Abstract

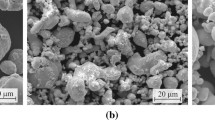

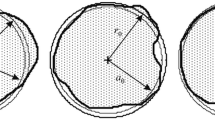

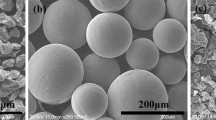

Amorphous calcium silicate hydrate (CSH) undergoes contact-hardening property, i.e. the powder can be hardened by compression. A compression calorimeter was designed to determine the temperature evolution during the compaction of the powder. A platinum sensor (Pt100) was used as the temperature sensor and was positioned in the powder as well as in the compression die. A resolution of 0.01 °C with a sampling time of every second was used to monitor the temperature. Both theoretical calculation and simulations by COMSOL multiphysics showed that the device reliably evaluated the temperature during the compaction of CSH powders. The measurement was taken under semi-adiabatic conditions. The temperature profiles obtained from the measurement revealed the compression process and bonding development during the compaction of the powders. Finally, a linear relationship was observed between the compressive strength and the maximum temperature increase. This provides insight into the contact-hardening mechanism during the compaction of CSH powders.

Similar content being viewed by others

References

Kurdowski W. Cement and concrete chemistry. London: Springer; 2014.

Taylor HFW. Cement chemistry. London: Thomas Telford; 1997.

Pu X, Qin L, Yan W, Liang J, Wang C, He G. The contact hardening performance of dispersive minerials with unstable structure. J Chin Ceram Soc. 1999;27(2):133–8.

Wang S, Peng X, Zeng L. Research on contact-hardening cementitious properties of Nano-amorphous calcium silicate hydrate. J Hunan Univ (Natural Sciences). 2017;44(12):97–102.

Wang S, Peng X, Tao Z, Tang L, Zeng L. Influence of drying conditions on the contact-hardening behaviours of calcium silicate hydrate powder. Constr Build Mater. 2017;136:465–73. https://doi.org/10.1016/j.conbuildmat.2017.01.037.

Wang S, Peng X, Tang L, Cao C, Zeng L. Contact-hardening behavior of calcium silicate hydrate powders. Materials (Basel, Switzerland). 2018. https://doi.org/10.3390/ma11122367.

Zavaliangos A, Galen S, Cunningham J, Winstead D. Temperature evolution during compaction of pharmaceutical powders. Pharm Technol. 2007;97(8):3291–304.

Pharmaceutical Powder Compaction Technology. 2nd ed. London: Informa Healthcare; 2011.

Alderborn G, Nyuström C. Pharmaceutical powder compaction technology. London: Marcel Dekker, Inc.; 1995.

Huang P. Principles of metallurgical powder. 2nd ed. Beijing: Metallurgical Industry Press; 2006.

Adolfsson Å, Olsson H, Nyström C. Effect of particle size and compaction load on interparticulate bonding structure for some pharmaceutical materials studied by compaction and strength characterisation in butanol. Eur J Pharm Biopharm. 1997;44(3):243–51. https://doi.org/10.1016/S0939-6411(97)00136-7.

Sevillano JG. Size effects in powder compaction. J Mater Res. 2001;16(5):1238–40.

Mohammed H, Briscoe BJ, Pitt KG. The intrinsic nature and the coherence of compacted pure pharmaceutical tablets. Powder Technol. 2006;165(1):11–21. https://doi.org/10.1016/j.powtec.2006.03.010.

Nokhodchi A. An overview of the effect of moisture on compaction and compression. Pharm Technol. 2005;29(1):46–66.

Pizette P, Martin CL, Delette G, Sornay P, Sans F. Compaction of aggregated ceramic powders: from contact laws to fracture and yield surfaces. Powder Technol. 2010;198(2):240–50. https://doi.org/10.1016/j.powtec.2009.11.013.

Glukhovsky VD, Runova PF, Maxcunov CE. Contact-hardening cementitious materials and compounds. Chongqing: Chongqing University Press; 2004.

Coffin-Beach DP. A calorimetric evaluation of the compression process of several selected pharmaceutical powders. PhD, University of Maryland, Baltimore, Ann Arbor; 1982.

Coffin-Beach DP, Gary HR. Determination of the energy of tablet formation during compression of selected pharmaceutical powders. Int J Pharm. 1983;17(2–3):313–24. https://doi.org/10.1016/0378-5173(83)90042-X.

Rowlings CE, Wurster DE, Ramsey PJ. Calorimetric analysis of powder compression: II. The relationship between energy terms measured with a compression calorimeter and tableting behavior. Int J Pharm. 1995;116(2):191–200. https://doi.org/10.1016/0378-5173(94)00290-L.

Buckner IS. Compression calorimetry, powder compaction thermodynamics and deformation mechanisms. PhD, The University of Iowa, Ann Arbor; 2008.

Hanus EJ, King LD. Thermodynamic effects in the compression of solids. J Pharm Sci. 1968;57(4):677–84. https://doi.org/10.1002/jps.2600570431.

DeCrosta MT, Schwartz JB, Wigent RJ, Marshall K. Thermodynamic analysis of compact formation; compaction, unloading, and ejection: II. Mechanical energy (work) and thermal energy (heat) determinations of compact unloading and ejection. Int J Pharmaceut. 2001;213(1–2):45–62. https://doi.org/10.1016/S0378-5173(00)00645-1.

Damidot D, Lothenbach B, Herfort D, Glasser FP. Thermodynamics and cement science. Cem Concr Res. 2011;41(7):679–95. https://doi.org/10.1016/j.cemconres.2011.03.018.

Hagentoft C-E. Introduction to building physics. Sweden: Holmbergs i Malmö AB; 2012.

Feldman RF. Mechanism of creep of hydrated portland cement paste. Cem Concr Res. 1972;2(5):521–40. https://doi.org/10.1016/0008-8846(72)90107-X.

Livesey P, Donnelly A, Tomlinson C. Measurement of the heat of hydration of cement. Cem Concr Compos. 1991;13(3):177–85. https://doi.org/10.1016/0958-9465(91)90018-D.

Wang S, Peng X, Tang L, Cao C, Zeng L. Contact-hardening behavior of calcium silicate hydrate powders. Materials. 2018;11(12):2367. https://doi.org/10.3390/ma11122367.

Nyström C, Alderborn G, Duberg M, Karehill P-G. Bonding surface area and bonding mechanism-two important factors for the understanding of powder comparability. Drug Dev Ind Pharm. 1993;19(17–18):2143–96. https://doi.org/10.3109/03639049309047189.

Brovelli A, Cassiani G. A combination of the Hashin–Shtrikman bounds aimed at modelling electrical conductivity and permittivity of variably saturated porous media. Geophys J Int. 2010;180(1):225–37. https://doi.org/10.1111/j.1365-246X.2009.04415.x.

DeCrosta MT, Schwartz JB, Wigent RJ, Marshall K. Thermodynamic analysis of compact formation; compaction, unloading, and ejection: I. Design and development of a compaction calorimeter and mechanical and thermal energy determinations of powder compaction. Int J Pharm. 2000;198(1):113–34. https://doi.org/10.1016/S0378-5173(99)00466-4.

Schneider H, Vasudevan R, Hornemann U. Deformation of experimentally shock-loaded quartz powders: X-ray line broadening studies. Phys Chem Miner. 1984;10(3):142–7. https://doi.org/10.1007/BF00309650.

Pellenq RJM, Van Damme H. Why does concrete set? The nature of cohesion forces in hardened cement-based materials. MRS Bull. 2004;29(05):319–23. https://doi.org/10.1557/mrs2004.97.

Begaye ML, Aboubakr SH, Kim JJ, Taha MMR, editors. Nano-creep of synthetic CSH produced using 1.5 and 0.7 CaO/SiO2 mixture ratios. International conference on creep, shrinkage, and durability mechanics. Cambridge, Massachusetts; 2013.

Wang S, Peng X, Lan C, Tang L. High-strength light weight blocks prepared from the by-product of aluminium removal from fly ash. International symopsium EcoCrete Iceland 2014 on sustainablity, environmental friendly concrete; 13–15, August; Reykjavik, Iceland; 2014.

Kaliyan N, Morey RV. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Biores Technol. 2010;101(3):1082–90. https://doi.org/10.1016/j.biortech.2009.08.064.

Heckel RW. Density pressure relationships in powder compaction. Trans Metall Soc AIME. 1961;221:671–7.

Führer C. Interparticulate attraction mechanisms. In: Alderborn G, Nyström C, editors. Pharmaceutical powder compaction technology. London: Marcel Dekker, Inc.; 1995.

Adolfsson Å, Gustafsson C, Nyström C. Use of tablet tensile strength adjusted for surface area and mean interparticulate distance to evaluate dominating bonding mechanisms. Drug Dev Ind Pharm. 1999;25(6):753.

Bentz DP, Barrett T, De la Varga I, Weiss WJ. Relating compressive strength to heat release in mortar. Adv Eng Mater. 2012;1(1):14.

Acknowledgements

This work was primarily supported by the Fundamental Research Funds for the Central Universities (Grant Number 2019CDJGFCL002) and the National Natural Science Foundation of China (Grant Numbers 50972171 and 51678093). The microscopy facilities were supported in part by the Large Equipment Fund of Chongqing University under Agreement KF201612150031. The authors also greatly appreciate the support of the China Scholarship Council.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., Peng, X., Tang, L. et al. Temperature evolution during the compaction of calcium silicate hydrate powders using a compression calorimeter. J Therm Anal Calorim 139, 863–875 (2020). https://doi.org/10.1007/s10973-019-08495-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08495-z