Abstract

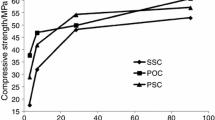

The influence of phosphate slag with different finenesses and activators on the hydration of high-belite cement has been studied by using the hydration heat of binders, the DTA curves, the SEM images, and the specific strength. Results indicated that doped phosphorus slag in the cement will reduce heat of hydration. The activity of phosphate slag was low at early stage, but pozzolanic activity of phosphorus slag is higher than that of fly ash. Increasing the specific surface area and curing time and using Ca(OH)2 combined with gypsum can clearly promote the hydration degree of phosphorus slag. The findings in this paper show that since phosphorus slag can promote the hydration of high-belite cement, the strength contribution of cement is increased. Moreover, the greater the specific surface area is, the more significant the promotion effect at 90 d is.

Similar content being viewed by others

References

Xue Y, Hou H, Zhu S. Characteristics and mechanisms of phosphate adsorption onto basic oxygen furnace slag. J Hazard Mater. 2009;162(2–3):973–80.

Niu Q, Feng N, Yang J. Effect of superfine slag powder on cement properties. Cem Concr Res. 2002;32(4):615–21.

Liu DM. Effect of phosphorus slag and fly ash on mechanical properties of high belite cement. Adv Mater Res. 2012;598:535–8.

Liu SH, Wang L, Gao YX, Yu BY, Bai Y. Comparing study on hydration properties of various cementitious systems. J Therm Anal Calorim. 2014;118(3):1483–92.

Chen SJ. Comprehensive utilization of phosphorus furnace slag in China. Phosphate Compd Fertil. 2006;21(3):41–4.

Živica V. Properties of blended sulfoaluminate belite cement. Constr Build Mater. 2000;14(8):433–7.

Winnefeld F, Barlag S. Calorimetric and thermogravimetric study on the influence of calcium sulfate on the hydration of ye’elimite. J Therm Anal Calorim. 2010;101(3):949–57.

Chatterjee AK. High belite cements—present status and future technological options: part I. Cem Concr Res. 1996;26(8):1213–25.

Gies A, Knofel D. Influence of sulfur on the composition of belite-rich clinkers and the technological properties of the resulting cements. Cem Concr Res. 1987;17(2):317–28.

Goñi S, Guerrero A. Study of alkaline hydrothermal activation of belite cements by thermal analysis. J Therm Anal Calorim. 2010;99(2):471–7.

Kacimi L, Simon-Masseron A, Salem S, et al. Synthesis of belite cement clinker of high hydraulic reactivity. Cem Concr Res. 2009;39(7):559–65.

Liu SH, Ya NK, Wang L. A comparison of hydration properties of cement–low quality fly ash binder and cement–limestone powder binder. J Therm Anal Calorim. 2014;116(2):937–43.

Wang S, Liu B, Zhao P. Effect of early-strength-enhancing agents on setting time and early mechanical strength of belite–barium calcium sulfoaluminate cement. J Therm Anal Calorim. 2018;131(3):2337–43.

Ma B, Li X, Shen X, et al. Enhancing the addition of fly ash from thermal power plants in activated high belite sulfoaluminate cement. Constr Build Mater. 2014;52(52):261–6.

Liu S, Li L. Influence of fineness on the cementitious properties of steel slag. J Therm Anal Calorim. 2014;117(2):629–34.

Binici H, Temiz H, Köse MM. The effect of fineness on the properties of the blended cements incorporating ground granulated blast furnace slag and ground basaltic pumice. Constr Build Mater. 2007;21(5):1122–8.

Criado M, Fernández-Jiménez A, Palomo A. Alkali activation of fly ash. Part III: effect of curing conditions on reaction and its graphical description. Fuel. 2010;89(11):3185–92.

Pu X. Investigation on pozzolanic effect of mineral additives in cement and concrete by specific strength index. Cem Concr Res. 1999;29(6):951–5.

Acknowledgements

This project is funded by the Natural Science Foundation of China (51668021), Science and Technology Projects of Educational Commission of Jiangxi Province of China (GJJ171020, GJJ180968), Natural Science Foundation of Jiangxi Province (20171BAB206052), and National Natural Science Foundation of Jiangxi University of Technology (ZR1713), and the authors also wish to acknowledge the Nanchang Knowledge Innovative Team of Green and Energy Conservation Building for their generous assistance throughout the experimental program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, J., Zhu, J. Hydration heat evolution of high-belite cement–phosphate slag binder. J Therm Anal Calorim 138, 135–143 (2019). https://doi.org/10.1007/s10973-019-08241-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08241-5