Abstract

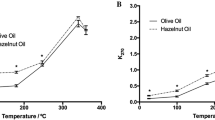

Moringa oleifera L. is an unconventional source of edible oil. Like olive oil, it is rich in oleic acid (monounsaturated fatty acid) with a high potential to be used in food preparation. The present investigation reports on a study of oxidative stability of moringa oil compared with olive and canola oils, employing the Rancimat and PetroOxy accelerated techniques and Schaal test. The values of induction periods obtained in the Rancimat test showed that moringa oil (23.68 ± 0.54 h) presented an oxidative stability similar to that of olive oil (23.43 ± 0.24 h) and both moringa and olive oils were significantly more stable than canola oil, (7.58 ± 0.33 h), although the PetroOxy test found the highest oxidative stability for moringa oil. Thermal degradation assessment of the oil samples was carried out using a thermogravimetric (TG) analysis. TG curves of the oils showed three stages of mass loss, and the moringa oil showed the higher thermal stability among the studied oils. In addition, the moringa oil remained practically unchanged in the Schaal test, whereas the olive and canola oils had undergone isomerization, evidenced by the absorbance of fatty acids with trans double bonds observed in the infrared spectra. Results obtained showed that moringa oil presented the good thermal and oxidative stability, being indicative that its shelf life would be longer when compared to the other oils evaluated.

Similar content being viewed by others

References

Contreras-Gallegos E, Domínguez-Pacheco FA, Hernández-Aguilar C, Salazar-Montoya JA, Ramos-Ramírez EG, Cruz-Orea A. Specific heat of vegetable oils as a function of temperature obtained by adiabatic scanning calorimetry. J Therm Anal Calorim. 2017;128:523–31.

Valero A, Carrasco E, Ma R. Principles and methodologies for the determination of shelf-life in foods. Trends Vital Food Control Eng. Prof. Ayma. InTech; 2012. p. 42.

Chen B, Mcclements DJ, Decker EA. Impact of diacylglycerol and monoacylglycerol on the physical and chemical properties of stripped soybean oil. Food Chem. 2014;142:365–72.

Decker EA, Elias RJ, Julian McClements D, Matthäus B. 6—Oxidation of edible oils. Oxid Foods Beverages Antioxid Appl. 2010. p. 183–238.

Fasina OO, Hallman H, Craig-Schmidt M, Clements C. Predicting temperature-dependence viscosity of vegetable oils from fatty acid composition. J Am Oil Chem Soc. 2006;83:899–903.

Schaich KM. Analysis of lipid and protein oxidation in fats, oils, and foods. In: Jacobsen MHC, editor. Oxidative stab shelf life foods contain oils fats. New Brunswick: Elsevier Inc.; 2016. p. 1–131.

Kapich AN, Korneichik TV, Hatakka A, Hammel KE. Oxidizability of unsaturated fatty acids and of a non-phenolic lignin structure in the manganese peroxidase-dependent lipid peroxidation system. Enzyme Microb Technol. 2010;46:136–40.

Codex Alimentarius. Codex standard for named vegetable oils cx-stan 210 - 1999. 2001. p. 11–25.

Douny C, Razanakolona R, Ribonnet L, Milet J, Baeten V, Rogez H, et al. Linseed oil presents different patterns of oxidation in real-time and accelerated aging assays. Food Chem. 2016;208:111–5.

Santos CSP, Molina-Garcia L, Cunha SC, Casal S. Fried potatoes: impact of prolonged frying in monounsaturated oils. Food Chem. 2018;243:192–201.

Youseff MM, Gordon Michael H, Ezeh Onyinye NK. Aqueous enzymatic extraction of Moringa oleifera oil. Food Chem. 2016;211:400–8.

Bhutada PR, Jadhav AJ, Pinjari DV, Nemade PR, Jain RD. Solvent assisted extraction of oil from Moringa oleifera Lam. seeds. Ind Crops Prod. 2016;82:74–80.

Ruttarattanamongkol K, Siebenhandl-Ehn S, Schreiner M, Petrasch AM. Pilot-scale supercritical carbon dioxide extraction, physico-chemical properties and profile characterization of Moringa oleifera seed oil in comparison with conventional extraction methods. Ind Crops Prod. 2014;58:68–77.

Machado YL, Neto AAD, Fonseca JLC, Dantas TNC. Antioxidant stability in vegetable oils monitored by the ASTM D7545 method. J Am Oil Chem Soc. 2014;91:1139–45.

Rahman IMM, Barua S, Nazimuddin M, Begum ZA, Rahman MA, Hasegawa H. Physicochemical properties of Moringa oleifera lam. Seed oil of the indigenous-cultivar of bangladesh. J Food Lipids. 2009;16:540–53.

Anwar F. Enhancement of the oxidative stability of some vegetable oils by blending with Moringa oleifera oil. Food Chem. 2007;103:1181–91.

Zenebon O, Neus Sadocco Pascuet PT. Physicochemical methods for food analysis. 4th ed. São Paulo: Adolfo Lutz Institute; 2008.

AOCS. Official methods and recommended practices of the American Oil Chemists’ Society. AOCS Off Methods Cd 1-25- Iodine Value Fats Oils, Wijs Method. Champaign, IL: AOCS Press; 1984.

AOCS C d 8-53. Official Methods and Recommended Practices of the American Oil Chemists’Society. Off Methods-C d 8-53. Champaign, IL: AOCS Press; 2012.

Brazilian Association of Technical Standards. ABNT NBR 10441:2014. Pet Prod—Transparent opaque Liq—Determ kinematic viscosity Calc Dyn viscosity. São Paulo: Brazilian Association of Technical Standards; 2014. p. 22.

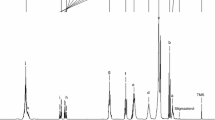

Guillén MD, Ruiz A. 1H nuclear magnetic resonance as a fast tool for determining the composition of acyl chains in acylglycerol mixtures. Eur J Lipid Sci Technol. 2003;105:502–7.

AOCS. Official Methods and Recommended Practices of the American Oil Chemists’Society. Off Method - Cd 12-92 Oil Stab Index. Champaign, IL: AOCS Press; 2017.

Guillen MD, Goicoechea E. Oxidation of corn oil at room temperature: primary and secondary oxidation products and determination of their concentration in the oil liquid matrix from 1H nuclear magnetic resonance data. Food Chem. 2009;116:183–92.

Neumann A, Jebens T, Wierzbicki V. A method for determining oxidation stability of petrodiesel, biodiesel, and blended fuels. Am Lab. 2008;40:22–6.

Wójcicki K, Khmelinskii I, Sikorski M, Sikorska E. Near and mid infrared spectroscopy and multivariate data analysis in studies of oxidation of edible oils. Food Chem. 2015;187:416–23.

Qi B, Zhang Q, Sui X, Wang Z, Li Y, Jiang L. Differential scanning calorimetry study—assessing the influence of composition of vegetable oils on oxidation. Food Chem. 2016;194:601–7.

Zhong J, Wang Y, Yang R, Liu X, Yang Q, Qin X. The application of ultrasound and microwave to increase oil extraction from Moringa oleifera seeds. Ind Crops Prod. 2018;120:1–10.

Sánchez-machado DI, López-cervantes J, Núñez-gastélum JA, Servín G, Mora-lópez D, López-hernández J, et al. Effect of the refining process on Moringa oleifera seed oil quality. Food Chem. 2015;187:53–7.

Li X, Wu X, Liu R, Jin Q, Wang X. Effect of frying conditions on fatty acid profile and total polar materials via viscosity. J Food Eng. 2015;166:349–55.

Santos OV, Corrêa NCF, Soares FASM, Gioielli LA, Costa CEF, Lannes SCS. Chemical evaluation and thermal behavior of Brazil nut oil obtained by different extraction processes. Food Res Int. 2012;47:253–8.

Barradas Filho AO, Barros AKD, Labidi S, Viegas IMA, Marques DB, Romariz ARS, et al. Application of artificial neural networks to predict viscosity, iodine value and induction period of biodiesel focused on the study of oxidative stability. Fuel. 2015;145:127–35.

Li R, Huang J, Huang L, Teng J, Xia N, Wei B, et al. Comparison of GC and DSC monitoring the adulteration of camellia oil with selected vegetable oils. J Therm Anal Calorim. 2016;126:1735–46.

Tsaknis J, Lalas S. Stability during frying of Moringa oleifera seed oil variety Periyakulam 1. J Food Compos Anal. 2002;15:79–101.

Vicente J, Cappato LP, de Araújo Calado VM, de Carvalho MG, Garcia-Rojas EE. Thermal and oxidative stability of Sacha Inchi oil and capsules formed with biopolymers analyzed by DSC and 1H NMR. J Therm Anal Calorim. 2018;131:2093–104.

Ratusz K, Popis E, Zytkiewicz HC. Oxidative stability of camelina (Camelina sativa L.) oil using pressure differential scanning calorimetry and Rancimat method. J Therm Anal Calorim. 2016;126:343–51.

Floratech. Oxidative stability determination. Floratech Tech. Bull. MKT 11. 2015. p. http://www.floratech.com/fleMgr/upload/fles/ARTICL.

Martin-Rubio AS, Sopelana P, Ibargoittia ML, Guillén MD. Prooxidant effect of α-tocopherol on soybean oil. Global monitoring of its oxidation process under accelerated storage conditions by 1H nuclear magnetic resonance. Food Chem. 2018;245:312–23.

Souza AL, Martínez FP, Ferreira SB, Kaiser CR. A complete evaluation of thermal and oxidative stability of chia oil. J Therm Anal Calorim. 2017;130:1307–15.

Guillén MD, Goicoechea E. Detection of primary and secondary oxidation products by fourier transform infrared spectroscopy (FTIR) and 1H nuclear magnetic resonance (NMR) in sunflower oil during storage. J Agric Food Chem. 2007;55:10729–36.

GuillénN MD, Cabo N. Fourier transform infrared spectra data versus peroxide and anisidine values to determine oxidative stability of edible oils. Food Chem. 2002;77:503–10.

Navarra G, Cannas M, D’Amico M, Giacomazza D, Militello V, Vaccaro L, et al. Thermal oxidative process in extra-virgin olive oils studied by FTIR, rheology and time-resolved luminescence. Food Chem. 2011;126:1226–31.

Acknowledgements

The authors acknowledge the FINEP, MCT/CGTS, CNPq, CAPES and UFPB. The English text of this paper has been revised by Sidney Pratt, Canadian, MAT (The Johns Hopkins University), RSAdip - TESL (Cambridge University).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duarte, A.M., Aquino, J.S., Queiroz, N. et al. A comparative study of the thermal and oxidative stability of moringa oil with olive and canola oils. J Therm Anal Calorim 134, 1943–1952 (2018). https://doi.org/10.1007/s10973-018-7651-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7651-7