Novella R, Antonio G, Sanchez J. HD Diesel engine equipped with a bottoming Rankine cycle as a waste heat recovery system. Part 1: study and analysis of the waste heat energy. Appl Therm Eng. 2011;36:269–78.

Tica A, Gueguen H, Dumur D, Faille D, Davelaar F. Design of a combined cycle power plant model for optimization. Appl Energy. 2012;98:256–65.

Tiwari AK, Hasan MM, Islam M. Effect of ambient temperature on the performance of a combined cycle power plant. Trans Can Soc Mech Eng. 2013;37(4):1177–88.

Ghazikhani M, Khazaee I, Abdekhodaie E. Exergy analysis of gas turbine with air bottoming cycle. Energy. 2014;72:599–607.

Alklaibi AM, Khan MN, Khan WA. Thermodynamic analysis of gas turbine with air bottoming cycle. Energy. 2016;107:603–11.

Farzaneh-Gord M, Deymi-Dashtebayaz M. Effect of various inlet air cooling methods on gas turbine performance. Energy. 2011;36:1196–205.

Tlili I, Timoumi Y, Nasrallah SB. Analysis and design consideration of mean temperature differential Stirling engine for solar application. Renew Energy. 2008;33:1911–21.

Tlili I. Renewable energy in Saudi Arabia: current status and future potentials. Environ Dev Sustain. 2015;17(4):859–86. https://doi.org/10.1007/s10668-014-9579-9.

Tlili I, Timoumi Y, Ben Nasrallah S. Numerical simulation and losses analysis in a Stirling engine. Int J Heat Technol. 2006;24(1):97–105.

Tlili I, Timoumi Y, Ben Nasrallah S. Thermodynamic analysis of Stirling heat engine with regenerative losses and internal irreversibilities. Int J Engine Res. 2007;9:45–56.

Timoumi Y, Tlili I, Ben Nasrallah S. Performance optimization of Stirling engines. Renew Energy. 2008;33:2134–44.

Ahmadi MH, Ahmadi MA, Pourfayaz F, Hosseinzade H, Acıkkalp E, Tlili I, Feidt M. Designing a powered combined Otto and Stirling cycle power plant through multi-objective optimization approach. Renew Sustain Energy Rev. 2016;62:585–95. https://doi.org/10.1016/j.rser.2016.05.034.

Sa’ed A, Tlili I. Numerical Investigation of working fluid effect on Stirling engine performance. Int J Therm Environ Eng. 2015;10(1):31–6.

Tlili I. Finite time thermodynamic evaluation of endoreversible Stirling heat engine at maximum power conditions. Renew Sustain Energy Rev. 2012;16(4):2234–41. https://doi.org/10.1016/j.rser.2012.01.022.

Tlili I. Thermodynamic study on optimal solar Stirling engine cycle taking into account the irreversibilities effects. Energy Procedia. 2012;14:584–91. https://doi.org/10.1016/j.egypro.2011.12.979.

Tlili I. A numerical investigation of an alpha Stirling engine. Int J Heat Technol. 2012;30(1):23–35.

Tlili I, Musmar SA. Thermodynamic evaluation of a second order simulation for Yoke Ross Stirling engine. Energy Convers Manag. 2013;68:149–60. https://doi.org/10.1016/j.enconman.2013.01.005.

Ibrahim TK, Rahman MM. Effect of compression ratio on performance of combined cycle gas turbine. Int J Energy Eng. 2012;2(1):9–14.

Khan MN, Tlili I, Khan WA. Thermodynamic optimization of new combined gas/steam power cycles with HRSG and heat exchanger. Arab J Sci Eng. 2017;42(11):4547–58.

Saghafifar M, Gadalla M. A critical assessment of thermo-economic analyses of different air bottoming cycles for waste heat recovery. Int J Energy Res. 2018;43(4):1–27.

Moon SW, Kwon HM, Kim TS, Kang DW, Sohn JL. A novel coolant cooling method for enhancing the performance of the gas turbine combined cycle. Energy. 2018;160:625–34.

Colera M, Soria Á, Ballester J. A numerical scheme for the thermodynamic analysis of gas turbines. Appl Therm Eng. 2019;147:521–36.

Bazmi AA, Zahedi G, Hashim H. Design of decentralized biopower generation and distribution system for developing countries. J Clean Prod. 2015;86:209–20.

Chatzimouratidis AI, Pilavachi PA. Decision support systems for power plants impact on the living standard. Energy Convers Manag. 2012;64:182–98.

Atmaca E, Basar HB. Evaluation of power plants in Turkey using Analytic Network Process (ANP). Energy. 2012;44:555–63.

Salpingidou C, Tsakmakidou D, Vlahostergios Z, Misirlis D, Flouros M, Yakinthos K. Analysis of turbine blade cooling effect on recuperative gas turbines cycles performance. Energy. 2018;164:1271–85.

Maheshwari M, Singh O. Comparative evaluation of different combined cycle configurations having simple gas turbine, steam turbine and ammonia water turbine. Energy. 2019;168:1217–36.

Salpingidou C, Vlahostergios Z, Misirlis D, Donnerhack S, Flouros M, Goulas A, Yakinthos K. Thermodynamic analysis of recuperative gas turbines and aero engines. Appl Therm Eng. 2017;124:250–60.

Pandžić H, Morales JM, Conejo AJ, Kuzle I. Offering model for a virtual power plant based on stochastic programming. Appl Energy. 2013;105:282–92.

Yazawa K, Hao M, Wu B, Silaen AK, Zhou CQ, Fisher TS, Shakouri A. Thermoelectric topping cycles for power plants to eliminate cooling water consumption. Energy Convers Manag. 2014;84:244–52.

Mohammadi K, Saghafifar M, McGowan JG. Thermo-economic evaluation of modifications to a gas power plant with an air bottoming combined cycle. Energy Convers Manag. 2018;172:619–44.

Colmenar-Santosa A, Gómez-Camazóna D, Rosales-Asensiob E, Blanes-Peiró J-J. Technological improvements in energetic efficiency and sustainability in existing combined-cycle gas turbine (CCGT) power plants. Appl Energy. 2018;223:30–51.

De Paepe W, Carrero MM, Bram S, Contino F, Parente A. Waste heat recovery optimization in micro gas turbine applications using advanced humidified gas turbine cycle concepts. Appl Energy. 2017;207:218–29.

Ibrahim TK, Basrawi F, Awad OI, Abdullah AN, Najafi G, Mamat R, Hagos FY. Thermal performance of gas turbine power plant based on exergy analysis. Appl Therm Eng. 2017;115:977–85.

Chacartegui R, Sánchez D, Muñoz JM, Sánchez T. Alternative ORC bottoming cycles for combined cycle power plants. Appl Energy. 2009;86:2162–70.

Saidur R, Rezaei M, Muzammil WK, Hassan MH, Paria S, Hasanuzzaman M. Technologies to recover exhaust heat from internal combustion engines. Appl Therm Eng. 2012;16(8):5649–59.

Khan MN, Tlili I. New advancement of high performance for a combined cycle power plant: thermodynamic analysis. Case Stud Therm Eng. 2018;12:166–75.

Ghazikhani M, Passandideh-Fard M, Mousavi M. Two new high-performance cycles for gas turbine with air bottoming. Energy. 2011;36:294–304.

Khan MN, Tlili I. Performance enhancement of a combined cycle using heat exchanger bypass control: a thermodynamic investigation. J Clean Prod. 2018;192:443–52.

Timoumi Y, Tlili I, Nasrallah SB. Design and performance optimization of GPU-3 Stirling engines. Energy. 2008;33:1100–14.

Timoumi Y, Tlili I, Nasrallah SB. Reduction of energy losses in a Stirling engine. Heat Technol. 2007;25(1):84–93.

Tlili I, Alkanhal TA. Nanotechnology for water purification: electrospun nanofibrous membrane in water and wastewater treatment. J Water Reuse Desalin. 2019. https://doi.org/10.2166/wrd.2019.057.

Al-Qawasmi A-R, Tlili I. Energy efficiency audit based on wireless sensor and actor networks: air-conditioning investigation. J Eng. 2018;2018: Article ID: 3640821. https://doi.org/10.1155/2018/3640821.

Al-Qawasmi A-R, Tlili I. Energy efficiency and economic impact investigations for air-conditioners using wireless sensing and actuator networks. Energy Rep. 2018;4:478–85. https://doi.org/10.1016/j.egyr.2018.08.001.

Tlili I, Khan WA, Ramadan K. MHD flow of nanofluid flow across horizontal circular cylinder: steady forced convection. J Nanofluids. 2019;8(1):179–86. https://doi.org/10.1166/jon.2019.1574.

Tlili I, Khan WA, Ramadan K. Entropy generation due to MHD stagnation point flow of a nanofluid on a stretching surface in the presence of radiation. J Nanofluids. 2018;7(5):879–90. https://doi.org/10.1166/jon.2018.1513.

Almutairi MM, Osman M, Tlili I. Thermal behavior of auxetic honeycomb structure: an experimental and modeling investigation. ASME J Energy Resour Technol. 2018;140(12):122904-8–122904-8. https://doi.org/10.1115/1.4041091.

Tlili I, Hamadneh NN, Khan WA. Thermodynamic analysis of MHD heat and mass transfer of nanofluids past a static wedge with Navier slip and convective boundary conditions. Arab J Sci Eng. 2018. https://doi.org/10.1007/s13369-018-3471-0.

Tlili I, Hamadneh NN, Khan WA, Atawneh S. Thermodynamic analysis of MHD Couette–Poiseuille flow of water-based nanofluids in a rotating channel with radiation and Hall effects. J Therm Anal Calorim. 2018;132(3):1899–912. https://doi.org/10.1007/s10973-018-7066-5.

Ramadan K, Tlili I. Shear work, viscous dissipation and axial conduction effects on microchannel heat transfer with a constant wall temperature. Proc Inst Mech Eng Part C J Mech Eng Sci. 2016;230(14):2496–507. https://doi.org/10.1177/0954406215598799.

Ma X, Sheikholeslami M, Jafaryar M, Shafee A, Nguyen-Thoi T, Li Z. Solidification inside a clean energy storage unit utilizing phase change material with copper oxide nanoparticles. J Clean Prod. 2019. https://doi.org/10.1016/j.jclepro.2019.118888.

Sheikholeslami M. Omid Mahian, Enhancement of PCM solidification using inorganic nanoparticles and an external magnetic field with application in energy storage systems. J Clean Prod. 2019;215:963–77.

Sheikholeslami M, Rezaeianjouybari B, Darzi M, Shafee A, Li Z, Nguyen TK. Application of nano-refrigerant for boiling heat transfer enhancement employing an experimental study. Int J Heat Mass Transf. 2019;141:974–80.

Alkanhal TA, Sheikholeslami M, Usman M, Haq R-u, Shafee A, Al-Ahmadi AS, Tlili I. Thermal management of MHD nanofluid within the porous medium enclosed in a wavy shaped cavity with square obstacle in the presence of radiation heat source. Int J Heat Mass Transf. 2019;139:87–94.

Sheikholeslami M, Jafaryar M, Hedayat M, Shafee A, Li Z, Nguyen TK, Bakouri M. Heat transfer and turbulent simulation of nanomaterial due to compound turbulator including irreversibility analysis. Int J Heat Mass Transf. 2019;137:1290–300.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z, Haq R-u. Heat transfer of nanoparticles employing innovative turbulator considering entropy generation. Int J Heat Mass Transf. 2019;136:1233–40.

Sheikholeslami M, Seyednezhad M. Simulation of nanofluid flow and natural convection in a porous media under the influence of electric field using CVFEM. Int J Heat Mass Transf. 2018;120:772–81.

Sheikholeslami M, Rokni HB. Numerical simulation for impact of Coulomb force on nanofluid heat transfer in a porous enclosure in presence of thermal radiation. Int J Heat Mass Transf. 2018;118:823–31.

Sheikholeslami M, Haq R-u, Shafee A, Li Z, Elaraki YG, Tlili I. Heat transfer simulation of heat storage unit with nanoparticles and fins through a heat exchanger. Int J Heat Mass Transf. 2019;135:470–8.

Sheikholeslami M, Haq R, Shafee A, Li Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int J Heat Mass Transf. 2019;130:1322–42.

Sheikholeslami M, Shehzad SA, Li Z, Shafee A. Numerical modeling for Alumina nanofluid magnetohydrodynamic convective heat transfer in a permeable medium using Darcy law. Int J Heat Mass Transf. 2018;127:614–22.

Sheikholeslami M, Ellahi R. Three dimensional mesoscopic simulation of magnetic field effect on natural convection of nanofluid. Int J Heat Mass Transf. 2015;89:799–808.

Sheikholeslami M. New computational approach for exergy and entropy analysis of nanofluid under the impact of Lorentz force through a porous media. Comput Methods Appl Mech Eng. 2019;344:319–33.

Sheikholeslami M. Magnetic field influence on CuO–H2O nanofluid convective flow in a permeable cavity considering various shapes for nanoparticles. Int J Hydrogen Energy. 2017;42:19611–21.

Li Y, Aski FS, Barzinjy AA, Dara RN, Shafee A, Tlili I. Nanomaterial thermal treatment along a permeable cylinder. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08706-7.

Sheikholeslami M, Li Z, Shafee A. Lorentz forces effect on NEPCM heat transfer during solidification in a porous energy storage system. Int J Heat Mass Transf. 2018;127:665–74.

Sheikholeslami M. Numerical approach for MHD Al2O3-water nanofluid transportation inside a permeable medium using innovative computer method. Comput Methods Appl Mech Eng. 2019;344:306–18.

Sheikholeslami M. Influence of magnetic field on Al2O3–H2O nanofluid forced convection heat transfer in a porous lid driven cavity with hot sphere obstacle by means of LBM. J Mol Liq. 2018;263:472–88.

Sheikholeslami M. Numerical simulation for solidification in a LHTESS by means of Nano-enhanced PCM. J Taiwan Inst Chem Eng. 2018;86:25–41.

Tlili I, Alkanhal TA, Othman M, Dara RN, Shafee A. Water management and desalination in KSA View 2030: case study of solar humidification and dehumidification system. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08700-z.

Sheikholeslami M, Jafaryar M, Saleem S, Li Z, Shafee A, Jiang Yu. Nanofluid heat transfer augmentation and exergy loss inside a pipe equipped with innovative turbulators. Int J Heat Mass Transf. 2018;126:156–63.

Sheikholeslami M, Ghasemi A, Li Z, Shafee A, Saleem S. Influence of CuO nanoparticles on heat transfer behavior of PCM in solidification process considering radiative source term. Int J Heat Mass Transf. 2018;126:1252–64.

Sheikholeslami M, Darzi M, Li Z. Experimental investigation for entropy generation and exergy loss of nano-refrigerant condensation process. Int J Heat Mass Transf. 2018;125:1087–95.

Sheikholeslami M, Shehzad SA, Li Z. Water based nanofluid free convection heat transfer in a three dimensional porous cavity with hot sphere obstacle in existence of Lorenz forces. Int J Heat Mass Transf. 2018;125:375–86.

Manh TD, Nam ND, Abdulrahman GK, Shafee A, Shamlooei M, Babazadeh H, Jilani AK, Tlili I. Effect of radiative source term on the behavior of nanomaterial with considering Lorentz forces. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09077-9.

Sheikholeslami M, Jafaryar M, Li Z. Nanofluid turbulent convective flow in a circular duct with helical turbulators considering CuO nanoparticles. Int J Heat Mass Transf. 2018;124:980–9.

Sheikholeslami M, Ghasemi A. Solidification heat transfer of nanofluid in existence of thermal radiation by means of FEM. Int J Heat Mass Transf. 2018;123:418–31.

Sheikholeslami M, Sheremet MA, Shafee A, Li Z. CVFEM approach for EHD flow of nanofluid through porous medium within a wavy chamber under the impacts of radiation and moving walls. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08235-3.

Sheikholeslami M, Shehzad SA. CVFEM simulation for nanofluid migration in a porous medium using Darcy model. Int J Heat Mass Transf. 2018;122:1264–71.

Sheikholeslami M, Darzi M, Sadoughi MK. Heat transfer improvement and Pressure Drop during condensation of refrigerant-based Nanofluid: an experimental Procedure. Int J Heat Mass Transf. 2018;122:643–50.

Sheikholeslami M, Sadoughi MK. Simulation of CuO–water nanofluid heat transfer enhancement in presence of melting surface. Int J Heat Mass Transf. 2018;116:909–19.

Seyednezhad M, Sheikholeslami M, Ali JA, Shafee A, Nguyen TK. Nanoparticles for water desalination in solar heat exchanger: review. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08634-6.

Acknowledgements

The author acknowledges the Deanship of Scientific Research (DSR) at Majmaah University, Majmaah, Saudi Arabia, for technical and financial support through vote number 38/111, 2017–2018, for this research project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, M.N., Alkanhal, T.A., Majdoubi, J. et al. Performance enhancement of regenerative gas turbine: air bottoming combined cycle using bypass valve and heat exchanger—energy and exergy analysis. J Therm Anal Calorim 144, 821–834 (2021). https://doi.org/10.1007/s10973-020-09550-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09550-w