Abstract

In this study, new thermoplastic sulfur-containing poly(carbonate-urethane)s (PCURs) were synthesized via a one-step melt polyaddition from diphenylethane-derivative diols with two or ten methylene groups in the aliphatic chain, i.e., 4,4′-(ethane-1,2-diyl)bis(benzenethioethanol) (diol E) and 4,4′-(ethane-1,2-diyl)bis(benzenethiodecanol) (diol D) as nonconventional chain extenders, 1,1′-methanediylbis(4-isocyanatobenzene) and 20–60 mol% poly(hexane-1,6-diyl carbonate) diol of \(\overline{M}_{\rm{n}}\) = 860 g mol−1 as a soft segment. The PCURs were studied mainly to describe their thermal and mechanical behaviors by means of DSC, TG and TG coupled with FTIR, and Shore hardness and tensile tests. Moreover, their structure and physicochemical and adhesive properties were determined. The results of the study showed that the kind of the chain extender as well as soft-segment content had an impact on the properties of the polymers obtained. They were amorphous or semicrystalline high molar mass materials. The PCURs based on diol D exhibited lower glass transition temperatures in comparison with those based on diol E with shorter aliphatic chain (− 1–24 °C vs. 13–55 °C). Unfortunately, the former polymers revealed somewhat poorer tensile strengths (up to 45.0 MPa vs. 51.8 MPa). Nevertheless, these values were similar to or higher than those obtained for their commercial analogs. The PCURs being diol D derivatives also showed, in general, lower hardness and the modulus of elasticity but higher elongation at break. All the PCURs exhibited a relatively good thermal stability. However, the polymers derived from diol D revealed higher temperatures of 1, 10 and 50% mass losses compared with diol E-based ones (290–298 °C vs. 285–287 °C, 325–336 °C vs. 314–323 °C, 360–381 °C vs. 348–356 °C, respectively). The newly synthesized sulfur-containing PCURs showed better adhesive properties to copper than the analogous polymer based on butane-1,4-diol as a chain extender.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyurethanes are among the polymeric materials that are subjected to constant development in view of their convenient properties required in various industrial applications. The way they are obtained is either thermoplastic or thermosetting. Thermoplastic polyurethanes are usually synthesized from diisocyanates and difunctional compounds that contain hydroxyl groups, most often being a combination of a polymer diol and a short-chain diol (chain extender). As a result of this reaction, block copolymers comprising hard and soft segments are created. Due to the soft segment, formed by a polymer diol, polyurethanes have flexibility, softness, long elongation at break and low temperature resistance, whereas the hard segment, composed of a diisocyanate and a short-chain diol, exerts strong influence on the modulus, hardness, tear strength and thermal stability. Polymer diols available for the synthesis of thermoplastic polyurethanes include polyethers, polyesters, polycarbonates, hydrocarbons and polydimethylsiloxanes [1, 2]. However, those most commonly used are polyether, polyester and polycarbonate diols. The polyurethanes based on polyester diols exhibit relatively good physical properties; however, they are susceptible to hydrolytic cleavage of the ester linkages. In turn, the polyurethanes synthesized from polyether diols possess a higher resistance to hydrolysis and are favored for usage in applications where hydrolytic stability is needed. Unfortunately, the latter polymers are sensitive to oxidation [3]. Poly(carbonate-urethane)s (PCURs), i.e., polyurethanes containing polycarbonate soft segment, which are recently quite popular reveal improved oxidative resistance and hydrolytic stability. These polymers additionally show superior mechanical and biological properties and thus are preferred as biopolymers for long-term implantation [4,5,6]. As diisocyanate components, they are used as both aliphatic and aromatic compounds, of which 1,1′-methanediylbis(4-isocyanatobenzene) (MDI), 1,1′-methanediylbis(4-isocyanatocyclohexane) and 1,6-diisocyanatohexane (HDI) are the most frequently utilized. Much like the diisocyanates, chain extenders can include aliphatic or aromatic units. Their choice has a significant effect on the properties of thermoplastic polyurethanes. When aliphatic–aromatic and aromatic “bulky” diols are employed, harder materials of higher modulus of elasticity compared with those from aliphatic diols are generally produced. However, from among those “bulky” diols, aliphatic–aromatic ones give polyurethanes with higher elongation at break and somewhat lower hardness [3, 7, 8]. Both the aliphatic–aromatic and aromatic diols are also used for the synthesis of polyurethanes with enhanced thermal stability [9, 10] or liquid crystalline properties [11]. Additionally, introducing bromine atoms into the structure of these diols results in improved flame retardancy of the resulting materials [12]. My co-workers’ and my own scientific interests cover aliphatic–aromatic diols with sulfur atoms being the derivatives, among others, of diphenylmethane [13,14,15], diphenyl ether and diphenyl sulfide [16,17,18]. They allow to obtain thermoplastic polyurethanes with good thermal stability and mechanical properties, but at the same time with higher adhesive strength to metals and refractive index in comparison with a conventional aliphatic diol [18,19,20,21]. Although it is possible to prepare thermoplastic PCURs from the above-mentioned sulfur-containing chain extenders with good performance characteristics, it is interesting to check whether the use of the chain extenders with symmetric and linear structure instead of those with an angled one [17, 18] will improve the properties of obtained PCURs. The main aim of this work was to study the effect of diphenylethane-derivative diols differing in the length of the aliphatic chain on the structure and thermal, mechanical, physicochemical and adhesive properties of new thermoplastic PCURs. The PCURs were synthesized from 4,4′-(ethane-1,2-diyl)bis(benzenethioethanol) (diol E) or 4,4′-(ethane-1,2-diyl)bis(benzenethiodecanol) (diol D), MDI and 20–60 mol% poly(hexane-1,6-diyl carbonate) diol (PHCD) of \(\overline{M}_{\rm {n}}\) = 860 g mol−1 as a soft segment.

Experimental

Materials

The diols E (m.p. = 122–123 °C) and D (m.p. = 125–126 °C) were prepared by the condensation reaction of 4,4′-(ethane-1,2-diyl)bis(benzenethiol) with 2-chloroethanol or 10-chlorodecan-1-ol, respectively, in 10% aqueous solution of sodium hydroxide [22]. PHCD of \(\overline{M}_{\rm{n}}\) = 860 g mol−1 was purchased from Aldrich (USA), and prior to use, it was heated at 90 °C in vacuo for 10 h. MDI (98%) from Sigma-Aldrich (Germany) was used as received, while butane-1,4-diol (BD) from POCH (Poland) was distilled at 118 °C/18 mm Hg.

PCURs synthesis

In accordance with the scheme in Fig. 1, two series of new PCURs were obtained by using the diphenylethane-derivative diols (E or D) and MDI as components of the hard segments and 20, 40, 50 or 60 mol% PHCD as a soft segment.

The reactions were conducted in the following way: The diols E or D and PHCD (0.01 mol together) were heated under dry nitrogen to 130 °C in an oil bath. MDI (0.01 mol) was added to melted and mixed dihydroxy compounds, and the reaction was continued until increase in viscosity made stirring impossible. Then, the reaction temperature was raised to 140 °C and the formed product was conditioned at this temperature for 2 h.

Measurements

Reduced viscosities (ηreds, dL g−1) of 0.5 mass% polymer solution in a phenol (Ph)/1,1,2,2-tetrachloroethane (TChE) (Ph/TChE) mixture with a mass ratio of 1:3 were measured in an Ubbelohde viscometer (Poland) at 25 °C.

Attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR) spectra were obtained with a Nicolet 8700 FTIR spectrophotometer (Thermo Scientific, USA). The spectra were recorded in the spectral range of 600–4000 cm−1 with 32 scans per spectrum with a resolution of 4 cm−1.

Differential scanning calorimetry (DSC) was performed with a Netzsch 204 calorimeter (Germany). The measurements were done in aluminum pans with pierced lid (mass of 40 ± 1 mg). As a reference, empty aluminum crucible was used. Dry nitrogen gas with a flow rate of 30 mL min−1 was purged through the sample cell. Cooling was accomplished with the liquid nitrogen. Samples of 10 ± 0.2 mg were cooled to − 100 °C, heated to 200 or 230 °C, cooled again to − 100 °C and reheated to 200 or 230 °C. The heating/cooling rate of 10 °C min−1 was used. The reported transitions were taken from first and second heating scans. The inflection point on the curves of the heat capacity changes has been chosen to represent the glass transition temperatures (Tgs) for the polymer samples. Melting temperatures (Tms) were read at endothermic peak maxima.

TG was carried out with a Netzsch STA 449 F1 Jupiter thermal analyzer (Germany) in the range of 40–1000 °C in helium (flow = 20 mL min−1), at the heating rate of 10 °C min−1, with the sample mass of 10 ± 0.2 mg. The composition of the gas evolved during the decomposition process was analyzed by a Bruker Tensor 27 FTIR spectrometer (Germany) coupled online to a Netzsch STA instrument by Teflon transfer line with 2 mm diameter heated to 200 °C. The FTIR spectra were recorded in the spectral range of 600–4000 cm−1 with 16 scans per spectrum at 4 cm−1 resolution.

X-ray diffraction (XRD) measurements were performed using a DRON-3 X-ray apparatus (Russia) with a copper tube and a nickel filter. The XRD patterns of the investigated samples were obtained by measuring the number of impulses within a given angle over 6 s. The measurements were taken every 0.04°. The XRD patterns were analyzed by WAXSFIT computer program [23]. The program resolves a diffraction curve on diffraction peaks and an amorphous halo which allows to estimate the degree of crystallinity.

Atomic force microscopy (AFM) was carried out on a Nanoscope V (Veeco, USA) microscope, in tapping mode in air. Silicon probes that were used (NSG30, NT-MDT, Russia) had a nominal spring constant of 20–100 N m−1. In order to compare the structure of investigated samples, the imaging parameters were kept constant. Medium tapping technique was used to obtain phase images at 1 μm scan size. The specimens used were the cuttings from crude polymers after one-month conditioning at room temperature.

The hardness of the polymers was measured by the Shore A/D method on a Zwick 7206/H04 hardness tester (Germany) at 23 °C, and values were taken after 15 s.

Tensile testing was performed on a Zwick/Roell Z010 (Germany) tensile testing machine according to Polish Standard PN-81/C-89034 (EN ISO Standard 527-1:1996 and 527-2:1996) at the speed of 100 mm min−1 at 23 °C; tensile test pieces which were 1 mm thick and 6 mm wide (for the section measured) were cut from the pressed sheet.

Press molding was done with a Carver hydraulic press (USA) at 155–170 °C under 10–30 MPa pressure.

The single-lap shear strength of the polymers to copper plate, 100 mm × 25 mm × 1.5 mm, was measured in accordance with Polish Standard PN–EN 1465:2009 by using a Zwick/Roell Z010 (Germany). The adhesive joint, 12.5 mm × 25 mm × 0.2 mm, was prepared by pressing the polymer between the ends of two copper plates at 155–165 °C (prepared according to PN-EN-13887:2005) and then leaving them under a pressure of 30 MPa to cool to room temperature. Next, the plates were fixed by tensile testing machine clips and underwent tensile testing at the speed of 2 mm min−1 at 23 °C.

Results and Discussion

The PCURs were colorless materials showing high resistance against common organic solvents. They were insoluble in dimethyl sulfoxide, tetrahydrofuran, N,N-dimethylacetamide, N,N-dimethylformamide, N-methyl-2-pyrrolidone, chloroform and TChE and partially or completely dissolved at room temperature only in a Ph/TChE mixture. The high ηred values received in this mixture indicate high molar masses of all the PCURs (see Table 1).

The chemical structures of the PCURs were confirmed by ATR–FTIR spectroscopy. All the spectra revealed significant absorptions of the urethane and carbonate groups as well as benzene ring and methylene group, but did not show absorption of the isocyanate group about 2270 cm−1, which points to full NCO conversion. The main absorption bands are given below, whereas representative spectra are shown in Fig. 2.

ATR–FTIR (cm−1): 1531–1525 (N–H bending) and 3343–3318 (N–H stretching) of the urethane group; 1737–1699 (C=O stretching of the urethane and carbonate groups); 1253–1245 (C–O stretching of the carbonate group); 2937–2921 and 2860–2851 (asymmetric and symmetric C–H stretching of methylene group); 1597–1595 and 1496–1493 (C–C stretching of benzene ring); and 816–814 (C–H bending of p-disubstituted benzene ring).

Thermal properties

DSC

DSC measurements were made during two heating cycles within the temperature range of − 100 to 200 or 230 °C. The numerical data obtained (Tg, Tm and heat of melting (ΔHm) values) for all the PCURs after one-month conditioning at room temperature are summarized in Table 2, while Figs. 3 and 4 illustrate the DSC curves. To facilitate the interpretation of the results, Table 2 and Figs. 3 and 4 give the earlier presented data determined for the regular polyurethanes (RPURs) synthesized from the diols E or D and MDI in melt, which are the models of hard segments in the PCURs [22], and PHCD used as a soft segment [24] as well.

On the curves received, for the both diol E- and diol D-based PCURs, steps connected with the glass transition can be observed. Tgs registered in the first heating cycles were in the range of 13–45 °C for the former polymers, and − 1–24 °C for the latter ones. In the second cycles of heating, they generally moved to higher temperatures and amounted to 18–55 °C and 8–24 °C, respectively. This is due to the fact that successive melting and quenching promote phase mixing and lead to less pure soft-segment domains. Comparing the Tg values obtained for these PCURs and PHCD, one can say that all the newly synthesized PCURs had a low degree of microphase separation, yet it increased as the soft-segment content grew. However, a better microphase separation was exhibited by the polymers containing more flexible units, i.e., those being the derivatives of diol D with longer aliphatic chain. Such a relationship was also observed in the case of familiar PCURs based on diols containing diphenylmethane units, MDI [13] or HDI [25], as well as in the case of poly(ester-urethane)s derived from MDI and various aliphatic diols with an even number of methylene groups [26]. Unfortunately, the Tg values limit the usefulness of the studied polymers as elastomers at room temperature (for three of them, they were above 20 °C). Similar or somewhat higher Tg values were discovered for the PCURs derived from MDI, PHCD of \(\overline{M}_{\rm{n}}\) = 860 g mol−1 and other aliphatic–aromatic chain extenders [13, 18].

The DSC curves obtained for PCURs E-2–E-5 displayed in the first heating scan, apart from glass transition, one or two superimposing endothermic peaks with the maxima at 172–199 °C, associated with the melting of hard segments. In turn, the curve of E-6 sample was typical of amorphous polymers since it showed no endothermic peaks (Fig. 3). In the case of polymers E-2 and E-4, the Tms of hard segments were close to those of RPUR E. It points to the formation of well-ordered structures within the hard-segment-domains. The creation of these well-ordered structures is also indicated by the high ∆Hm values (17.9 and 21.9 J g−1). The curves from the second heating scans of all diol E-derived PCURs presented only glass transition, which is a sign that these polymers had a low ability to form ordered structures at the used cooling rate (10 °C min−1).

On the curves taken for the PCURs based on diol D (Fig. 4) in the first heating cycles, the glass transition was followed by two, three or four overlapping endothermic peaks connected with their melting. Taking into account the PHCD and RPUR D curves, it can be said that all these peaks were related to the melting of hard-segment domains. The lower temperature peaks at 48–57 °C could be ascribed to the melting of the short-range ordered structures, whereas those at 101–154 °C corresponded to the melting of the more ordered structures, including long-range ordered ones. With the increase in the soft-segment content, the ordering in hard-segment domains diminished. Namely, the maxima of the higher temperature endothermic peaks were shifted toward lower values, and the ∆Hm values decreased. The curves from the second heating cycles for D-2 and D-4 samples showed endothermic peaks preceded by exothermic peaks associated with the so-called cold crystallization. It means that these polymers were unable to completely crystallize during the cooling, but they were able to crystallize on heating. Due to the fact that the values of the heat of cold crystallization and melting were very similar, it could be stated that amorphous polymers were obtained using a cooling rate of 10 °C min−1. In the case of the remaining PCURs of this series, just as it was observed for all diol E-based PCURs, neither endothermic nor exothermic peaks were seen. That finding is also typical of amorphous polymers. It can be a result of the applied cooling rate, too fast to allow the polymer chains to reorganize in an ordered state.

Analyzing the DSC curves from the first heating scans, it could be concluded that among the PCURs with a high hard-segment content (20 and 40 mol% of PHCD), those based on diol E showed more ordered structures, while for the remaining ones the opposite trend was observed. Similar situation was seen in the case of polyurethanes whose synthesis used poly(oxytetramethylene oxide) diol (PTMO) instead of PHCD [27]. In turn, the PHCD-based PCURs obtained from diols containing diphenylmethane units, with one exception, did not exhibit ordered structures [13]. It can therefore be assumed that diphenylethane unit present in the chain extender structure, which is linear, symmetric and flexible, allowed better packing of the hard segments in comparison with diphenylmethane one with an angled structure. This led to the better ordering within the hard-segment domains.

TG

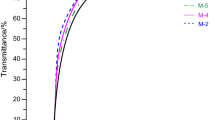

The thermal stability of the PCURs and RPURs was investigated in inert conditions using TG method. Based on the course of TG curves, the temperatures of 1, 5, 10 and 50% mass loss (T1, T5, T10 and T50) were designated, whereas the temperature of the maximum rate of mass loss (Tmax) for particular decomposition stages was designed on the basis of differential TG (DTG) curves. Table 3 presents all the determined values, while Figs. 5–7 display the curves obtained for the RPURs and selected PCURs. Moreover, for the RPURs and PCURs with 50 mol% PHCD content (E-5 and D-5), an analysis of volatile decomposition products was performed by the TG coupled with FTIR spectroscopy (TG-FTIR). Figure 8 presents representative 3D FTIR plots (for RPUR E and PCUR E-5), while Figs. 9–12 show FTIR spectra obtained at the maximum rate of the thermal decomposition of all examined polymers. In order to make easier the interpretation of the results, TG-FTIR studies were also carried out for diols E and D. The data obtained are presented in Fig. 13.

The DTG curves obtained for both RPURs (Fig. 5) show two overlapping peaks of different intensities, indicating a two-stage decomposition process. In the case of polymer based on diol E, sharp large intense peak with the maximum at 349 °C and low intense one with the maximum at 463 °C are observed that relate to ~ 76 and 10% mass losses, respectively. In turn, in the case of diol D-based polymer, there are peaks with the maxima at 377 and 428 °C, with a higher intensity of the higher temperature one. They correspond to ~ 42 and 55% mass losses. The peaks with the maxima at 349 and 377 °C can relate to the decomposition of urethane and sulfide bonds [13], while those with maxima at 428 and 463 °C are probably associated with the decomposition of aliphatic chains and aromatic units [24, 28]. These assumptions require the analysis of volatile decomposition products.

From the analysis of TG data (Table 3 and Fig. 5), it follows that RPUR D was characterized by a somewhat better thermal stability. It revealed higher T1 (300 vs. 294 °C), T5 (327 vs. 318 °C), T10 (343 vs. 329 °C) and T50 (409 vs. 355 °C) than RPUR E. Diol D-based RPUR containing longer aliphatic chain is more difficult to decompose than that with shorter chain because more bonds require breaking down. Moreover, these results are in agreement with the rule that the more easily the urethanes are formed, the less stable they are (easily dissociate) [7, 29]. So, more reactive diol E gives polyurethane with a somewhat worse thermal stability. The TG data also show that RPUR D at 1000 °C lost 96.5% of the initial mass while RPUR E only 88.5%. This is due to the higher content of aromatic rings in RPUR E sample.

The FTIR spectra (Figs. 9 and 10) from the first decomposition stage (Tmax at 349 and 377 °C) for both RPURs show bands typical of carbon dioxide (at 2359–2310 cm−1 connected with asymmetric stretching vibrations, at 669 cm−1—with the degenerate bending vibrations and at ~ 3700–3550 cm−1—with combination bands), carbonyl sulfide (at 2072 and 2047 cm−1, characteristic of asymmetric and symmetric C=O stretching vibrations, respectively) and water (at ~ 4000–3500 and ~ 1800–1300 cm−1, associated with stretching and bending vibrations, respectively). In the FTIR spectrum of RPUR E, one can also notice bands originating from carbonyl products, among others aldehydes (at 1771–1747 cm−1—C=O stretching vibrations and at 2737 cm−1—C–H stretching vibrations of aldehyde group) and unsaturated compounds (at 968 cm−1—C–H out-of-plane deformation vibrations of –CH=CH2 group). In turn, the spectrum of RPUR D additionally displays the bands characteristic of aliphatic unsaturated compounds and alcohols. The creation of the former products is evidenced by the bands at 913 and 990 cm−1 as well as at 3085 cm−1 attributed to the C–H out-of-plane deformation and stretching vibrations, respectively, of –CH=CH2 group and at 2980 and 2935 cm−1 related to the asymmetric C–H stretching vibrations of –CH3 and =CH2 groups, respectively, as well as at 2868 cm−1 connected with the symmetric C–H stretching vibrations of –CH3 and =CH2 groups. The formation of the alcohols is manifested by the band at 1047 cm−1 associated with the C–OH stretching vibrations.

The FTIR spectrum recorded during the second decomposition step of RPUR D (Fig. 10, Tmax at 428 °C) still shows the bands coming from carbon dioxide and carbonyl sulfide (of lower intensities), water (of similar intensity) and aliphatic unsaturated products, including alcohols (of higher intensities). In addition, the bands confirming the existence of aliphatic unsaturated compounds appear, i.e., at 1637 cm−1 (the C=C stretching vibrations of –CH3 and =CH2 groups) and at 1457 and 1379 cm−1 (the C–H bending vibrations of –CH3 and =CH2 groups). In the spectrum, there are also bands at 2181 and 2110 cm−1 which are a sign of the presence of carbon monoxide.

The FTIR spectrum from the second step of RPUR E decomposition (Fig. 9, Tmax at 463 °C) exhibits the same bands as in the first step, but of different intensities. The bands from carbon dioxide and aldehydes decrease while those from carbonyl sulfide increase.

On the basis of the presented spectra, it can be stated that in the case of both RPURs, urethane (the presence of bands typical of carbon dioxide) and sulfide linkages (the presence of bands typical of carbonyl sulfide) decomposed in the first and second stages. One can also note that the main decomposition of urethane linkages occurred in the first one. Furthermore, the existence of the bands characteristic of aliphatic unsaturated alcohols (probably 9-decen-1-ol [30] in the RPUR D spectra and aldehydes (probably acetaldehyde [30] in the RPUR E spectra), being the products of diol D and E decomposition, respectively (Fig. 13), indicates that the decomposition of these polymers was attached to the dissociation of the urethane bonds to MDI and diol, followed by the carbodiimization of isocyanate and accompanied by the emission of carbon dioxide, according to the following way:

Due to the lack of bands typical of amine compounds, it can be assumed that the urethane linkage degradation did not proceed according to such mechanisms, as a result of which primary amine, alkenes and carbon dioxide or secondary amines and carbon dioxide were generated, just as it was found in the case of some other types of MDI-based polyurethanes [29, 31]:

From the analysis of the spectra obtained from the decomposition of RPUR D, it also follows that the main decomposition of the aliphatic chains took place in the second stage.

Subsequently, taking into account the spectra recorded from the beginning of the decomposition (see Fig. 8 for RPUR E), it is evident that in the case of both RPURs, the urethane bond degradation occurred at a lower temperature than the sulfide one. It is so as the evolution of carbonyl sulfide began at higher temperature (~ 330 °C) than carbon dioxide (~ 230 °C).

The DTG curves received for PCURs based on diol E have a similar appearance to that obtained for RPUR E. As an example, the curve for PCUR E-5 is presented in Fig. 6. The maxima of the higher temperature and lower temperature peaks are contained in the range of 342–359 °C and 465–468 °C, respectively. In the case of PCURs derived from diol D, just as for RPUR D, two overlapping peaks are observed, with maxima at 359–363 °C and 421–425 °C, however with a different intensity ratio. The lower temperature peak is more intense here, as shown in Fig. 7. It can also be noted that the increase in the PHCD content caused an increase in the peak intensity at lower temperature and a decrease at higher temperature. And so, from ~ 67% (for D-2) to ~ 88% (for D-6) of mass was lost at the first decomposition stage, whereas at the second decomposition stage the range was from ~ 30% (for D-2) to ~ 11% (for D-6). All the diol D-derived PCURs decomposed almost completely (the residual masses 0.5–2.0%). The higher residual masses were detected for PCURs being diol E derivatives (2.7–6.7%).

The comparison of DTG data obtained for PCURs, relevant RPURs and PHCD shows that the decomposition of the urethane and sulfide bonds in PCURs was simultaneous with the decomposition of polycarbonate soft segments. From the TG data (Table 3), it results that PCURs synthesized from diol D showed higher T1, T5, T10 and T50 than those from diol E, as it was stated for RPURs. However, with the increase in PHCD content, these differences became smaller. The PCURs of both series were characterized by similar or better thermal stability in comparison with the MDI-based PCURs prepared from other sulfur-containing aliphatic–aromatic chain extenders [17, 18] or aliphatic one [32, 33].

The FTIR spectrum from the first stage of PCUR D-5 decomposition (Fig. 12, Tmax at 363 °C) is very similar to the spectrum obtained in the first stage of RPUR D decomposition; i.e., there are absorption bands typical of carbon dioxide, carbonyl sulfide, water and aliphatic unsaturated alcohols. However, the bands coming from carbonyl sulfide have lower intensity, which is caused by a smaller share of hard segments in this polymer. Additionally, the bands at 1143 and 2185 cm−1 appear, indicating the presence of aliphatic ethers (C–O stretching vibrations of the ether group) and carbon monoxide, respectively. It can therefore be supposed that carbon monoxide and ethers are the products of the soft-segment decomposition. Similarly, a much greater intensity of the bands characteristic of carbon dioxide indicates that also carbon dioxide originates from the decomposition of soft segments, which the spectrum obtained for the PHCD [20] confirmed.

In the second stage of PCUR D-5 decomposition (Fig. 12, Tmax at 425 °C), characteristic bands but of higher intensity can be observed for the above-mentioned compounds. There are also bands suggesting the formation of aldehydes (at 2720 and 1748 cm−1), which were not found in the decomposition products of RPUR D. Moreover, the spectrum shows bands confirming the formation of unsaturated aliphatic compounds as well (at 1647 cm−1 – the C=C stretching vibrations of –CH=CH2 group and at 1457 and 1375 cm−1—the C–H bending vibrations of =CH2 and –CH3 groups).

When analyzing all existing data, it can be concluded that carbon dioxide, ethers and aldehydes come from the decomposition of polycarbonate chains, while carbon monoxide, alcohols and unsaturated compounds can originate from both the decomposition of diol D and polycarbonate chains.

The spectra, from both the first and second stages of the PCUR E–5 decomposition (Fig. 11, Tmax at 353 and 468 °C), look almost like the spectra obtained for PCUR D-5. Only slight differences in the intensity of the individual absorption bands are visible. In the case of this polymer, in contrast to the PCUR D-5, aldehydes are products of decomposition not only of polycarbonate soft segments but also of hard segments, while alcohols and unsaturated compounds are associated with the decomposition of soft segments only.

XRD

The XRD studies were carried out for all the synthesized PCURs, and the obtained patterns are presented in Figs. 14 and 15. The WAXFIT program analysis of these patterns showed that only three of the PCURs had partially crystalline structures. That is to say, the peaks originating from a crystalline phase (full width at half maximum (FWHM) in the range of 0.3–1.8°) were found just on the XRD patterns of E-2, E-4 and D-2 (see Fig. 16). The degree of crystallinity calculated for these polymers, as the ratio of the sum of crystalline to the total sum of crystalline and amorphous peaks areas, equals 29.6, 22.8 and 10.0%, respectively. These results agree well with those obtained with DSC method. Only on curves of the above-mentioned polymers (Figs. 3 and 4) can be seen relatively sharp peaks with the maxima at 191 and 199 °C (for E-2 and E-4) and 154 °C (for D-2), which indicate their high degree of ordering. In addition, taking the DSC plots into account, it can be stated that the crystallinity was connected with the hard-segment crystallization.

AFM

Bulk morphology of the selected PCURs (E-5 and D-5) was analyzed using AFM in tapping mode. Tapping-mode AFM generates phase images with dark regions of lower modulus corresponding to the soft-segment-rich domains and bright regions of higher modulus attributed to the hard-segment-rich domains. As can be seen in Fig. 17, no great differences in the appearance of the images obtained are observed. In both cases, there are no distinct dark areas indicating well-separated soft segments, which agrees with the DSC results. What can be seen, however, are bright rod-like and circular elements against a gray background, corresponding to the ordered domains of hard segments. On the other hand, in the case of sample E-5, in which hard segments are built of a diol with a shorter aliphatic chain, these objects form larger aggregates.

Mechanical properties

As can be seen from the data given in Table 4, all the PCURs showed very good tensile strength that ranged from 40.8 to 51.8 MPa. Their elongation at break, contained in the range of 60–390%, increased with increasing aliphatic length in the chain extender used. The opposite dependence, in the main, was observed in the case of other parameters, i.e. hardness, the modulus of elasticity and tensile strength. Among the obtained PCURs, those showing partially crystalline structures (E-2, E-4 and D-5) were characterized by the highest values of the modulus of elasticity (104–1290 MPa) and hardness (88–90 °Sh A, 51–71 °Sh D). The stress–strain curves of the polymers with the highest hard-segment content (their Tgs were above 23 °C) showed yield stress, characteristic of plastics, as is illustrated in Fig. 18 for sample D-2. The remaining polymers displayed elastomeric stress–strain curves (see Fig. 18 for samples D-4–D-6).

Moreover, from the data presented in this table, it follows that as PHCD content increased, hardness and the modulus of elasticity decreased, while elongation at break increased. Particularly, high differences in the modulus of elasticity were observed between polymers E-2 and E-4.

These newly obtained polymers exhibited higher tensile strength, hardness and in most cases modulus of elasticity, as well as lower elongation at break than the materials described earlier containing the same types of hard segments and a PTMO soft segment with a similar \(\overline{M}_{\rm{n}}\) [27]. Generally, the studied PCURs also possessed higher tensile strength compared to the analogous PCURs based on diols with diphenylmethane and diphenyl sulfide units [13, 18].

Adhesive properties

The impact of the introduction of nonconventional chain extenders containing sulfur atoms to the polymer chains was determined by comparing the lap shear strength to copper (adhesion) of the PCURs obtained from diol E or D and their conventional counterpart synthesized in the same conditions from BD as a chain extender. The studies were conducted for the polymers with 50 mol% soft-segment content, and the results are given in Fig. 19. They reveal that the introduction of both diol E and D caused over two times increase in adhesive strength of the PCURs (17.0 and 15.6 MPa vs. 7.0 MPa). Moreover, it is evident that the polymer derived from diol E (with a shorter aliphatic chain and thus a higher percentage of sulfur) exhibited higher value of this parameter.

Conclusions

The sulfur-containing diphenylethane-derivative diols with two (diol E) or ten (diol D) methylene groups in the aliphatic chain were employed for the preparation of colorless, high molar mass MDI-based PCURs. A DSC analysis revealed that diol D series PCURs were characterized by better low-temperature properties (lower glass transition temperatures: − 1–24 °C vs. 13–55 °C) than their analogs of diol E series. This analysis also showed that the PCURs of both series (with the exception of E-6) exhibited ordered structures within hard-segment domains. The crystalline phase, however, was found only for PCURs E-2, E-4 and D-2. As is clear from the TG study of the PCURs, they all revealed a relatively good thermal stability. Their temperatures of 1% mass loss were contained in the range of 285–298 °C, with somewhat higher values shown by those from diol D. The thermal decomposition of PCUR samples of both types took place in two stages and partially overlapped. Nevertheless, the main decomposition of both the hard and soft segments, occurred in the first one. From the TG-FTIR analysis, it follows that the decomposition of the hard segments began not with the decomposition of sulfide but of urethane bonds and was associated with the dissociation of the latter. The volatile products of the PCUR decomposition were carbon dioxide, carbon monoxide, water, carbonyl sulfide as well as aliphatic ethers, aldehydes, alcohols and unsaturated compounds. Results obtained from the analysis of mechanical properties demonstrated that all the PCURs possessed very good tensile strength: 40.8–51.8 MPa (from diol E) and 42.4–45.0 MPa (from diol D). Their elongations at break were within the range of 60–315% and 150–390%, respectively. The PCURs, with hardness ranging between 77 and 85 °Sh A, showed higher or similar tensile strength but lower elongation at break compared to their commercial analogs with an MDI/BD hard segment and poly(hexane-1,6-diyl-ethylene carbonate) diol soft segment, i.e., ChronoFlex C® 80A (37.9–45.5 MPa, 400–490%) and Bionate® 80A (46.6 MPa, 530%) [34]. Furthermore, these newly synthesized sulfur-containing PCURs exhibited better adhesive properties to metals (as was measured by the adhesive strength to copper) than analogous conventional PCUR derived from BD as a chain extender.

References

The polyurethanes book. Randall D, Lee S, editors. Everberg, Belgium: Huntsman Polyurethanes; New York: distributed by John Wiley & Sons; 2002.

Sonnenschein MF. Polyurethanes: science, technology, markets, and trends. Hoboken: Wiley; 2014.

Hepburn C. Polyurethane elastomers. London: Elsevier Science Publishers Ltd; 1992.

Spirkova M, Poreba R, Pavlicevic J, Kobera L, Baldrian J, Pekarek M. Aliphatic polycarbonate-based polyurethane elastomers and nanocomposites. I. The influence of hard-segment content and macrodiol-constitution on bottom-up self-assembly. J Appl Polym Sci. 2012;126:1016–30.

Christenson EM, Anderson JM, Hiltner A. Antioxidant inhibition of poly(carbonate urethane) in vivo biodegradation. J Biomed Mater Res. 2006;76A:480–90.

Rokicki G, Kowalczyk T. Synthesis of oligocarbonate diols and their characterization by MALDI-TOF spectrometry. Polymer. 2000;41:9013–31.

Wirpsza Z. Polyurethanes: chemistry, technology and applications. New York: Ellis Horwood; 1993.

Karak N. Vegetable oil-based polymers. properties, processing and applications. Cambridge: Woodhead Publishing Ltd; 2012.

Oprea S, Joga A, Zorlescu B, Oprea V. Effect of the hard segment structure on properties of resorcinol derivatives-based polyurethane elastomers. High Perform Polym. 2014;26:859–66.

Liu X, Wang T, Li J, Cheng J, Zhang J. Synthesis and properties of segmented polyurethanes with hydroquinone ether derivatives as chain extender. J Polym Res. 2015;22:149.

Padmavathy T, Srinivasan KSV. Liquid crystalline polyurethanes - a review. J Macromol Sci, Polym Rev. 2003;C43:45–85.

Liaw DJ. The relative physical and thermal properties of polyurethane elastomers: effect of chain extenders of bisphenols, diisocyanate, and polyol structures. J Appl Polym Sci. 1997;66:1251–65.

Kultys A, Rogulska M, Pikus S. New thermoplastic segmented polyurethanes with hard segments derived from 4,4’-diphenylmethane diisocyanate and methylenebis(1,4-phenylenemethylenethio)dialcanols. J Appl Polym Sci. 2012;123:331–46.

Kultys A, Rogulska M. New thermoplastic poly(carbonate-urethane) elastomers. Pol J Chem Tech. 2011;13:23–30.

Puszka A, Kultys A. New thermoplastic polyurethane elastomers based on aliphatic diisocyanate: synthesis and characterization. J Therm Anal Calorim. 2017;128:407–16.

Rogulska M, Kultys A, Lubczak J. New thermoplastic polyurethane elastomers based on aliphatic-aromatic chain extenders with different content of sulfur atoms. J Therm Anal Calorim. 2015;121:397–410.

Rogulska M, Kultys A, Pikus S. The effect of chain extender structure on the properties of new thermoplastic poly(carbonate-urethane)s derived from MDI. J Therm Anal Calorim. 2017;127:2325–39.

Rogulska M, Kultys A, Puszka A. New thermoplastic poly(carbonate-urethane)s based on chain extenders with sulfur atoms. Chem Pap. 2017;71:1195–204.

Rogulska M, Kultys A. Aliphatic polycarbonate-based thermoplastic polyurethane elastomers containing diphenyl sulfide units. J Therm Anal Calorim. 2016;126:225–43.

Rogulska M. Transparent sulfur-containing thermoplastic polyurethanes with polyether and polycarbonate soft segments. Polym Bull. 2018;75:1211–35.

Puszka A, Kultys A. The influence of soft segments on some properties of new transparent segmented polyurethanes. Polym Adv Technol. 2017;28:1937–44.

Rogulska M, Podkościelny W, Kultys A, Pikus S, Poździk E. Studies on thermoplastic polyurethanes based on new diphenylethane-derivative diols. I. Synthesis and characterization of nonsegmented polyurethanes from HDI and MDI. Eur Polym J. 2006;42:1786–97.

Rabiej M, Rabiej S. Analysis of X-ray diffraction pattern of polymers by means of WAXSFIT computer program (in Polish). Poland: ATM; 2006.

Rogulska M, Kultys A, Olszewska E. New thermoplastic poly(thiourethane-urethane) elastomers based on hexane-1,6-diyl diisocyanate (HDI). J Therm Anal Calorim. 2013;114:903–16.

Kultys A, Rogulska M, Pikus S, Skrzypiec K. The synthesis and characterization of new thermoplastic poly(carbonate-urethane) elastomers derived from HDI and aliphatic-aromatic chain extenders. Eur Polym J. 2009;45:2629–43.

Zia KM, Barikani M, Bhatti IA, Zuber M, Bhatti HN. Synthesis and thermomechanical characterization of polyurethane elastomers extended with α, ω-alkane diols. J Appl Polym Sci. 2008;109:1840–9.

Rogulska M, Kultys A, Podkoscielny W. Studies on thermoplastic polyurethanes based on new diphenylethane-derivative diols. II. Synthesis and characterization of segmented polyurethanes from HDI and MDI. Eur Polym J. 2007;43:1402–14.

Xu Y, Petrovic Z, Das S, Wilkes GL. Morphology and properties of thermoplastic polyurethanes with dangling chains in ricinoleate-based soft segments. Polymer. 2008;49:4248–58.

Chattopadhyay DK, Webster DC. Thermal stability and flame retardancy of polyurethanes. Prog Polym Sci. 2009;34:1068–133.

The website http://webbook.nist.gov/chemistry/.

Simon J, Barla F, Kelemen-Haller A, Farkas F, Kraxner M. Thermal stability of polyurethanes. Chromatographia. 1988;25:99–106.

Kim S-M, Park S-A, Hwang SY, Kim ES, Jegal J, Im C, Jeon H, Oh DX, Park J. Environmentally-friendly synthesis of carbonate-type macrodiols and preparation of transparent self-healable thermoplastic polyurethanes. Polymers. 2017;9:663.

Cipriani E, Zanetti M, Brunella V, Costa L, Bracco P. Thermoplastic polyurethanes with polycarbonate soft phase: effect of thermal treatment on phase morphology. Polym Degrad Stab. 2012;97:1794–800.

The website http://www.matweb.com.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Rogulska, M. New thermoplastic poly(carbonate-urethane)s based on diphenylethane-derivative chain extenders—the effect of chain extender structure on thermal and mechanical properties. J Therm Anal Calorim 139, 3107–3121 (2020). https://doi.org/10.1007/s10973-019-08661-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08661-3